High-strength heat-resistant chip removal titanium film saw blade and machining process thereof

A processing technology, high-strength technology, applied in metal processing equipment, heat treatment furnaces, manufacturing tools, etc., can solve the problems of easy distortion, unstable saw blade cutting workpiece, saw blade brittleness and toughness, poor flatness and accuracy, etc. Reduce brittleness, improve service life and adaptability, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

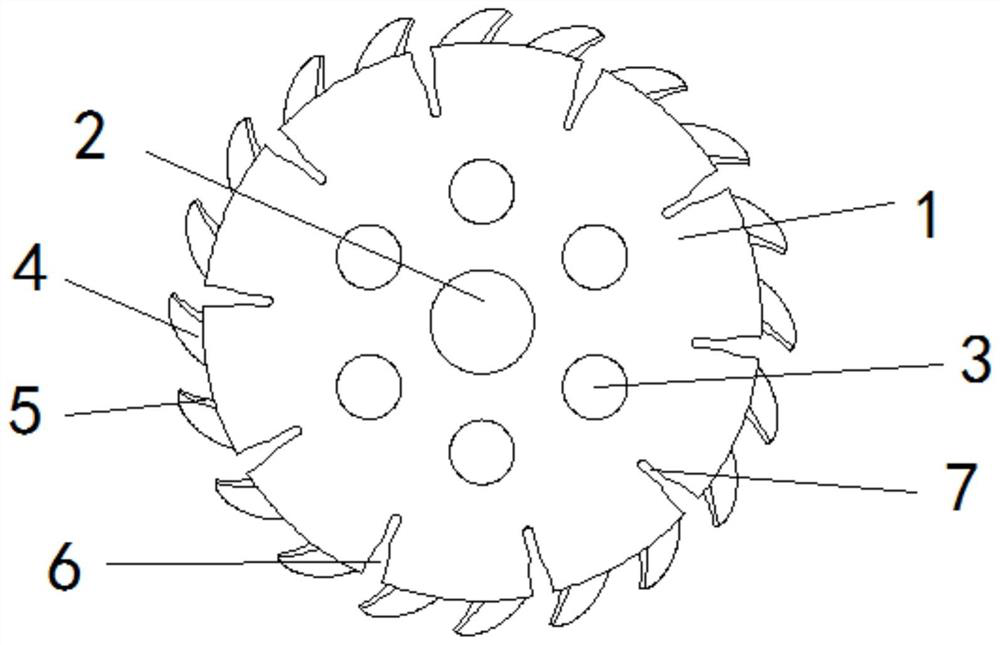

[0043] Such as Figure 1-2 As shown, the high-strength heat-resistant and chip-removing titanium film saw blade according to the embodiment of the present invention includes a saw blade base 1, the outer surface of the saw blade base 1 is coated with a titanium film, and a center is provided at the center of the saw blade base 1. hole 2, the outer side of the central hole 2 is provided with several heat dissipation holes 3 along the circumferential direction, and the outer surface of the saw blade base 1 is provided with several saw teeth 4 and chip removal grooves 6 alternately, and the saw teeth 4 are welded and fixed There is a cutter head 5, and an extension groove 7 is communicated with one side of the chip removal groove 6 close to the center of the saw blade base body 1 .

Embodiment 2

[0045] Such as Figure 1-4 As shown, the material of the saw blade substrate 1 is alloy, the thickness of the titanium alloy film is 2-7 microns, the cutter head 5 is a ceramic alloy cutter head, and is welded by a high-frequency welding method by a fully automatic gear welding machine Welded on the sawtooth 4, both sides of the chip removal groove 6 are arc-shaped structures, the number of the chip removal groove 6 is ten, and the length of the chip removal groove 6 and the extension groove 7 is One-fifth of the radius of the saw blade substrate 1. It is not difficult to see from the above design that through the design of the chip removal groove 6, the accumulation of flying chips generated by the saw blade on the saw blade is reduced, and the saw blade will generate a lot of heat during the high-speed cutting process, and several cooling holes 3 are formed. Convection heat dissipation, good heat dissipation effect, improving the service life and adaptability of saw blades ...

