Road paving method

A pavement laying and road technology, applied in the field of construction technology, can solve the problems of uneven concrete materials, accelerate road damage, reduce the service life of the road, achieve uniform strength and beautiful appearance, eliminate bumps and potholes, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention are described in detail below.

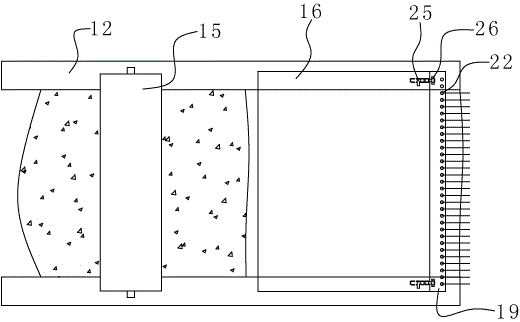

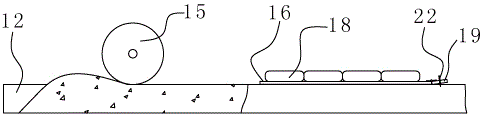

[0015] refer to figure 1 , figure 2 As shown, the present invention relates to a road pavement laying method, which mainly includes the following construction steps: S1, proofreading the road construction standard steel plates used as guard plates 12 on both sides, adjusting them to meet the horizontal waterline, and checking whether the thickness of the guard plate 12 is Compliance with the standard, that is, whether it meets the design requirements and whether it meets the enclosure height required by the thickness of the road surface. At the same time, check the preparation of materials to see if they meet the construction needs and various requirements. S2. Install a roller-shaped road beam 15 on the upper side of the guard plate 12 at the starting position of paving. The road beam 15 is a pressure roller for rolling concrete with both ends spanning the guard plate 12 . S3. Prepare concrete sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com