Method and system for matching and combining heavy steel pipes

A steel pipe and pairing technology, which is applied in the field of heavy steel pipe matching and pairing methods and systems, can solve problems such as construction bottlenecks and low pairing efficiency, and achieve low cost, low cost, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

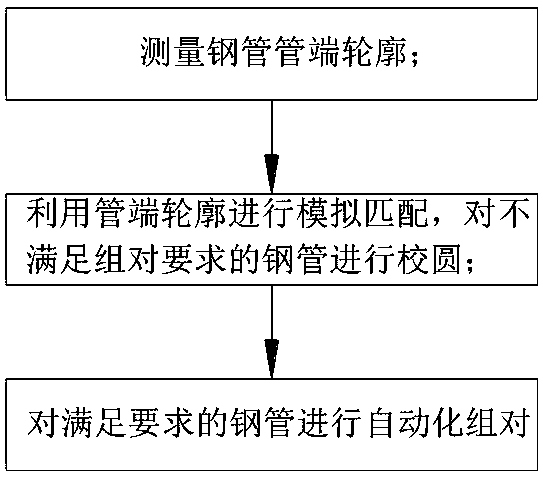

[0044] A method for matching and assembling heavy steel pipes of the present invention A method for matching and assembling heavy steel pipes, comprising the following steps:

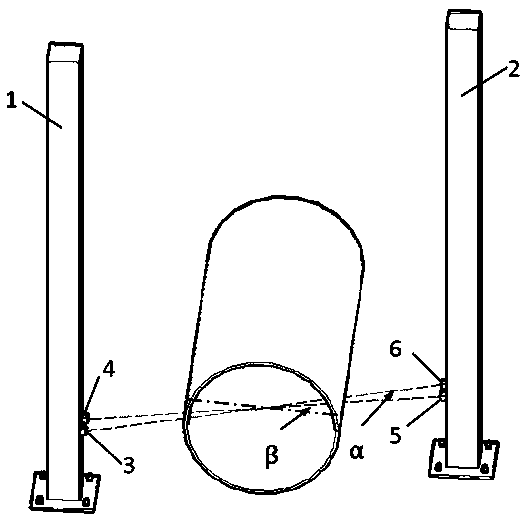

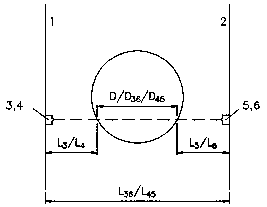

[0045] S1 Place the assembled steel pipe 1 and the steel pipe section 2 to be assembled on the V-shaped conveying roller 7 of the conveying frame 9 and the roller 12 of the electric trolley 15 respectively, and measure the steel pipe end profile respectively;

[0046] S2 uses the pipe end profile to perform simulated matching, and corrects the circle of the steel pipes that do not meet the pairing requirements;

[0047] S3 conducts automatic grouping of steel pipes that meet the requirements.

[0048] The step S2 can be subdivided into the following steps:

[0049] S21 Real-time pipe end profile monitoring during the steel pipe rolling process;

[0050] S22 Simulate and match the contours of adjacent pipe ends that need to be paired;

[0051] S23 If the amount of misalignment after the matching of ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com