Processor fixing structure, component and computer equipment

A fixed structure and fixed component technology, applied in the computer field, can solve problems such as inability to maintain heat dissipation, difficulty in providing total pressure load requirements for radiators, difficulty in ensuring contact reliability between CPU and processor sockets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

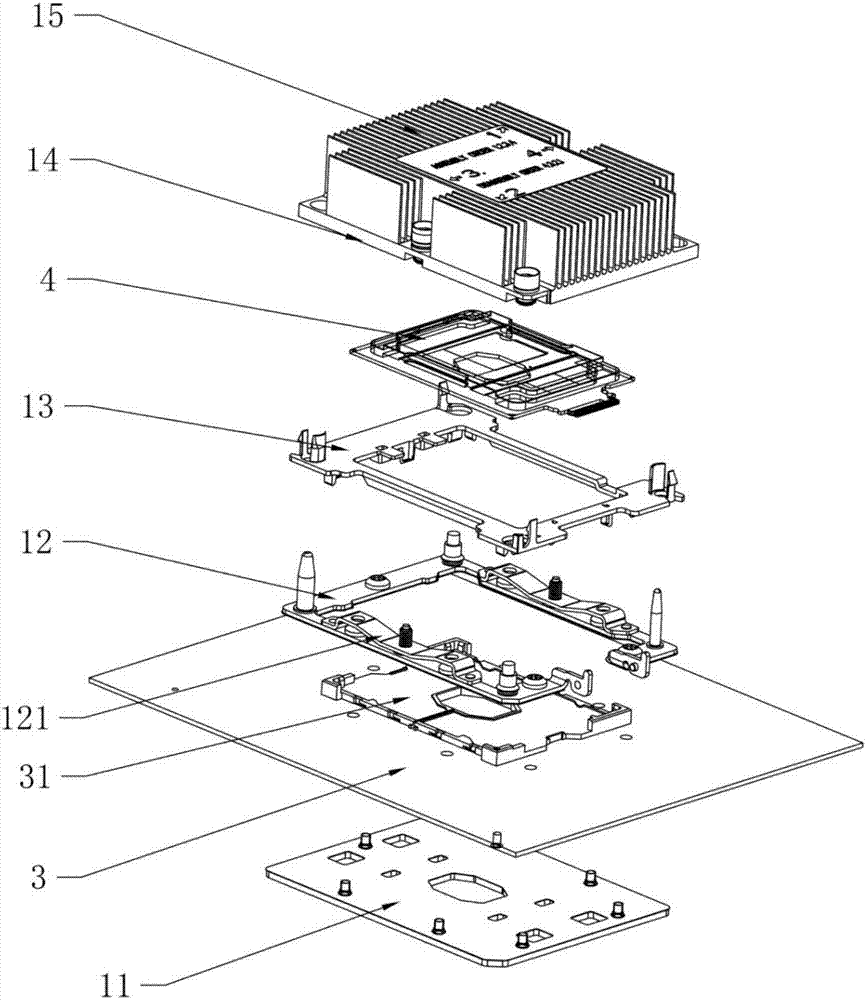

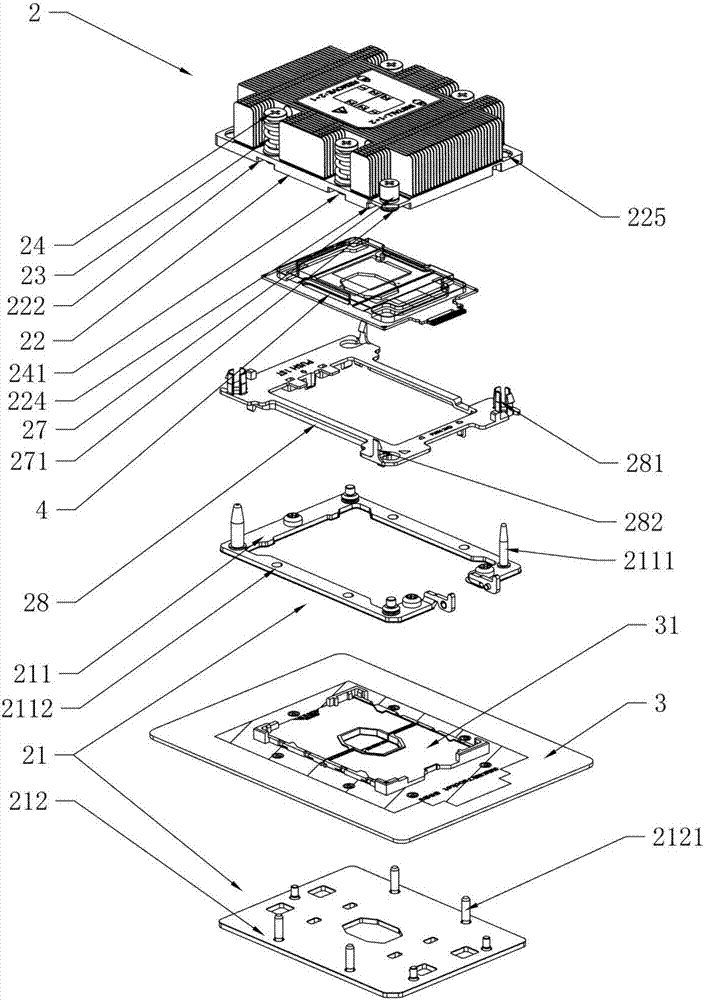

[0052] In order to solve the above problems, this application provides a processor fixed structure, please refer to figure 2 , figure 2 It is an exploded schematic view of the processor fixing structure of the embodiment of the present application, wherein the processor fixing structure 2 includes a heat sink substrate 22 , and the heat sink substrate 22 is in contact with the processor 4 .

[0053] Optionally, the processor fixing structure 2 further includes a fixing component 21. The fixing component 21 is fixed on the processor socket 31 on the PCB 3 , and the radiator substrate 22 in contact with the processor 4 is mounted on the fixing component 21 . Therefore, the heat sink substrate 22 is fixed on the fixing assembly 21 .

[0054] The sides of the heat sink substrate 22 are provided with an elastic structural member and a limiting structural member for limiting the elastic structural member. One end of the limiting structural member passes through the elastic struc...

Embodiment 2

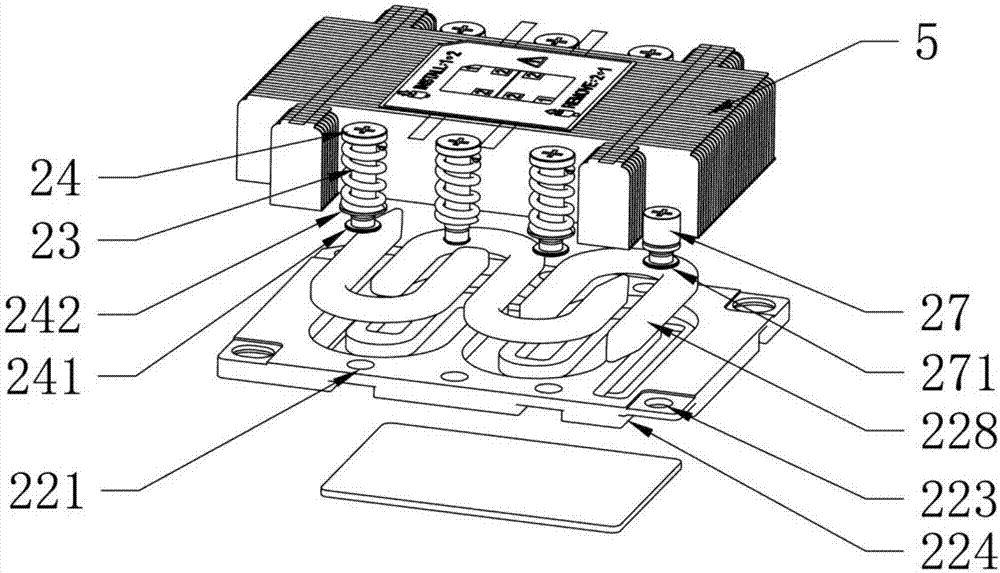

