Loom and method for guiding a woven fabric in a loom

A loom, fabric technology, applied in the direction of looms, flannel looms, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

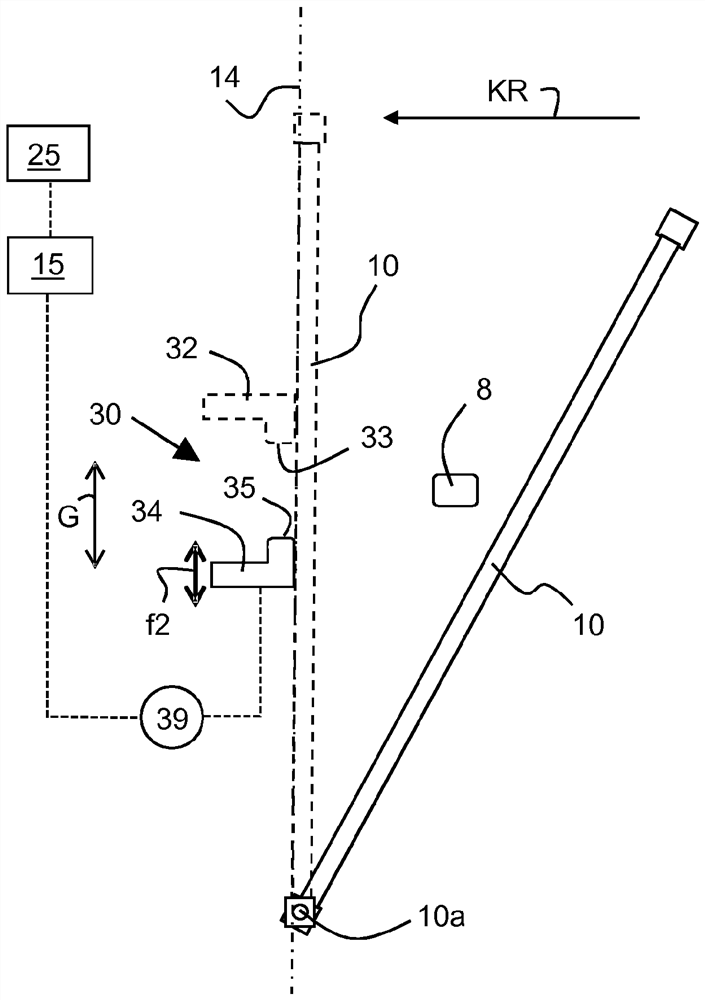

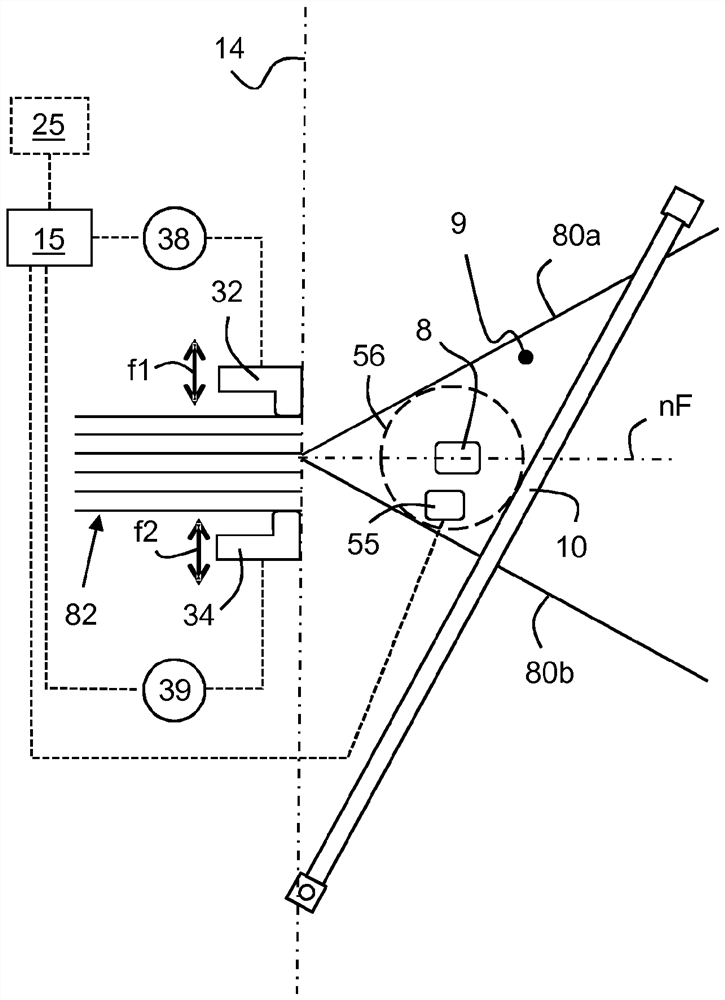

[0064] figure 1 A schematic side view of a possible embodiment of the weaving machine 1 is shown. A plurality of warp threads 80 extending side by side are provided, for example, by a warp beam 2 (alternatively by a creel) and are conveyed along the warp direction KR (see arrow) via the back rest 3 and after passing the warp monitor 4 to the shedding device 5, which opens The means are preferably formed by threads 6 known to be oscillating and movable against each other in order to open or close the weaving shed 9 . The opening means 5 are according to a preferred embodiment of the jacquard type.

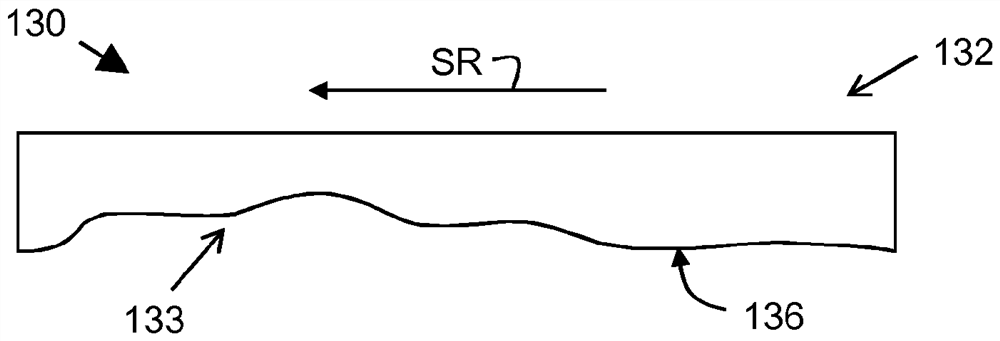

[0065] The weft thread feeder 7 (shown only schematically) has a weft thread feeder 8 , which is designed in the present case as a thread gripper, and which conveys the weft thread through an open weaving shed 9 . Furthermore, the loom 1 has a weaving board 10 , by means of which the incoming weft threads can be brought into contact with so-called connection points 11 of the alrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com