Wheel tooth type crusher

A technology of crushers and gear teeth, which is applied in the direction of grain processing, etc., can solve the problems of affecting the crushing efficiency of the machine, inconvenient tooth replacement, and small occlusal space, so as to reduce the number of start-up maintenance, good overload protection performance, and good starting performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

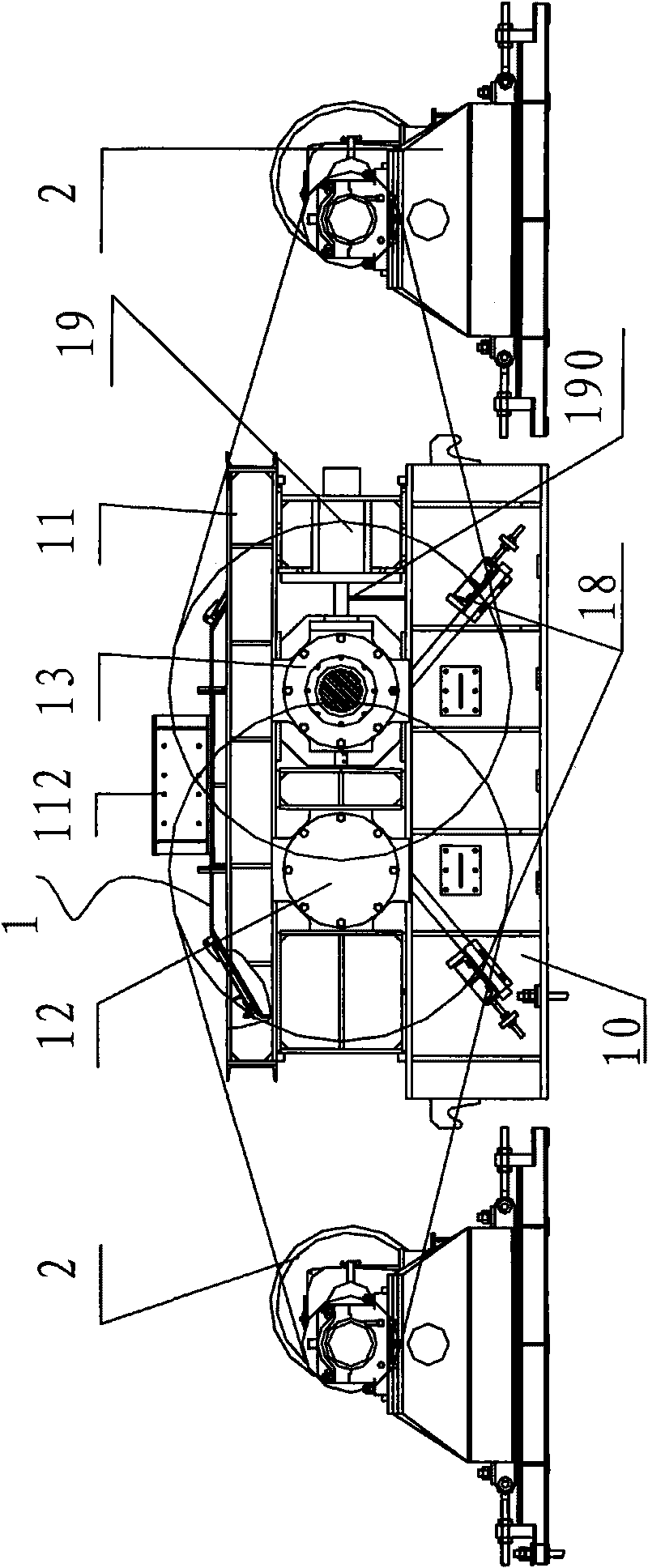

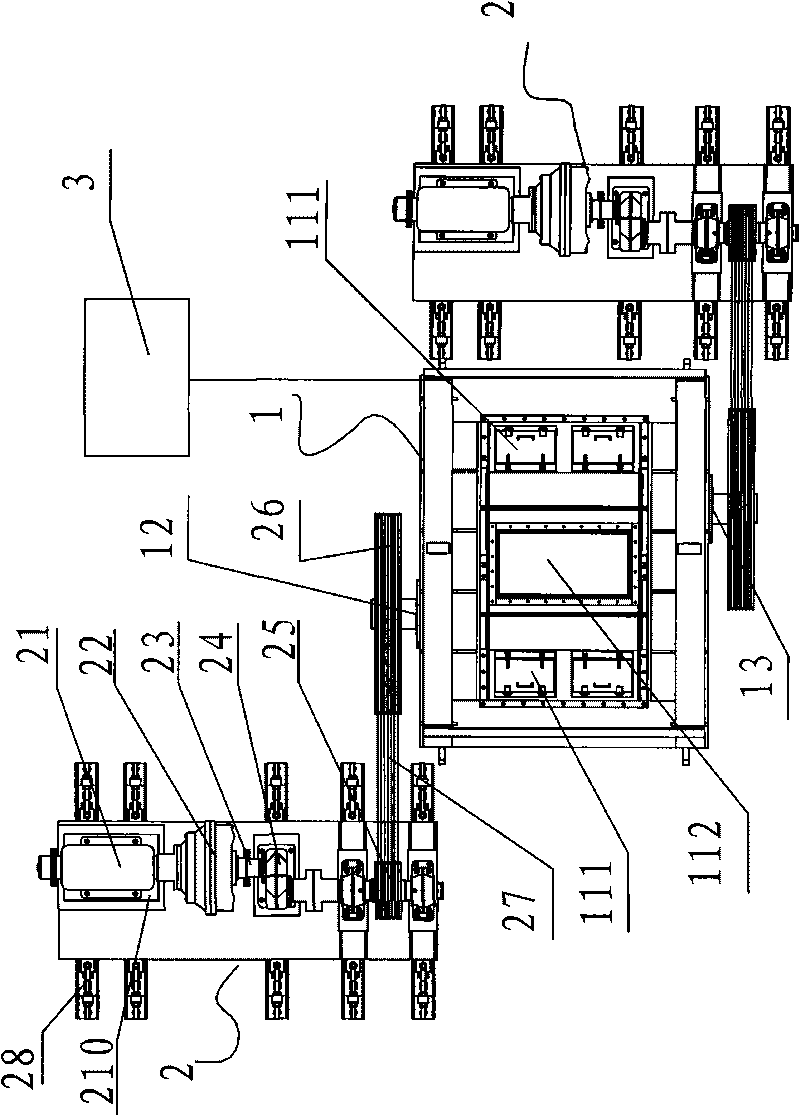

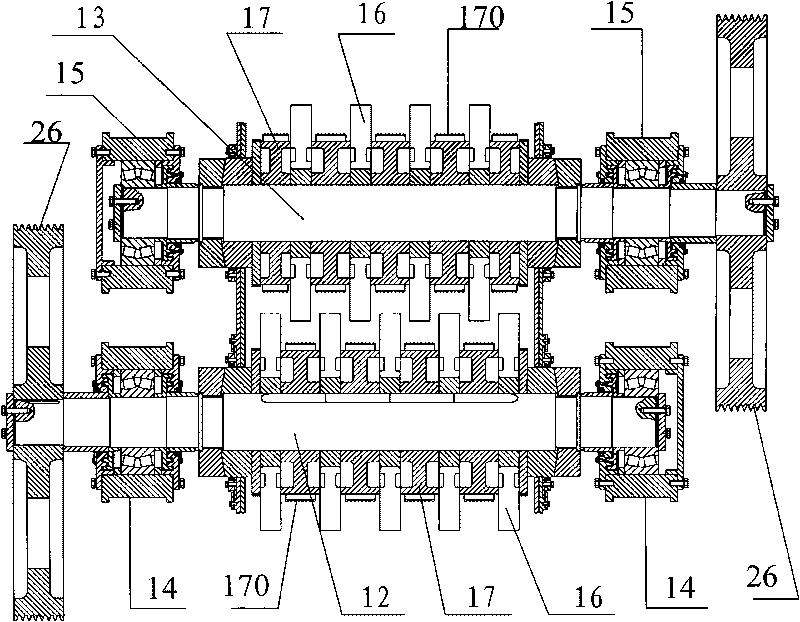

[0027] see Figure 1 to Figure 5 , a gear-toothed crusher of the present invention includes a main engine 1, two sets of transmission devices 2 and a hydraulic adjustment insurance system 3.

[0028] The main engine 1 is composed of a base 10, a casing 11 mounted on the upper end of the base 10, a rotor part disposed in the casing 11, a pair of sweepers 18 disposed in the base 10 and an adjusting device disposed on the casing 11.

[0029] The base 10 is a frame plate structure, and its front and rear side plate tops are provided with a fixed mount (not shown) at the shaft outlet of the fixed roller shaft 12, and its front and rear side plate tops are provided with hydraulic pressure on the near movable roller shaft 13 side. Cylinder frame (not shown in the figure);

[0030] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com