Efficient anti-corrosion ceramic ball valve

A ceramic ball valve, anti-corrosion technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve the problems that it can only be used in wear-resistant conditions, cannot be used in strong corrosion conditions, and has limited use. Achieve the effect of avoiding major safety hazards, preventing corrosion and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

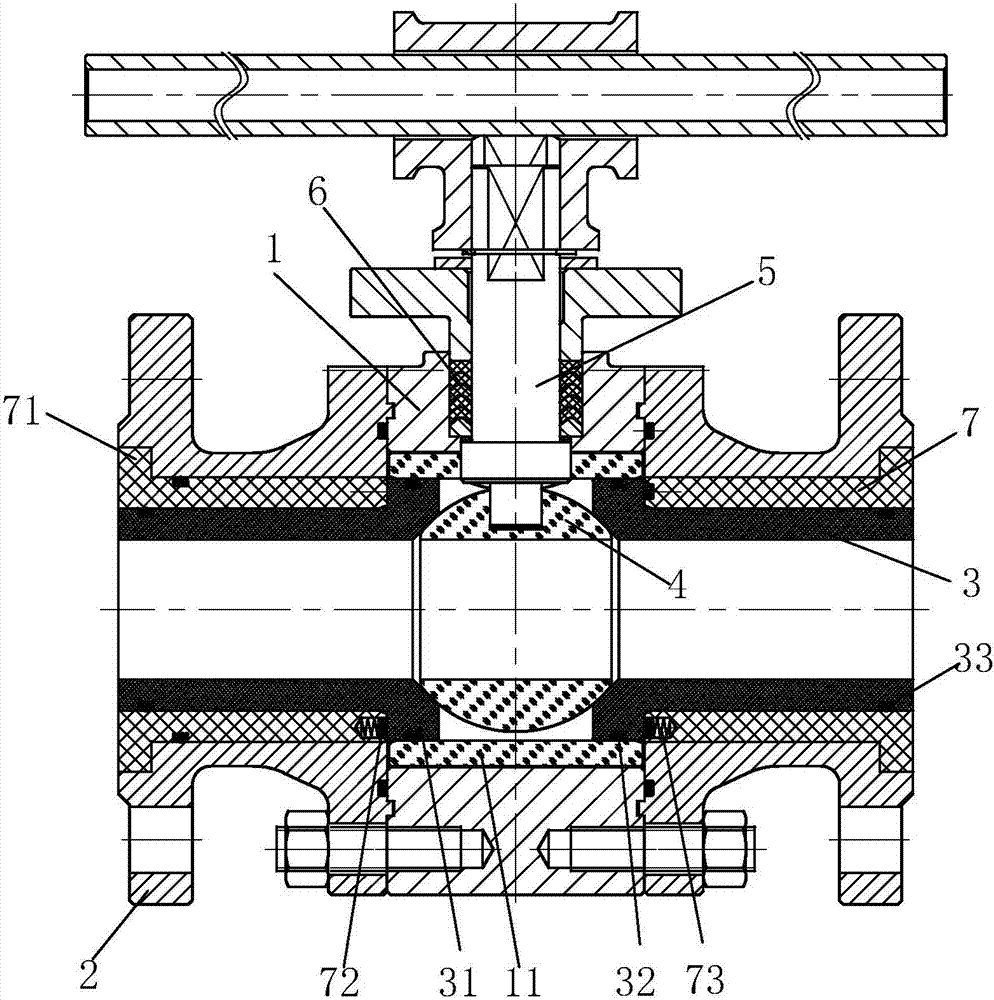

[0020] Such as figure 1 The high-efficiency anti-corrosion ceramic ball valve shown includes valve body 1, valve cover 2, valve seat 3, valve ball 4 and valve stem 5. Valve body 1 and valve cover 2 are made of metal materials, valve seat 3, valve ball 4 Made of ceramics, the valve cover 2 is assembled on the valve body 1, the valve seat 3 is sleeved in the valve body 1 and the valve cover 2, the valve stem 5 and the valve body 1 are closely matched through the packing layer 6, and one end of the valve stem 5 It is connected with the valve ball 3 arranged in the valve body 1, and its characteristic is that a valve cover liner 7 made of polytetrafluoroethylene is arranged between the valve seat 3 and the valve cover 2, and the valve cover liner 7 is in the form of a cylinder Shaped structure, the valve cover lining 7 is outside the valve seat 3 and inside the valve cover 2, the inner wall of the valve cover lining 7 is in close contact with the outer wall of the valve seat 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com