Embodiment 3

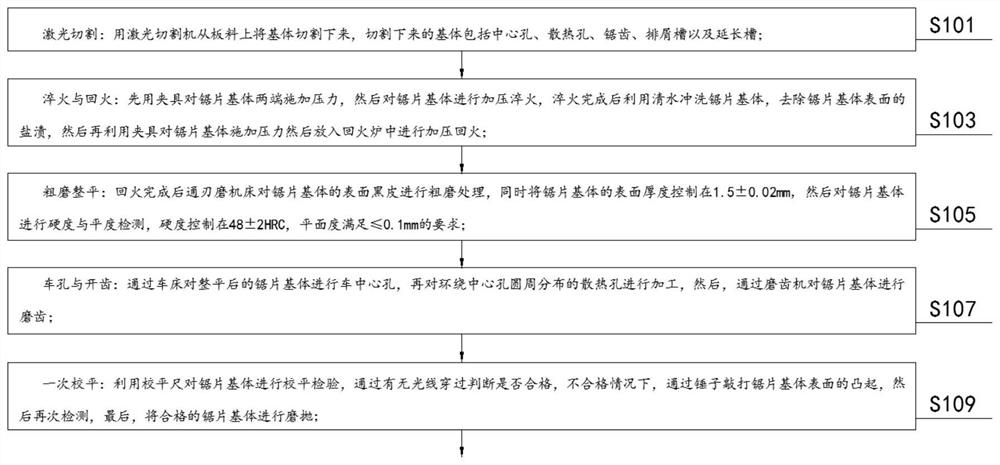

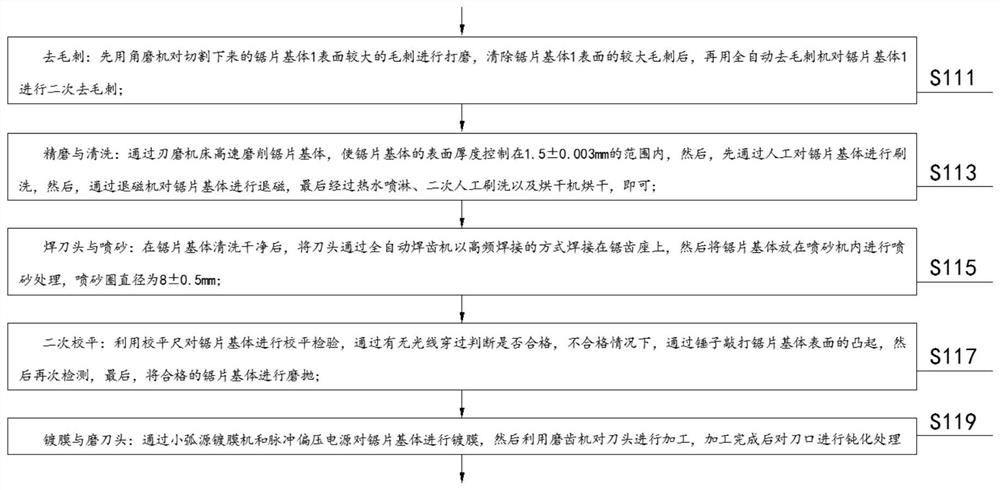

[0047] Such as Figure 1-2 As shown, according to an embodiment of the present invention, a high-strength heat-resistant and chip-removing titanium film saw blade processing technology is also provided, which is used for a high-strength heat-resistant and chip-removing titanium film saw blade, comprising the following steps;

[0048] Step S101, laser cutting: use a laser cutting machine to cut the substrate from the sheet material, the cut substrate includes the central hole 2, the heat dissipation hole 3, the serration 4, the chip removal groove 6 and the extension groove 7;

[0049] Step S103, quenching and tempering: first apply pressure to both ends of the saw blade base 1 with a clamp, then pressurize and quench the saw blade base 1, rinse the saw blade base 1 with clean water after quenching, and remove the surface of the saw blade base 1 salting, and then use the clamp to apply pressure to the saw blade substrate 1 and then put it into the tempering furnace for pressuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com