Front-and-back opening-closing split self-controllable power air door

A split-type, damper technology, used in mine/tunnel ventilation, mining equipment, earth-moving drilling, etc., can solve the problems of burning out the motor, motor protection, easy leakage failure, etc., and achieve the smooth and smooth process of the damper movement. Smooth running process and the effect of eliminating impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

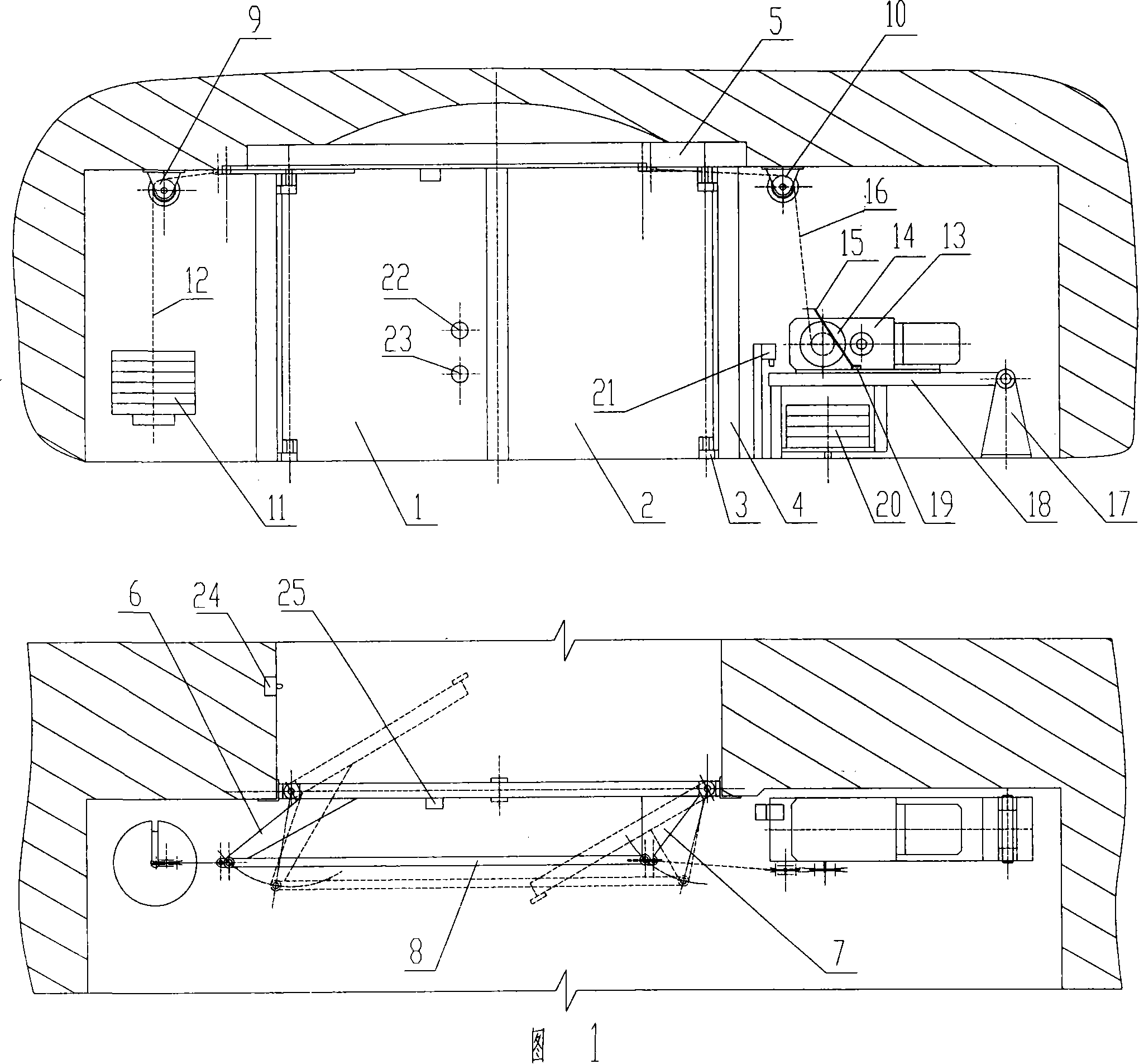

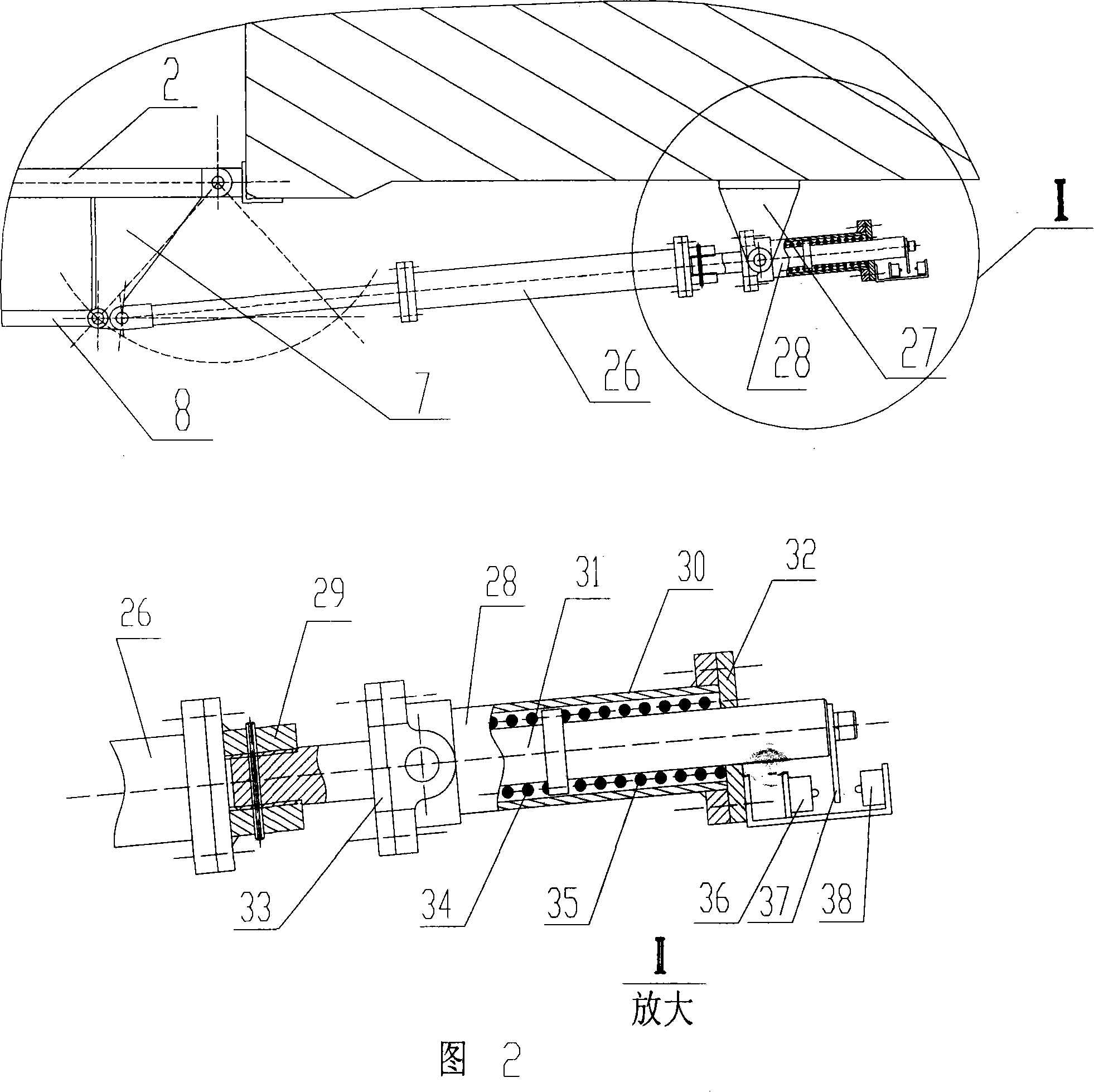

[0019] The front and rear opening and closing split type self-controlling power damper of the present invention is characterized in that the damper consists of a left damper (1), a right damper (2), a hinge (3), a frame (4), a beam (5), a left damper The door crank arm (6), the right door crank arm (7) and the damper power device are composed; the frame (4) is connected with the crossbeam (5) to form the door frame of the damper, which is embedded in the roadway, and the left and right dampers (1) (2) are connected by hinges ( 3) It is hinged with the frame (4), and the left and right door crank arms (6) (7) are respectively fixed to the upper ends of the left and right dampers (1) (2), and the hinged ends are hinged with the connecting rod (8) through the pin shaft, and The hinged end of the right damper or the left damper crank arm (6) (7) is connected with the damper power device. When the power unit dragged one of the curved arms and the damper to rotate, the connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com