Floating type numerical control rotary table safety locking structure

A CNC turntable and safety locking technology, which is used in large fixed members, metal processing mechanical parts, metal processing equipment, etc., can solve the accuracy of the rotary axis, the difficulty of manufacturing thin brake pads, the permanent deformation of the brake pads, and the abnormal friction and noise. problem, to achieve the effect of rapid braking, no influence on the accuracy of the turntable, and large braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

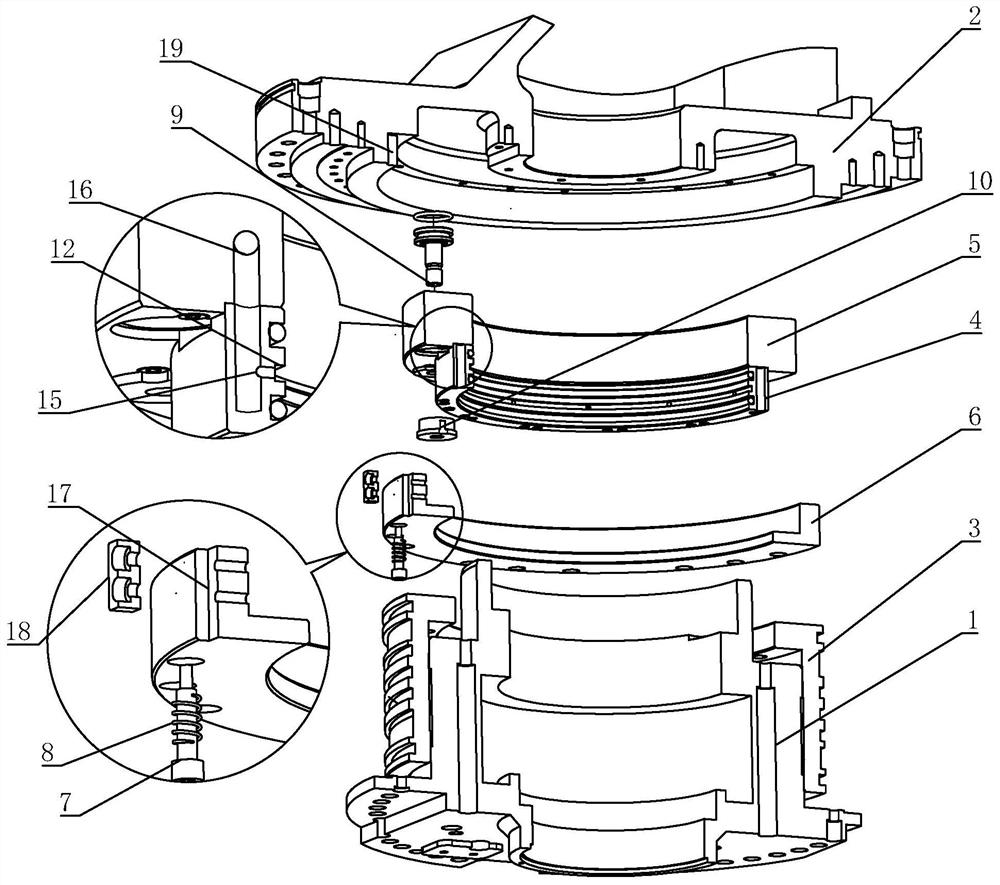

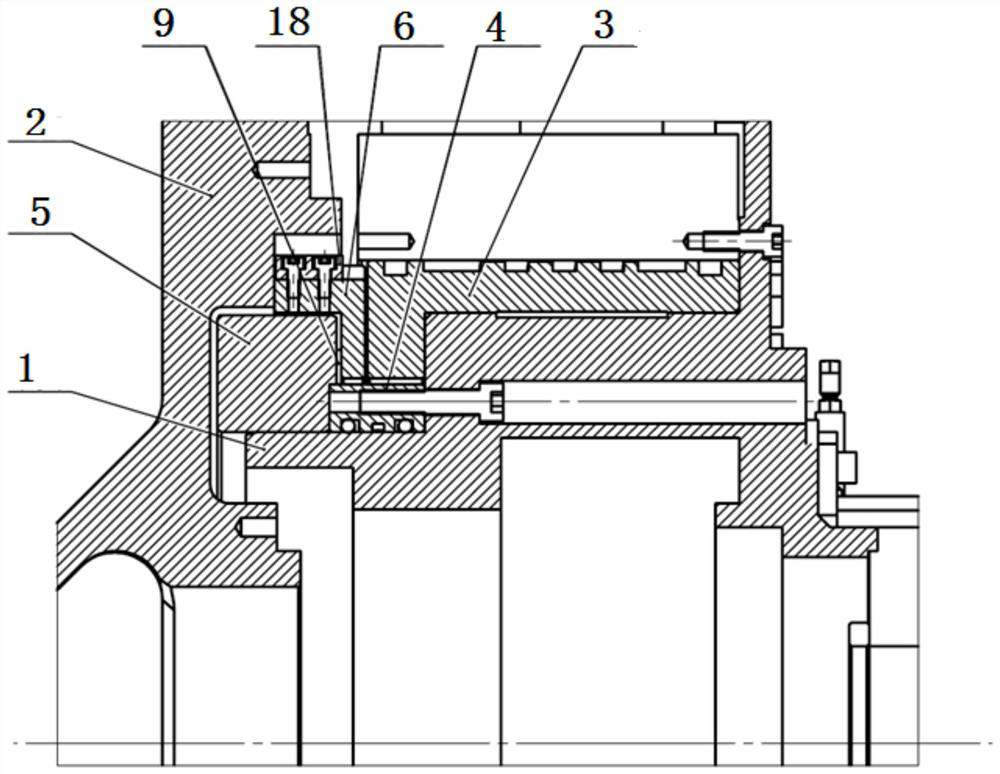

[0016] Such as figure 1 with figure 2 The safety locking structure of the CNC turntable shown includes a turntable base body 1 and a rotary motion body 2 , the turntable base body 1 is fixed on the machine tool, and the rotary motion body 2 can rotate relative to the turntable base body 1 .

