Multifunctional aluminum and aluminum alloy plate full-size hydraulic leveler

An aluminum alloy sheet, multi-functional technology, applied in the field of multi-functional aluminum and aluminum alloy sheet full-width hydraulic levelers, can solve the problems of difficult aluminum and aluminum alloy sheets, difficult to control the correction accuracy, etc., and achieves low investment and compact structure. , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

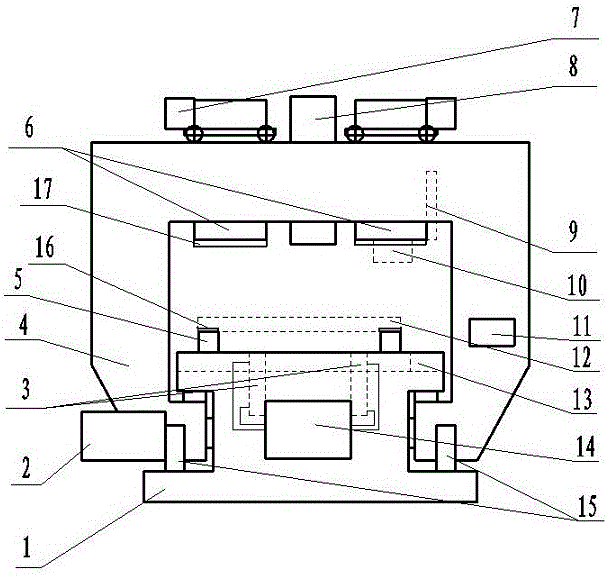

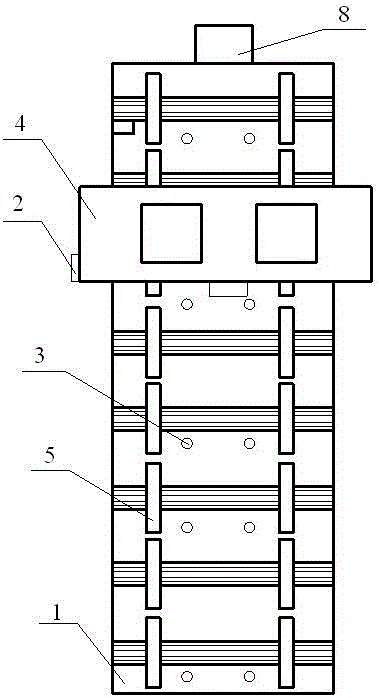

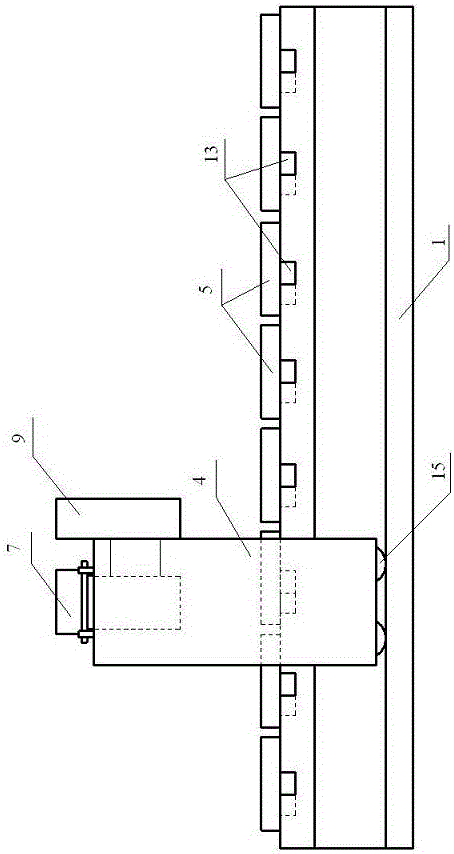

[0014] Embodiments, with reference to the accompanying drawings, a multifunctional aluminum and aluminum alloy plate full-scale hydraulic leveler, including a drive motor and a transmission 2, a hydraulic station 14 and an operating console 11, is characterized in that the drive motor and the transmission 2 and the gantry wheel 15 connections, the gantry wheel 15 is contained in the lower end of the mobile gantry 4, and is in movable contact with the workbench 1; the upper plane of the workbench 1 is equipped with eight groups of mobile anvil assemblies 5, and the right end of each mobile anvil assembly 5 is equipped with Mobile anvil drive device 13; ten hydraulic pallet oil cylinders 3 are installed on the upper plane of the workbench 1; a hydraulic station 8 is installed in the middle of the upper beam of the mobile gantry 4, and pressure heads are installed on both sides of the hydraulic station 8 Moving motor drive mechanism 7, pressure head 6 is housed below pressure head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com