Patents

Literature

124results about How to "Eliminate bumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

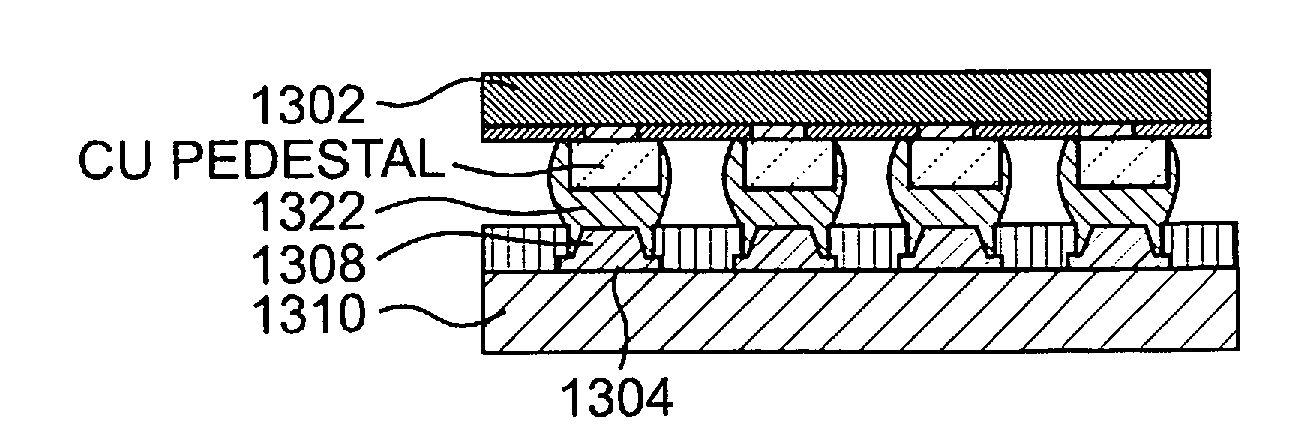

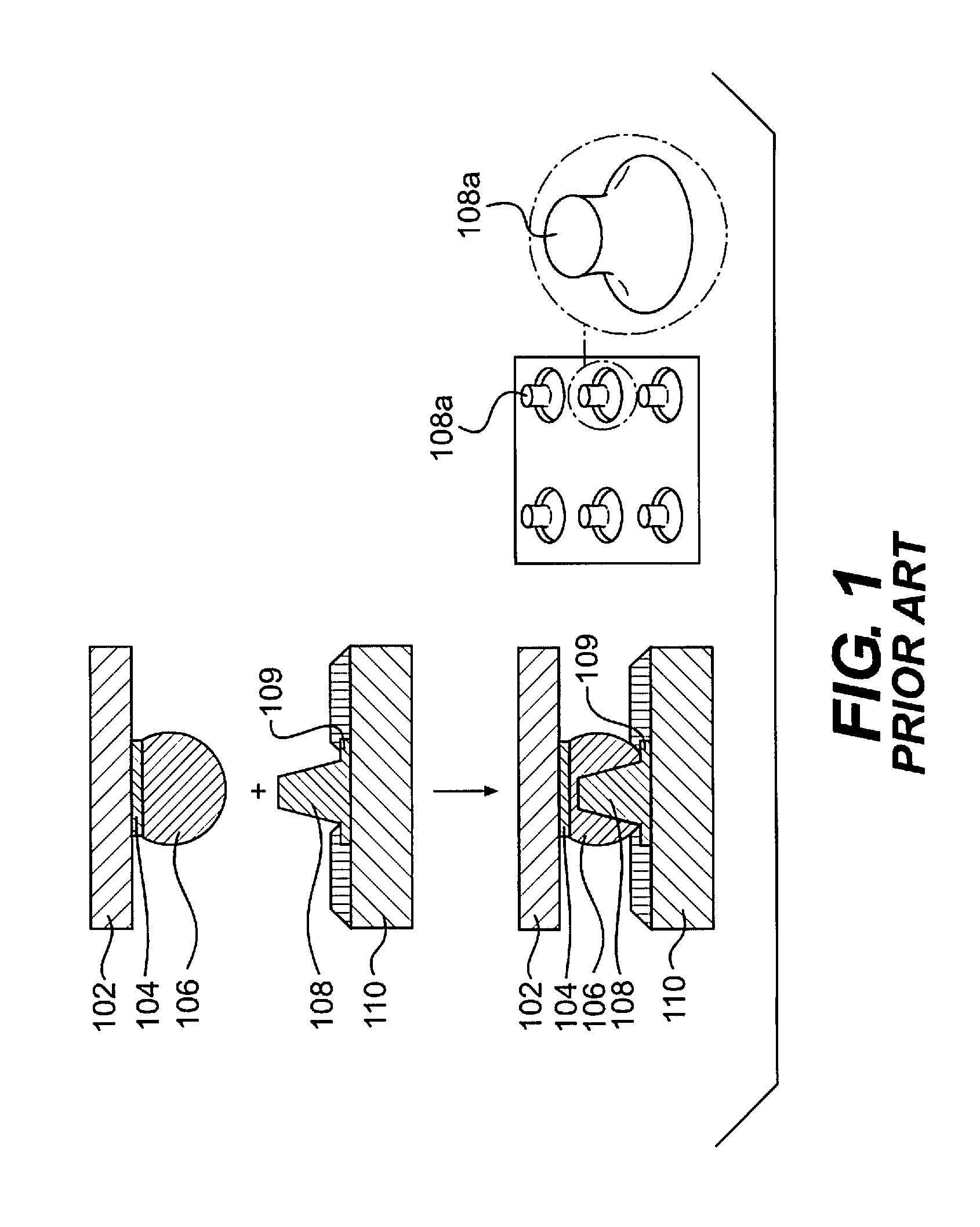

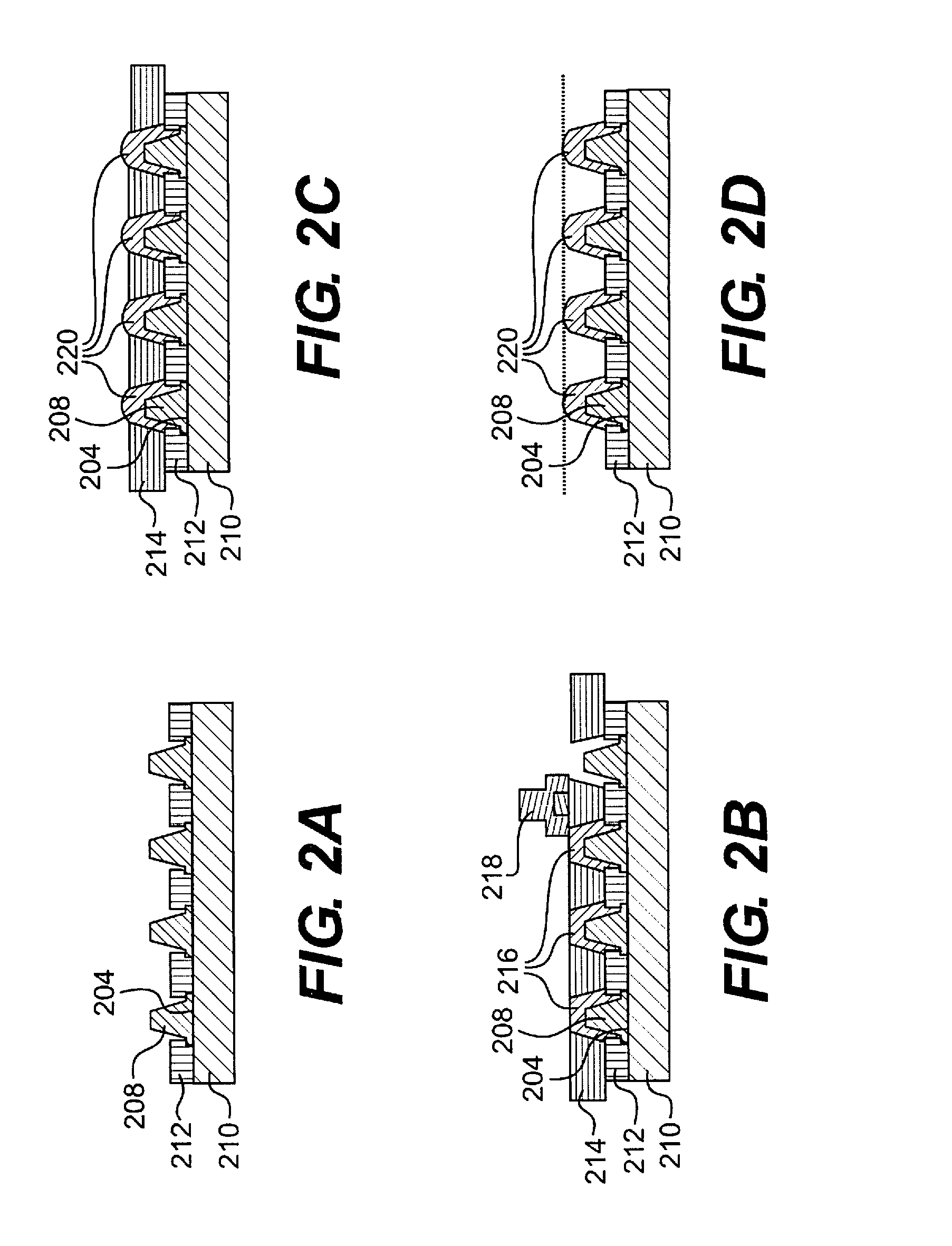

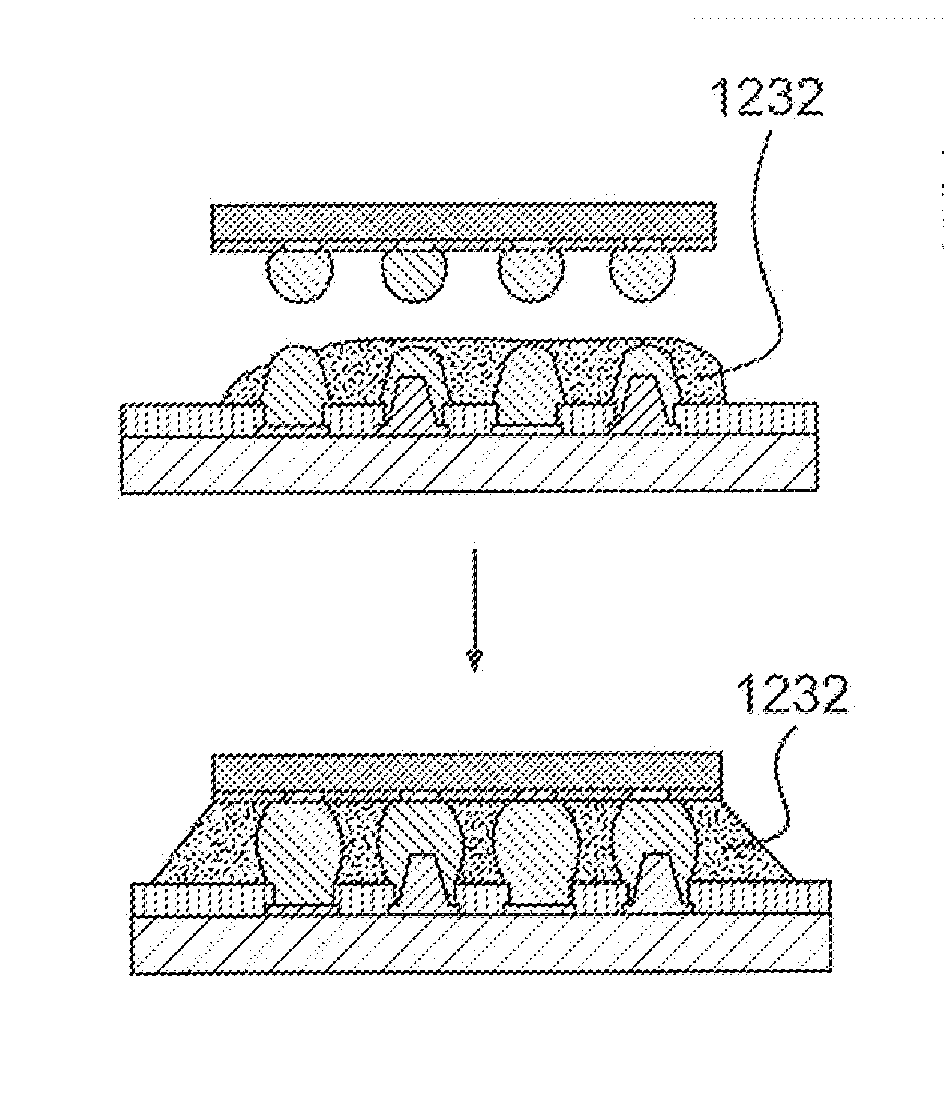

Copper Post Solder Bumps on Substrate

ActiveUS20120252168A1Relieve pressureEasy to cleanSemiconductor/solid-state device detailsSolid-state devicesFlip chip interconnectEngineering

A method comprises forming semiconductor flip chip interconnects where the flip chip comprises a wafer and a substrate having electrical connecting pads and electrically conductive posts operatively associated with the pads and extending away from the pads to terminate in distal ends. Solder bumping the distal ends by injection molding solder onto the distal ends produces a solder bumped substrate. Another embodiment comprises providing the substrate having the posts on the pads with a mask having a plurality of through hole reservoirs and aligning the reservoirs in the mask to be substantially concentric with the distal ends. This is followed by injecting liquid solder into the reservoirs to provide a volume of liquid solder on the distal ends, cooling the liquid solder in the reservoirs to solidify the solder, removing the mask to expose the solidified solder after the cooling and thereby provide a solder bumped substrate. This is followed by positioning the solder bumped substrate on a wafer in a manner that leaves a gap between the wafer and the substrate. The wafer has electrically conductive sites on the surface for soldering to the posts. Abutting the sites and the solder bumped posts followed by heating the solder to its liquidus temperature joins the wafer and substrate, after which, the gap is optionally filled with a material comprising an underfill.

