Compound control method of speed and position of hydraulic cylinder system based on displacement feedback

A composite control and system speed technology, applied in the direction of fluid pressure actuation device, servo motor, mechanical equipment, etc., can solve the problems of large energy loss, heat generation, and inability to realize the positioning system of the hydraulic system, so as to reduce the control time, reducing the cost of use, increasing the effect of ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

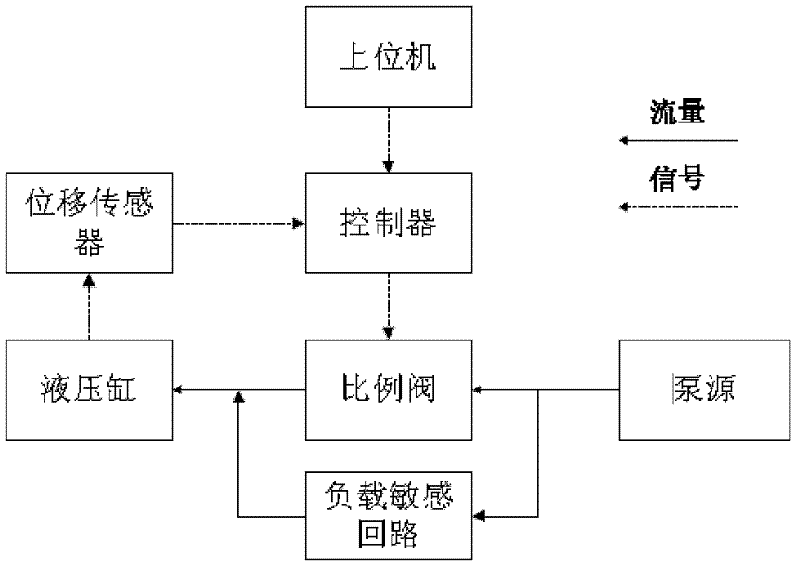

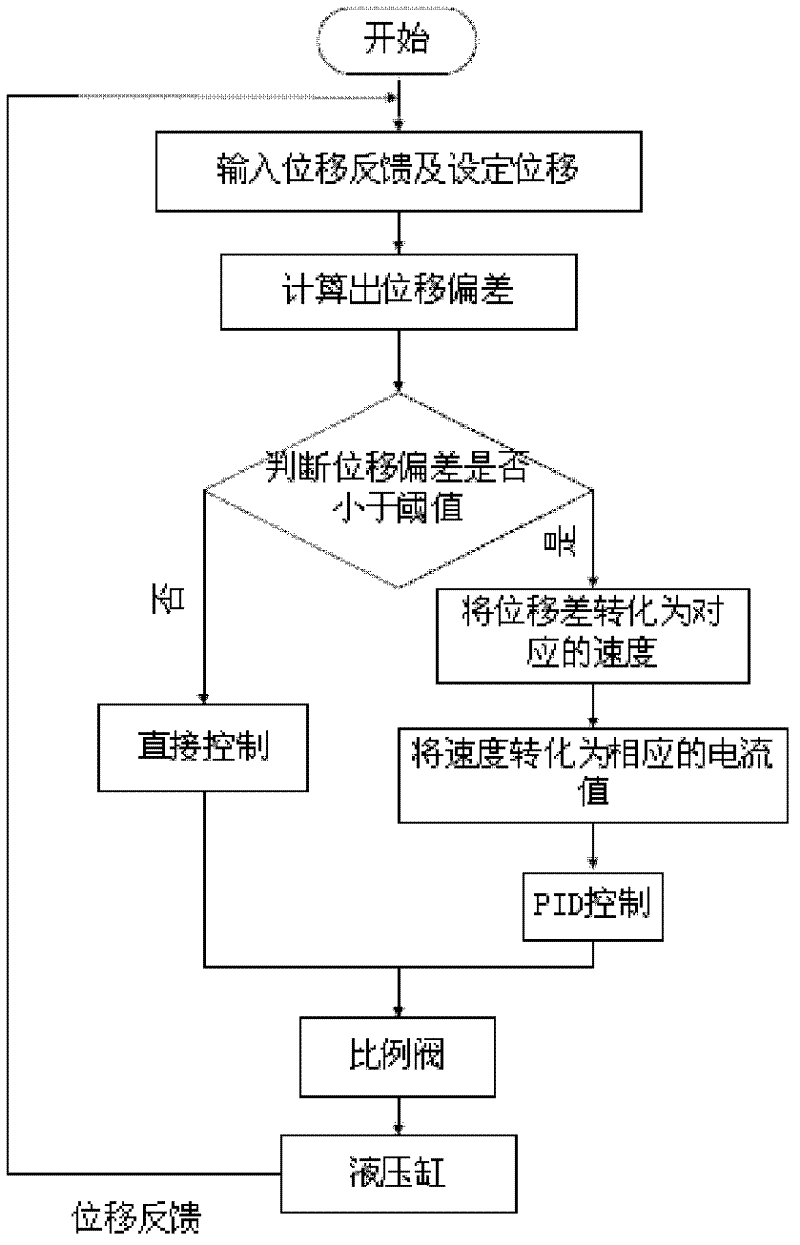

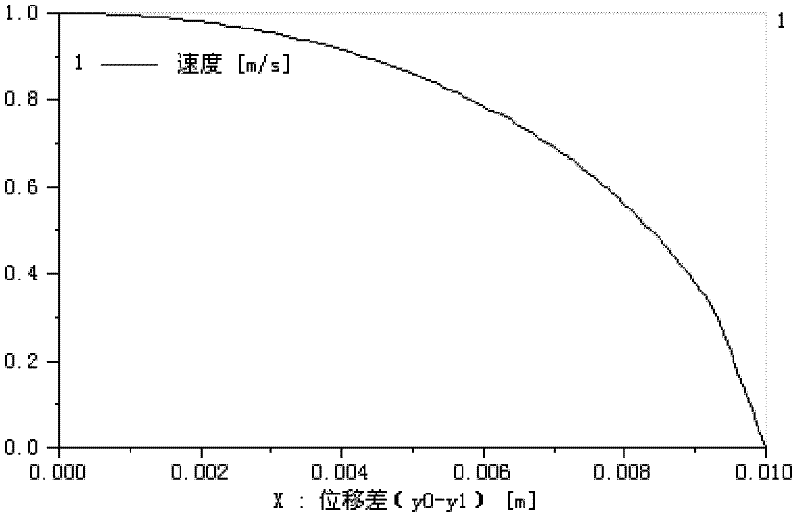

[0040] Such as figure 1 As shown, the valve-controlled cylinder system includes a pump source, a proportional valve, a hydraulic cylinder, a displacement sensor, a controller, and a load sensing circuit. The flow rate of the proportional valve is only related to the opening area of the proportional valve. The controller receives the set displacement value signal from the upper computer, and compares it with the actual displacement signal fed back by the displacement sensor. Such as figure 2 As shown in the flow chart, when the difference Δy has not reached the set threshold ε, the controller outputs the rated current of the proportional valve, and the hydraulic piston moves rapidly; when the difference Δy reaches the set threshold ε, the control The device converts the displacement difference Δy into a speed signal v through a sine function with an exponent; since the pressure difference on both sides of the proportional valve is constant, the flowing flow is only related...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com