Lifting roller displacement control device in plate rolling machine

A technology of displacement control and lifting rollers, which is applied in the field of displacement control devices for machine parts, can solve problems such as poor overload protection performance, low degree of automation, and inappropriate curvature of the coiling plate, and achieve good overload protection performance, high degree of automation, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

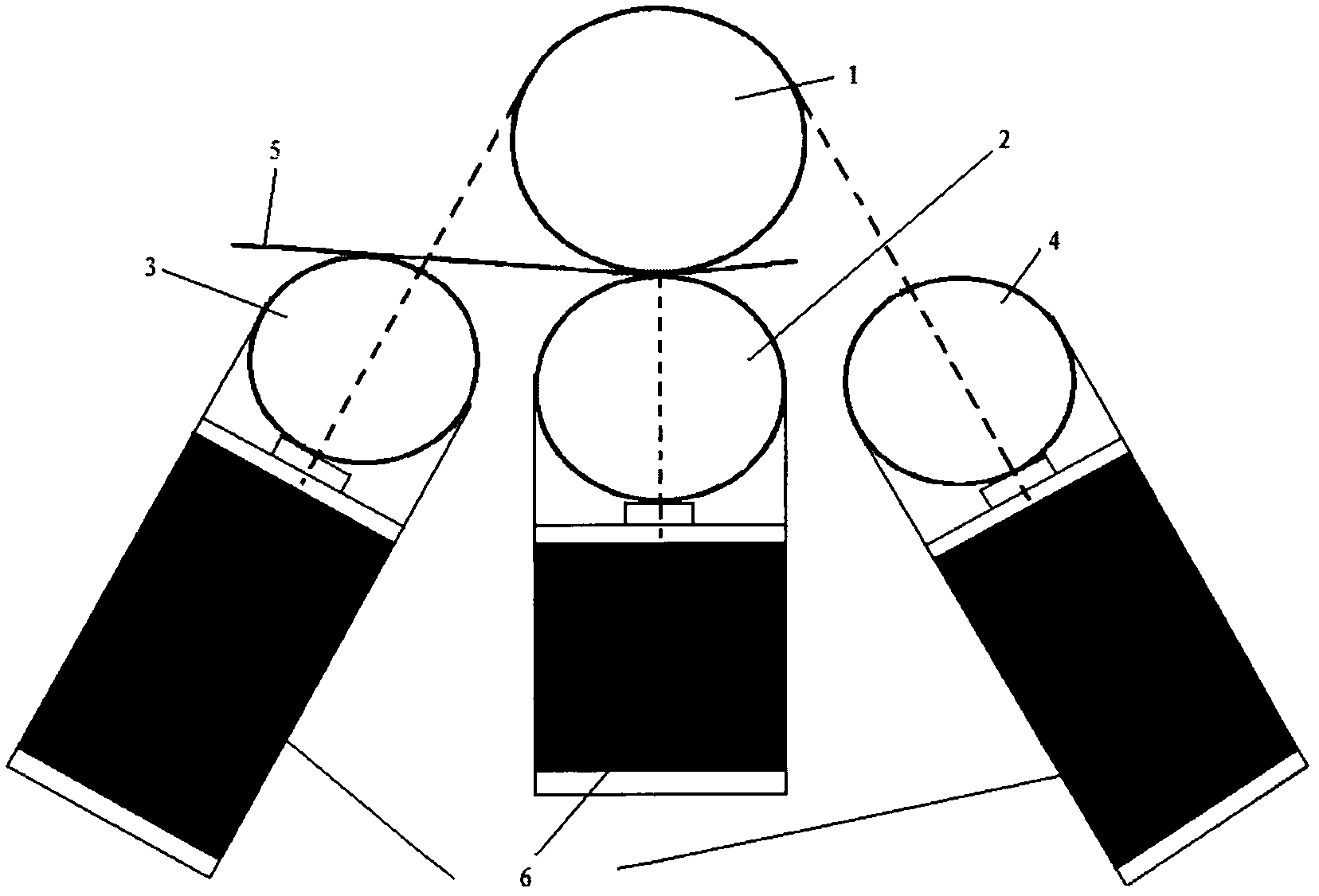

[0022] figure 1 Shown is the working principle diagram of the plate rolling machine. The upper roller 1 is fixed, the lower roller 2 moves vertically, and the front roller 3 and the rear roller 4 move along their respective tracks. figure 1 shown by the dotted line in . During the coiling process of the steel plate 5, the steel plate is first pressed by lifting the lower roller 2, and steel plates with different radii are rolled by lifting the height of the front roller 3 and the rear roller 4. The upper roller 1 and the lower roller 2 are always in a clamping state during the entire forming process of the sheet material 5, which enables the equipment to bend and form sheets of various thicknesses under its own maximum working capacity.