Owner:IBM CORP

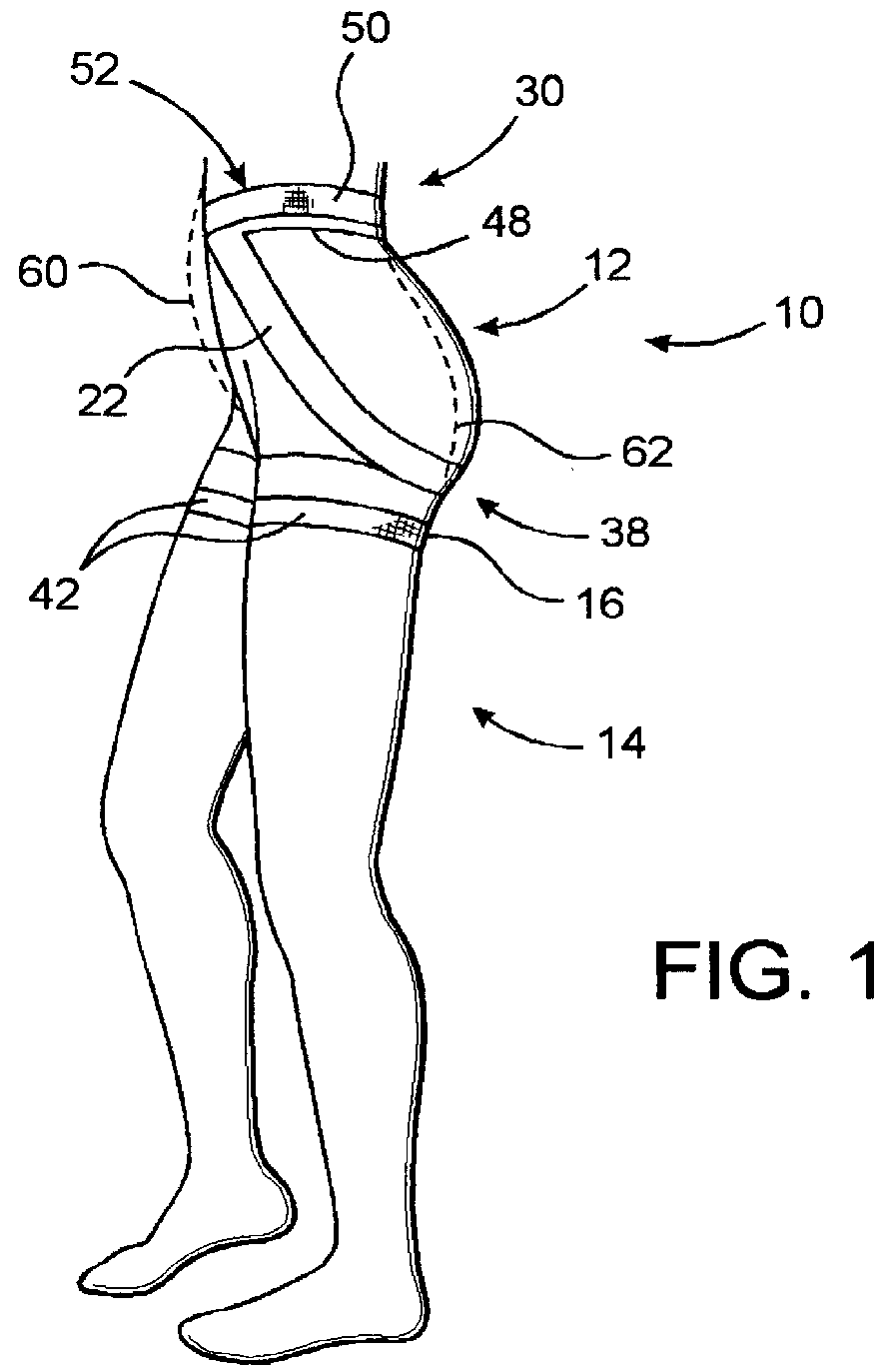

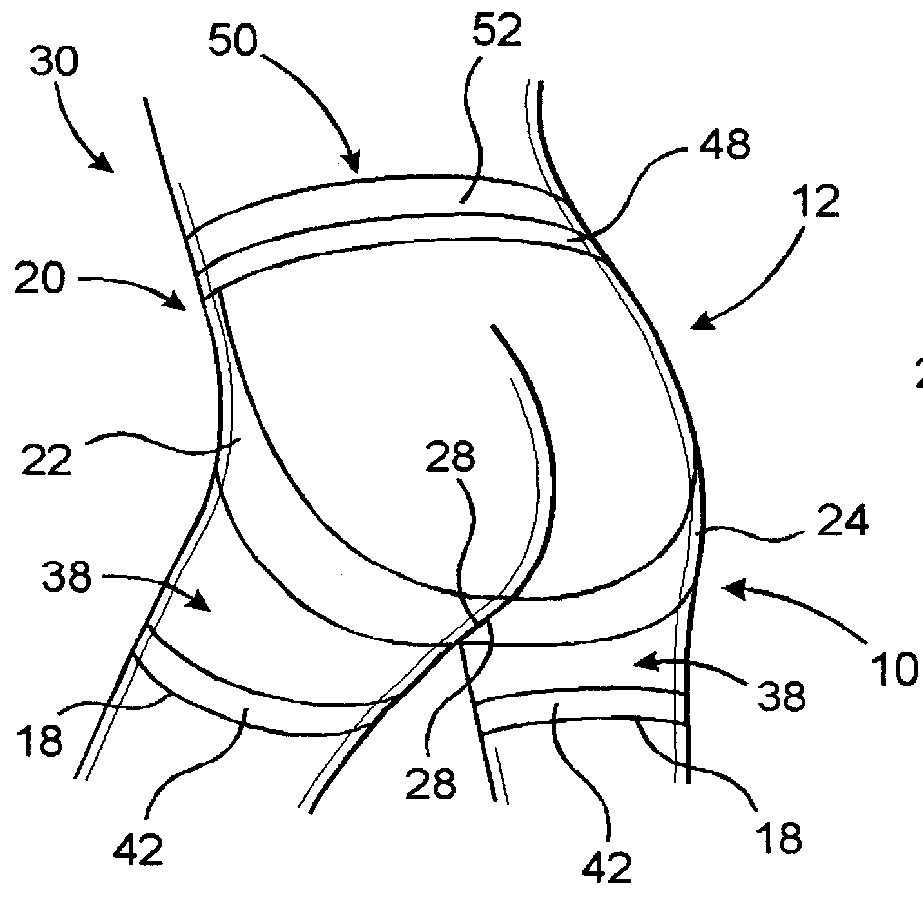

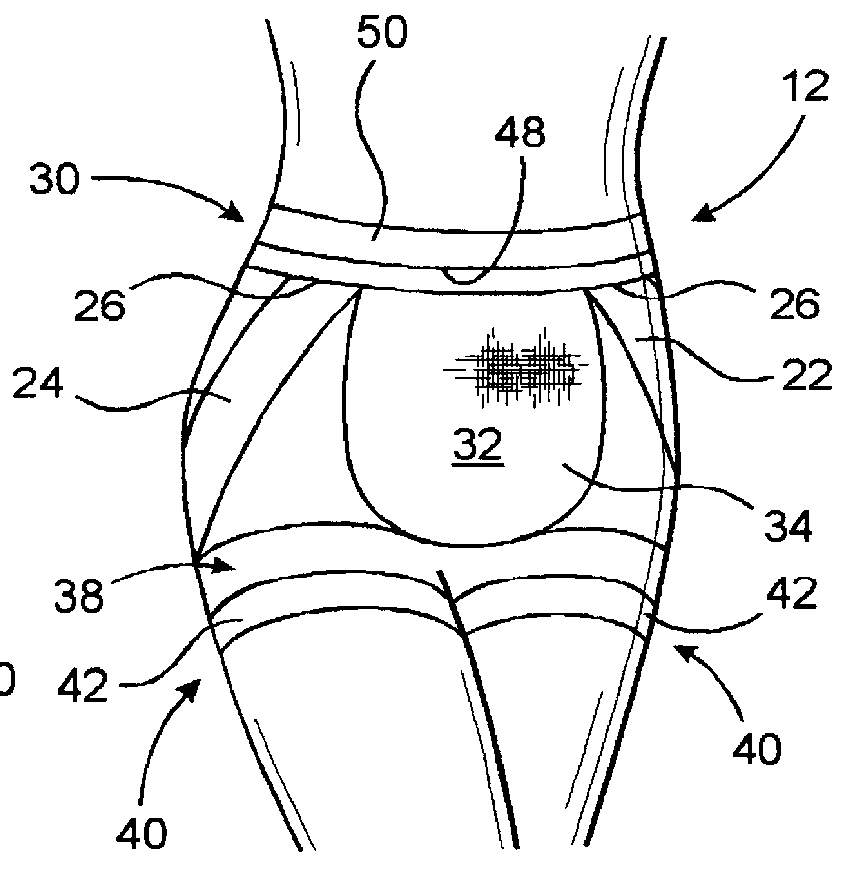

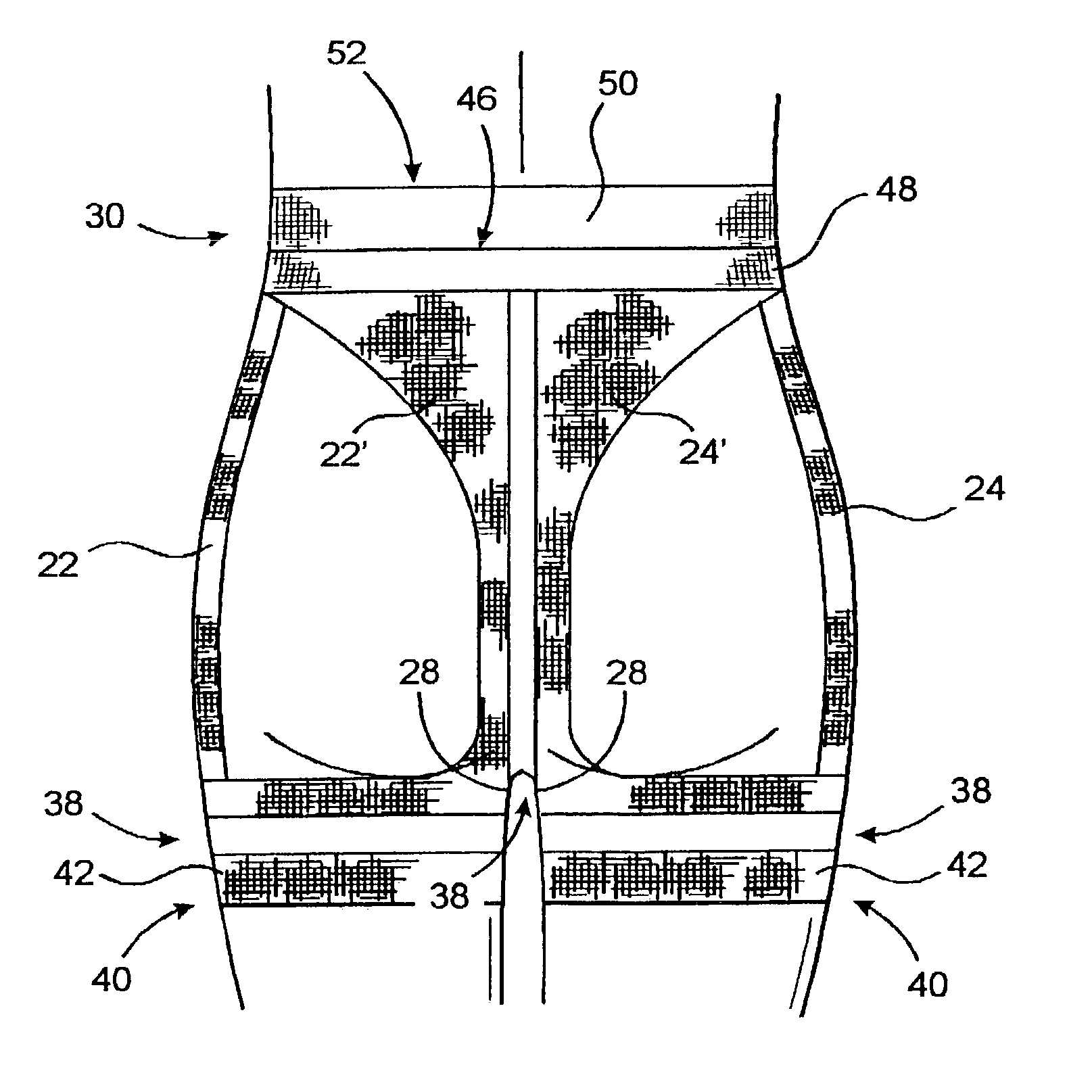

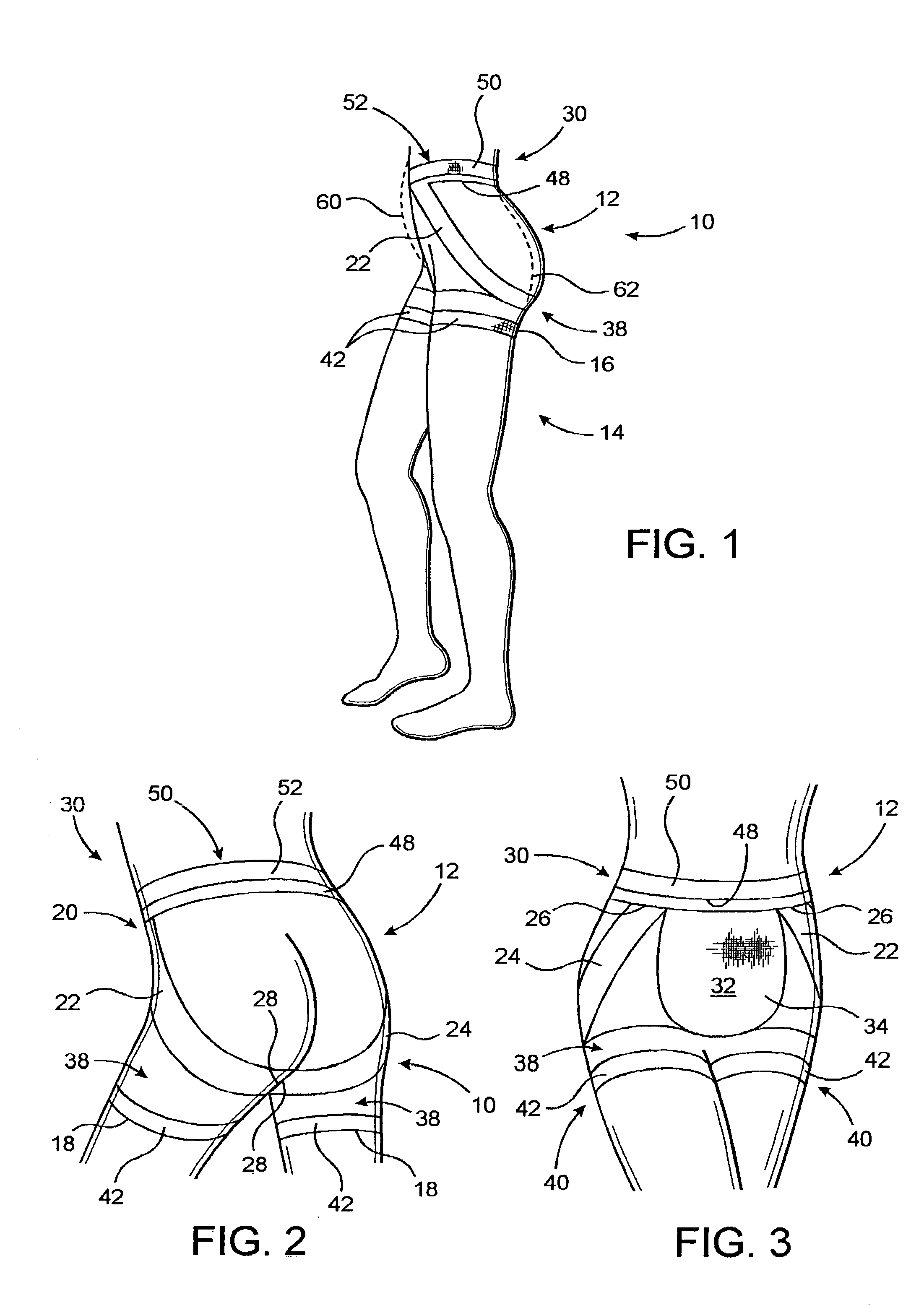

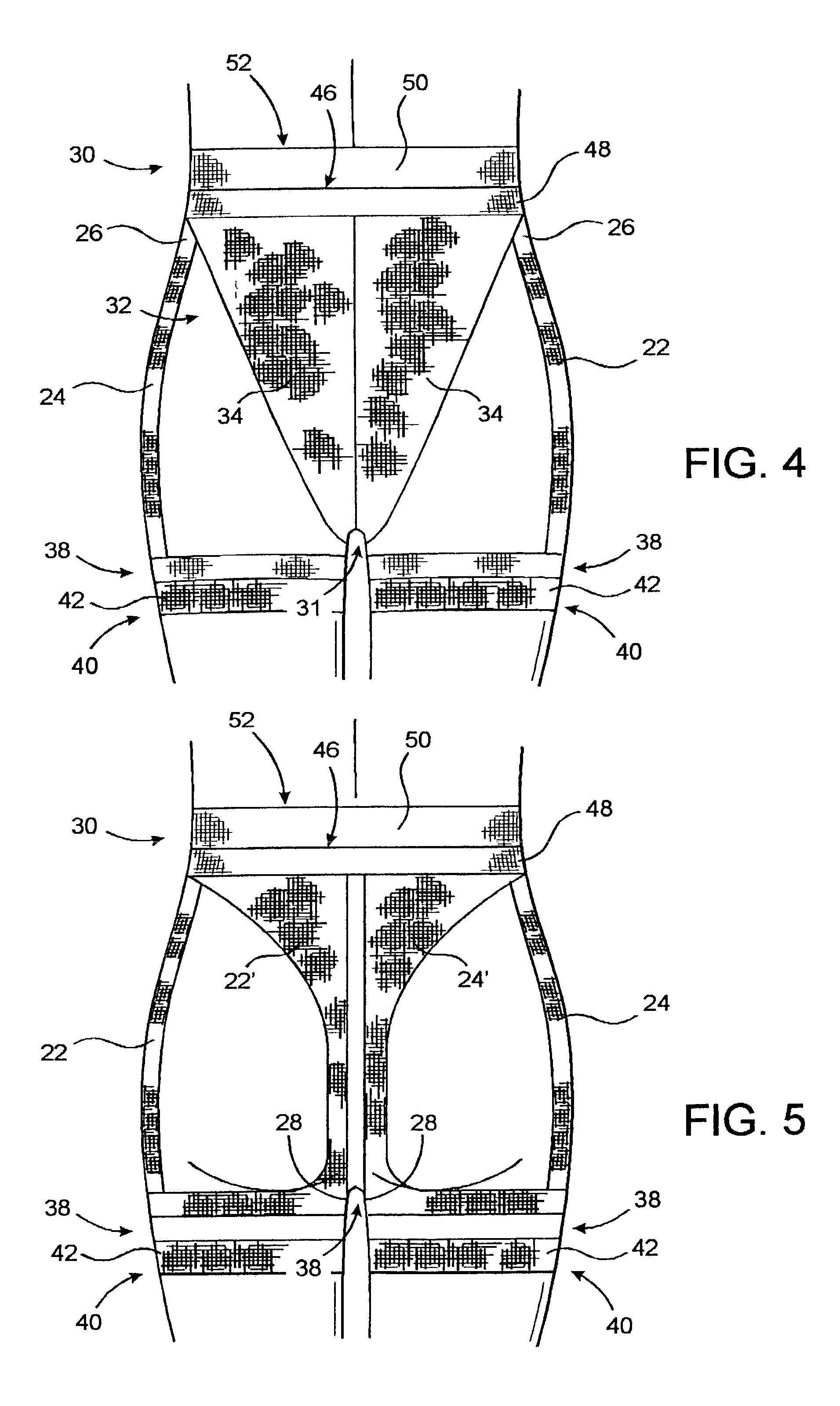

Reinforced undergarment

A reinforced undergarment at least including underpants and, in certain embodiments, a pair of hose or stockings permanently or removably secured to the underpants so as to define a pair of pantyhose, wherein the undergarment, and particularly the underpants are formed from a flexible material including a plurality of interconnected portions disposed and configured to overly predetermined areas of the wearer's body so as to exert a supporting and / or retaining force thereon and thereby shape the wearer's body, or at least certain portions thereof, into a desired configuration. The interconnected portions of the undergarment are at least partially formed from an elastic material of varying densities such that different support and / or retaining force are exerted on predetermined portions of the wearer's body. The underpants include at least a first support portion and a second support portion, wherein the first support portion is disposed beneath the buttocks of the wearer and has a sufficient density to exert an uplifting force thereon. The second support portion includes a reinforced panel of predetermined density disposed in overlying, retaining relation to the wearer's abdomen so as to exert an inwardly directed, retaining force thereon. The various embodiments of the undergarment may include additional support portions disposed in overlying, retaining relation to other predetermined portions of the wearer's body.

Owner:INTERMARKETING EXPRESS USA

Reinforced undergarment

A reinforced undergarment at least including underpants and, in certain embodiments, a pair of hose or stockings permanently or removably secured to the underpants so as to define a pair of pantyhose, wherein the undergarment, and particularly the underpants are formed from a flexible material including a plurality of interconnected portions disposed and configured to overly predetermined areas of the wearer's body so as to exert a supporting and / or retaining force thereon and thereby shape the wearer's body, or at least certain portions thereof, into a desired configuration. The interconnected portions of the undergarment are at least partially formed from an elastic material of varying densities such that different support and / or retaining force are exerted on predetermined portions of the wearer's body. The underpants include at least a first support portion and a second support portion, wherein the first support portion is disposed beneath the buttocks of the wearer and has a sufficient density to exert an uplifting force thereon. The second support portion includes a reinforced panel of predetermined density disposed in overlying, retaining relation to the wearer's abdomen so as to exert an inwardly directed, retaining force thereon. The various embodiments of the undergarment may include additional support portions disposed in overlying, retaining relation to other predetermined portions of the wearer's body.

