Pipe section supporting and assembling device

A technology for support groups and pipe sections, which is applied in the direction of workpiece clamping devices and manufacturing tools, and can solve the problems of difficult leveling of pier, difficult selection of pier, and difficulty in precision control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

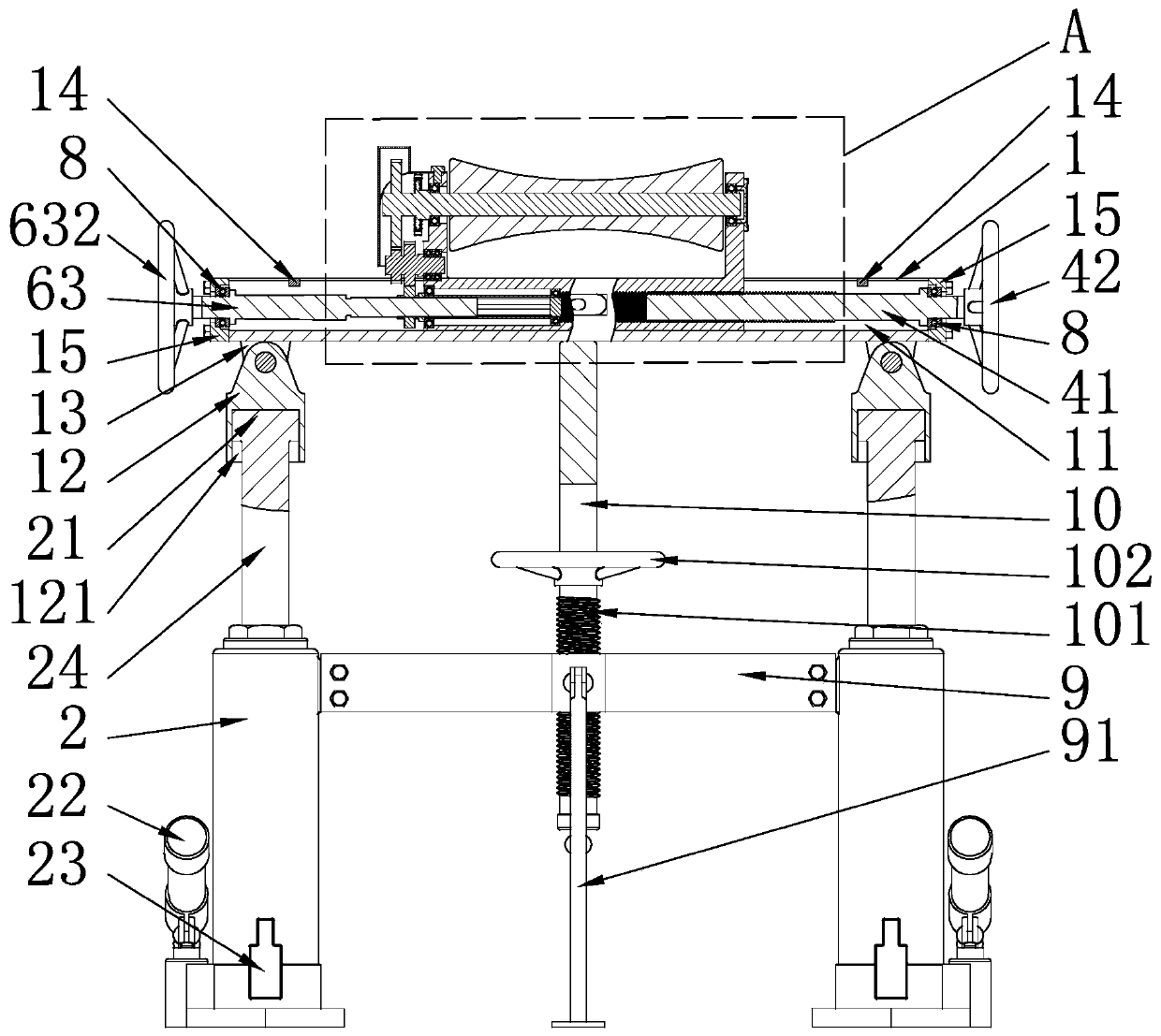

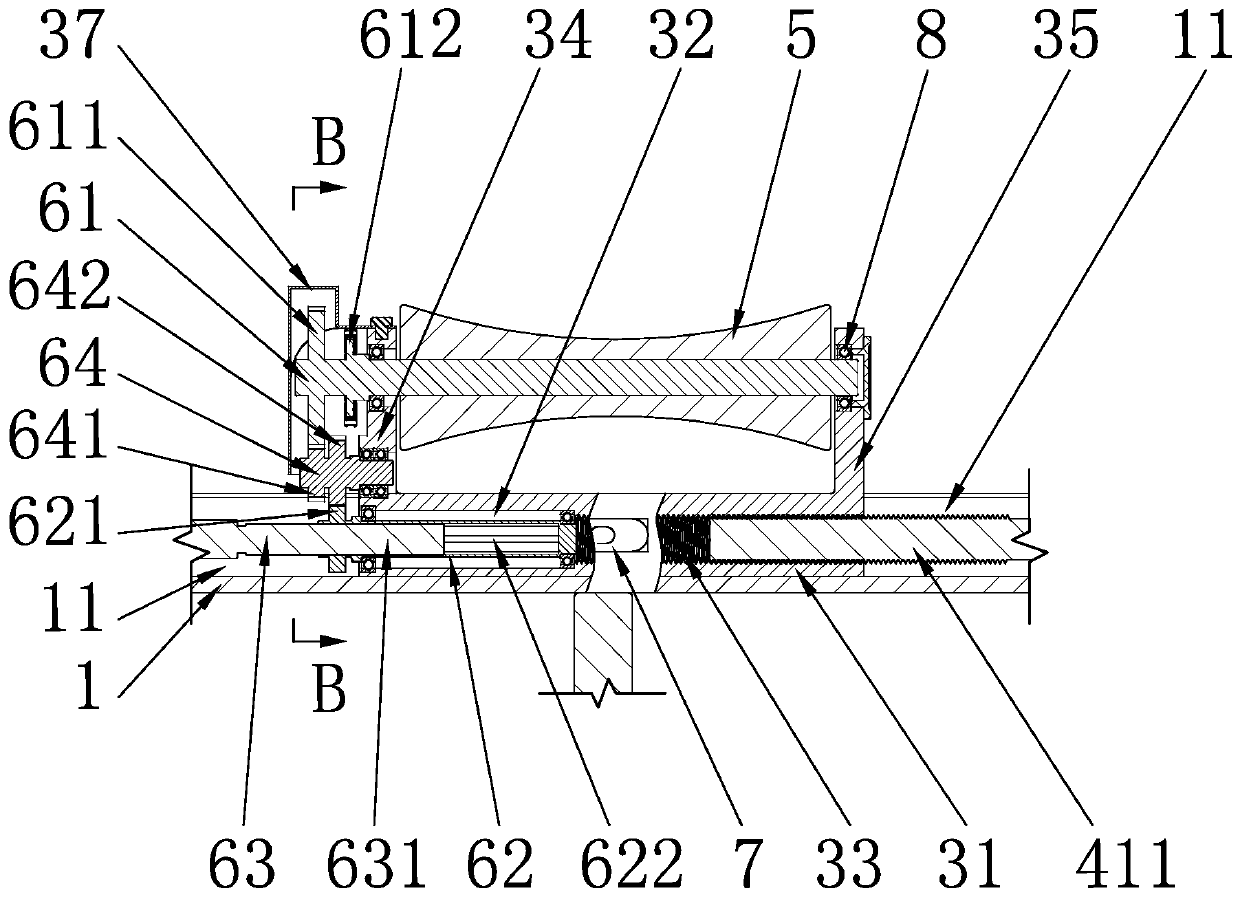

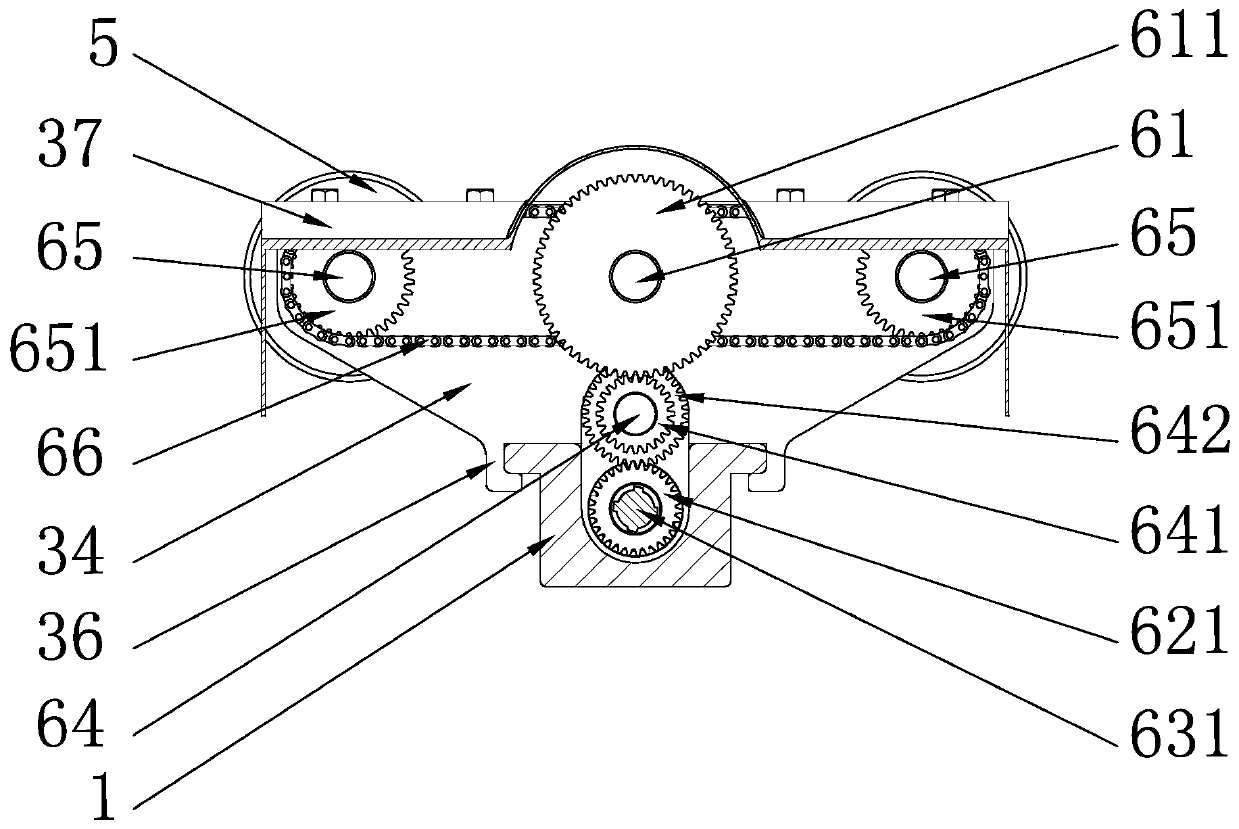

[0023] see figure 1 , Figure 4 and Figure 5 , a pipe section support grouping device of the present invention, comprising a slide rail 1 and a bubble level 7 located in the middle of the slide rail, the length of the slide rail 1 extends along the left and right directions, and the left and right ends of the lower end of the slide rail 1 are provided with There is a lifting mechanism 2, the slide rail 1 is provided with a sliding support 3, one end of the slide rail 1 is provided with a translation mechanism 4, the output end of the translation mechanism 4 is connected to the sliding support 3, and the translation The mechanism 4 can drive the sliding support 3 to slide left and right on the slide rail 1, the sliding support 3 is provided with a roller 5, the central axis of the roller 5 extends along the left and right direction, and the roller 5 can rotate, so The other end of the slide rail 1 is provided with a rolling mechanism 6 , and the output end of the rolling mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com