Micro-beam arc selective fusing and electric spark layered milling composite additive manufacturing method

An additive manufacturing and electric spark technology, which is applied in the field of micro-beam arc selective melting and EDM layered milling composite additive manufacturing, can solve problems such as warping, bulging and pilling of metal parts, and achieve increased density , Eliminate bulge and warpage, improve the effect of forming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

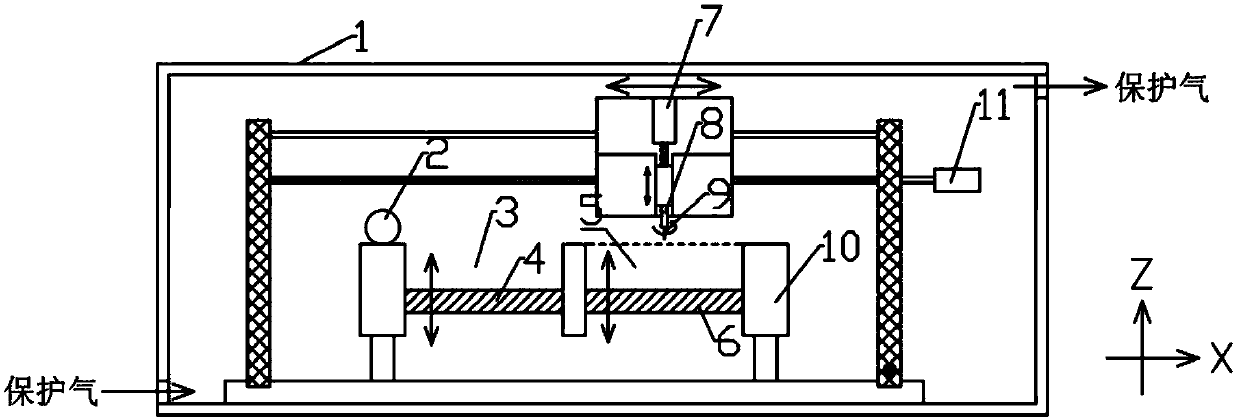

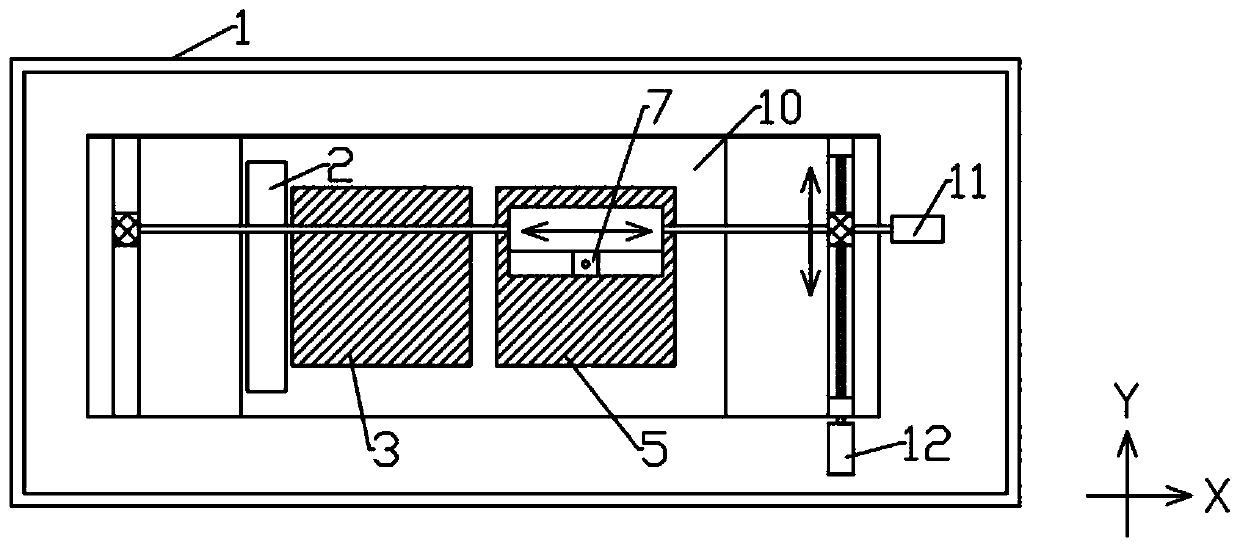

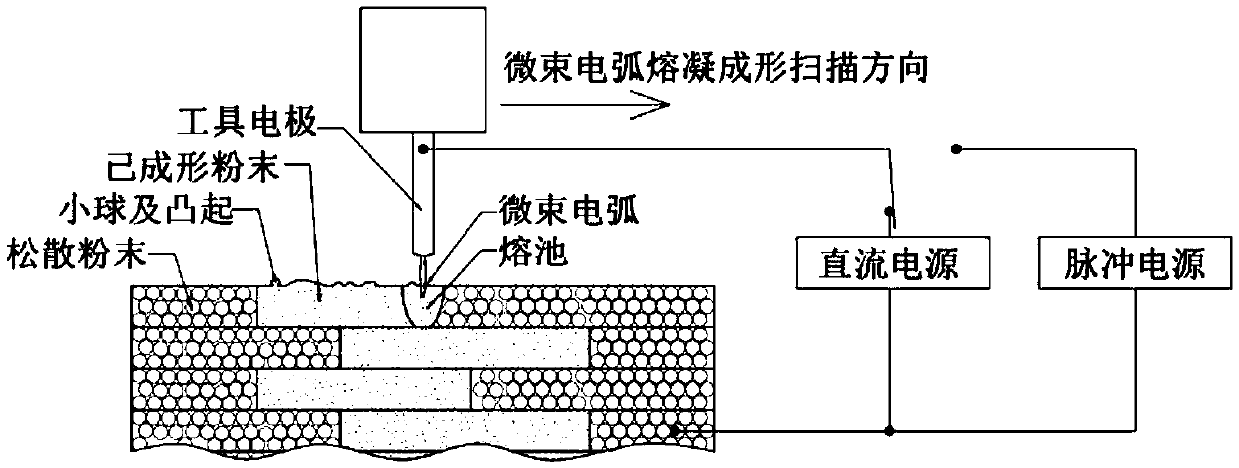

[0043] Specific embodiment: the composite additive manufacturing method of micro-beam arc selective melting and electric spark layered milling in this embodiment is realized by means of an additive manufacturing device, such as figure 1 and figure 2 As shown, the device includes an airtight chamber 1, a powder spreading preheating roller 2, a raw material chamber 3, a raw material chamber supporting plate 4, a forming cavity 5, a forming cavity supporting plate 6, a Z-axis servo feed mechanism 7, a high-speed spindle 8, Tool electrode 9, worktable base 10, X-direction feed part 11, Y-direction feed part 12; worktable base 10 is provided with two cavities, respectively: raw material cavity 3 and molding cavity 5, worktable base 10 The top surface is flat; the raw material cavity bottom plate 4 is set in the raw material cavity 3 and can move up and down; the molding cavity bottom plate 6 is set in the molding cavity 5 and can move up and down; the powder spreading preheating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com