Owner:INTERMARKETING EXPRESS USA

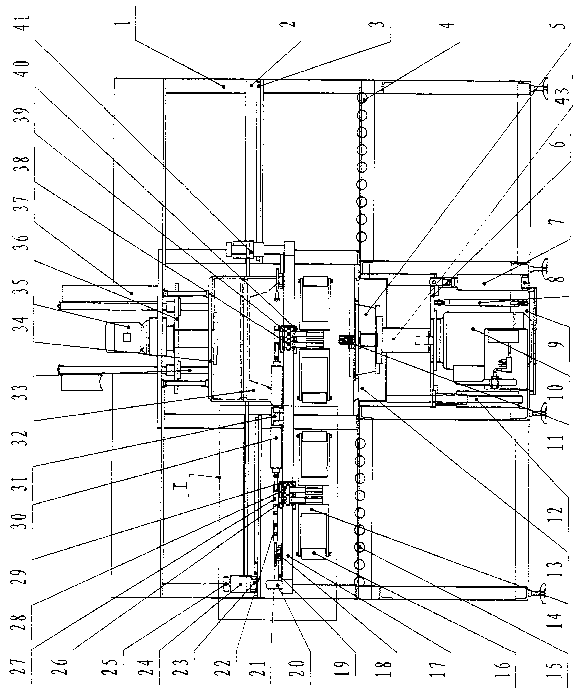

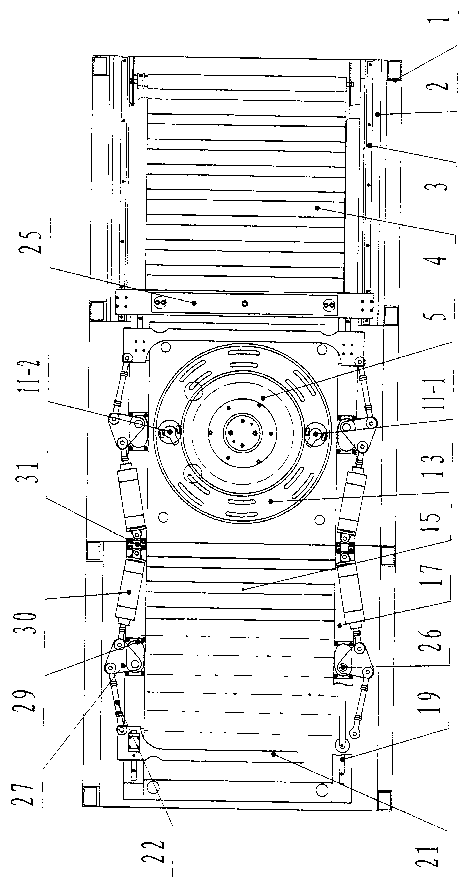

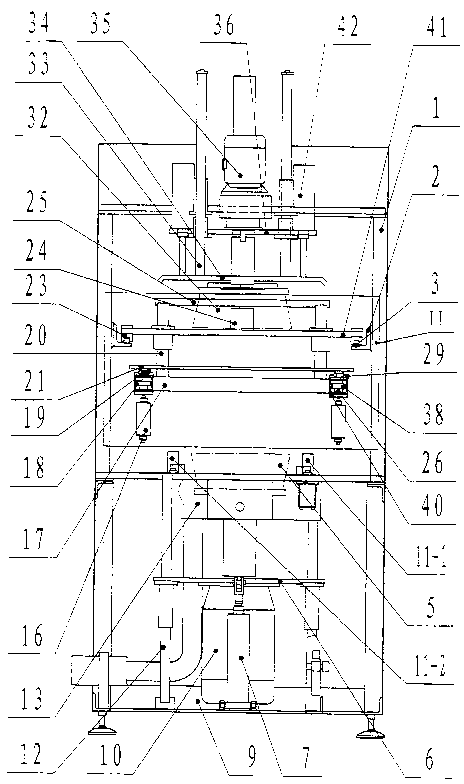

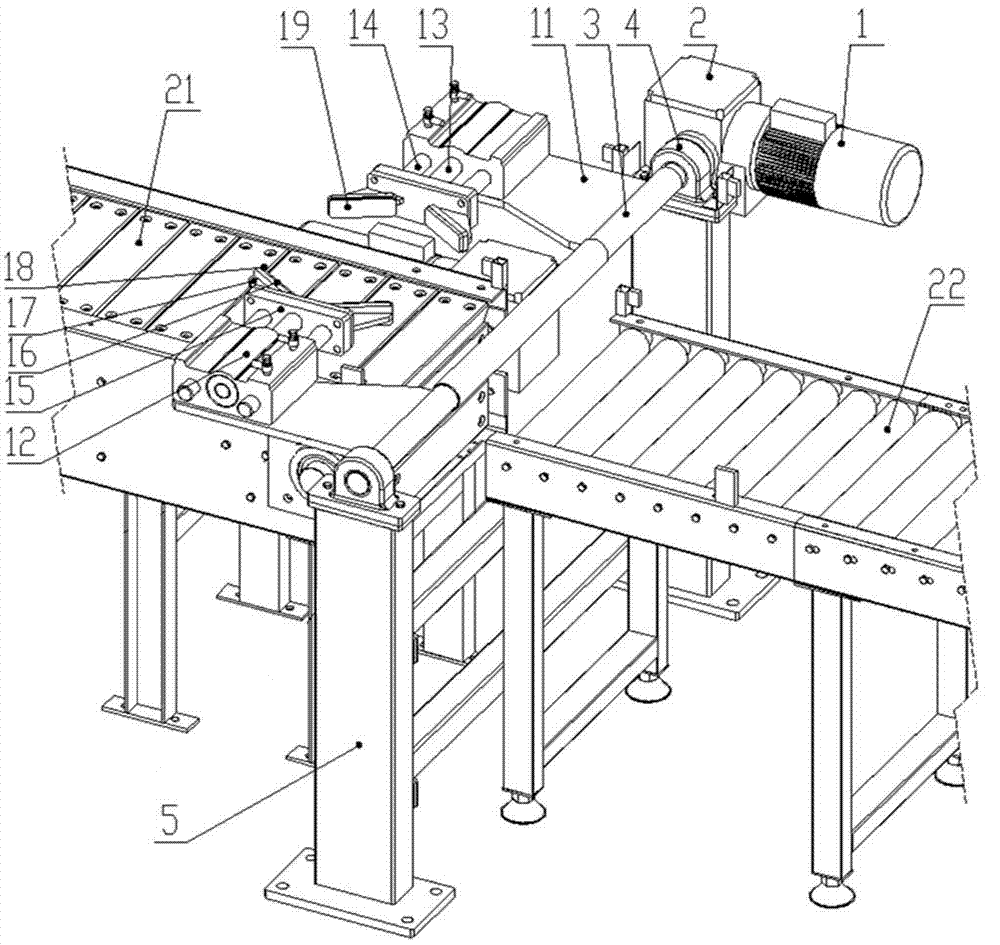

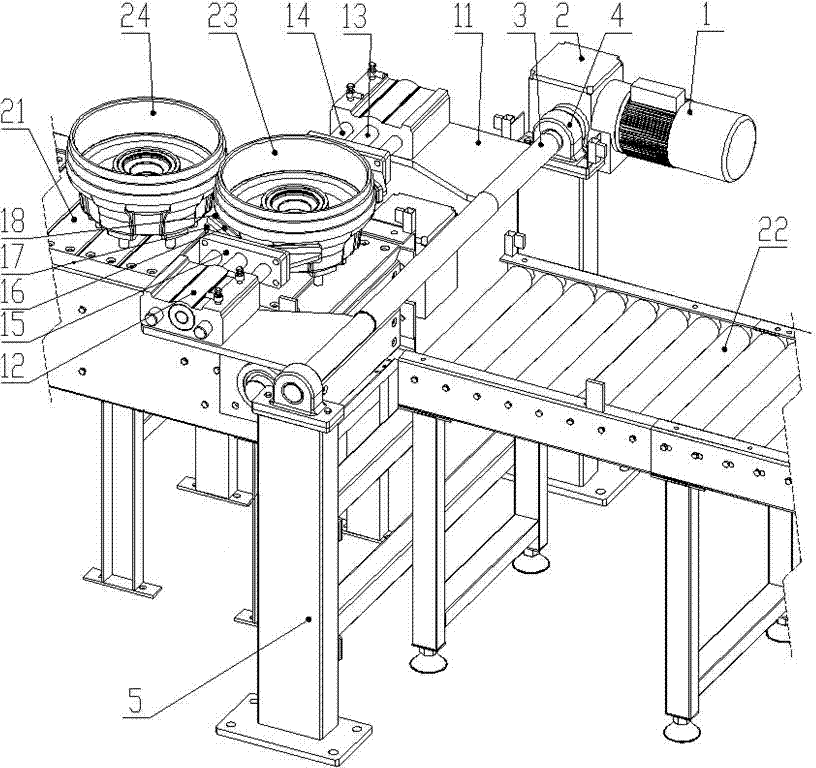

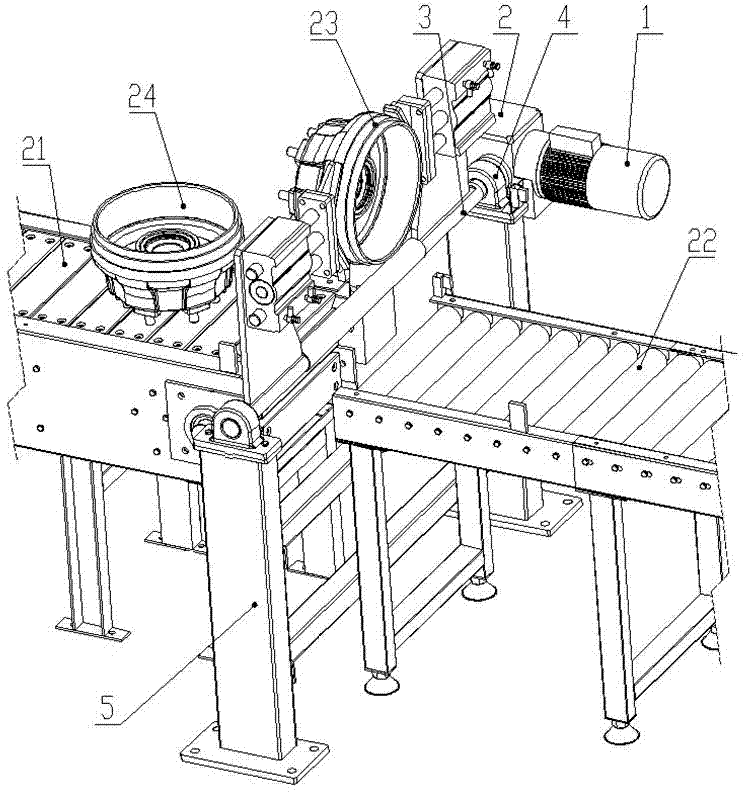

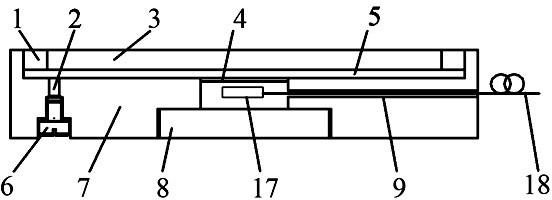

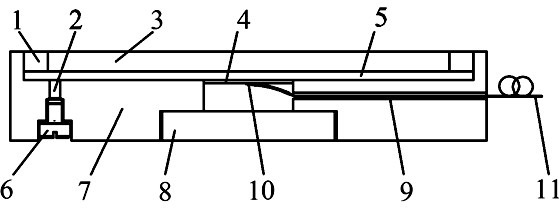

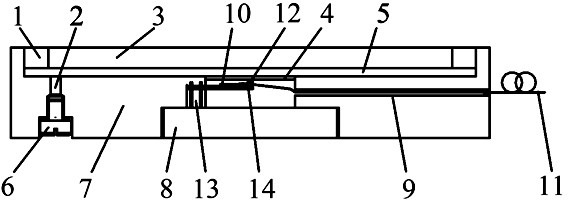

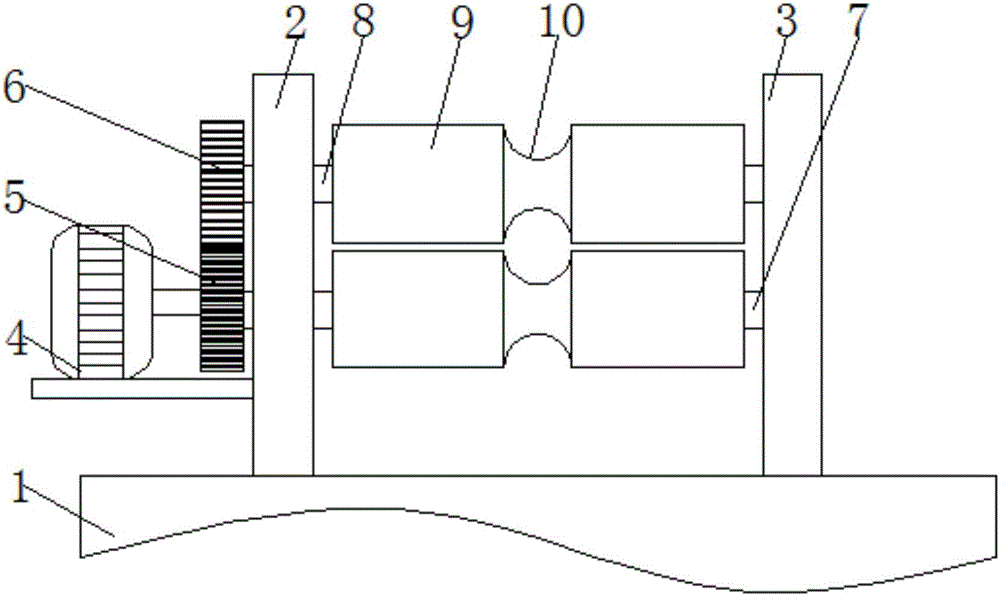

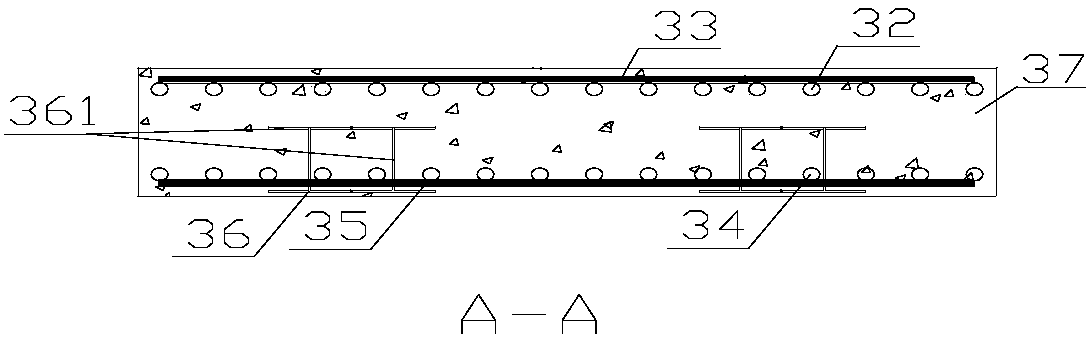

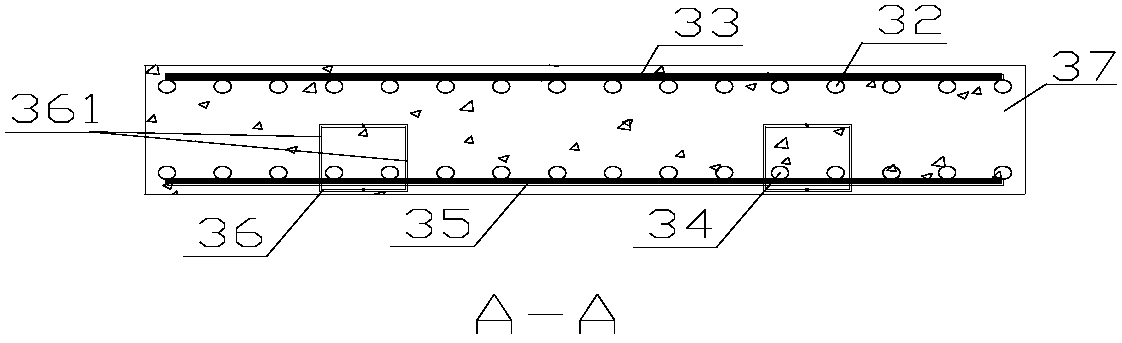

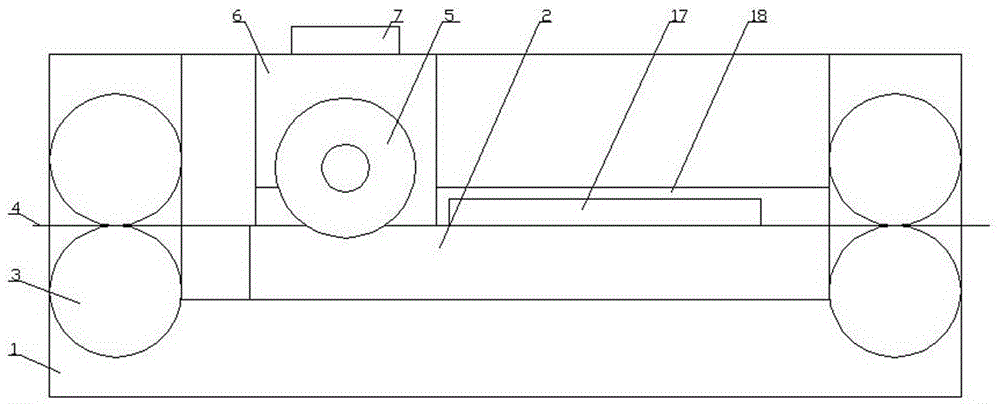

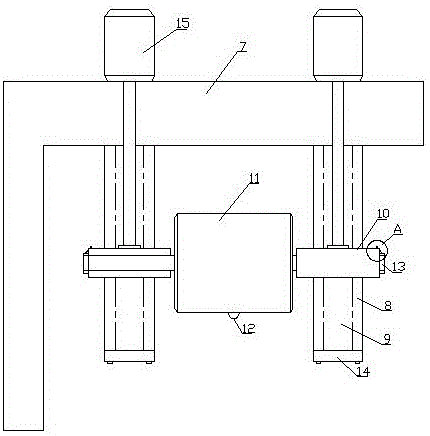

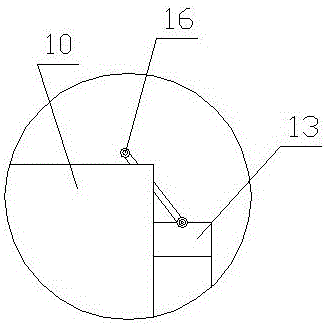

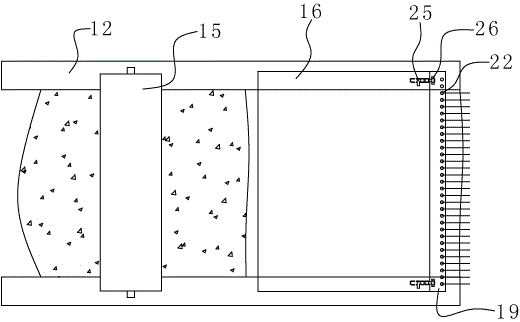

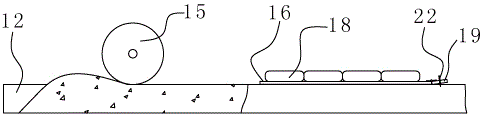

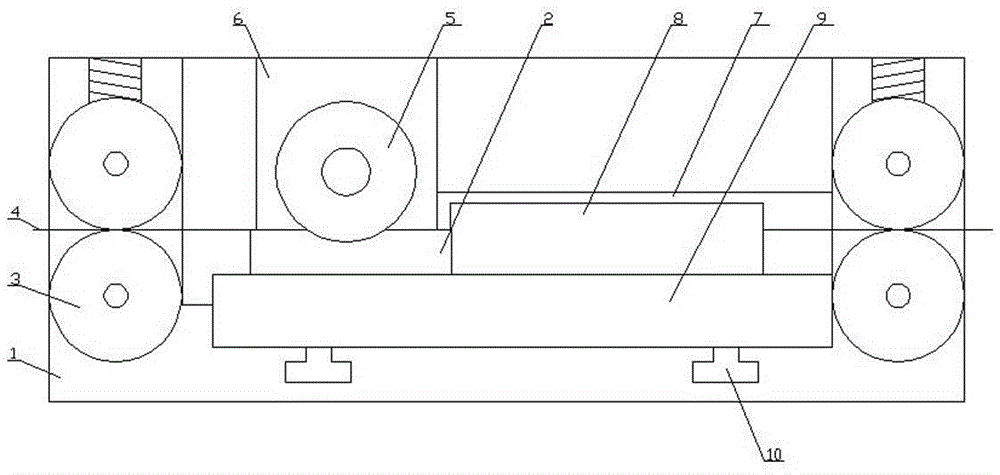

Full-automatic wheel hub deburring machine

InactiveCN102848282AImprove processing qualitySolve the problem of declining production efficiencyEdge grinding machinesCouplingElectric machinery

The invention belongs to technical equipment for machine manufacturing, and particularly relates to a full-automatic wheel hub deburring machine. The lower end of a lower brush feed rod (12) is vertically mounted on a bottom plate of a shell (1), and the upper end is fixed on a machining platform (13); upper and lower brush motor lifting plates (6) and a lower brush motor support plate (9) are respectively hinged on the upper end and the lower end of a support plate connection bar (8); a lower brush (5) is connected with the output shaft of a lower brush motor (10) through a coupling (43); a left locking device (11-1) and a right locking device (11-2) of a wheel hub lock (11) are respectively mounted at the left side and the right side of the machining platform (13); an upper brush motor support plate (36) provided with an upper brush motor (35) is movably sleeved on an upper brush feed rod (33) through a feed rod sleeve; an upper brush (32) is arranged in a dust shield (34) and is connected with the output shaft of the upper brush motor (35) through the coupling (43); and the shell (1) is provided a feeding path (15) and a discharging path (4) which are arranged at the left side and the right side of the machining platform (13). The full-automatic wheel hub deburring machine realizes the automatic unmanned production and improves the production efficiency.

Owner:FUXIN TONGSHENG HYDRAULIC MACHINERY MFGCO

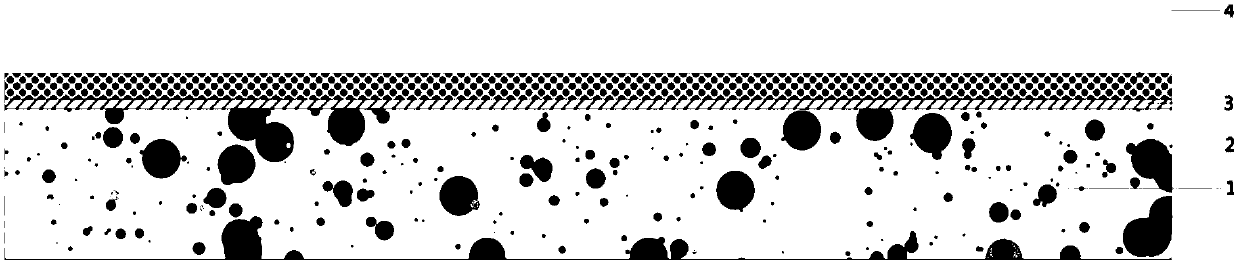

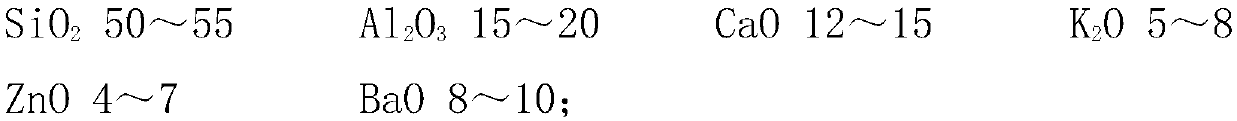

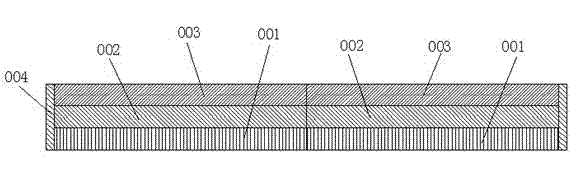

Full-body anti-slip ceramic brick and production method thereof

The invention relates to a full-body anti-slip ceramic brick and a production method thereof. According to the full-body anti-slip ceramic brick, a compound layer brick body is composed of a colored spot green body layer, large-particle colored spots mixed into the colored spot green body layer, a pattern decoration layer on the surface of the green body layer and a dry-particle glaze layer attached to the pattern decoration layer; the production method comprises the following steps: (1) pressing a green body, wherein green body powder is composed of conventional powder and large-particle powder; (2) drying under the conditions that the drying temperature is 80 to 100 DEG C and the drying time is 60 to 80 min; (3) decorating a pattern: before decorating the pattern, not applying any glazelayer or other protection layers on the surface of the blank body, so as to directly realize inkjet printing decoration on the surface of the blank body; (4) applying dry-particle glaze: spraying theglaze through a bell jar; (5) firing under the conditions that the temperature is 1150 to 1160 DEG C and the time is 50 to 60 min.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

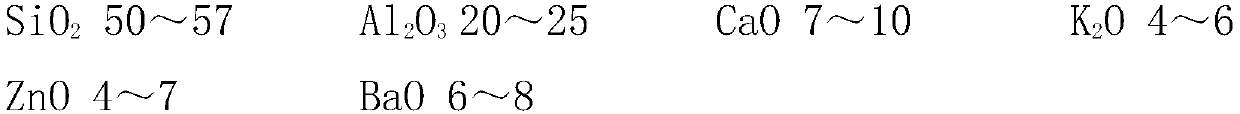

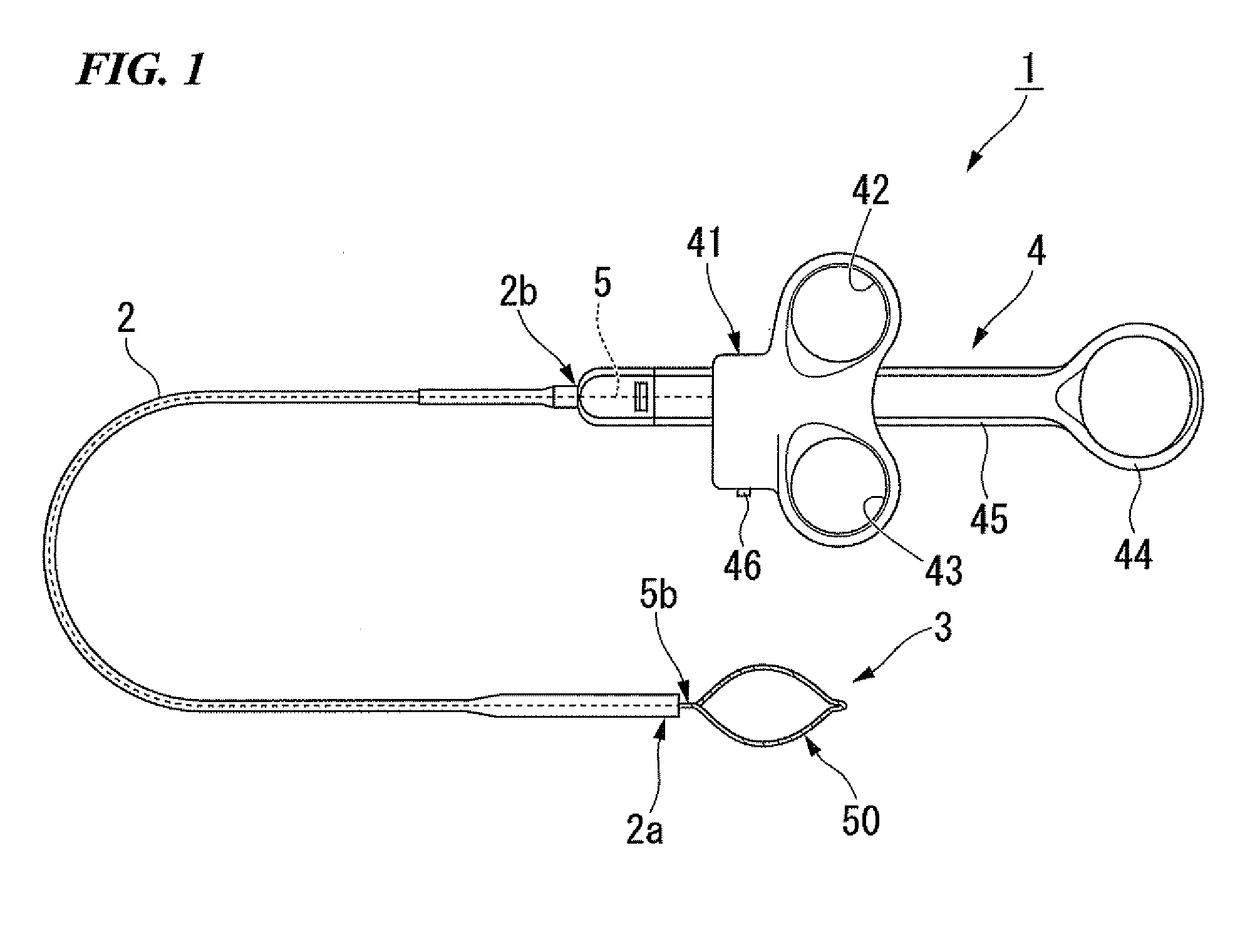

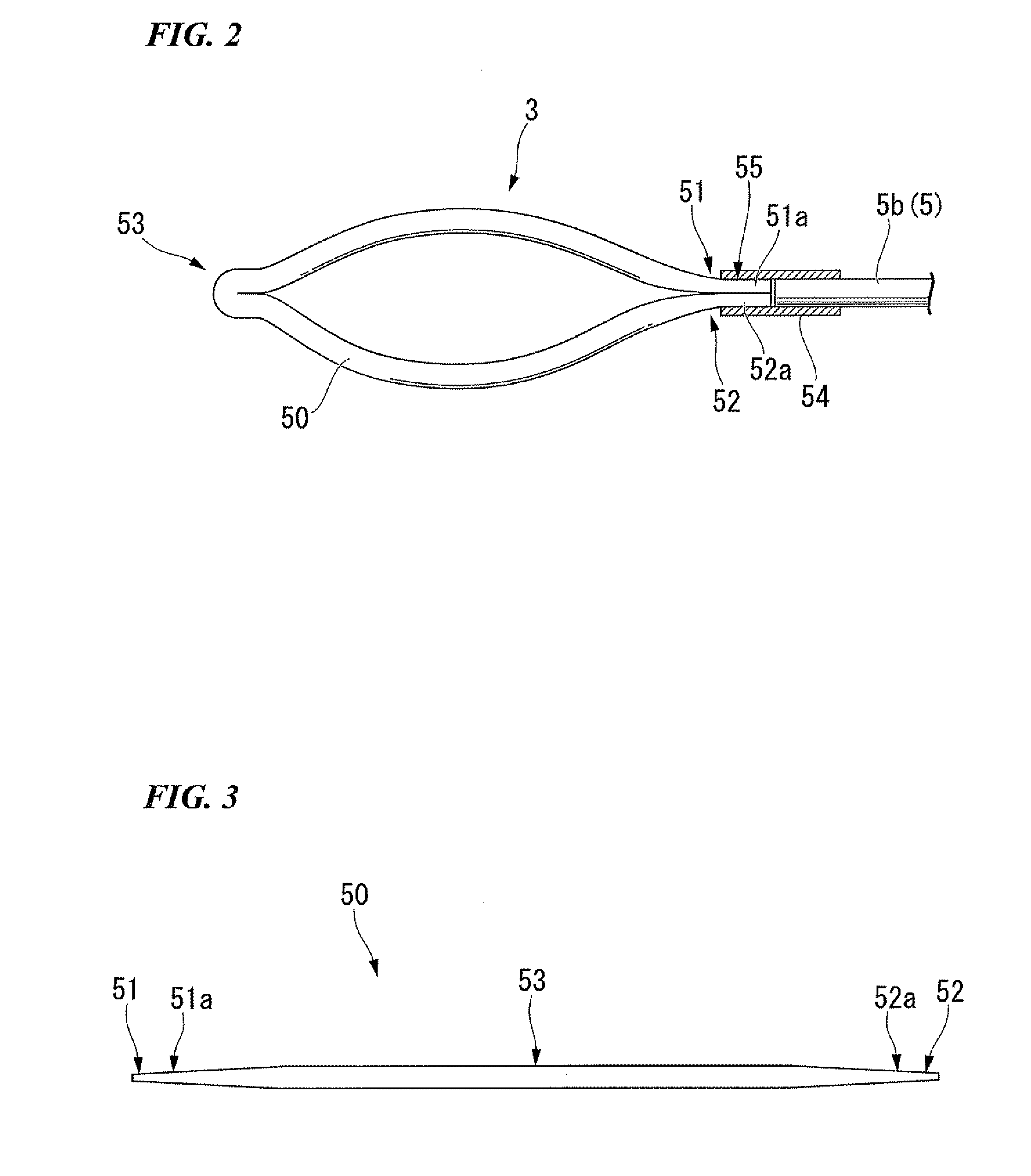

Treatment instrument

InactiveUS20110106077A1Reduce maximum external diameterReduced diameterExcision instrumentsSurgical instruments for heatingEngineeringBody cavity

This treatment instrument includes: a flexible wire that has a first end part and a second end part, and that has a treatment part at an intermediate part for conducting treatment within a body cavity; small-diameter parts where at least a portion of the outer circumferential face of the wire has a smaller diameter or is denuded relative to the rest; a bundled part where the wire is bundled so as to at least include the small-diameter parts; and a manipulation wire that is connected to this bundled part.

Owner:OLYMPUS MEDICAL SYST CORP

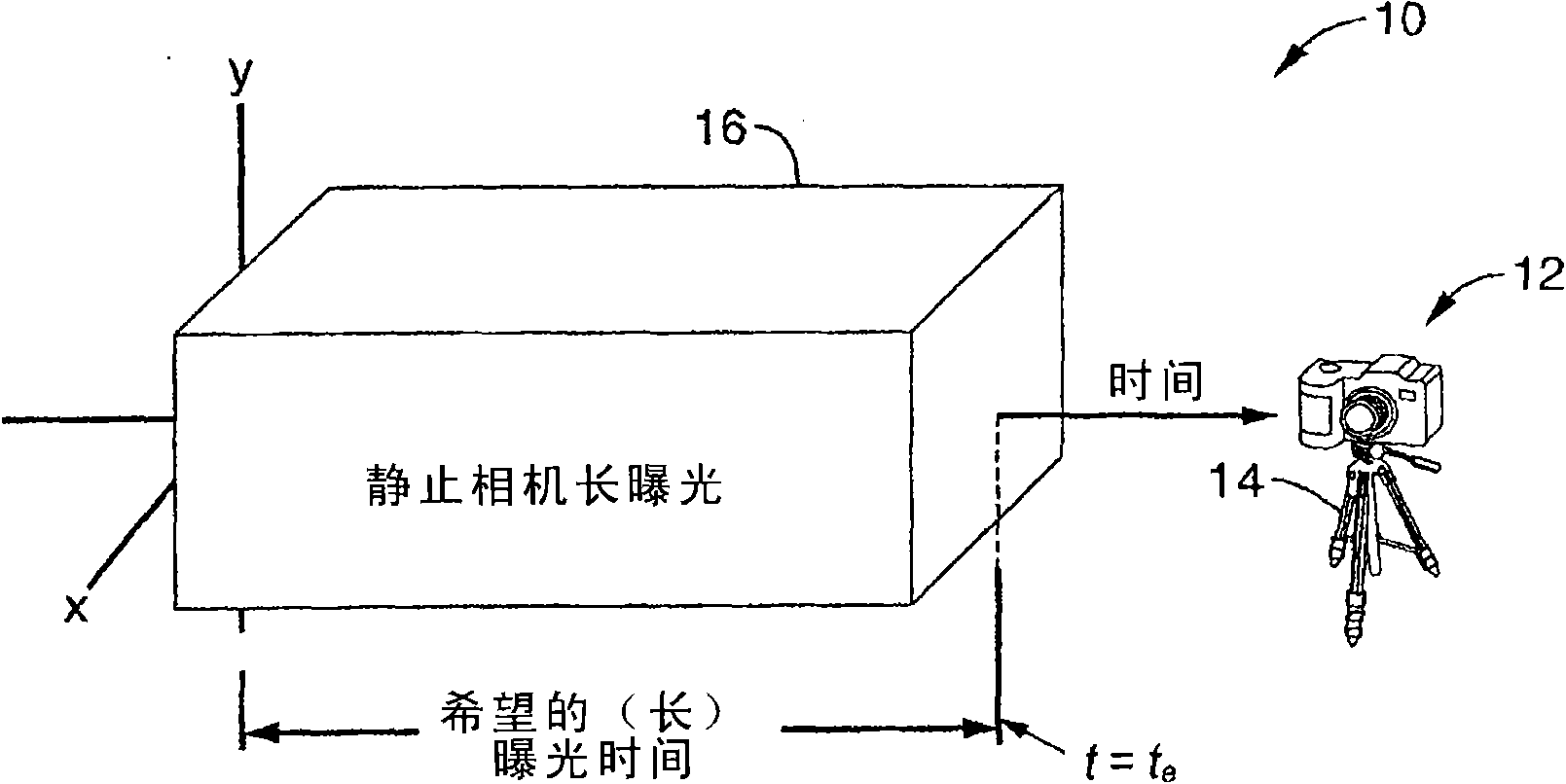

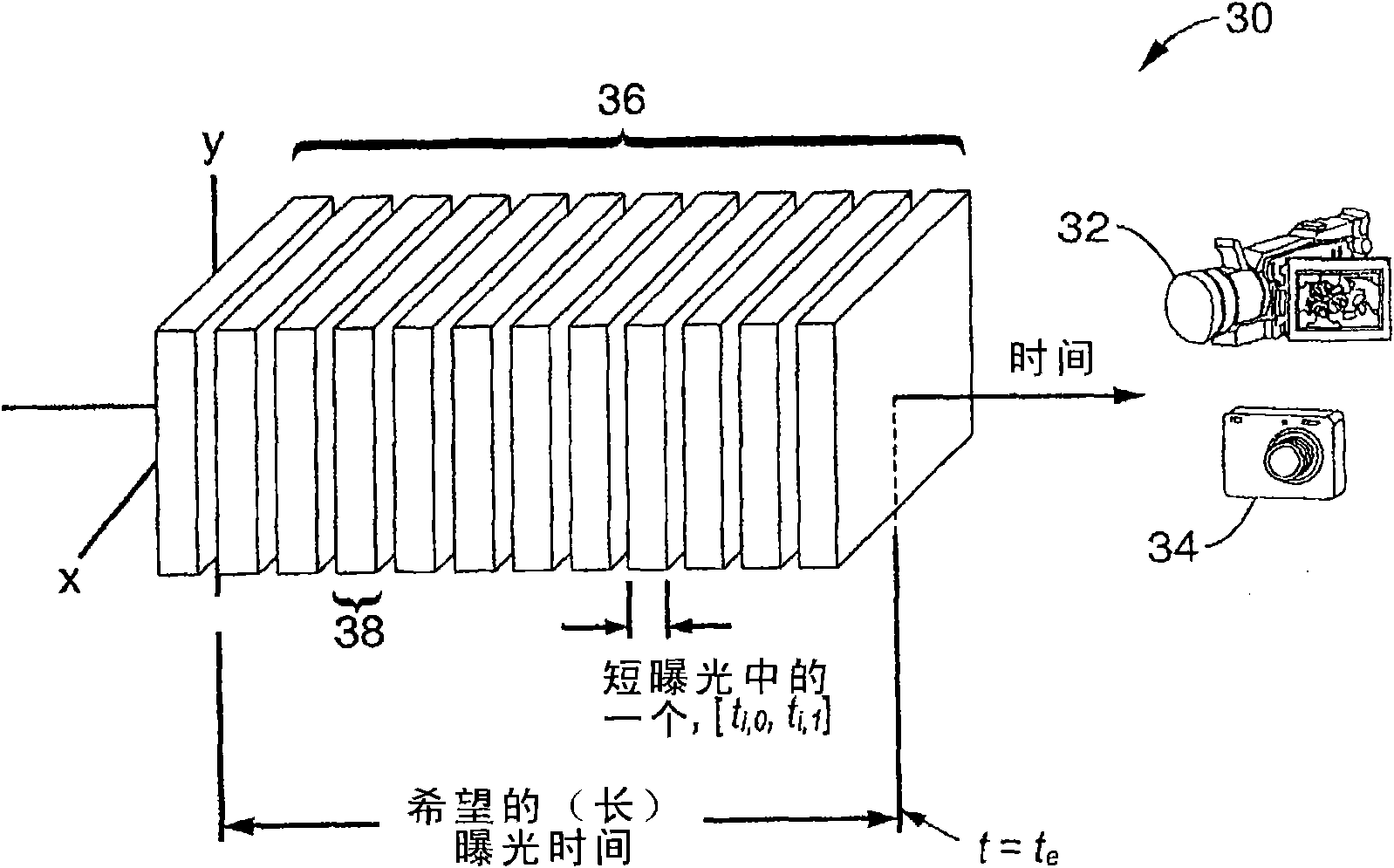

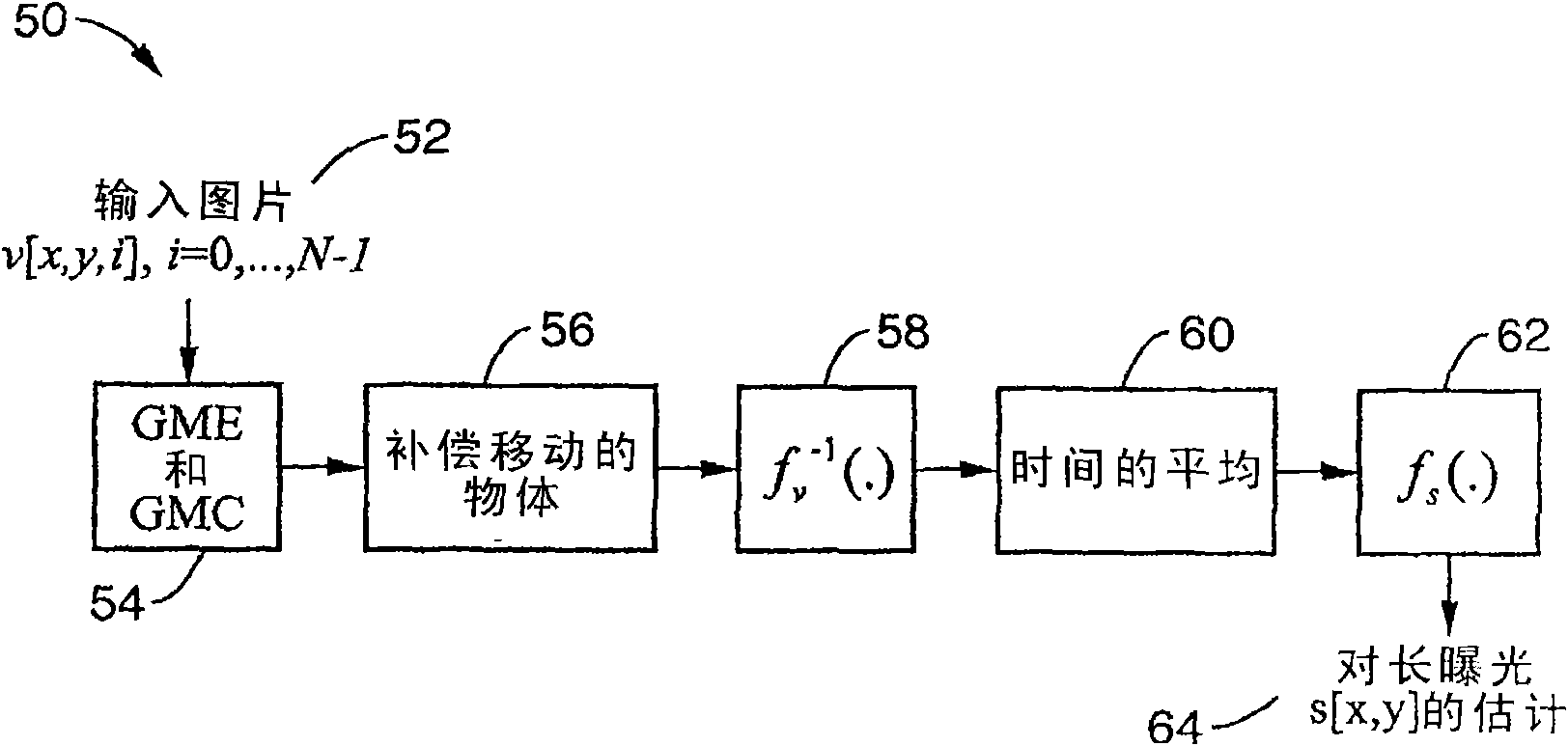

Generation of simulated long exposure images in response to multiple short exposures

InactiveCN101866092AChange the characteristics of the processingEasy Long Exposure ResultsImage enhancementTelevision system detailsComputer graphics (images)Hand held

The invention discloses simulating a generation of simulated long exposure images in response to multiple short exposures. long exposure-time image from a sequence of short exposure-time images captured at slightly different times. The sequence of images is combined in a temporal integration process to create a long exposure image that simulates the output from a still camera, steadied by a tripod, whose light-sensitive material has been exposed to the same scene from the time of the beginning of the first input image of the sequence to the last image of the input sequence. The method overcomes limitations of hand-held video and image recording devices, allowing the user to easily create effects normally associated with high-end digital still cameras under expert control.