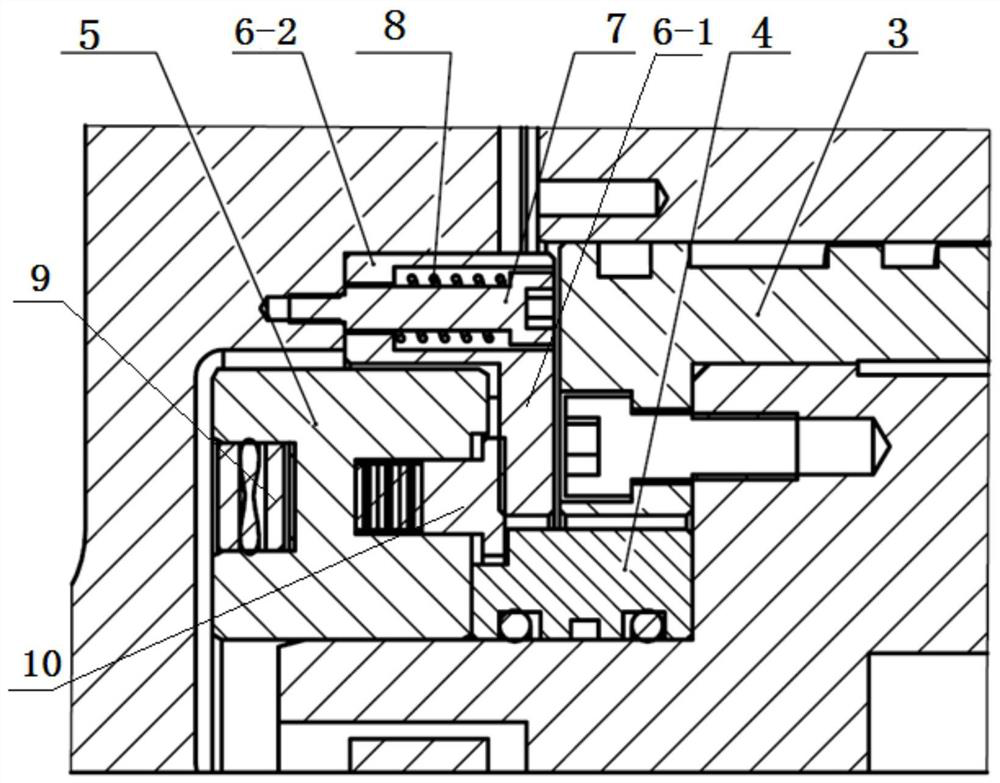

[0017] Such as figure 2 with image 3 As shown, a brake sleeve 3, an annular sleeve 4, and a fixed seat 5 are set on the turntable base 1, and the brake sleeve 3, annular sleeve 4, and fixed seat 5 are all fixed relative to the turntable base 1, as shown in the figure In the embodiment, the brake sleeve 3 is fixedly connected to the turntable base 1 by bolts, the annular sleeve 4 is fixedly connected to the turntable base 1 by bolts, and the fixing seat 5 is fixedly connected to the annular sleeve 4 by bolts.

[0018] Such as image 3 As shown, a locking ring 6 is connected to the rotary motion body 2, and the locking ring 6 can rotate synchronously with the rotary motion body 2. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com