Ball screw mechanism and linear motion device

A ball screw and ball technology, used in transmissions, mechanical equipment, belts/chains/gears, etc., can solve the problems of complex structure, hindering the smooth return of balls, and difficulty in restraining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

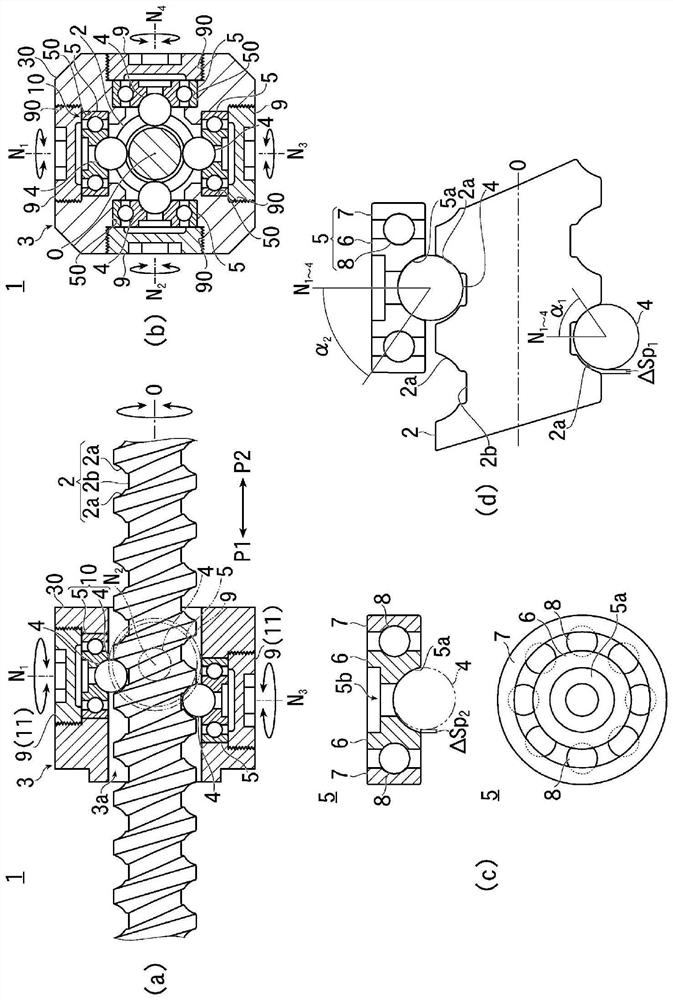

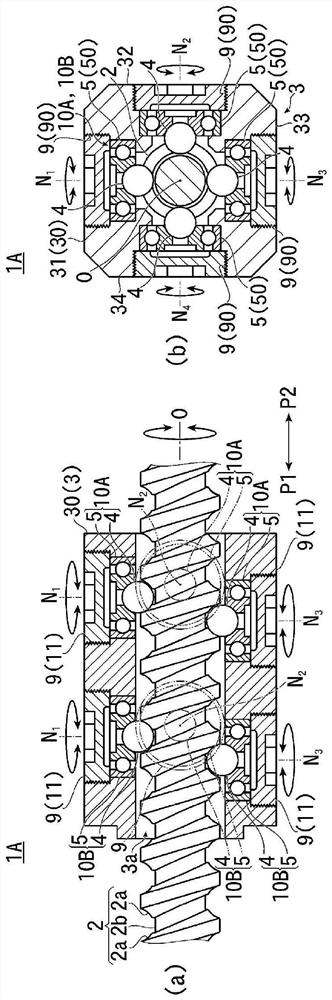

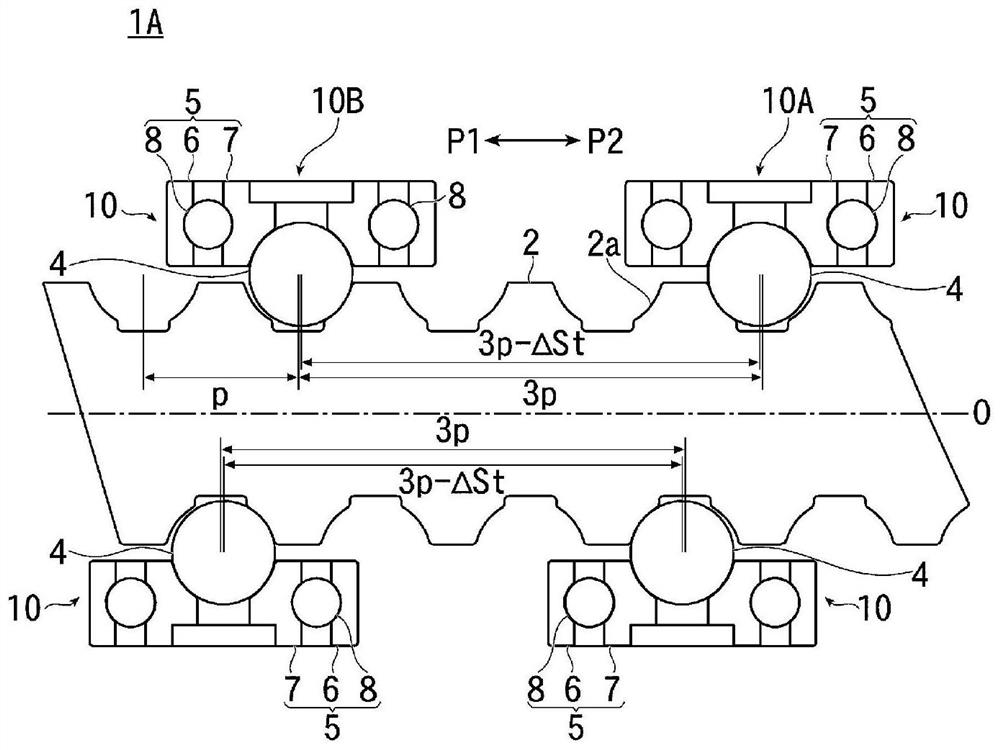

[0056] figure 1 (a) to figure 1 (d) in shows an embodiment of the ball screw according to the present invention, figure 1 (a) is a front partial sectional view showing the overall structure, figure 1 (b) is a side view partial sectional view showing the overall structure, figure 1 (c) is a front partial sectional view and a top view showing the structure of the ball bearing, figure 1 (d) is an explanatory diagram showing the dimensional relationship between the screw shaft and the balls.

[0057] Such as figure 1 As shown in (a), the ball screw mechanism 1 of this embodiment has: a screw shaft 2 extending linearly; a moving body 3 provided around the screw shaft 2; The thrust force of the screw shaft 2 is transmitted to the moving body 3 to move the moving body 3 along the screw shaft 2 .

[0058] The screw shaft 2 of the present embodiment has a solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com