Owner:SONY GRP CORP +1

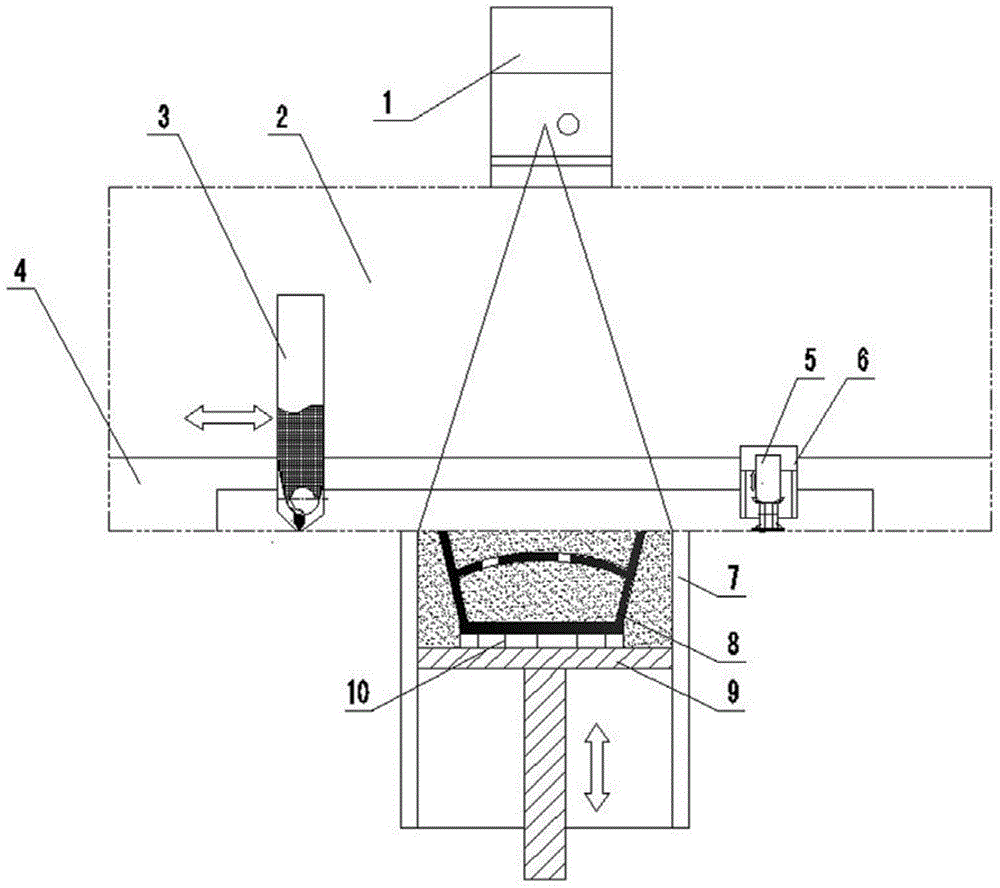

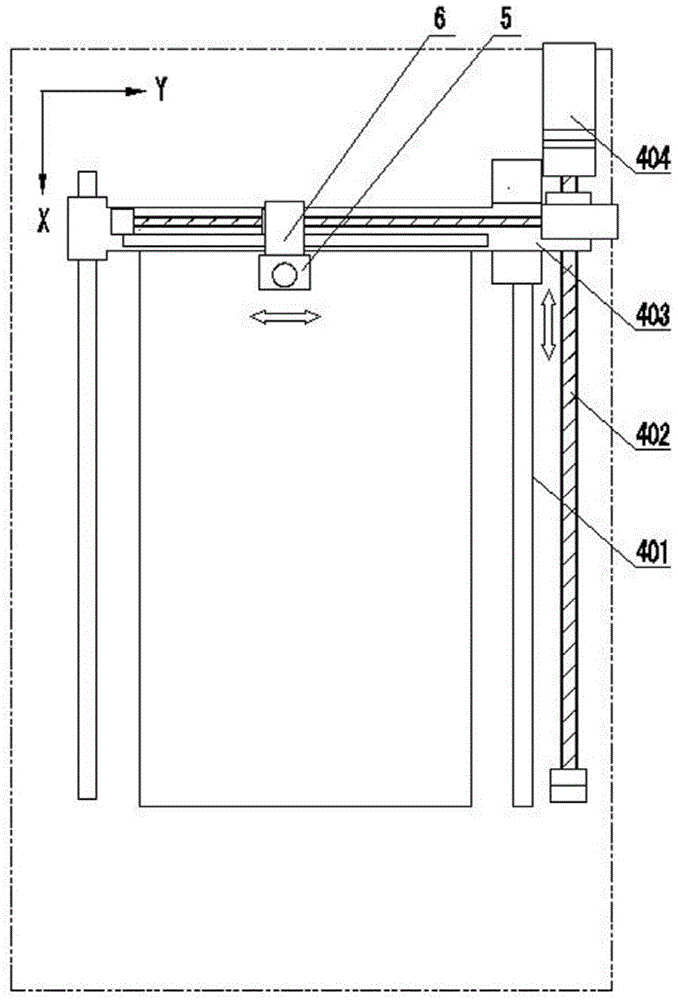

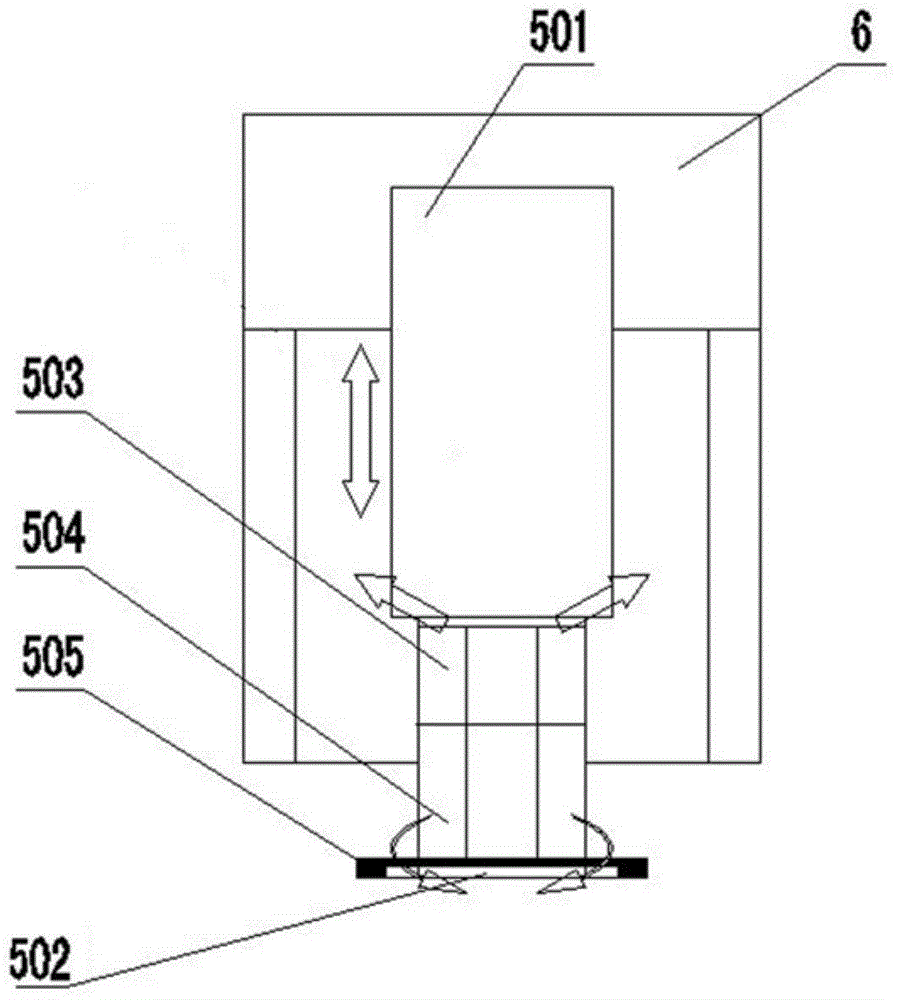

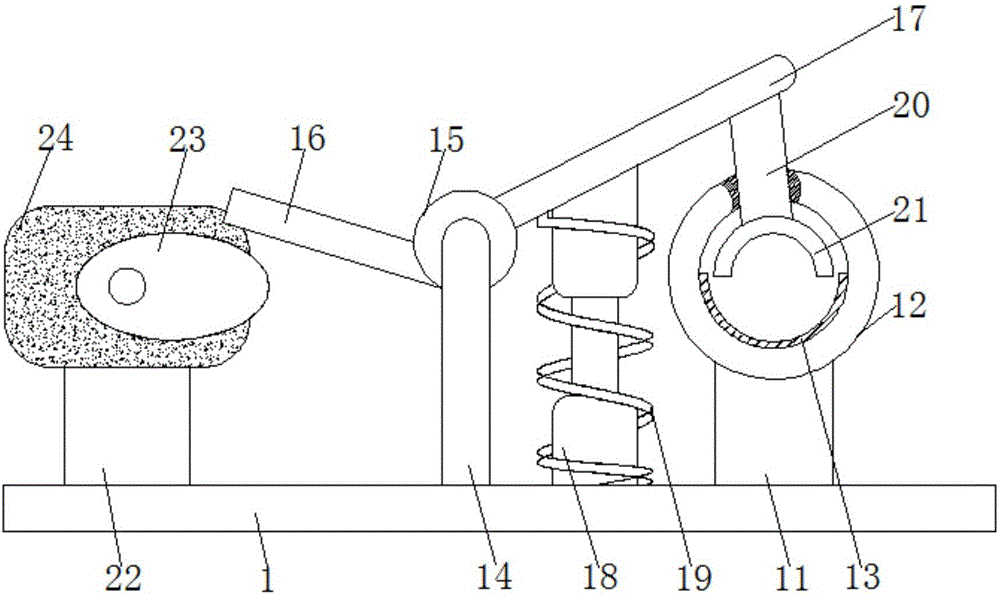

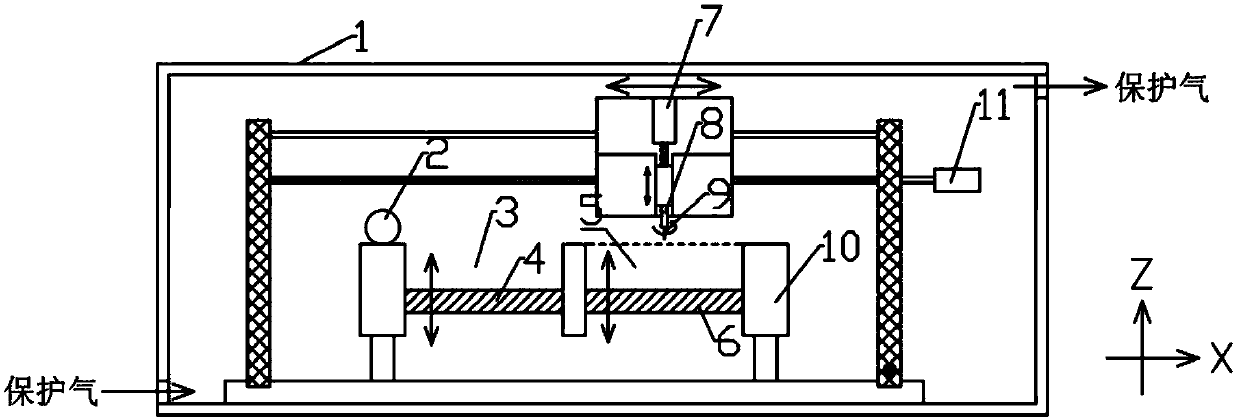

System suitable for metal powder melting material increasing manufacturing

InactiveCN104959603AEliminate bumpsEliminate warpingAdditive manufacturing apparatusIncreasing energy efficiencyHigh-speed grindingGalvanometer

The invention discloses a system suitable for metal powder melting material increasing manufacturing. The system is formed by compositing of a fiber laser galvanometer scanning mechanism and a high-speed grinding head. The fiber laser galvanometer scanning mechanism is provided with an XY workbench. The high-speed grinding head is arranged on a Y axis of the XY workbench through a Y axial sliding block. After multiple layers are manufactured on a workpiece, the high-speed grinding head slides along the Y axis of the XY workbench and carries out the feeding motion in the X axial direction at the same time, and high-speed grinding is carried out on the workpiece. The system suitable for the metal powder melting material increasing manufacturing has the advantages that after the high-speed grinding head is composited with the fiber laser galvanometer scanning mechanism, in the material increasing manufacturing process, scanning is carried out on a powder bed through the fiber laser galvanometer scanning mechanism, metal in a selected area is melted, a protrusion and a warpage in the partial workpiece can be removed by the high-speed grinding head, the upper surface of the workpiece can be maintained in smooth, the residual protruding peak on the surface of the workpiece and the plastic deformation degree can be effectively lowered, and the roughness on the surface of the workpiece is favorable to be lowered.

Owner:GUANGZHOU OGGI3D ELECTROMECHANICAL

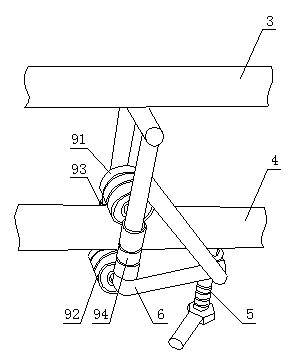

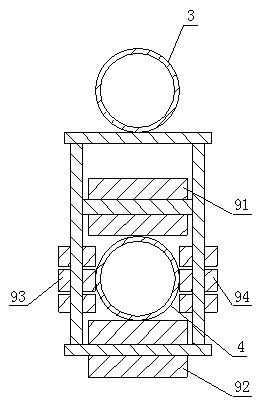

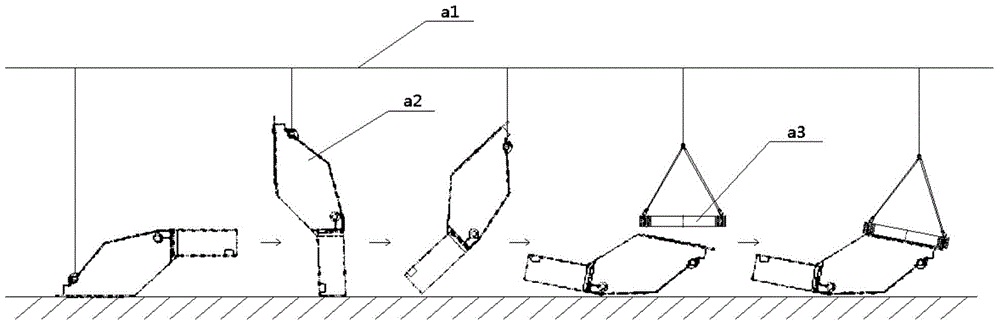

Automatic turnover device for conveying forklift hub brake drum assembly

The invention relates to an automatic turnover device for conveying a forklift hub brake drum assembly. The automatic turnover device comprises a motor, a speed reducer, a rotating shaft and a clamping mechanism, two sides of the rotating shaft are arranged at the tops of two vertical support legs through bearings and bearing blocks respectively, the two support legs are positioned on two sides of a conveying mechanism respectively, the rotating shaft is parallel to a power plate chain on a power plate chain output rail, one end of the rotating shaft is connected with the speed reducer and the motor, the clamping mechanism is arranged on the rotating shaft and comprises a pair of clamping arms, each clamping arm comprises a cantilever plate, one end of each cantilever plate is fixedly connected with the rotating shaft, a thin-walled cylinder is arranged at the other end of each cantilever plate, a piston rod of each thin-walled cylinder is parallel to the rotating shaft, the outer end of the piston rod of each thin-walled cylinder is connected with a connecting plate, two clamp plates are arranged on each connecting plate in a splayed manner to form a pair, and two pairs of clamp plates on the pair of clamping arms are folded. Labor intensity is reduced, and product quality is improved.

