Full-automatic wheel hub deburring machine

A deburring machine, fully automatic technology, used in machine tools, grinders, metal processing equipment and other directions suitable for grinding the edge of workpieces, can solve problems such as production efficiency decline, prolong service life, solve production efficiency decline, and eliminate bumps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

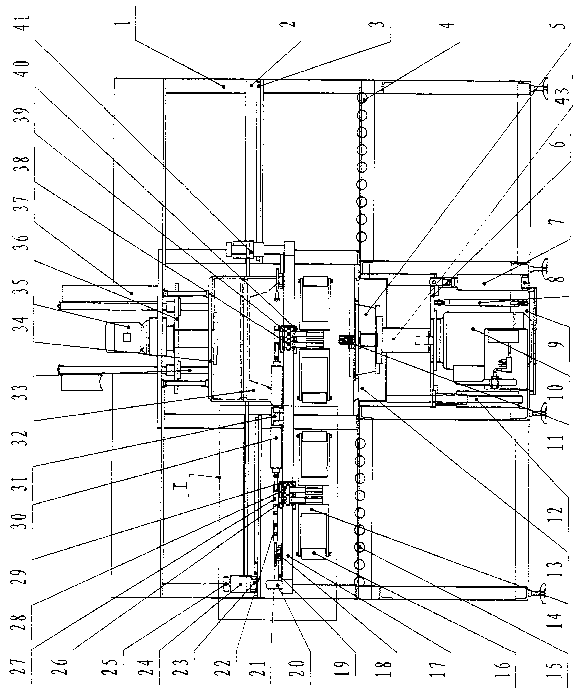

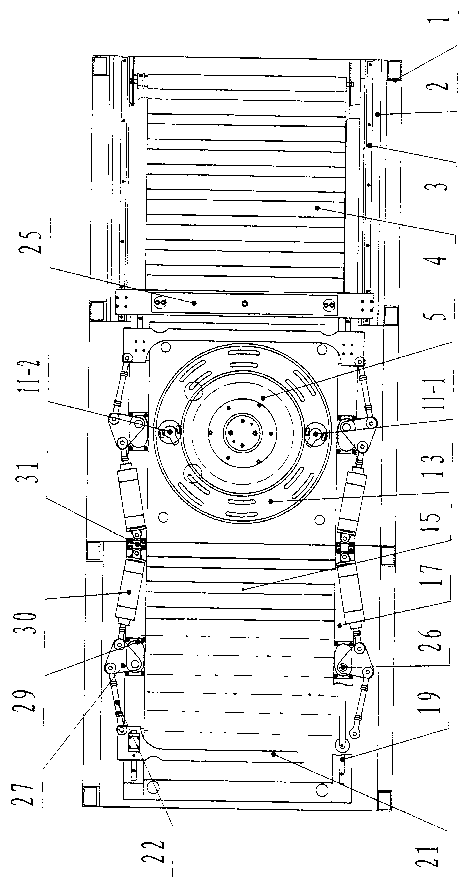

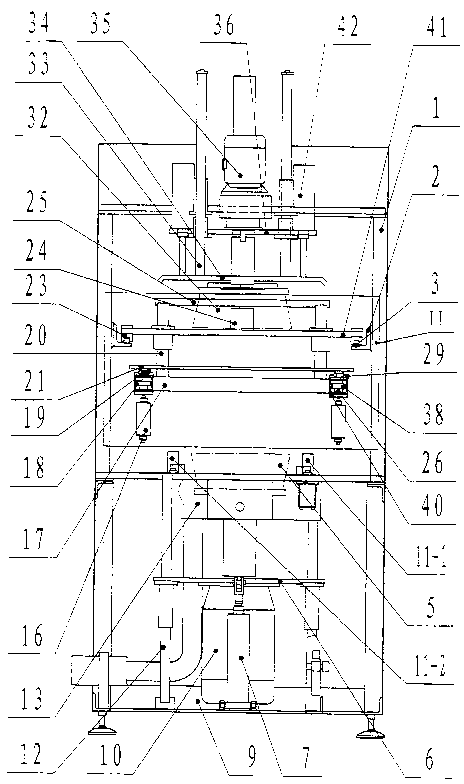

[0013] Examples, see attached Figure 1~5 , the left side of the casing 1 of the automatic hub deburring machine is equipped with a feeding channel 15, which can be used for feeding, and the upper right side of the casing 1 corresponding to the feeding channel 15 is equipped with a lower material channel 4, and the lower material channel 4 will process The rear hub is transported out. The wheel hub processing mechanism is installed in the middle of the feeding path 15 and the discharging path 4, and the clamping mechanism is installed above the feeding path 15, and the wheel hub clamping can be put into the wheel hub processing mechanism. The hub processing mechanism is to vertically install the lower brush light rod 12 on the base plate of the casing 1, and the upper end of the lower hair brush light rod 12 is fixed on the work platform 13, and the work platform 13 is installed in the middle part of the casing 1. The lower brush light rod 12 is installed in the circular hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com