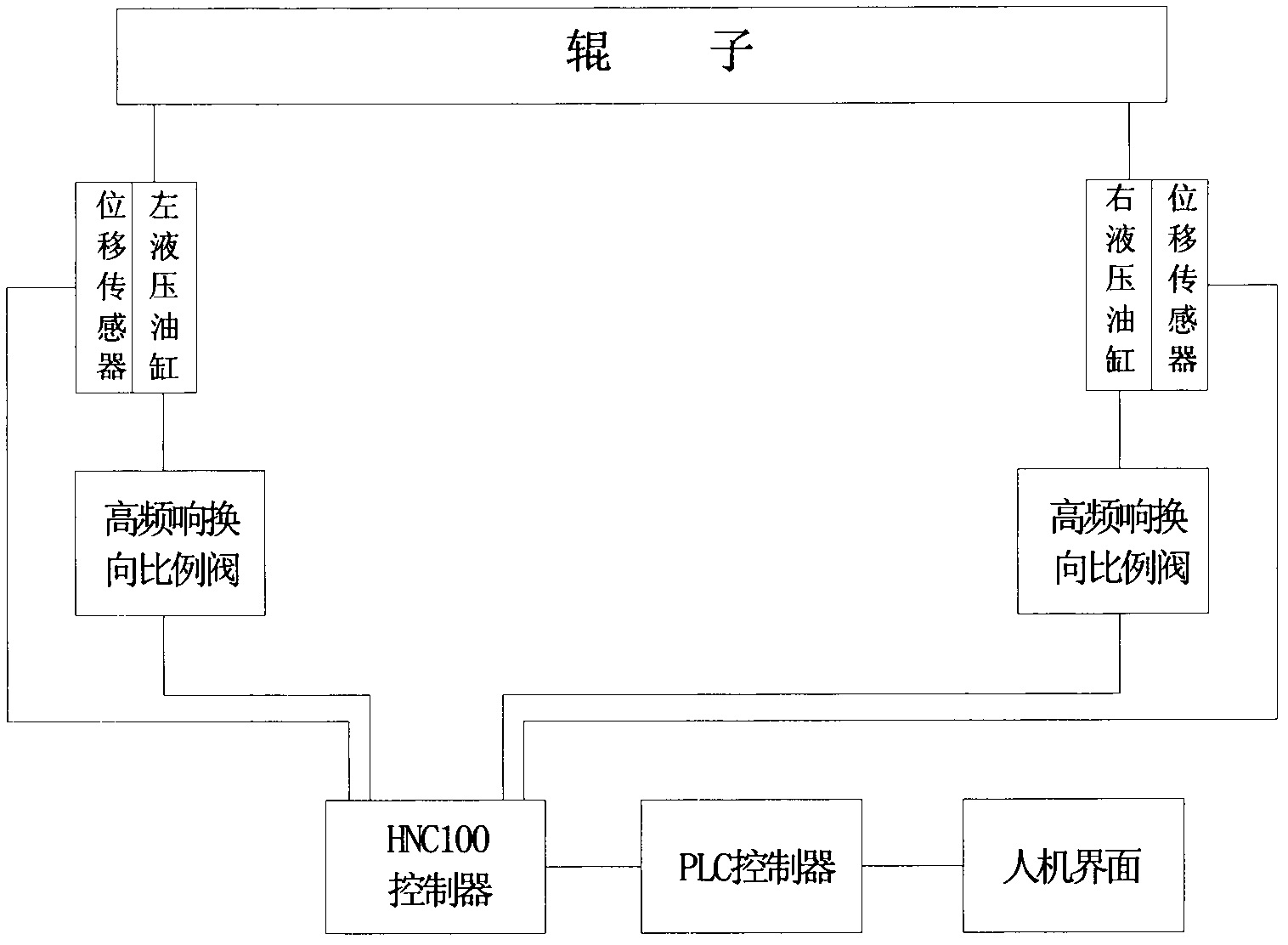

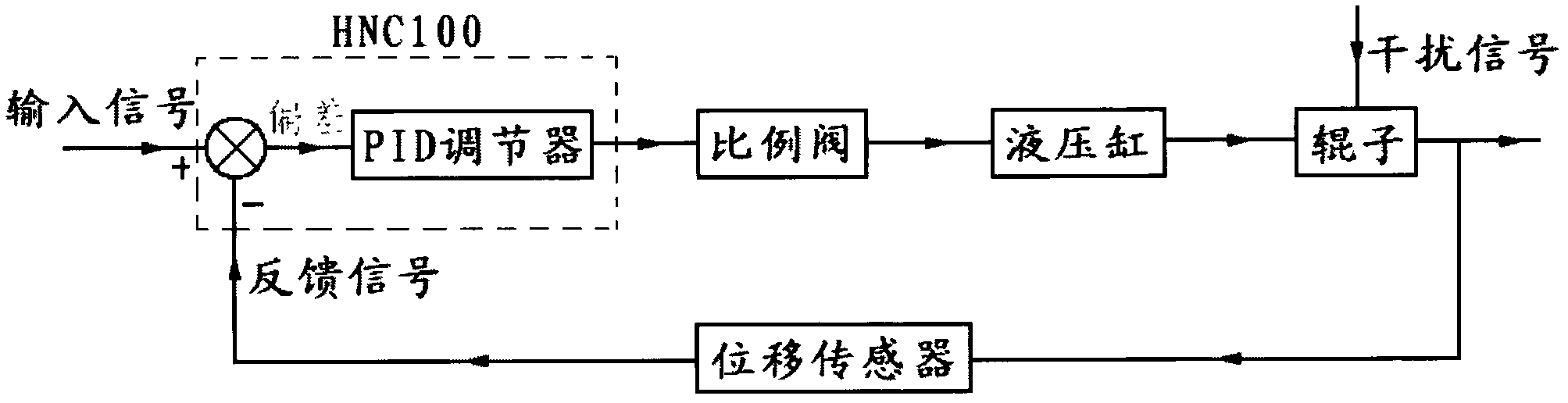

[0023] figure 2 Shown is the logical relationship diagram of the displacement closed-loop hydraulic control device, the PLC co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com