Owner:ANHUI HELI CO LTD

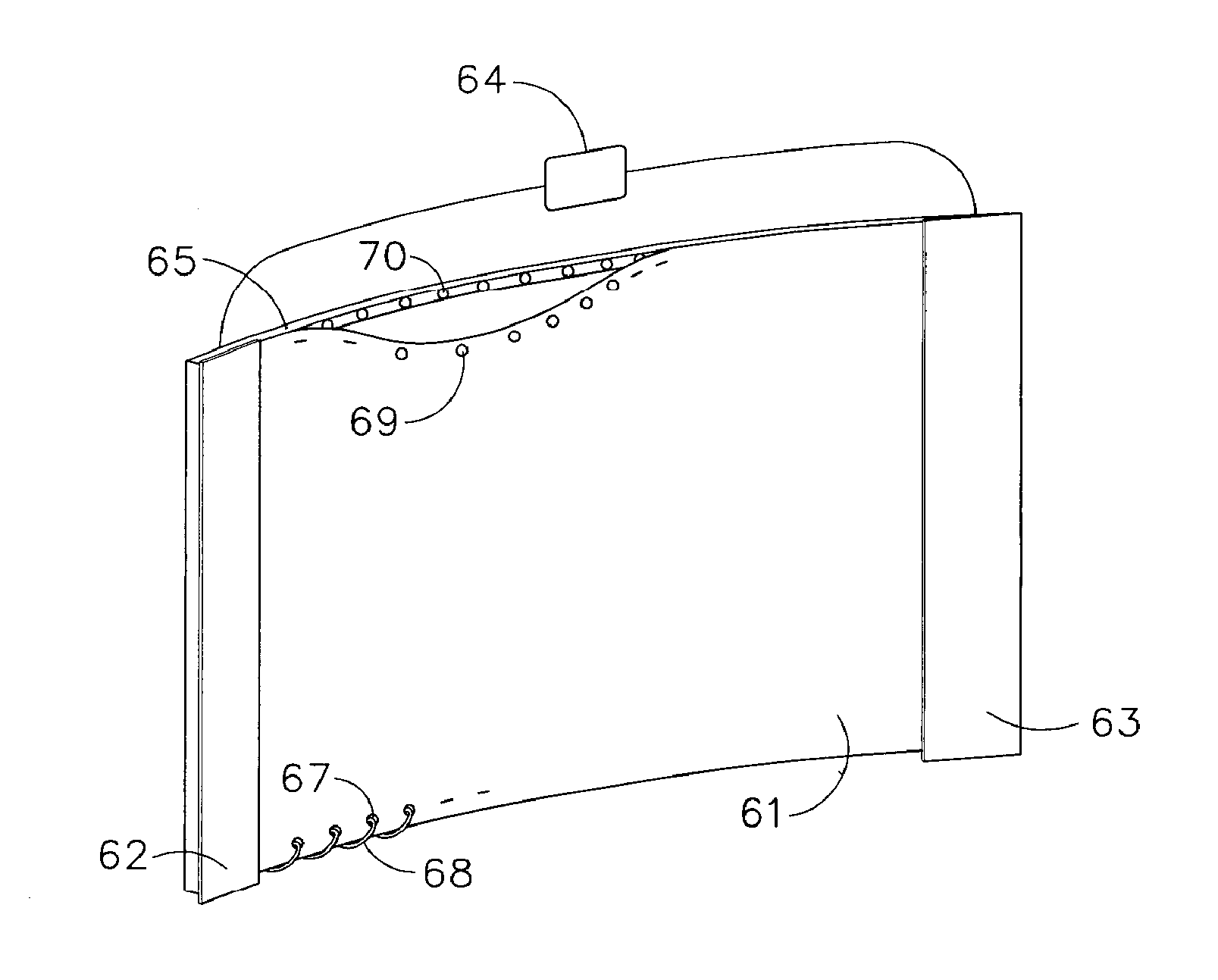

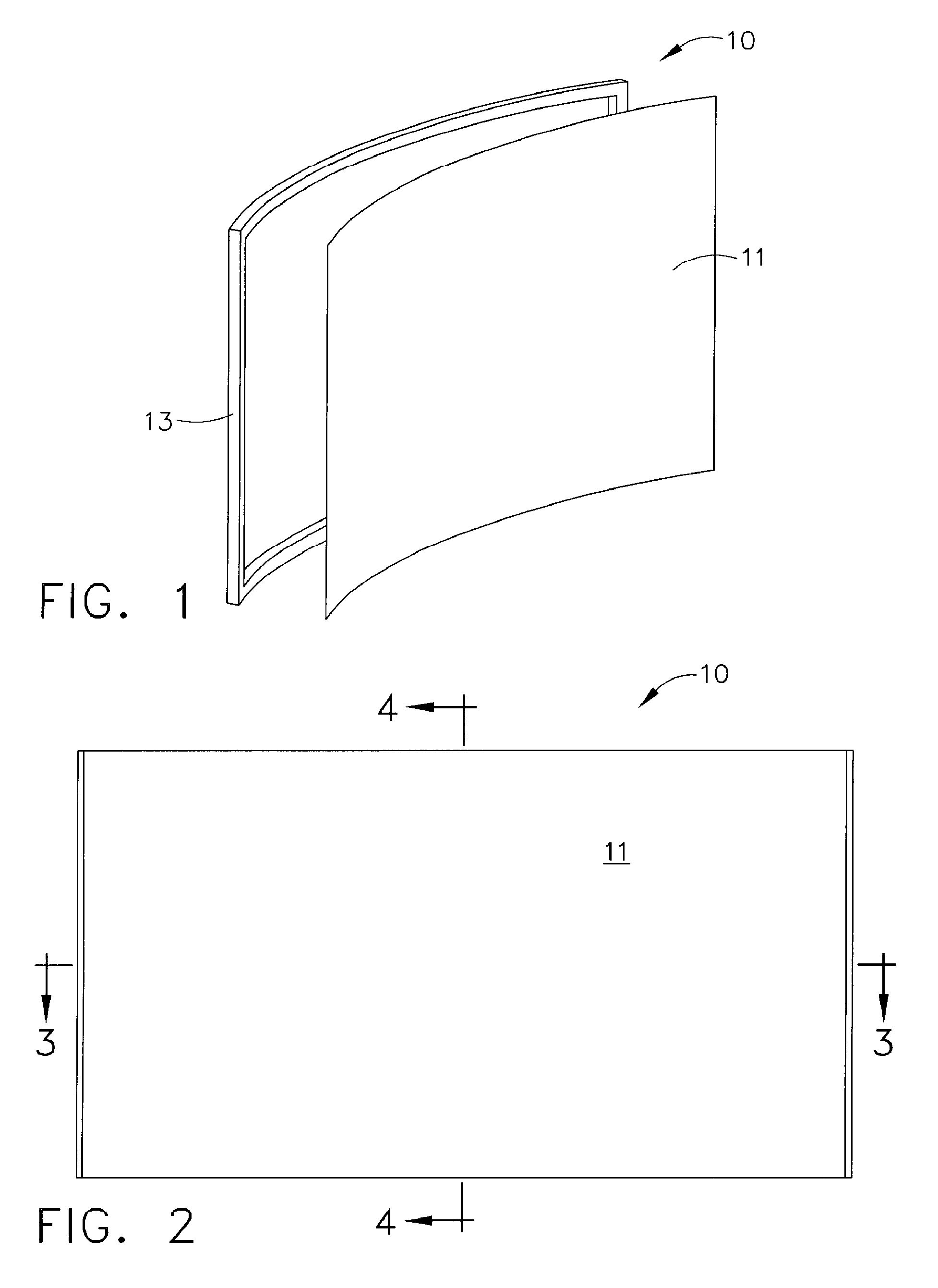

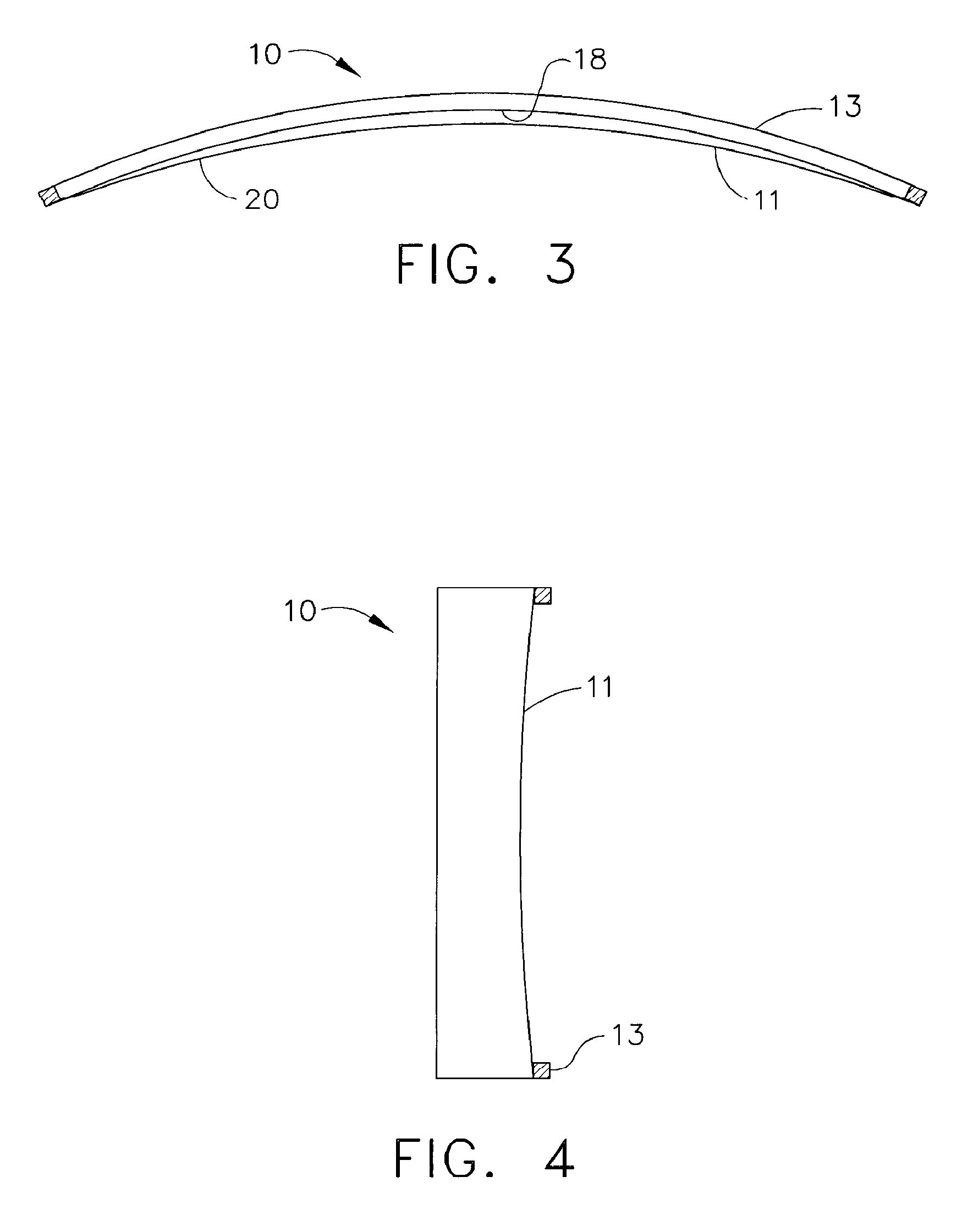

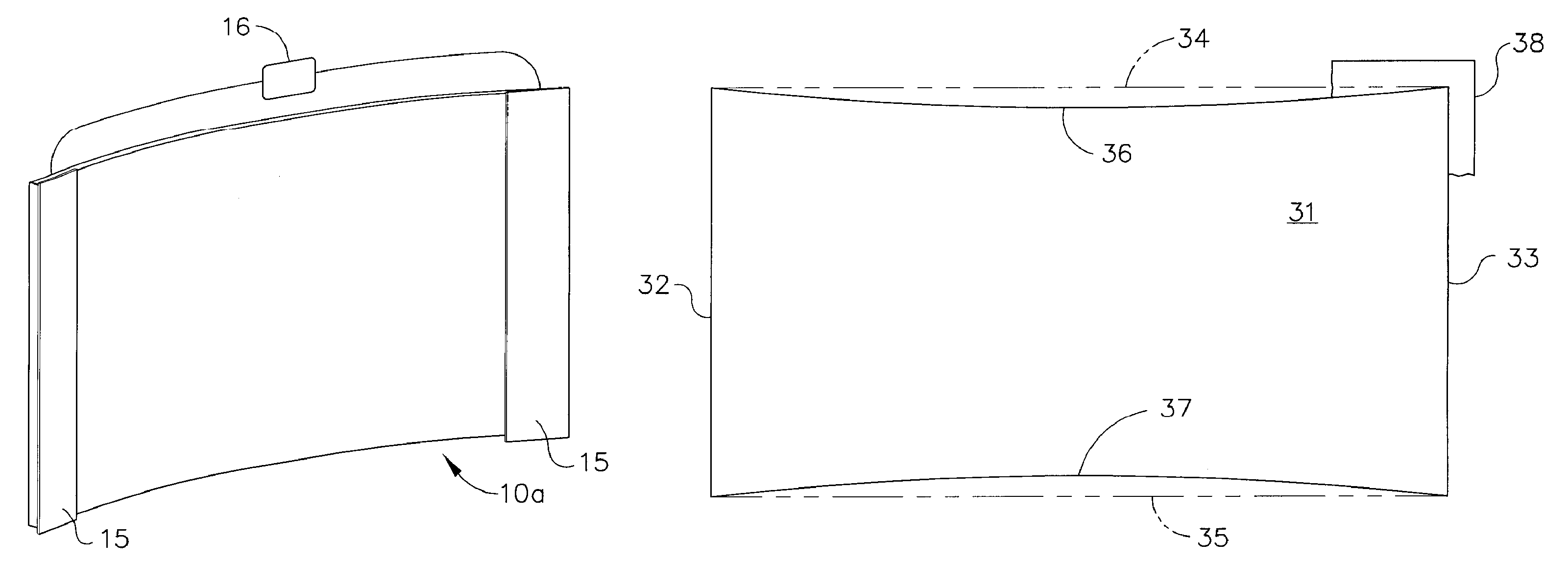

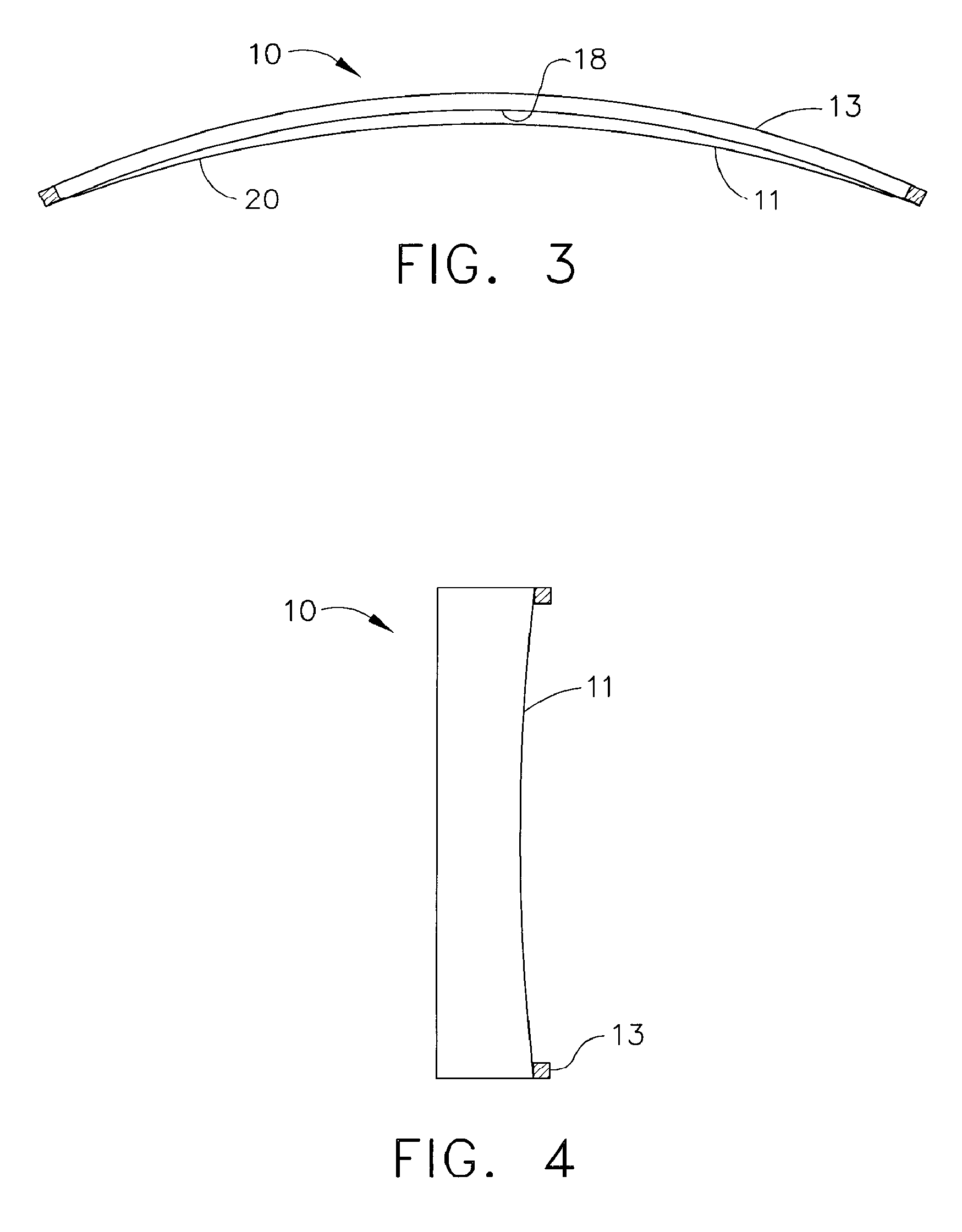

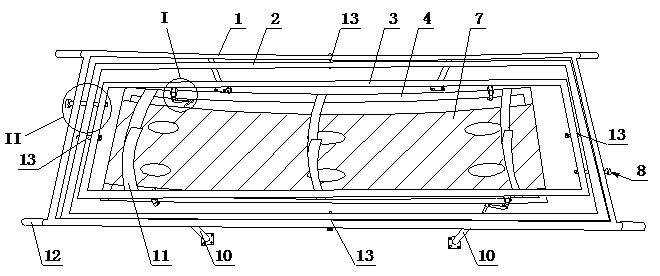

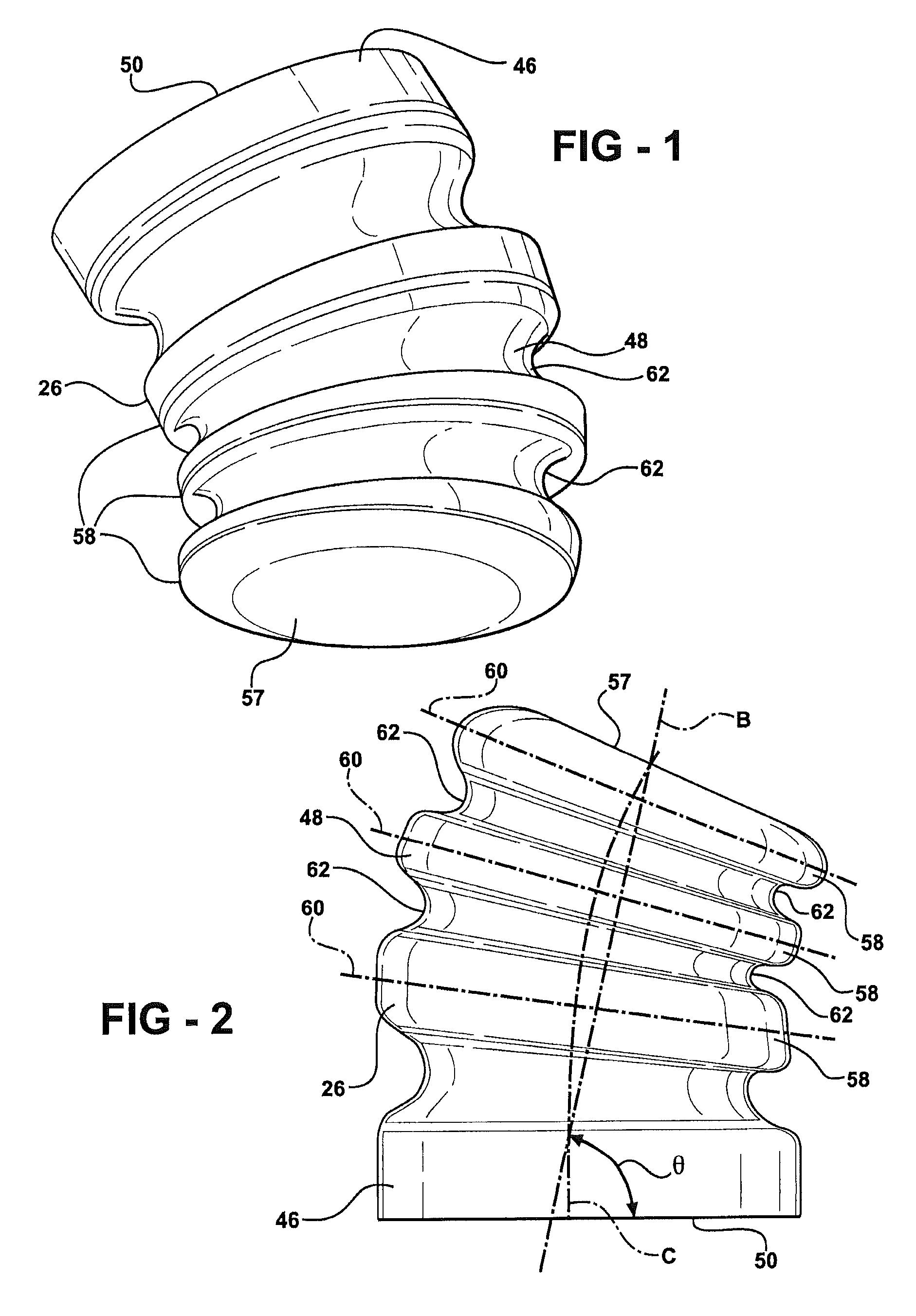

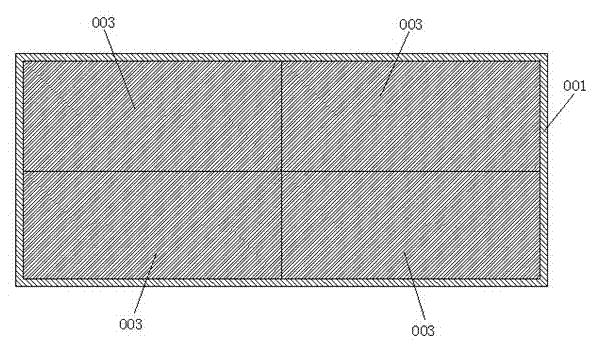

Anti-Bulging Projection Screen Structure

InactiveUS20080062516A1Bulging (bellying out) of the screen can be substantially eliminatedRelieving side-to-side tensionProjectorsProjection screenEngineering

A home cinema theater projection screen structure and method of making same are provided wherein a sheet of projection screen material of selected size is formed to a configuration having concave top and / or bottom edges, the projection screen material then being attached under tension to a mounting structure that defines an inwardly curved projection surface in the mounted condition whereby bulging of the projection surface of the screen is substantially eliminated. Movable side masking panels are included the structure in order to define a selected aspect ratio for the projection surface.

Owner:STEWART FILMSCREEN

Anti-bulging projection screen structure

InactiveUS7710646B2Bulging (bellying out) of the screen can be substantially eliminatedRelieving side-to-side tensionProjectorsProjection screenAspect ratio

A home cinema theater projection screen structure and method of making same are provided wherein a sheet of projection screen material of selected size is formed to a configuration having concave top and / or bottom edges, the projection screen material then being attached under tension to a mounting structure that defines an inwardly curved projection surface in the mounted condition whereby bulging of the projection surface of the screen is substantially eliminated. Movable side masking panels are included the structure in order to define a selected aspect ratio for the projection surface.

Owner:STEWART FILMSCREEN

Double-membrane soil pressure sensor based on hydraulic transmission

InactiveCN102519630AAdaptableEliminate bumpsHydraulic/pneumatic force measurementForce/torque/work measurement apparatus calibration/testingEpoxySoil science

The invention provides a double-membrane soil pressure sensor based on hydraulic transmission. The sensor employs a double layer membrane structure. A primary membrane is bonded with an outer ring of a housing by an annular membrane at an edge; and a secondary membrane is welded on an inner ring of the housing. An oil nozzle is used to enable a pressure transmission oil chamber formed between the primary membrane and the secondary membrane to be filled with hydraulic oil. A strain probe that is arranged below the secondary membrane and has a sensing element is connected with an external transmission line by a lead-out hole that is reserved and is arranged inside the housing; an epoxy resin is used for sealing the lead-out hole; and the housing and a bottom cap are threadedly connected. Therefore, a double-membrane soil pressure sensor based on hydraulic transmission is formed. According to the invention, influences caused by uneven distribution of soil pressures and difference of soil texture kinds can be eliminated; adaptability is strong; and calibration can be carried out simply.

