Ultra-long guide rail for three-coordinate measuring machine

A three-coordinate measuring machine and guide rail technology, applied in the field of ultra-long guide rails, can solve the problems of wide joints of divided guide rails, low utilization rate of Jinan blue granite resources, and many manual random factors, and achieves good straightness and simple structure. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

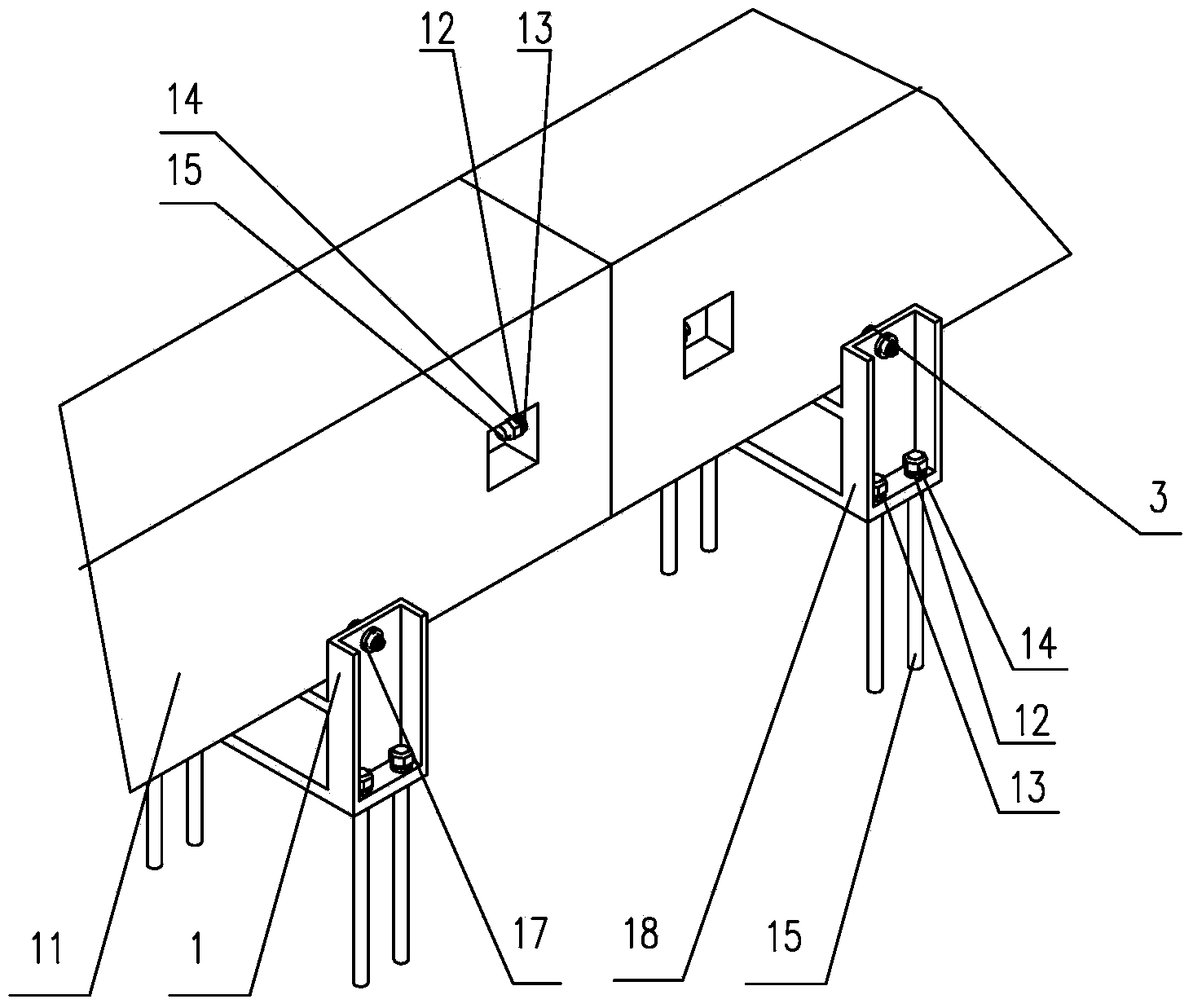

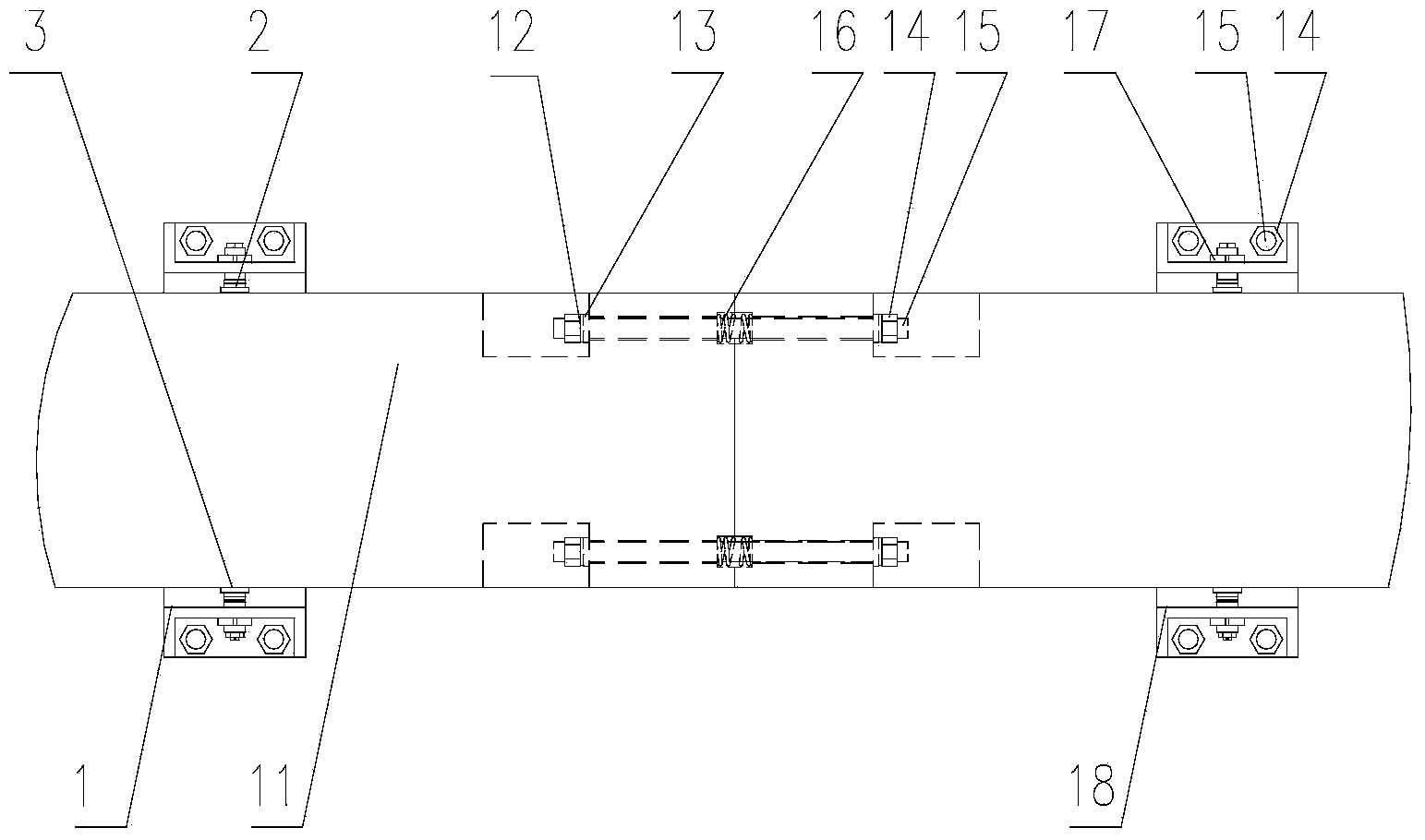

