MEMS (Micro-Electro-Mechanical System) cutting and cleaning as well as releasing method of wafer

A wafer and cutting blade technology, applied in the field of MEMS wafer cutting, cleaning and releasing, can solve the problems of easy touch of chips, low production efficiency, expensive thinning equipment and plasma cutting equipment, etc., and achieve the effect of good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

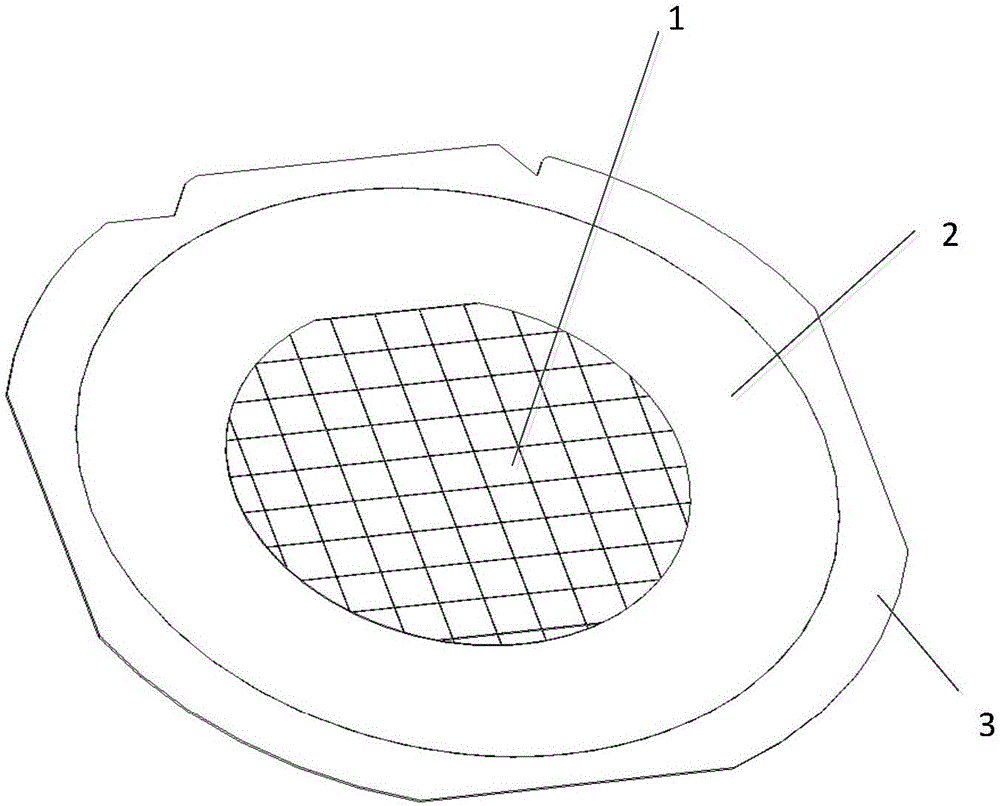

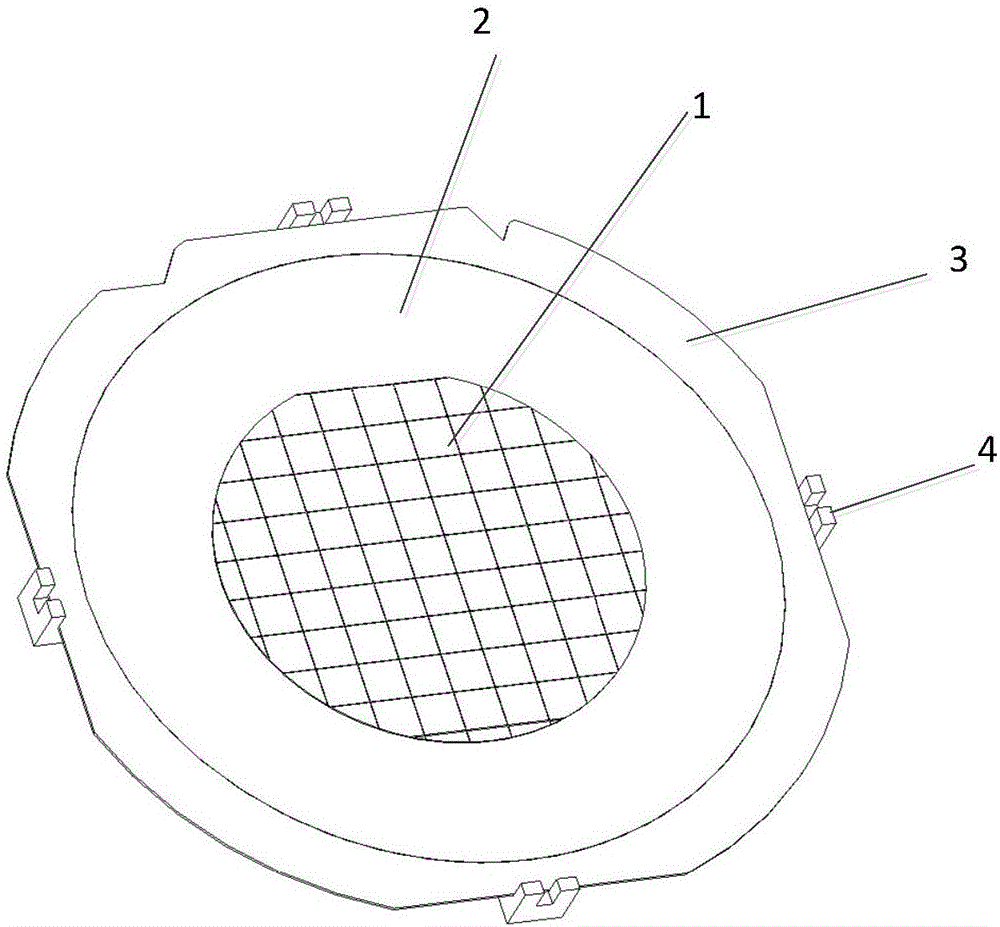

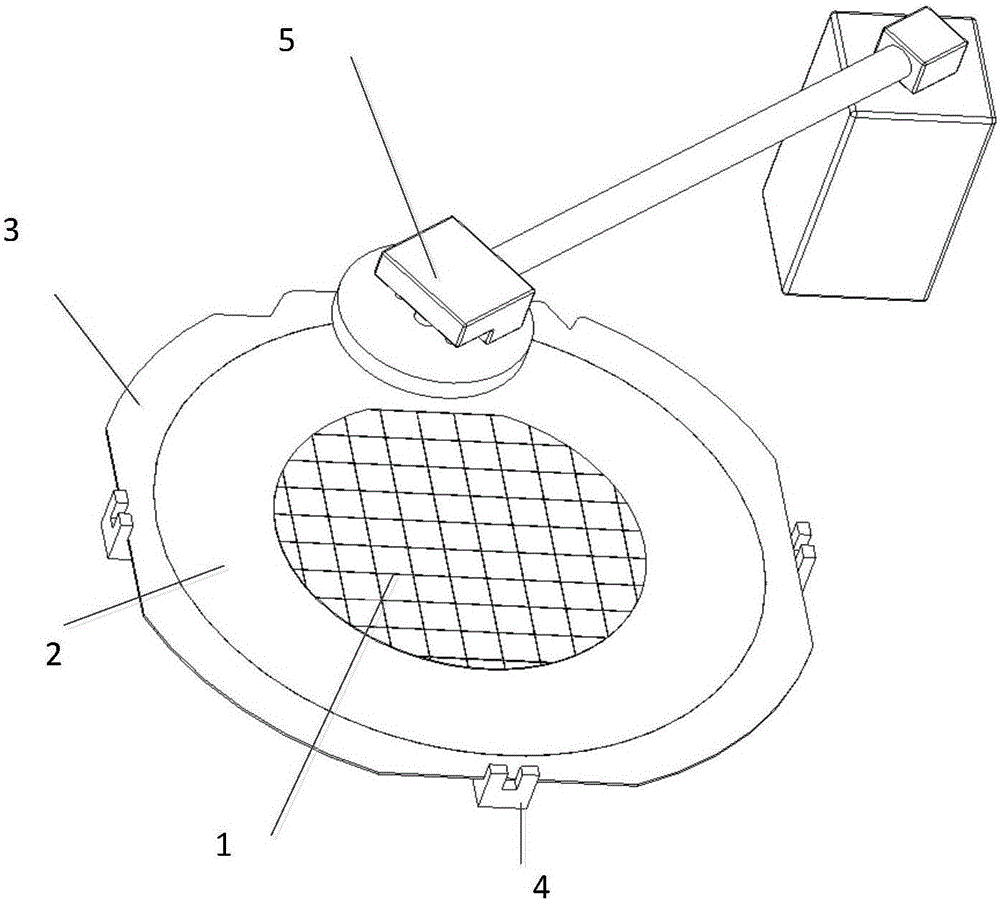

[0045] Such as Figure 1-Figure 4 Shown, a kind of MEMS wafer cutting cleaning and release method, comprises the following steps:

[0046] Step 1: Paste the UV film 2, place the wafer 1 face down on the center of the suction cup of the film mounter, the suction cup is a vacuum suction cup suspended in the middle; pull out the UV film from the rear drum of the film mounter, the length exceeds the stainless steel frame The outer circumference of 3 is 2 to 10 cm. If there are wrinkles locally, it needs to be further tightened until the surrounding area is even and flat, and then gently push the film with a roller to make the film flat and close to the back of wafer 1 and stainless steel frame 3; UV film 2 is cut off, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com