Owner:KUNMING UNIV OF SCI & TECH +1

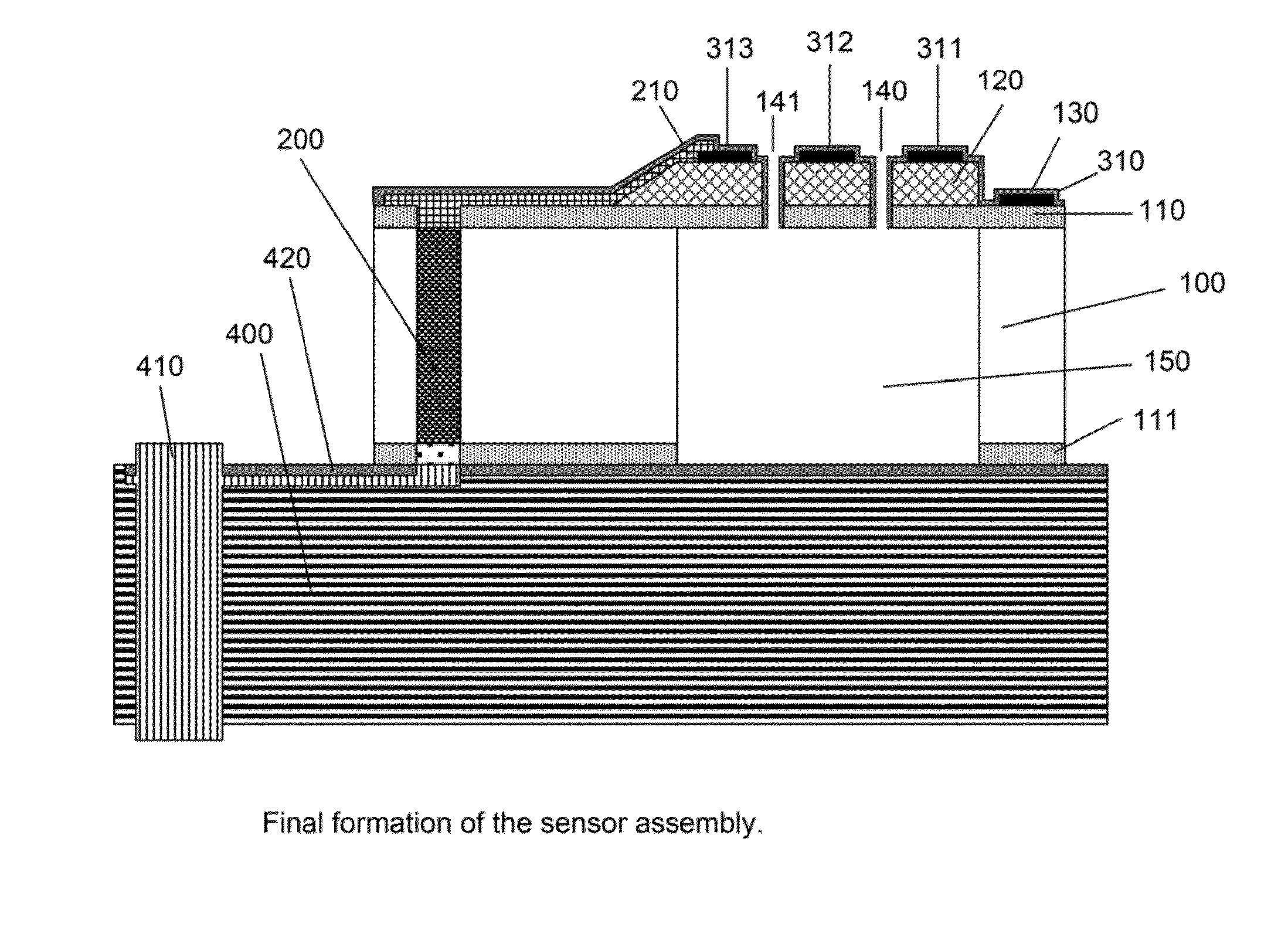

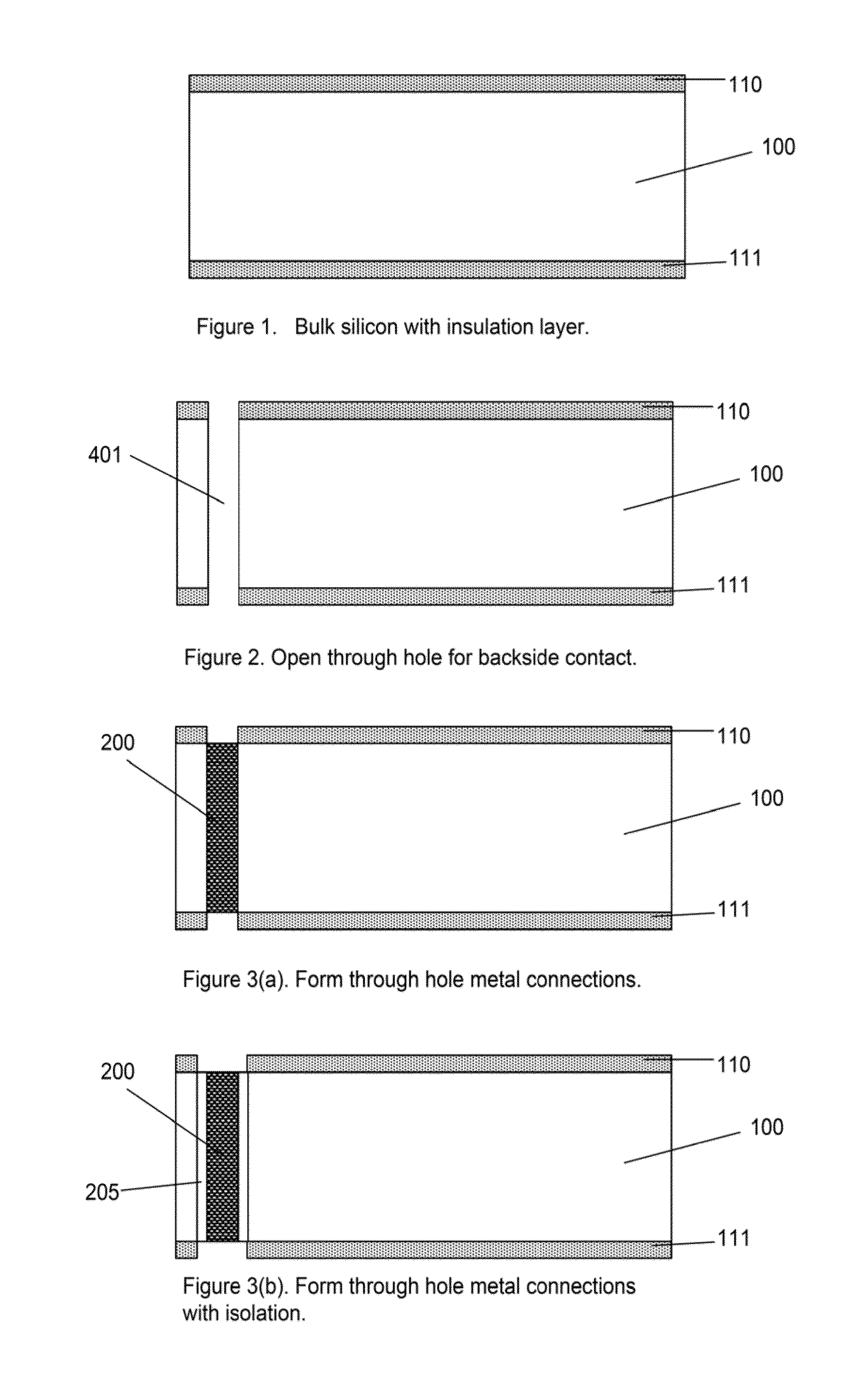

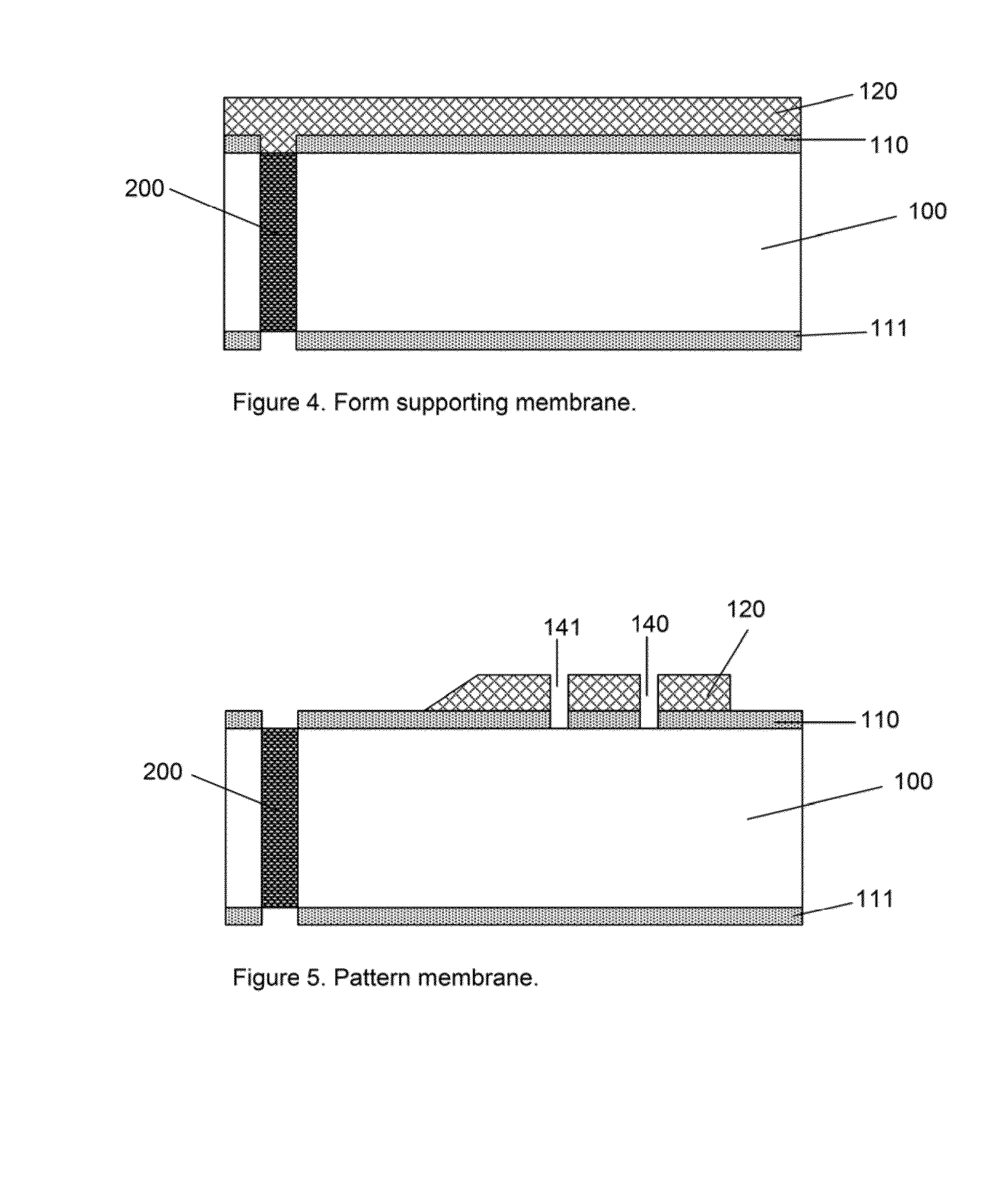

MEMS mass flow sensor assembly and method of making the same

ActiveUS20140190252A1Minimum footprintMinimizes instabilityVolume/mass flow by thermal effectsFlow transducerWire rod

A silicon mass flow sensor manufacture process that enables the backside contacts and eliminates the conventional front side wire binding process, and the assembly of such a mass flow sensor is disclosed in the present invention. The achieved assembly enhances the reliability by eliminating the binding wire exposure to the flow medium that may lead to detrimental failure due to the wire shortage or breakage while the miniature footprint could be maintained. The assembly further reduces flow instability from the flow sensor package including the bump of wire sealing. The invented mass flow sensor assembly can be a flow sensor module if the supporting sensor carrier is pre-designed with the control electronics. Without the control electronics, the said mass flow sensor assembly is easy to install into desired flow channels and connect to the external control electronics.

Owner:M TECH INSTR HLDG

Self-balancing stretcher

The invention relates to a self-balancing stretcher. The stretcher comprises a first framework layer, wherein a second framework layer and a third framework layer are arranged on the inner side of the first framework layer in turn; two support rods in a length direction or a width direction of the second framework layer are rotatably connected with two support rods on the first framework layer respectively, and the other two support rods on the second framework layer are rotatably connected with two support rods on a third framework layer; the connection joints of the first framework layer, the second framework layer and the third framework layer are positioned in the center of the support rods to which the connection joints belong respectively; a sliding mechanism is arranged on two support rods in the length direction of the third framework layer respectively; the third framework layer is in sliding connection with a fourth framework layer by the sliding mechanism; two support rods on the fourth framework layer which are connected with the third framework layer are arc-shaped; fastening bolts are arranged on the sliding mechanism; and the inner side of the fourth framework layer is connected with a bed surface. The stretcher of the invention has the advantages of high vibration damping performance, capacity of automatically adjusting the balance, simple structure, convenient and flexible use and low cost.

Owner:CHONGQING UNIV OF TECH

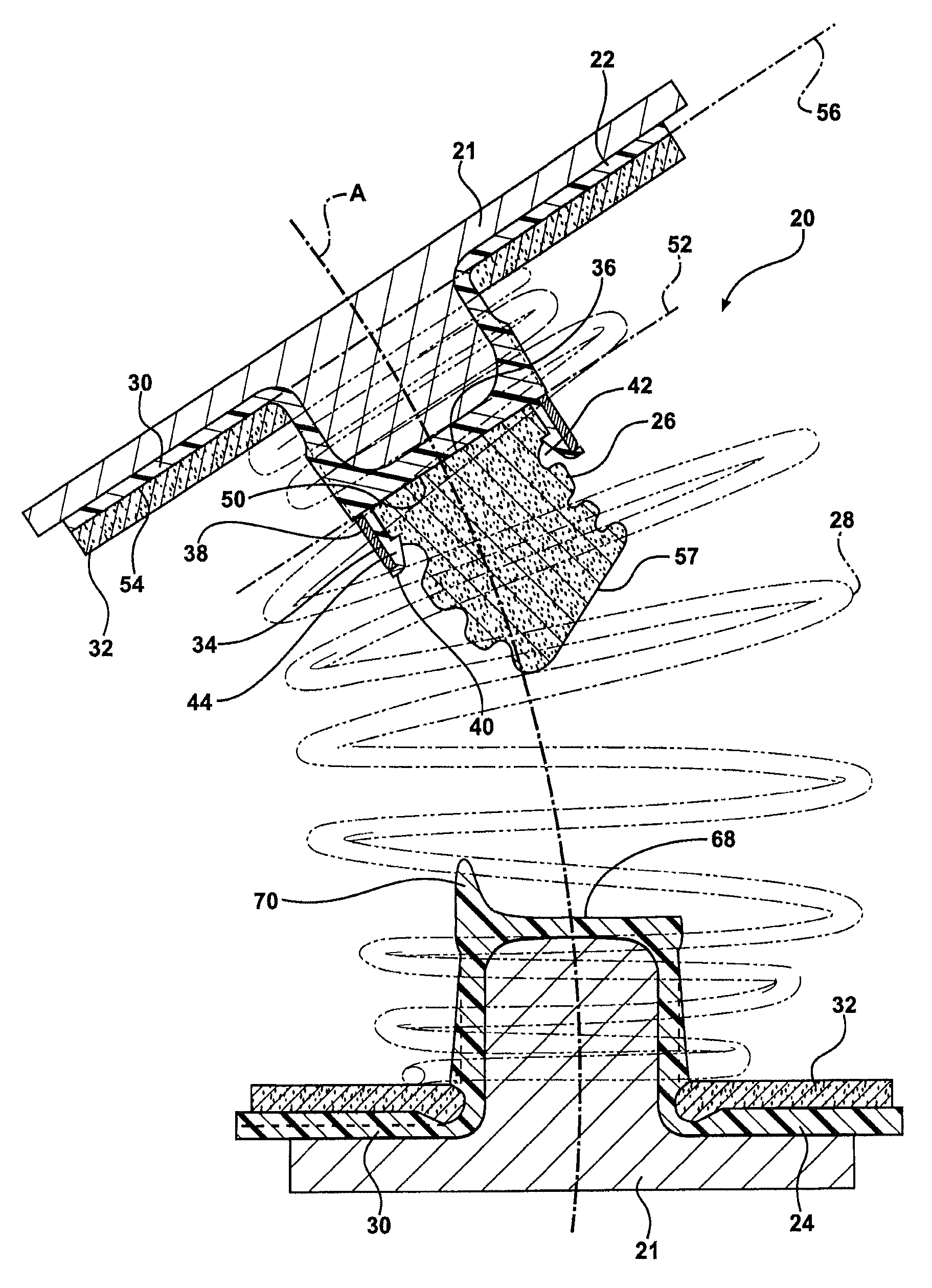

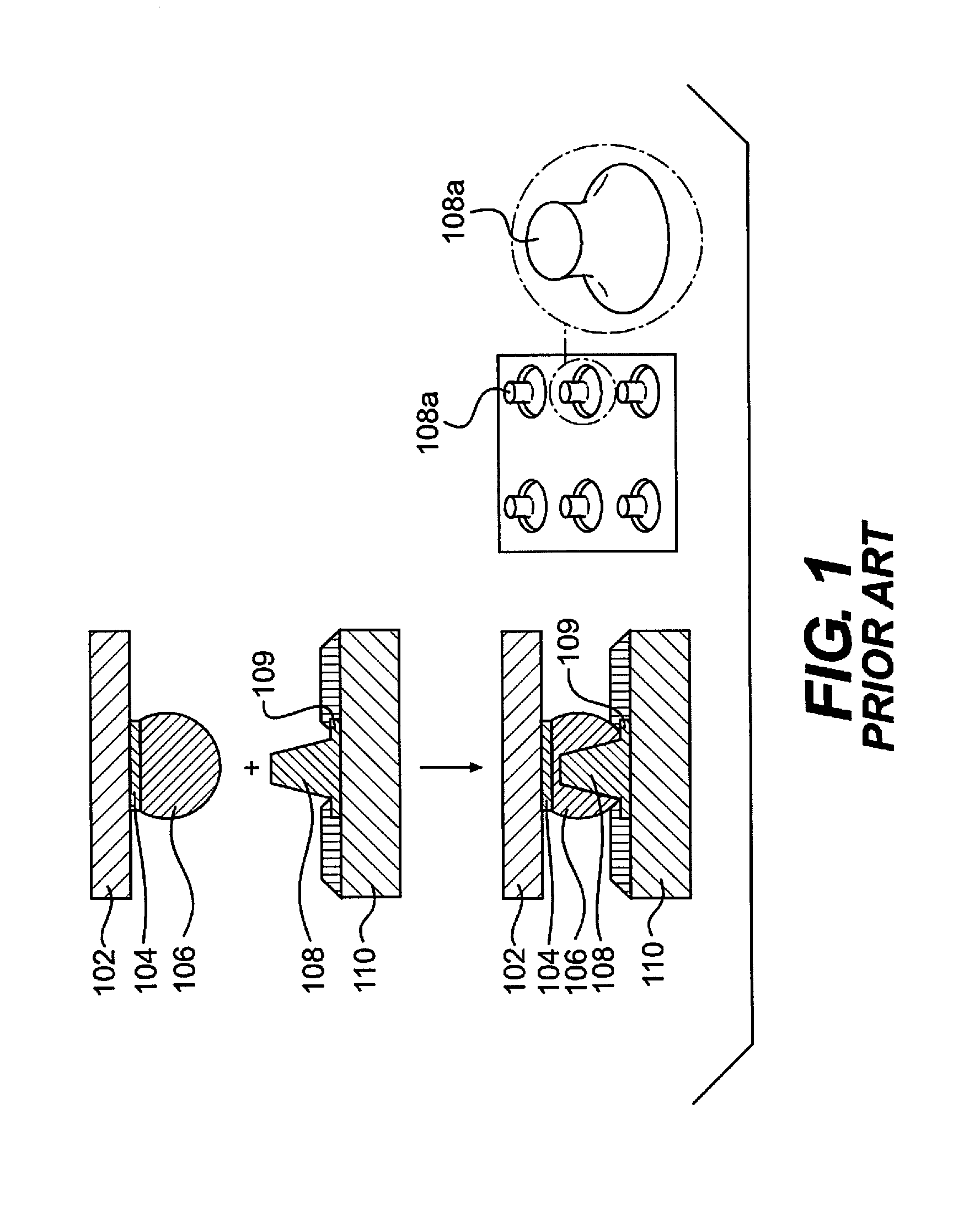

Insulator for a vehicle suspension system

InactiveUS8276894B2Improve reliability and durabilityEliminate bumpsPortable framesLiquid springsAcute angleEngineering

A wheel suspension system for a vehicle includes a mounting base and a striking base spaced from each other and moveable relative to each other along an arced line of motion. An insulator is coupled to and extends from the mounting base. The insulator is formed of an elastomeric material for compression between the mounting base and the striking base when the striking base contacts the insulator during movement of the mounting base and the striking base relative to each other. The insulator is compressed along the arced line of motion between the mounting base and the striking base. The insulator includes an impact portion extending at an acute angle relative to the base plane for distributing compressive forces within the insulator as the insulator is compressed along the arced line of motion. The distribution of the compressive forces within the insulator increases the durability and reliability of the insulator.

Owner:BASF CORP

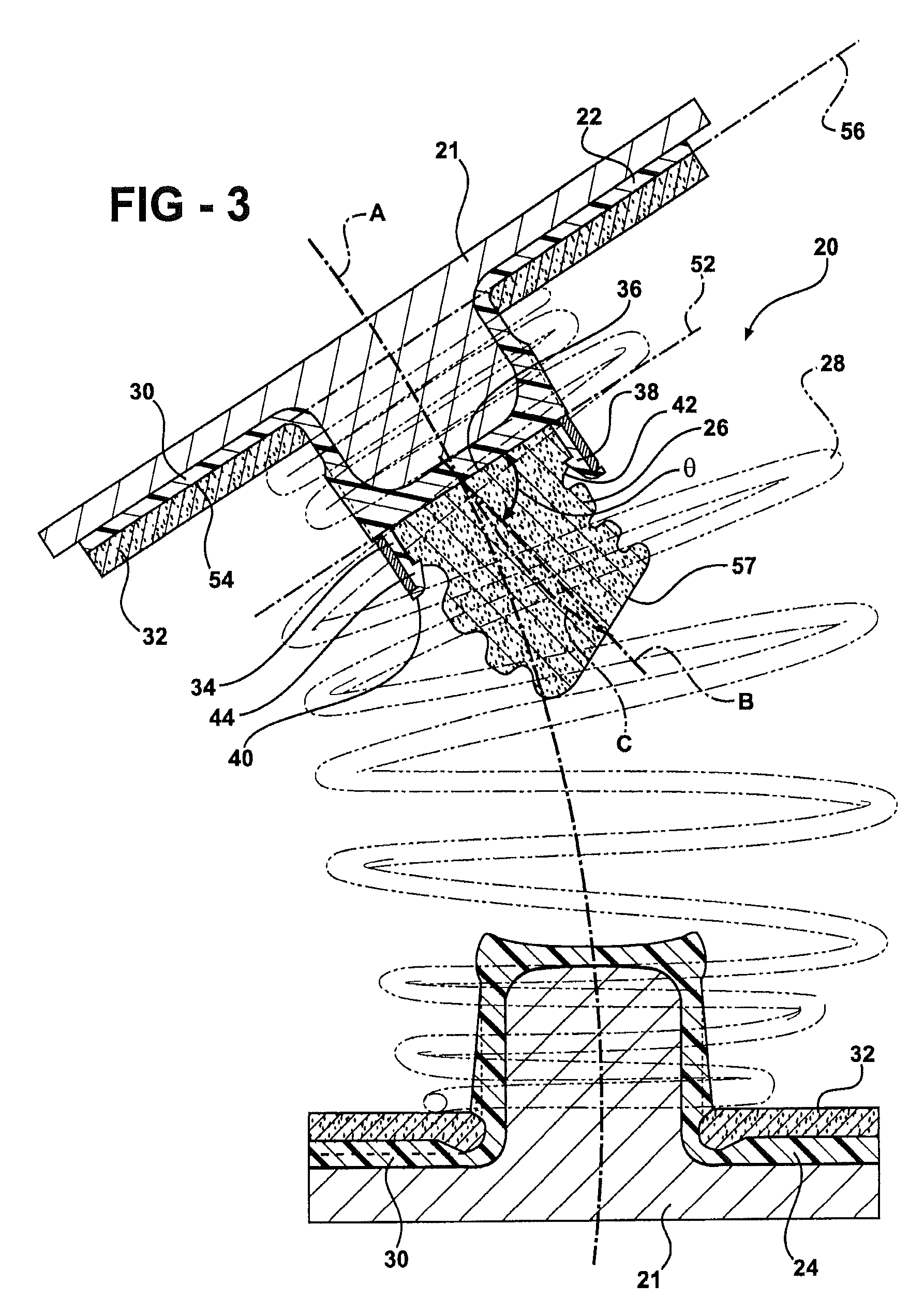

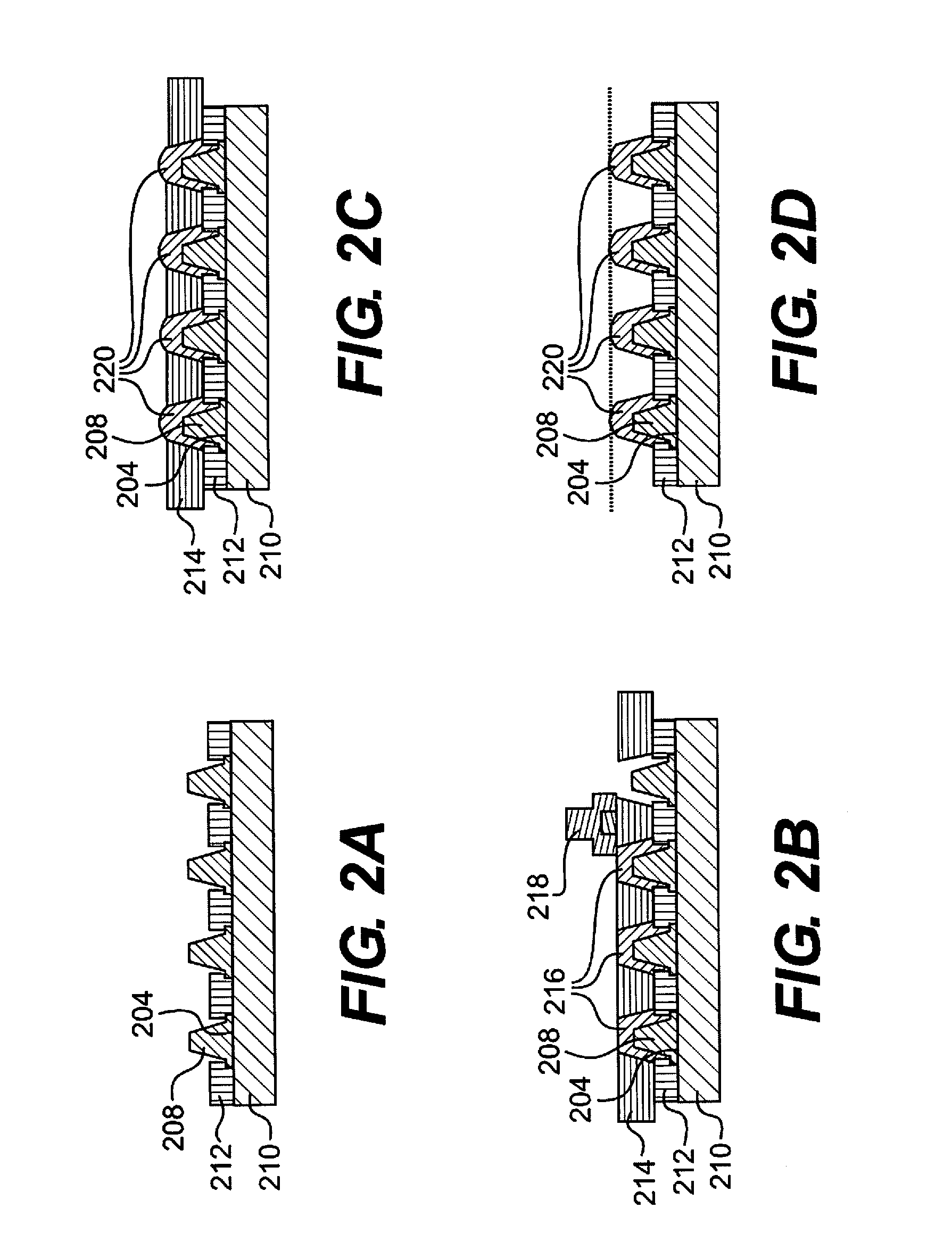

Copper Post Solder Bumps on Substrates

InactiveUS20140057392A1Small sizeReduce volumeSemiconductor/solid-state device detailsSolid-state devicesFlip chip interconnectEngineering

Owner:INT BUSINESS MASCH CORP

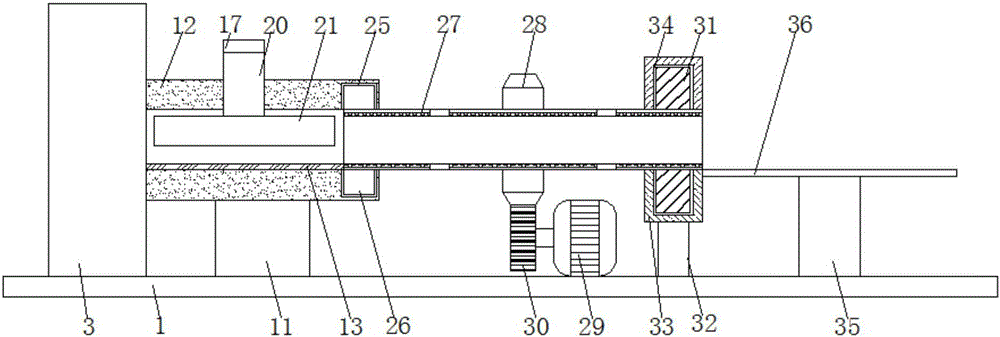

Fine adjustment beating type reinforcement bar straightening machine and use method

InactiveCN106540984AFlat surfaceEliminate bumpsRevolution surface grinding machinesGrinding feedersEngineeringRebar

The invention discloses a fine adjustment beating type reinforcement bar straightening machine. The fine adjustment beating type reinforcement bar straightening machine comprises a bottom plate. A first vertical plate and a second vertical plate are symmetrically arranged on the front side and the rear side of the upper surface of the bottom plate. One side of the first vertical plate is fixedly connected with a first motor through a supporting plate. The output end of the first motor is fixedly connected with the axis position on one side of a drive gear, the driven gear is engaged with a driven gear, the axis position of the side, back onto the first motor, of the drive gear is fixedly connected with one end of a first rotating rod, and the axis position of the side, back onto the first motor, of the driven gear is fixedly connected with one end of a second rotating rod. According to the fine adjustment beating type reinforcement bar straightening machine and a use method, by means of improvement of a beating plate, when a second motor knocks a stirring rod through an oval plate, in cooperation with a retractable rod and a spring, the arc-shaped beating plate continuously beats the surface of a reinforcement bar; and by means of improvement of a polishing pipe, the inner wall of the polishing pipe polishes the surface of the reinforcement bar, protrusions on the surface of the reinforcement bar are removed, and the reinforcement bar is thrown to be straight.

