Disc loading mechanism in a disc player for positioning a disc and an optical pickup while reducing mechanical shocks to the disc tray

a disc player and disc technology, applied in the direction of instruments, casings/cabinets/drawers, electrical apparatus, etc., can solve problems such as exerting influence, and achieve the effects of eliminating collision sounds, eliminating shocks, and improving loading gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

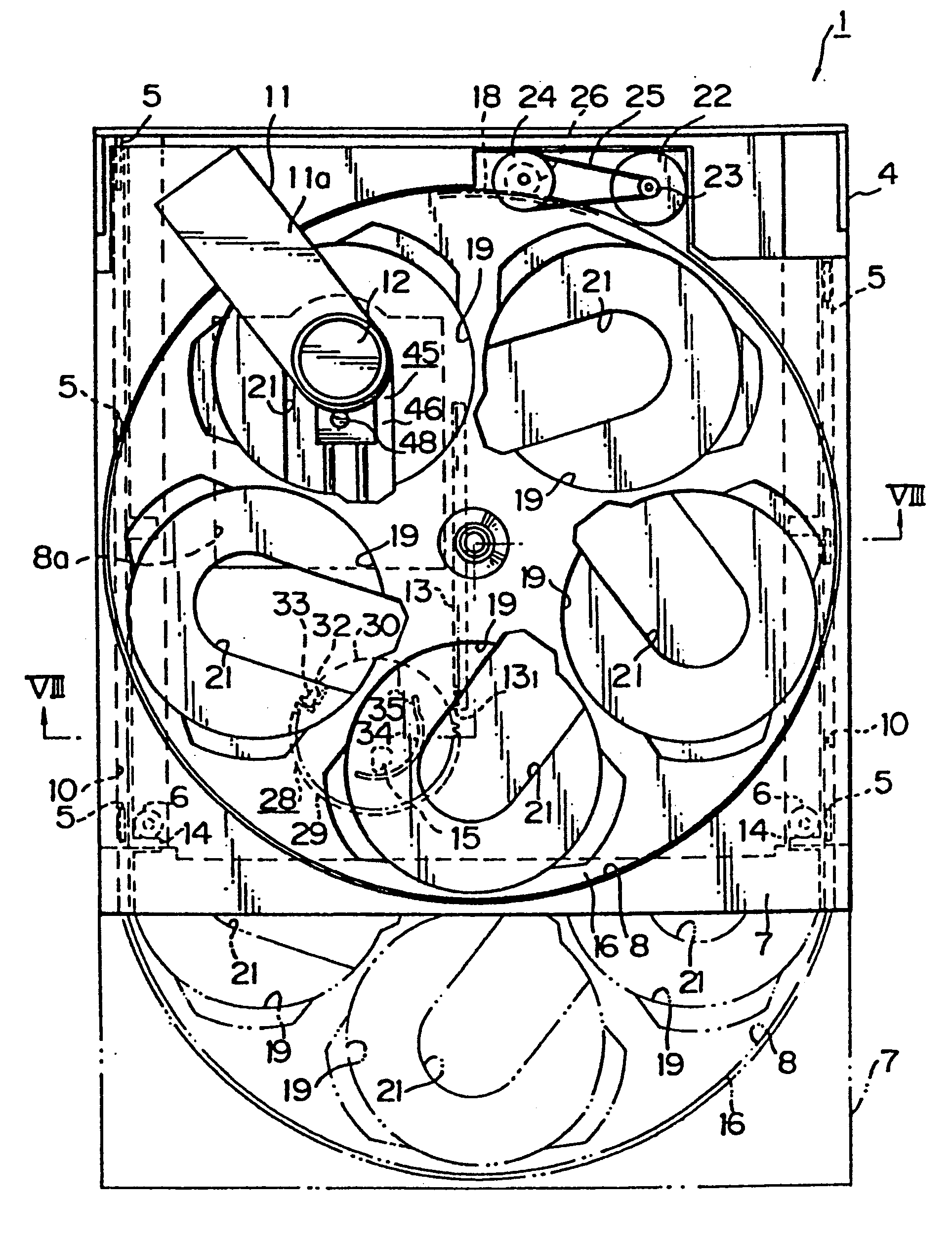

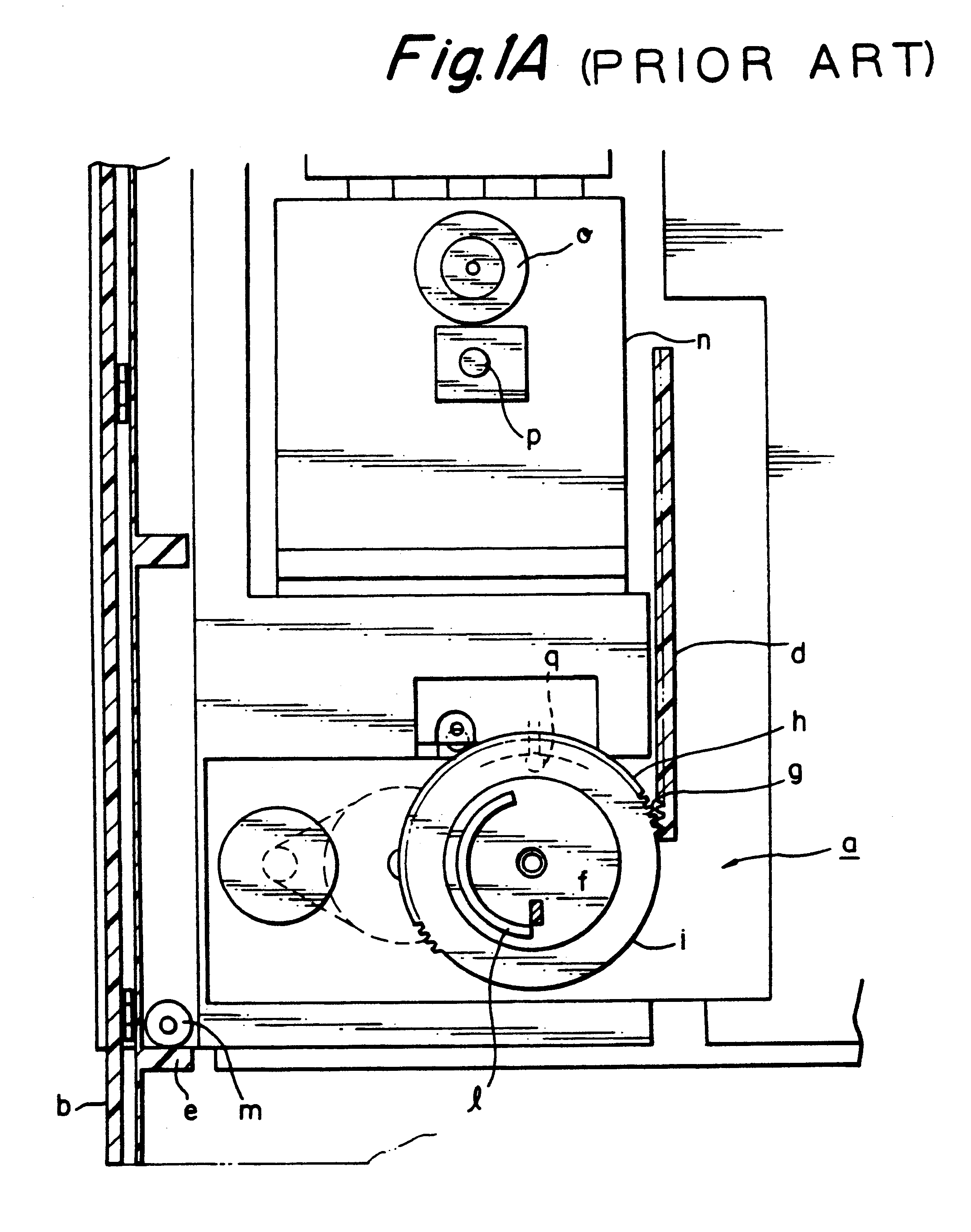

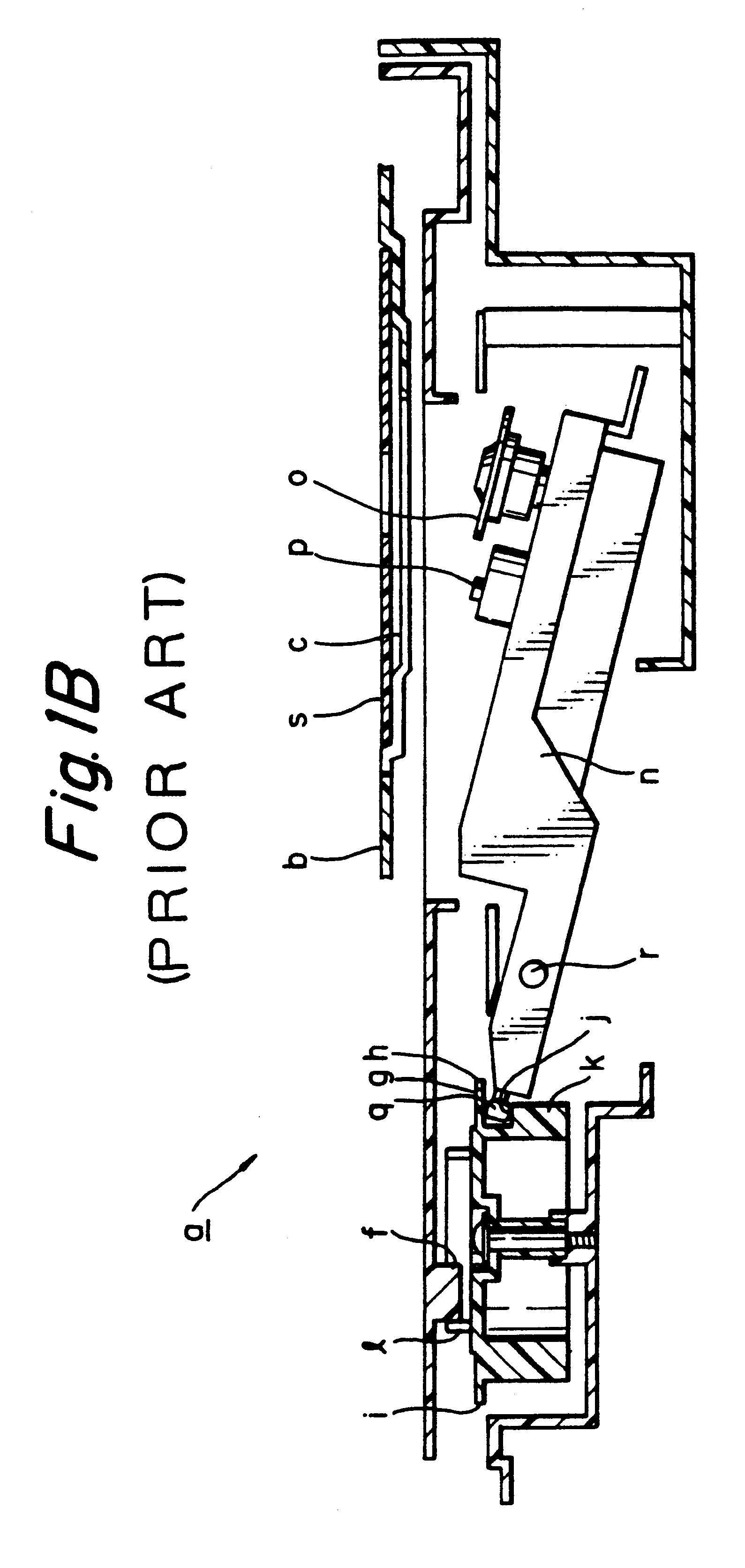

A disc tray loading mechanism of the invention will be described in detail hereinbelow in accordance with an embodiment shown in the drawings (FIGS. 3 to 16).

The embodiment shown in the drawings relates to the case where the disc tray loading mechanism of the invention is applied to a disc player of what is called an automatic changing type in which a plurality of compact discs are enclosed and one of the compact discs is selected and the reproduction is executed, wherein after completion of the pull-in operation of a disc tray, a mechanical deck is raised and the chucking of the compact disc is executed.

a. Casing (FIGS. 3 to 8)

Reference numeral 1 denotes a disc player.

Reference numeral 2 denotes an outer casing of the disc player 1. The outer casing 2 is formed into a relatively thin box shape whose lower and rear surfaces are opened. (The direction which is directed to the left oblique downward position in FIG. 3 assumes the front side and the direction which is directed to the ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| center span angle | aaaaa | aaaaa |

| center angle | aaaaa | aaaaa |

| center angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com