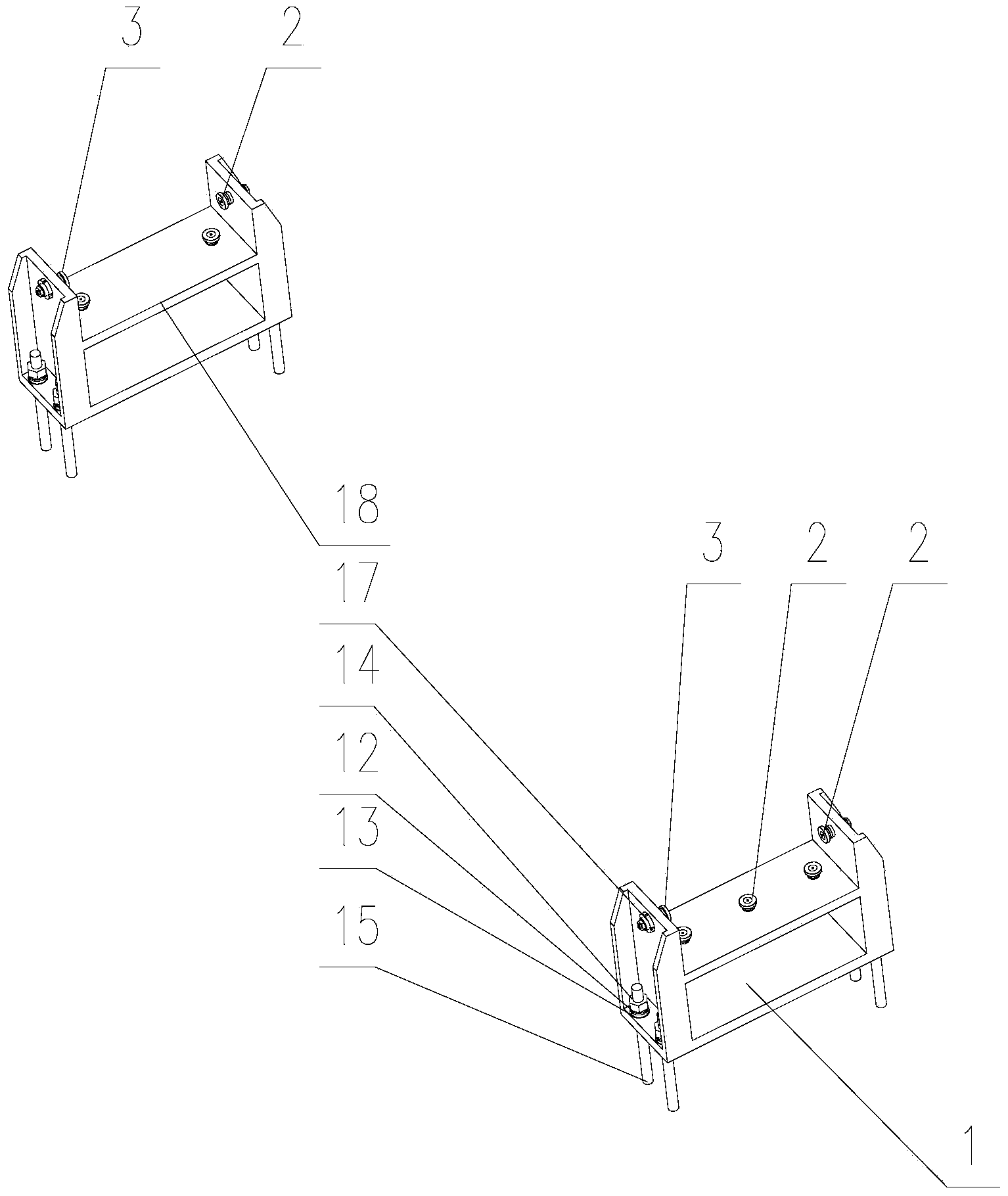

[0052] The ultra-long guide rail of the three-coordinate measuring machine of the present invention comprises a plurality of cuboids of high-precision granite material which are sequentially spliced and connected and supported in place by a plurality of support bodies; The side bottom surface and two end surfaces, the secondary side is parallel to the main side; two stepped holes are respectively arranged on the combined end surfaces, and the main side and the secondary side of the sub-guide rail 11 in the middle area each have a pair of holes, and the small holes of the stepped holes pass through the The first wall of the square hole; the left end of the first sub-guide rail 19 and the right end of the end sub-guide rail 20 do not need stepped holes and square holes, such as Figure 8 .

[0053] The cuboid all corresponds to a bench-shaped front base 1 and a rear base 18. The upper bottom surface of the front base 1 has three threaded holes each equipped with a rigid adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com