Owner:ANHUI UNIV OF SCI & TECH

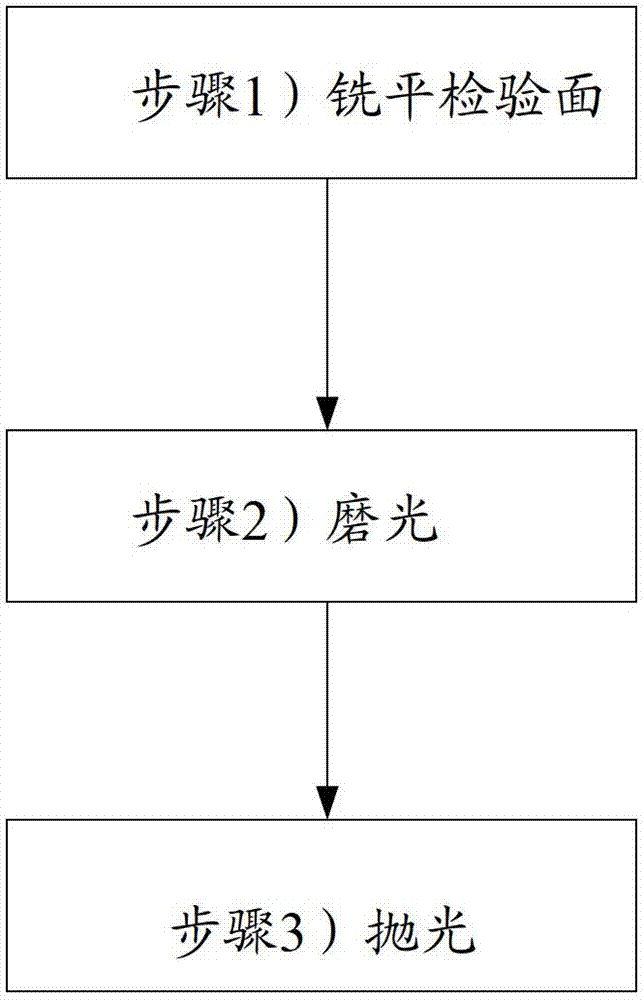

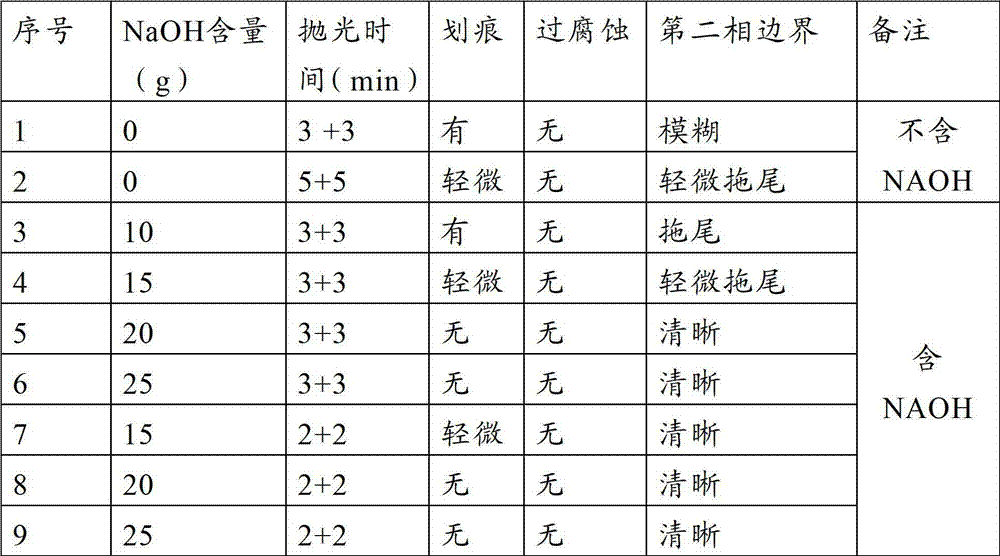

Preparation method of aluminium alloy metallographic sample

InactiveCN104198257AShort manufacturing timeImprove Surface DefinitionPreparing sample for investigationMetallurgyAluminium alloy

The invention provides a preparation method of an aluminium alloy metallographic sample. The preparation method disclosed by the invention comprises the following steps of sampling, coarsely grinding, finely grinding, coarsely polishing, finely polishing for the first time, electrolyzing, finely polishing for the second time, performing acid pickling on the surface and corroding. Compared with related technologies, the preparation method of the aluminium alloy metallographic sample disclosed by the invention has the benefits that the preparation time of the aluminium alloy metallographic sample is shortened; the preparation efficiency is increased; scratches are effectively eliminated; the surface definition of the aluminium alloy metallographic sample is increased; the problem that a part of phases is corroded, lost or raised is effectively solved; false observation is effectively avoided; and the accuracy for metallographic analysis is high.

Owner:中山市江润金属压铸有限公司

Multi-screen spliced seamless display screen

InactiveCN103489374ARealize seamless splicingImprove performanceIdentification meansFresnel lensText display

The invention discloses a multi-screen spliced seamless display screen. The multi-screen spliced seamless display screen comprises at least two mutually spliced display units, wherein image processing modules of the same size are laminated on the surface of each display unit, are a Fresnel lens, a cylindrical lens, a magnifier or an optical lens and are additionally overlapped by optical processing modules; the optical processing modules are anti-dazzle glass, organic glass, an acrylic plate, a resin material or an anti-scratch lens; the display units, the image processing modules and the optical processing modules are wrapped by a fixing module for fixed connection. The seamless splicing of the display units are truly realized, so that the integral performance of an image displayed by the display screen is just right, the situation of mismatch of pictures and characters produced during precise image-text display can be effectively prevented, and the sense of projection in vision is eliminated.

Owner:江苏清投视讯科技有限公司

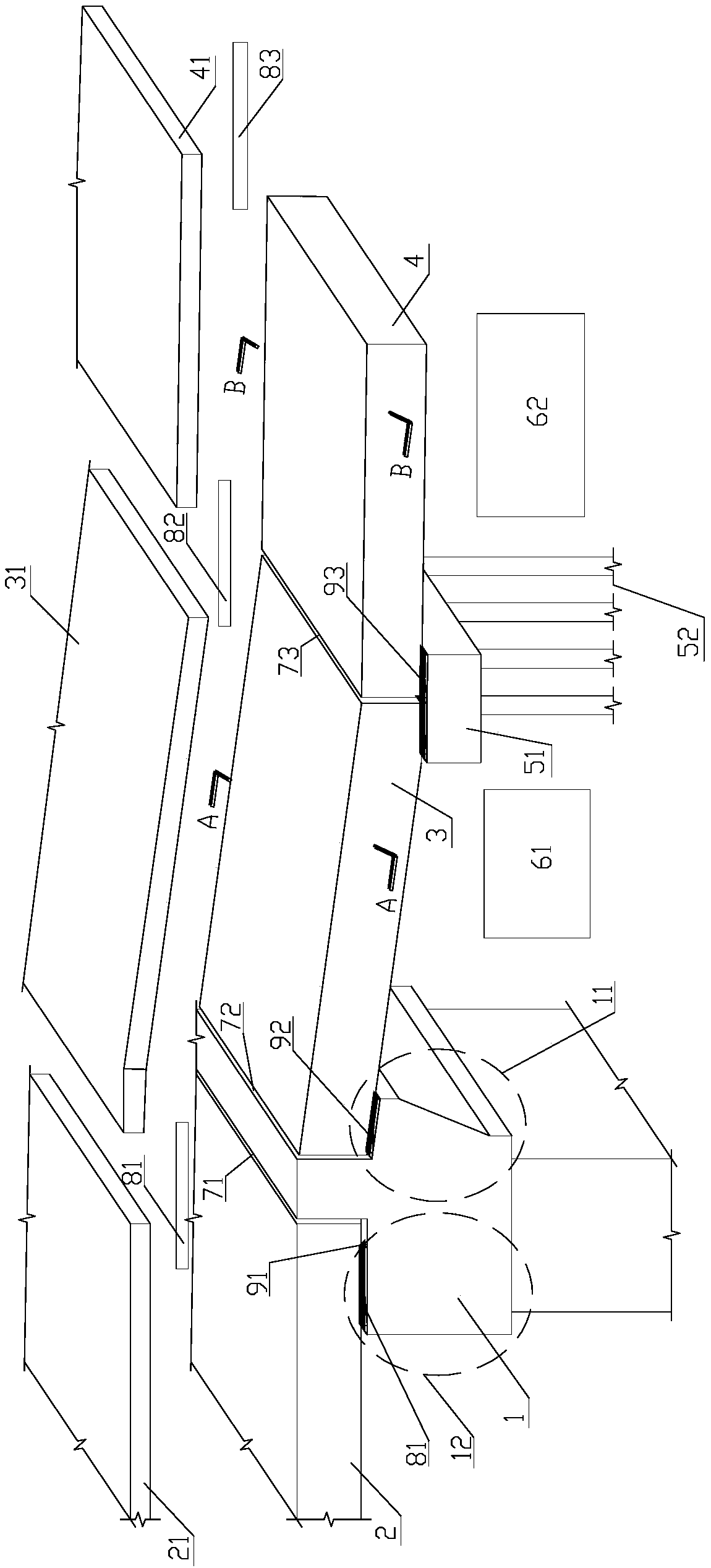

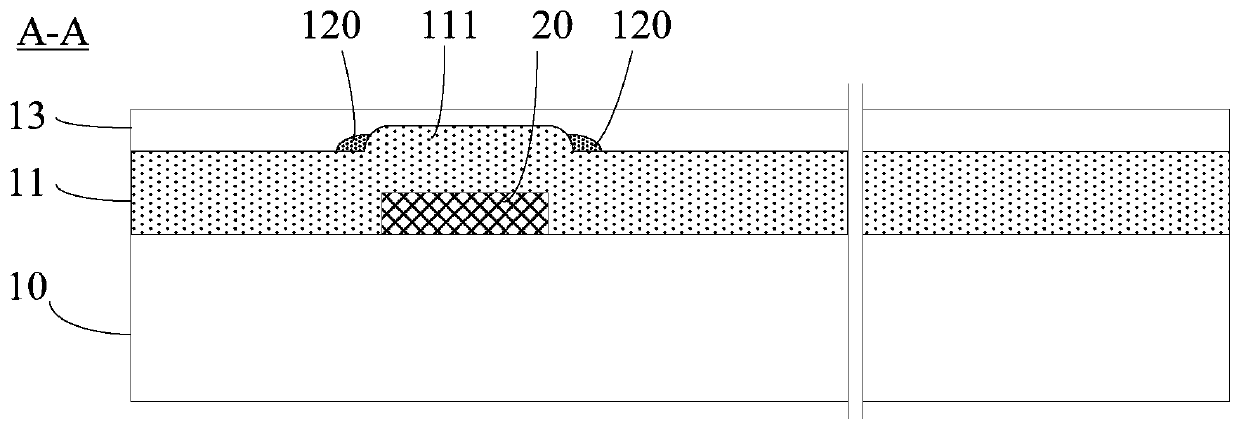

Rigidity-reinforced type bridge head structure for operating highway and governing bump at bridge head and construction method

PendingCN107740339AOvercome the breakOvercoming abutment damageRoadwaysBridge structural detailsEngineeringAbutment

The invention discloses a rigidity-reinforced type bridge head structure for operating a highway and governing a bump at a bridge head. The structure includes a bridge abutment, a bridge edge girder crossing board, a roadbed, a bridge surface paving structure, a first-level butting board, a second-level butting board, a first-level pavement layer, a second-level pavement layer and a supporting platform; the bridge edge girder crossing board is erected on a bridge abutment supporting base, and a bridge surface paving structure is paved on the bridge edge girder crossing board; the first-level butting board is erected between the bridge abutment and the supporting platform, one end of the first-level butting board is erected on a bridge abutment bracket; a far end of the first-level buttingboard is erected on the supporting platform, and the first-level pavement layer is paved on the first-level butting board; one end of the second-level butting board is erected on the supporting platform, the other end of the second-level butting board is erected on the roadbed, and the second-level pavement layer is paved on the second-level butting board; expansion joints exist between the bridgeedge girder crossing board and the bridge abutment, between the first-level butting board and a bridge abutment back, and between the first-level butting board and the second-level butting board. Theinvention also provides a construction method of the rigidity-reinforced type bridge head structure for operating the highway and governing the bump at the bridge head. The structure is great in reliability and low in maintenance cost.

Owner:ZHEJIANG INST OF COMM

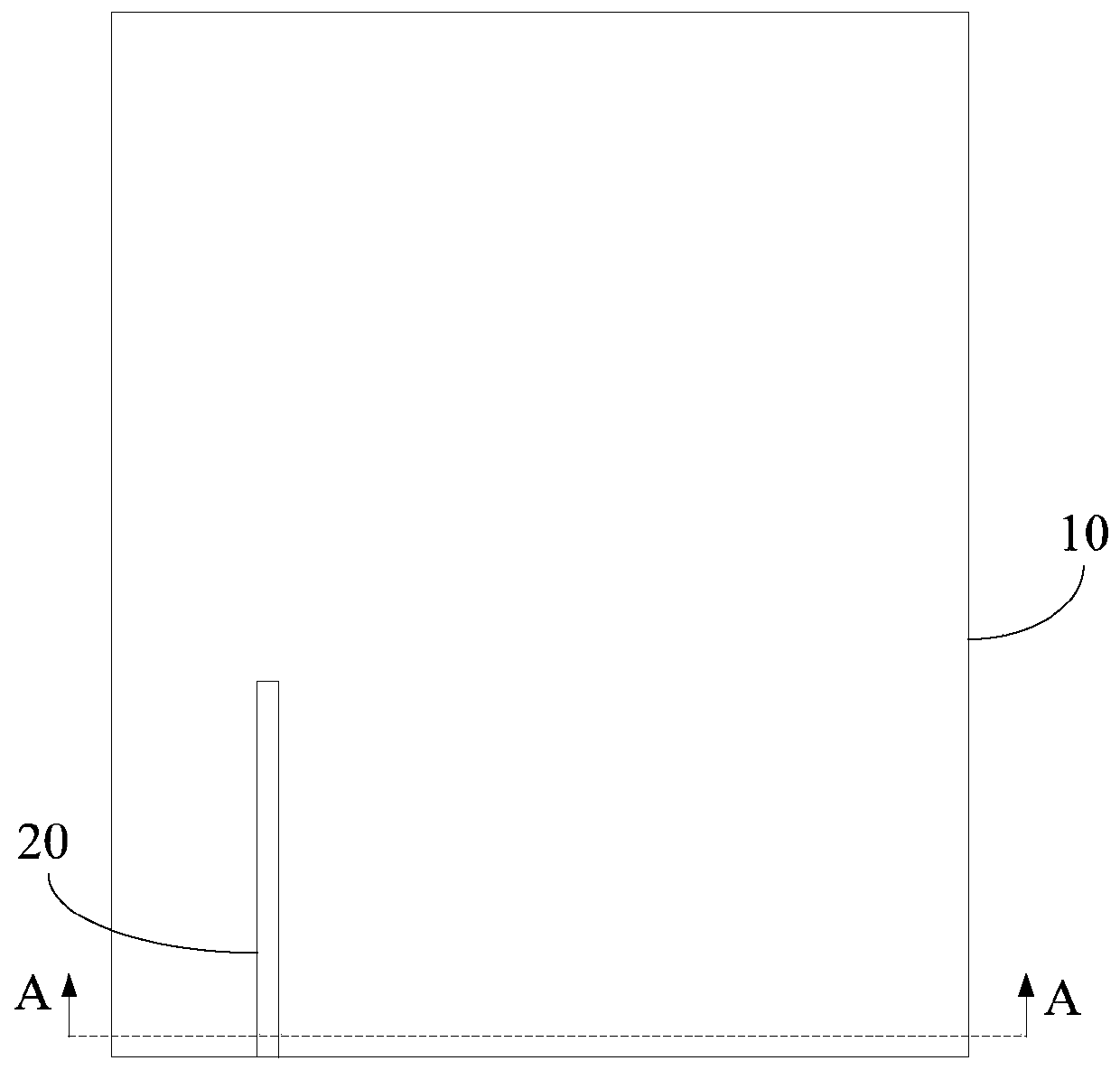

OLED (Organic Light Emitting Diode) display substrate, manufacturing method thereof and display device

InactiveCN110265460ALower the altitudeReduce or avoid residuesFinal product manufactureSolid-state devicesDisplay deviceEngineering

The invention discloses an OLED (Organic Light Emitting Diode) display substrate, a manufacturing method thereof and a display panel, and relates to the field of display devices. The OLED display substrate comprises an insulating substrate and a signal line, wherein one surface of the insulating substrate is provided with a groove, and the grooves extends from the edge of the insulating substrate to the middle of the insulating substrate; and the signal line is located on the surface, at least one segment of the signal line is located in the groove and extends to the edge of the insulating substrate along the groove. When the signal line is set, at least one segment of the signal line is enabled to be located in the groove, and the segment extends to the edge of the insulating substrate along the groove. Therefore, when a flattening layer is formed in the subsequent, the height of a bulge formed on the flattening layer can be reduced or the bulge can be eliminated because the signal line sinks into the groove, and the material residue formed at two sides of the bulge can be reduced or avoided when a pixel limiting layer is formed, thereby being capable of slowing down the erosion of water and oxygen into the OLED display substrate, and prolonging the life of the display panel.

Owner:BOE TECH GRP CO LTD +1

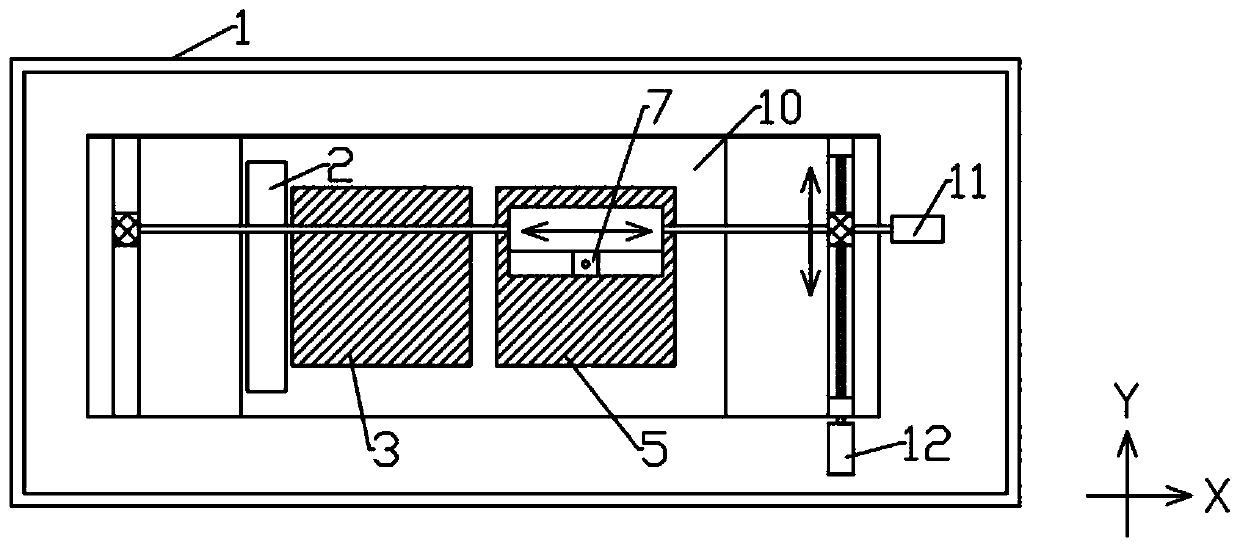

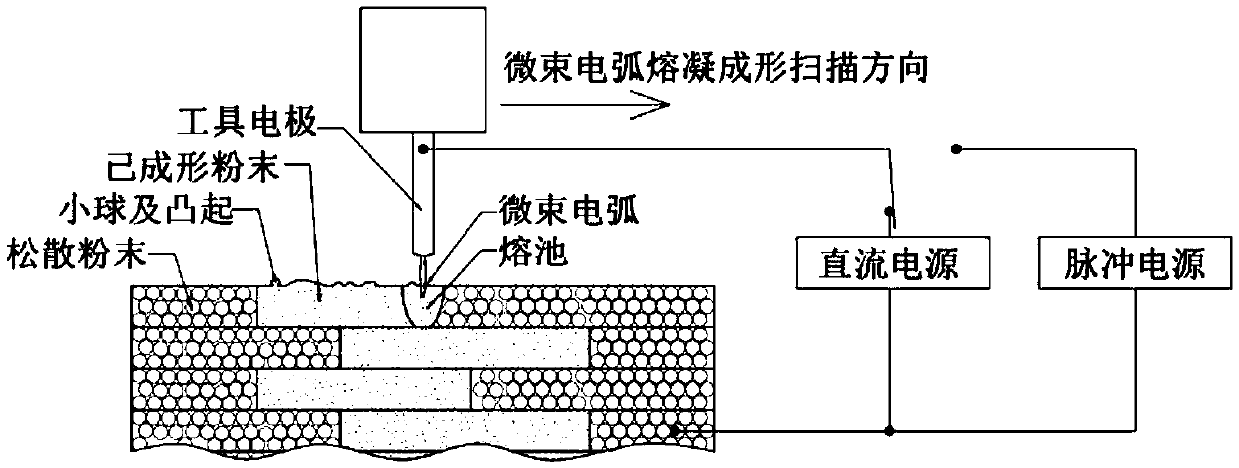

Micro-beam arc selective fusing and electric spark layered milling composite additive manufacturing method

ActiveCN108672849AEliminate bumpsEliminate warpingAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyAdditive layer manufacturing

The invention provides a micro-beam arc selective fusing and electric spark layered milling composite additive manufacturing method and belongs to the technical field of metal part forming manufacturing. The method aims at overcoming the defects that by means of an existing additive manufacturing method, local convex bulging, warpage and the like of metal parts are caused easily. The method comprises the steps that according to a model to be processed, layering and the cross-sectional shape to be processed of each layer are determined according to a model to be processed; a layer of powder material is uniformly laid, and the laid powder layer is preheated; a tool electrode is arranged above the powder layer, a direct current power source supplies power to a tool electrode, and the tool electrode scans the powder layer according to the cross-sectional shape corresponding to the current powder layer, and the fusing forming of the layer is completed; the direct current power source is switched into a pulse power source, meanwhile a main shaft is rotated, the tool electrode is driven to rotate, and primary electro-charge milling is performed on the cross-sectional shape; and after electro-charge milling of the layer is completed, the next layer of powder is flatly laid on the upper surface of the powder layer until fusing and electro-discharge milling of all layers are completed, and the operations are finished.

Owner:HARBIN INST OF TECH

Method for rolling high-precision titanium alloy pipes

ActiveCN104148439AImprove ovalityEliminate bumpsWork treatment devicesMetal rolling arrangementsMetallurgyMicrometer

The invention relates to a method for rolling high-precision titanium alloy pipes. A prepared titanium alloy pipe billet is rolled in a combination way of two rollers and three rollers, and the rolling method adopts single feeding and double slew. The value Q of two-roller rolling is 0.4-2, the value Q of multiple-roller rolling is 0.4-9, and the amount of clearance is 0.2-2mm. The rolled finished pipe is processed in a way of outer surface grinding and inner surface honing to obtain the titanium alloy pipes, wherein the outer surface roughness Ra is less than or equal to 0.6 micrometers, the inner surface roughness Ra is less than or equal to 0.2 micrometers, the outside-diameter size tolerance is less than or equal to 0.04mm, the inside-diameter size tolerance is less than or equal to 0.03mm, and the wall-thickness size tolerance is less than or equal to 3 percent of a nominal wall thickness. Compared with the prior art, the method has the advantages that the size tolerance precision of the obtained products is relatively high, and the inside and outside surface quality is relatively good.