[0058]In this embodiment, on the basis of embodiment 1, as figure 2 with image 3 as shown, image 3 It is a diagram of an embodiment of the processor fixing structure of the embodiment of the present application, wherein the elastic structural member is a compression spring 23, the limiting structural member is a first screw 24, and the compression spring 23 is sleeved on the first screw 24, The diameter of the head end of the first screw 24 is larger than the inner diameter of the compression spring 23 , and the two ends of the compression spring 23 are located between the head end of the first screw 23 and the radiator substrate 22 . In this case, since the head end of the first screw 24 is larger than the inner diameter of the compression spring 23, the compression can be achieved by tightening the first screw 24 to shorten the distance between the head end of the first screw 24 and the radiator substrate 22. The purpose of the spring 23 is to make the elastic force gen...

Embodiment 3

[0080] In this embodiment, on the basis of Embodiment 1, please refer to Figure 8a with Figure 8b , Figure 8a It is an embodiment diagram of the fixed structure of the processor in the embodiment of the present application, Figure 8b It is a diagram of an embodiment of the processor fixing structure of the embodiment of the present application, wherein the limiting structural member is a third screw 25, the elastic structural member is an elastic piece 26, and the curved part located in the middle of the elastic piece 26 is provided with a second Two limiting holes 261, the inner side of the curved portion is opposite to the radiator substrate 22, the third screw 25 passes through the second limiting hole 261 and is connected to the radiator substrate 22, the third screw The outer diameter of the head portion of 25 is larger than the inner diameter of the second limiting hole 261 , and the two ends of the elastic piece 26 are respectively connected with the heat sink sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com