Automatic turnover device for conveying forklift hub brake drum assembly

A technology for brake drums and wheels, which is applied in the direction of conveyor objects, transportation and packaging, motor vehicles, etc., can solve the problems that the automatic turning equipment cannot meet the requirements, and achieve the complete safety and reliability of the turning process, and reduce the labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following, the present invention will be further explained through embodiments with reference to the drawings.

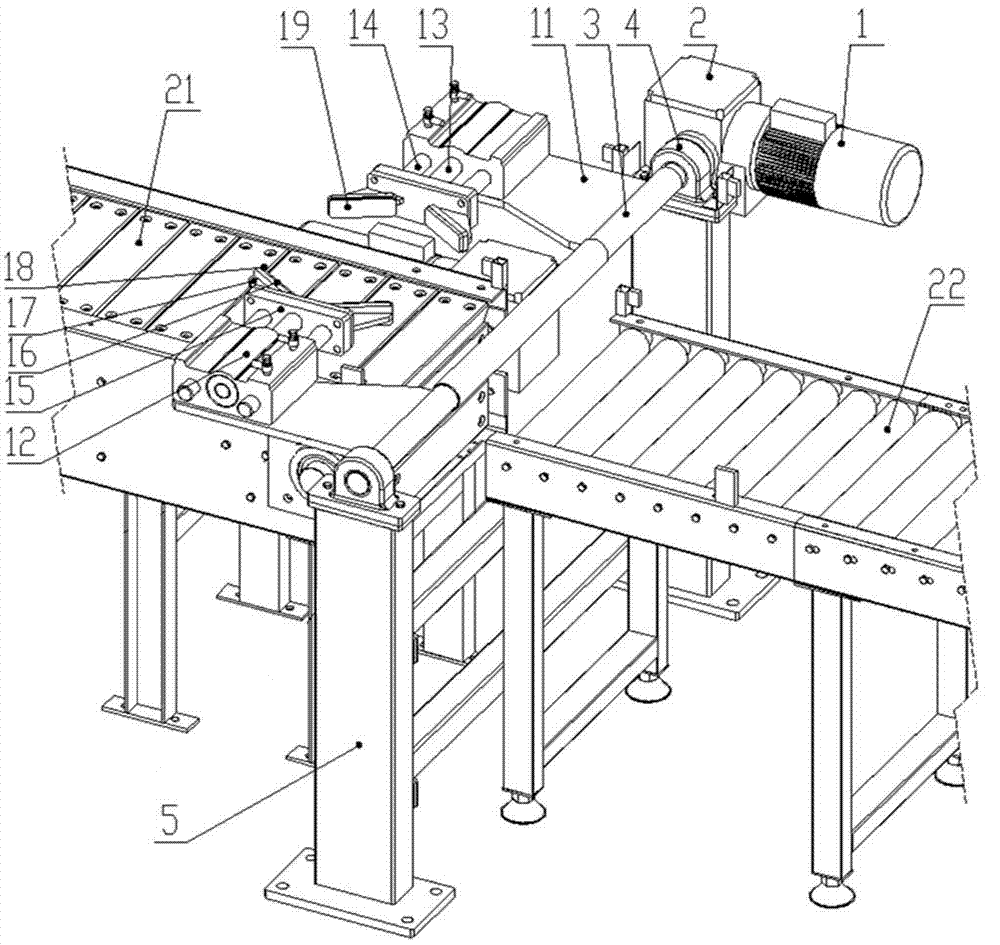

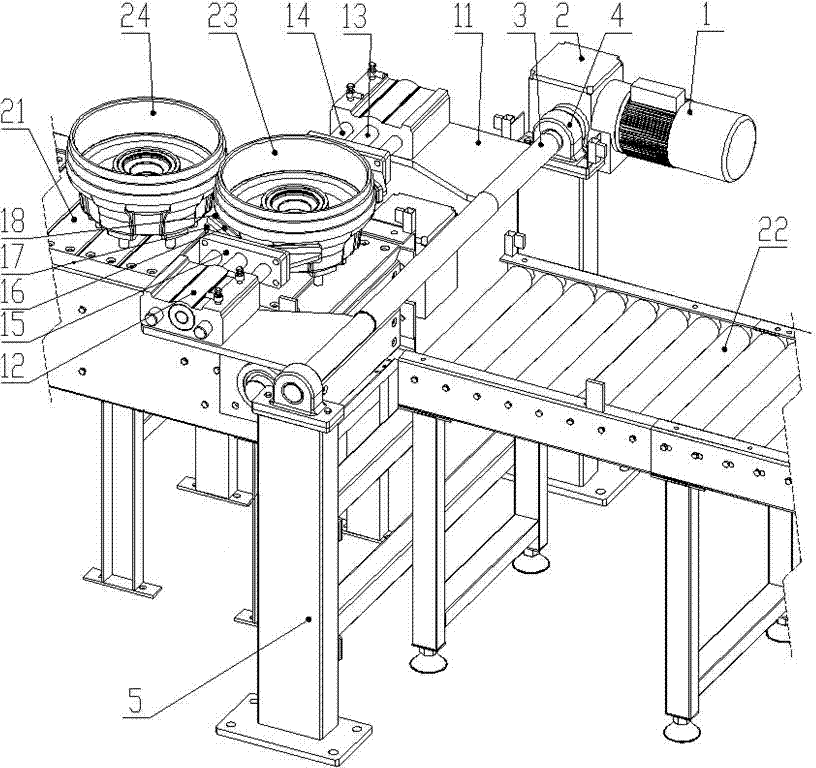

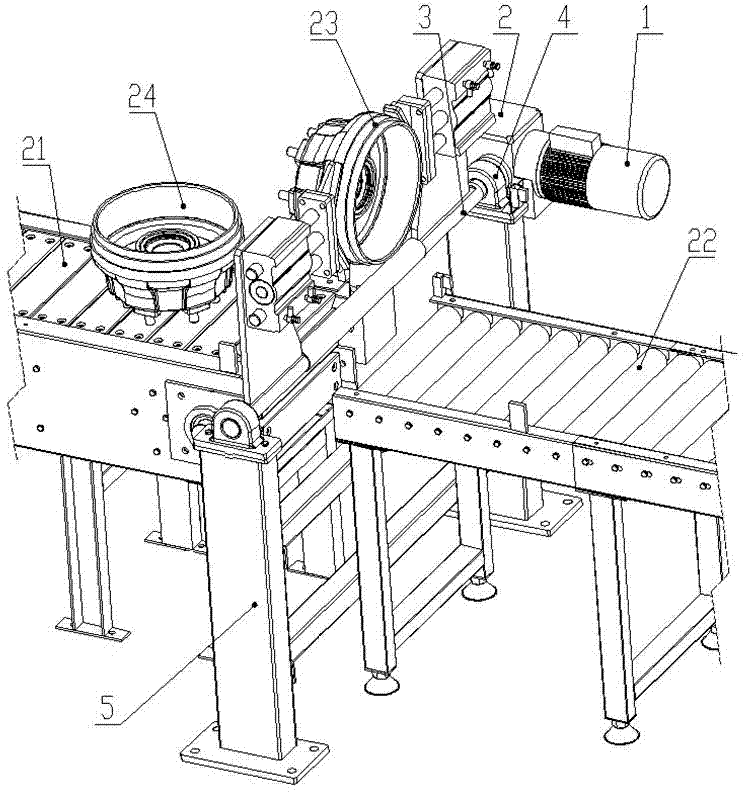

[0020] See figure 1 , The automatic turning device used for conveying the fork wheel hub brake drum assembly includes a conveying mechanism, which includes a power plate chain output track and a power roller conveyor mechanism that are adjacent to each other at the head and tail. The power plate chain output track is a flat conveying device, The power roller conveyor mechanism is a flexible conveyor device.

[0021] The automatic turning device includes a motor 1, a reducer 2, a rotating shaft 3 and a clamping mechanism. The two sides of the rotating shaft 3 are fixedly installed on the top of the two upright legs 5 through the bearing and the bearing seat 4 respectively, and the two legs 5 are respectively fixedly installed on both sides of the conveying mechanism. The rotating shaft 3 is parallel to the power plate chain output track The power plate chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com