Owner:宁夏中色金航钛业有限公司

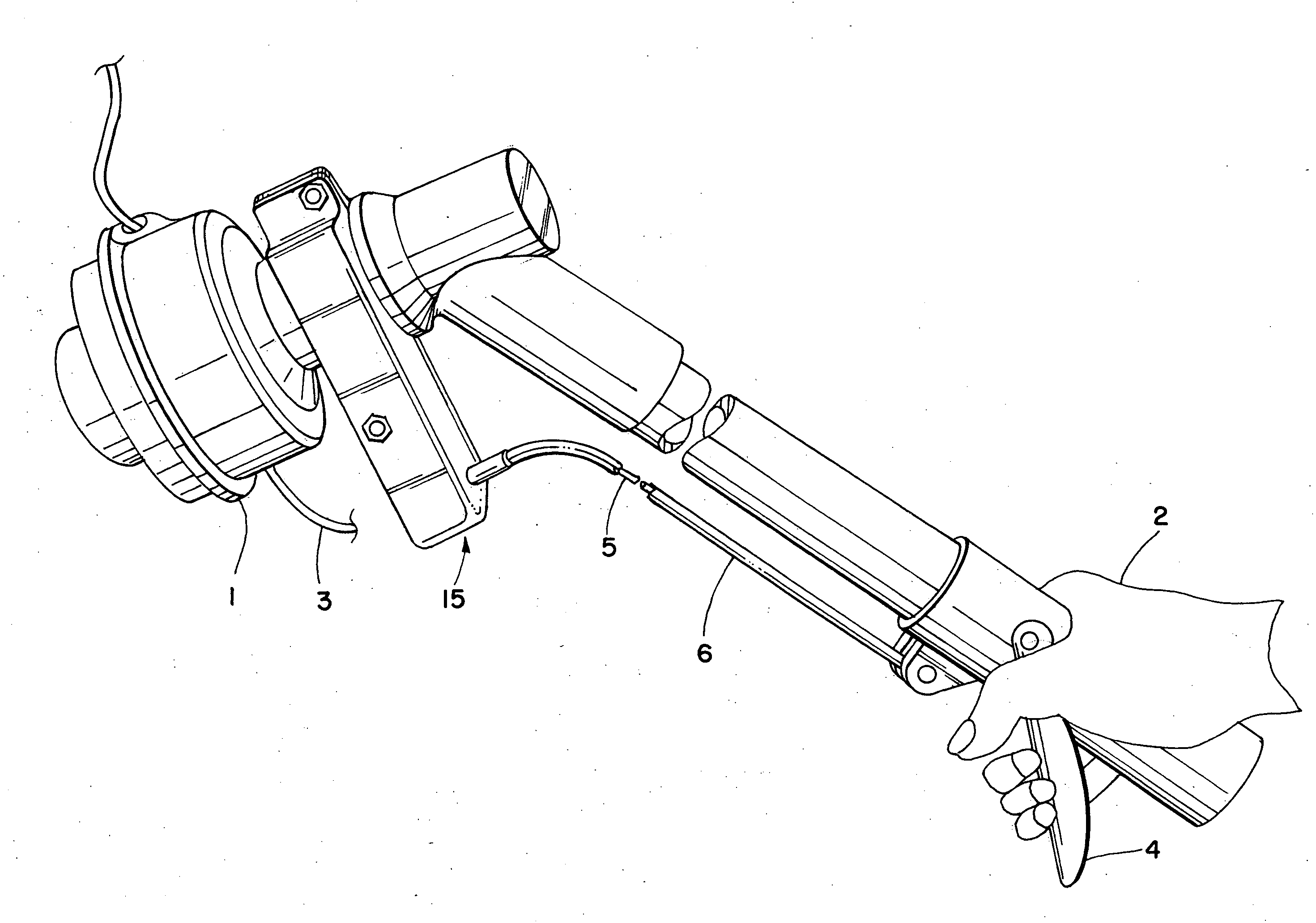

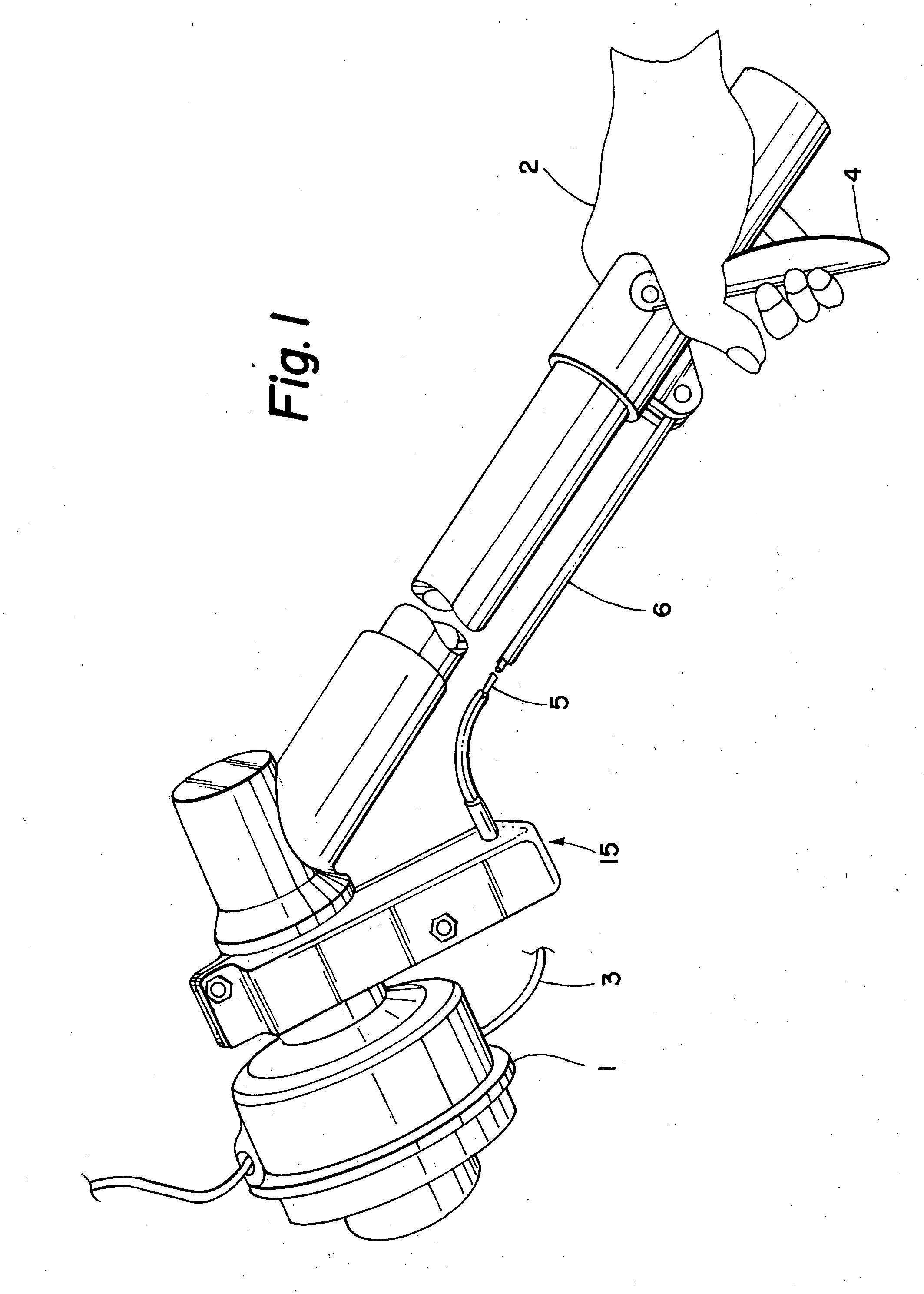

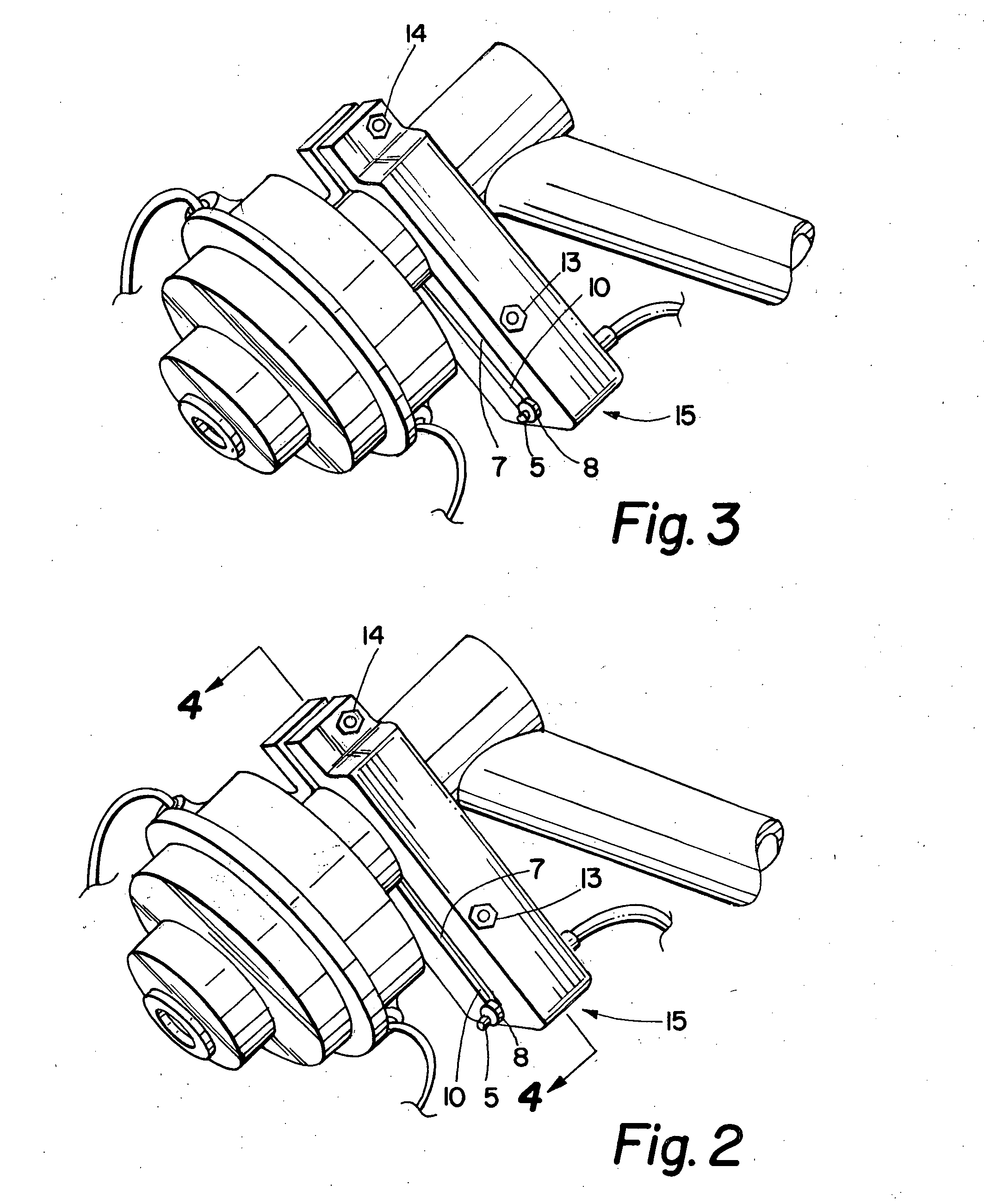

Cable actuated indexing trimmer head compressor

InactiveUS20080244914A1Cost-effectiveReduce manufacturing costMowersMetal working apparatusEngineeringElectric cables

The current invention provides a cable actuated string trimmer head compressor, adaptable to bump-n-feed type string trimmers. A handle operated by remotely actuates a lever that in turn exerts force on a first half of a string trimmer head, compressing the first half of the trimmer head relative to a second half of the trimmer head. The string trimmer head compresses as if it had been pressed to the ground.

Owner:HARRIS DAVID +1

High-efficiency slotting and grinding device for plates

InactiveCN105729262AOffset resistanceAvoid bulgingWood mortising machinesWood slotting machinesVertical planeEngineering

The invention belongs to the technical field of plate processing, and discloses a high-efficiency plate slotting and grinding device. The invention includes a frame, on which a workbench is arranged, and a group of vertically arranged Conveying rollers, the rear side of the worktable is provided with a limit baffle and a first grinding sheet, and the first grinding sheet is driven to rotate by a first driving device; the front side of the worktable is provided with a first Two driving devices, the second driving device is connected with a second grinding sheet, the centerlines of the first grinding sheet and the second grinding sheet are on the same straight line, and the rotation direction of the first grinding sheet and the second grinding sheet is On the contrary; the top of the workbench between the first grinding sheet and the second grinding sheet is provided with a grooved roller, and the center line of the grooved roller is on the same vertical plane as the center line of the first grinding sheet, so A scraper for grooving the plate is arranged on the grooving roller.

Owner:SICHUAN KAIMING MACHINERY MFG

Road paving method

ActiveCN104060512AUniform strength and beautiful appearanceEliminates bumps and potholesIn situ pavingsSteel platesDriving safety

The invention discloses a road paving method, which comprises the following steps: proofreading road building standard steel plates used as guard boards on both sides, adjusting to make it compatible with the horizontal line, and checking whether the thickness of the guard boards is consistent with the standards; installing a roller type road beam on the upper side of the guard board on the road paving starting position; blending a concrete slurry, pouring concrete on the position with height not more than 10 cm, and leveling with a shovel after pouring, wherein the pouring thickness is 2-4 cm higher than the guard board and pouring length is 0.5-1.5 m each time; rolling the road forwards with the road beam, then rolling backwards, and then rolling forwards; and before coagulation of the concrete pavement, using a dragging pressing plate of 2 cm thick and having a same width with the pavement to drag forward along the road direction. The method uses the low position pouring and reciprocating rolling to make the road strong and uniform in strength; the road treated by the dragging pressing plate is very smooth, so as to eliminate concave and convex potholes, prevent pavement damage, prolong the pavement life, and avoid slipping in heavy rain to ensure driving safety.

Owner:潘华益

Polishing agent for precise polishing of high-alloy-aluminium metallographic sample, and precise polishing method

InactiveCN103074631AFast preparationDe-perturbation layerPreparing sample for investigationElectrolysisAlloy

The invention discloses a polishing agent for precise polishing of a high-alloy-aluminium metallographic sample. The polishing agent comprises water, corundum particles and sodium hydroxide, namely, sodium hydroxide, which is an chemical aggressive agent, is added in corundum polishing suspension formed by water and corundum powder, so that not only can the problems of disturbance layers and scratches of mechanical polishing be avoid, but also the problem of disappearance or protrusion of part of phase corrosion of electrolysis and chemical polishing can be avoid, further, the circumstance of observation illusion can be avoided; and meanwhile, the time for precise polishing can be shortened greatly, so that the purpose of preparing high-quality metallographic samples quickly can be achieved. When the agent for precise polishing of a high-alloy-aluminium metallographic sample, provided by the invention, is in use, a polisher is started first, then a reagent bottle filled with the polishing agent is shaken until the polisher runs normally so as to ensure that the polishing agent is mixed uniformly, and the reagent bottle is compressed to enable the polishing agent to be uniformly sprayed onto polishing fabric of the polisher. The invention further discloses a precise polishing method for a high-alloy-aluminium metallographic sample.

Owner:SOUTHWEST ALUMINUM GRP

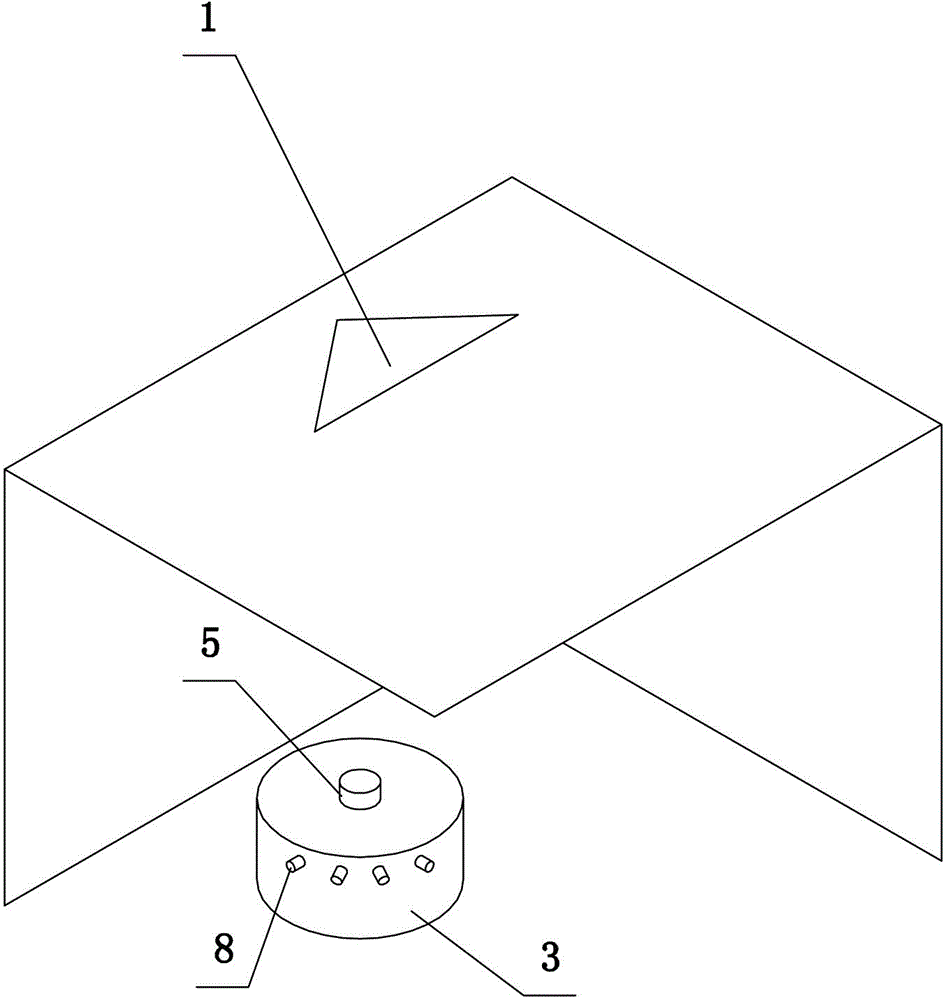

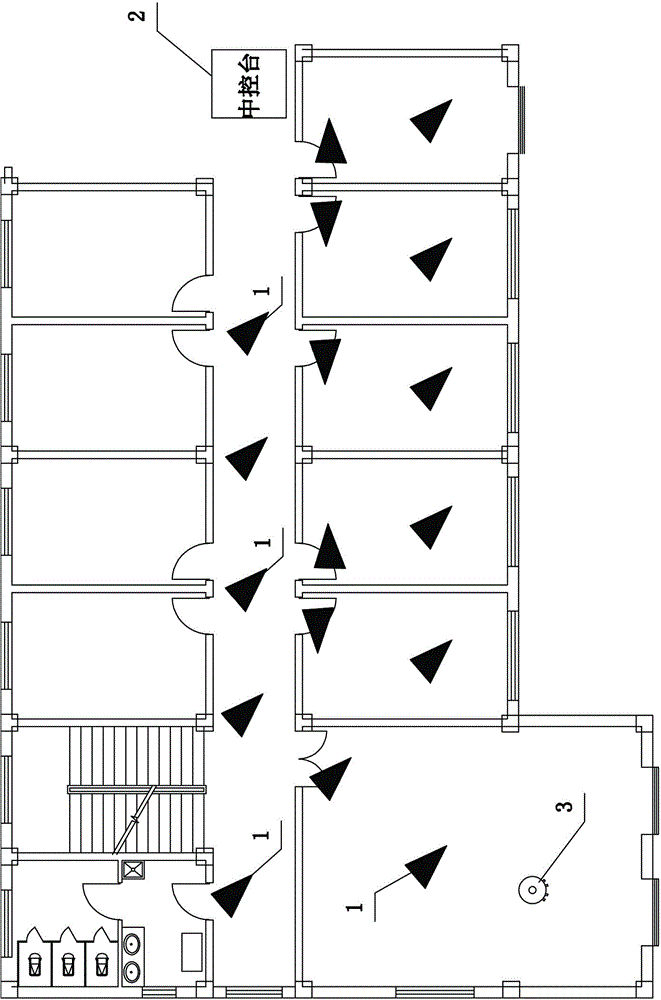

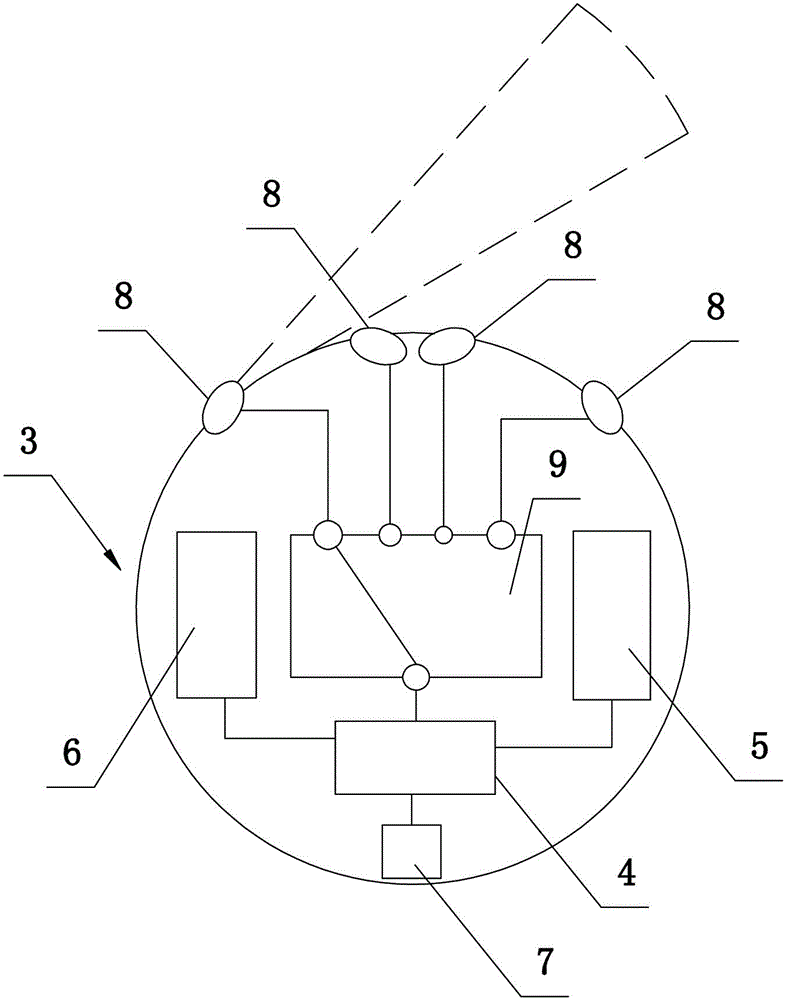

Walking control system and method for robot

ActiveCN104950892AReduce manufacturing costReduce intelligence requirementsPosition/course control in two dimensionsControl systemEngineering

A walking control system for a robot comprises a plurality of infrared light sources arranged in ceilings of each room or corridor, a wheeled robot and a console, wherein the wheeled robot can be used for moving from a first position to multiple different second positions, the infrared light sources are arranged in walking paths from the first position to the second positions, the wheeled robot comprises a control unit, a recognition unit and a moving unit, one moving path is formed from the first position to each second position, and the console forms multiple different infrared light source light-emitting combinations through controlling on or off of the infrared light sources. Each infrared light source light-emitting combination corresponds to one moving path, so that selection of the walking paths of the robot is completely realized through the console, the intelligence requirement for the wheeled robot is greatly reduced, the manufacturing cost of the robot is saved, and basic requirements for control accuracy and running efficiency can be met.

Owner:厦门狄耐克物联智慧科技有限公司

Panel side edge grinding equipment

InactiveCN105773343AImprove the effectEliminate bumpsEdge grinding machinesGrinding carriagesEngineeringMachining

The invention belongs to the technical field of panel machining, and discloses panel side edge grinding equipment. The panel side edge grinding equipment comprises a rack and a working table arranged on the rack and is characterized in that the two ends of the working table are each provided with a set of conveying rollers which are vertically arranged, and the rear side of the working table is provided with a limiting baffle and a first grinding piece; the first grinding piece is driven by a first driving device to rotate; a second driving device facing the working table to move is arranged on the front side of the working table, and is connected with a second grinding piece; and the center line of the first grinding piece and the center line of the second grinding piece are located on the same straight line, and the rotating direction of the first grinding piece is opposite to the rotating direction of the second grinding piece.

Owner:SICHUAN KAIMING MACHINERY MFG

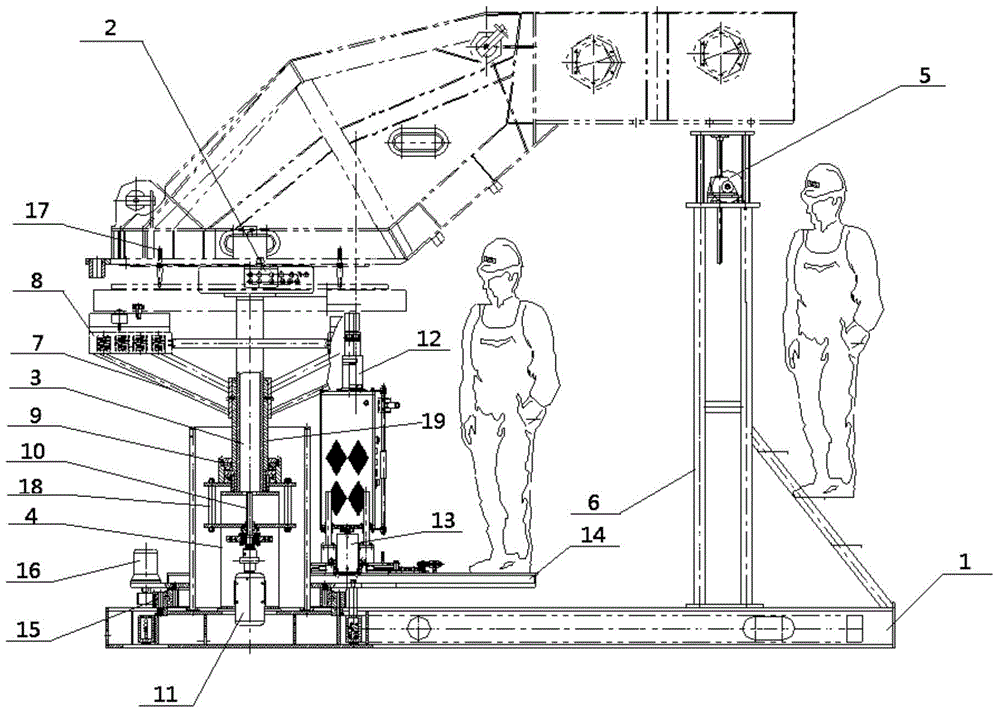

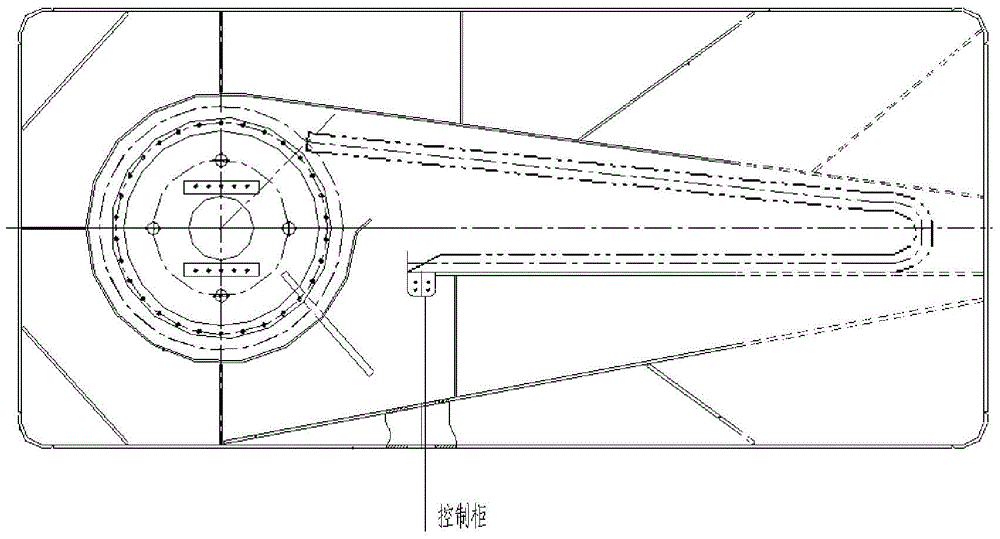

Turntable slewing bearing assembling equipment and method

ActiveCN105436872AEliminate bumpsEliminate the risk of scratchesMetal working apparatusSlewing bearingPetroleum engineering

The invention relates to turntable slewing bearing assembling equipment and method. The turntable slewing bearing assembling equipment comprises a turntable positioning device, a turntable back tail adjusting device and a slewing bearing suspending device. The turntable positioning device is used for positioning and supporting the front end of a turntable. The turntable back tail adjusting device is used for positioning and supporting the back tail of the turntable. The slewing bearing suspending device is used for bearing a slewing bearing, and the position of the slewing bearing can be adjusted according to the position of the turntable so that the butt joint of the turntable and the slewing bearing can be achieved. According to the turntable slewing bearing assembling equipment and method, the turntable positioning device and the turntable back tail adjusting device special for positioning and supporting the turntable are arranged, the process of turning over a turntable in an existing assembling mode is avoided, and therefore potential safety hazards in the overturning process of the turntable are eliminated, and the problems that the turntable is collided and the surface is scratched due to overturning of the turntable are solved.

Owner:XUZHOU HEAVY MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com