Preparing method of whole welding type guide rail

A welding type, guide rail technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of limited manufacturing accuracy of basic guide rails, poor overall accuracy of the upper surface, and low overall stability of the guide rails.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

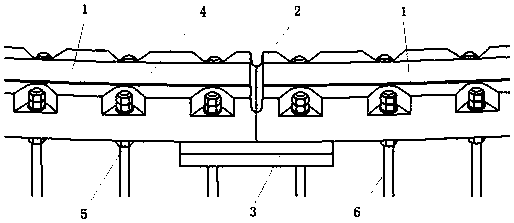

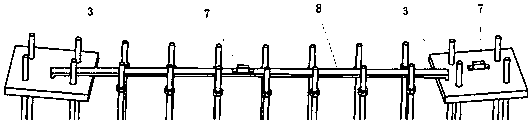

[0026] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

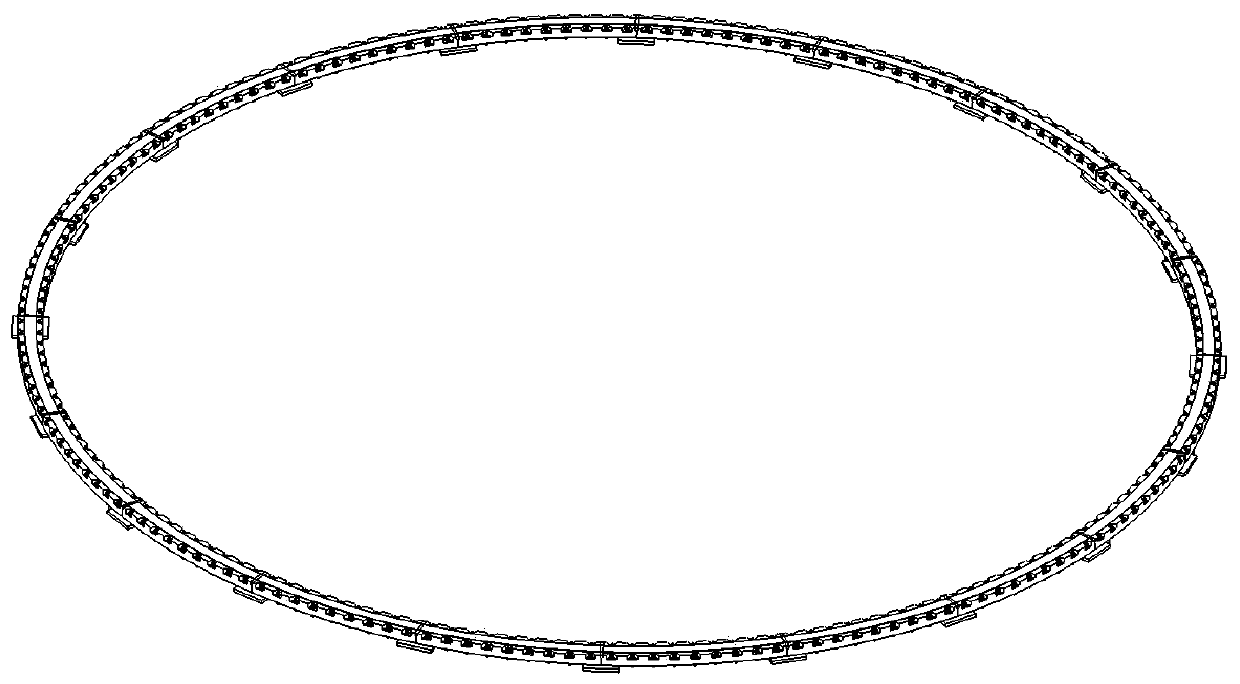

[0027] In this example, see the attached figure 1 , 3 As shown, the center diameter of the guide rail surface is 19.5m, the width of the guide rail surface is 190mm, the overall flatness of the guide rail surface is required to be 0.25mm, and the bearing capacity is greater than 550 tons. It consists of 20 sections of monorail parts 1 welded to form a whole. The design and manufacture are divided into six steps: monorail part 1 design, welding groove design, monorail part 1 manufacturing, guide rail installation, guide rail welding, and U-shaped weld 2 grinding, as follows:

[0028] Step 1. Monorail part 1 design

[0029] The material of monorail part 1 is high-strength steel 42CrMo, which has been quenched and tempered, and has good toughness and impact resistance. The cross-sectional size is 400mm×210mm, adopts circular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com