Zero-impact spring steel ball safety clutch

A safety clutch, steel ball technology, applied in clutches, automatic clutches, mechanical equipment, etc., can solve problems such as the maximum working torque limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Necessary explanation: In the main text of this manual and all the drawings, the same or similar components and their characteristic parts use the same symbols, and they will only be explained in detail when they appear for the first time, and will not be repeated when they appear again. Give repeated elaboration.

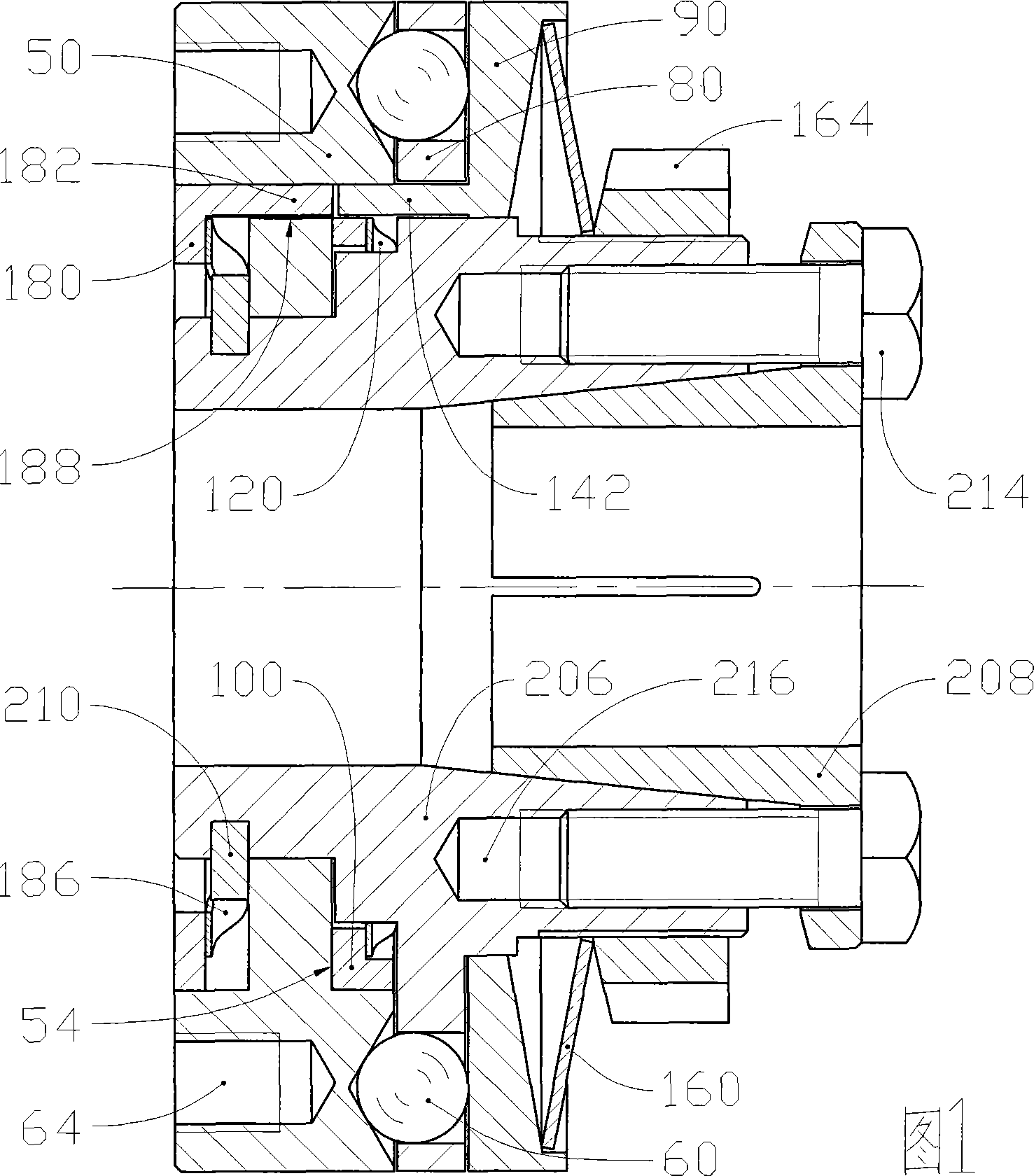

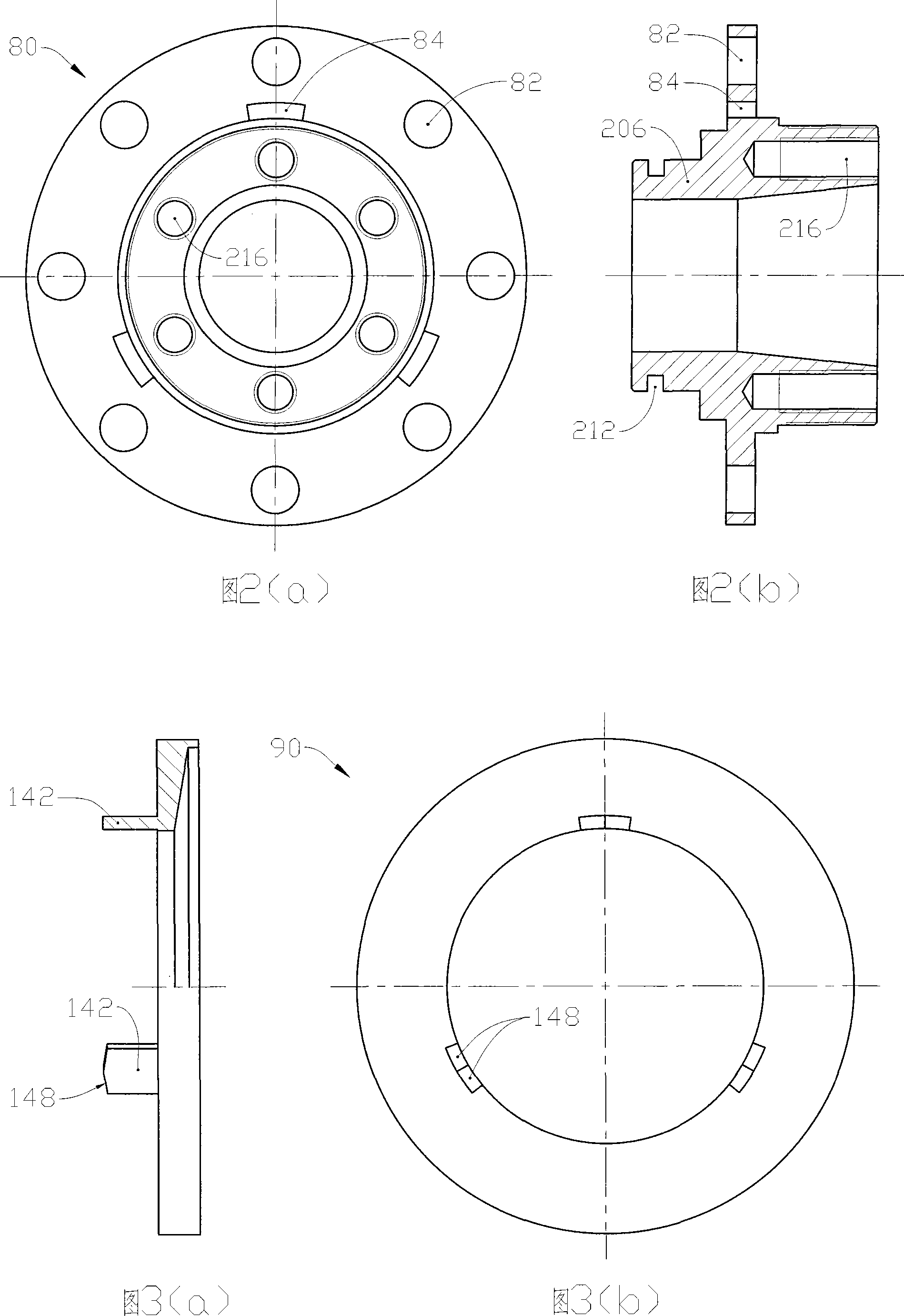

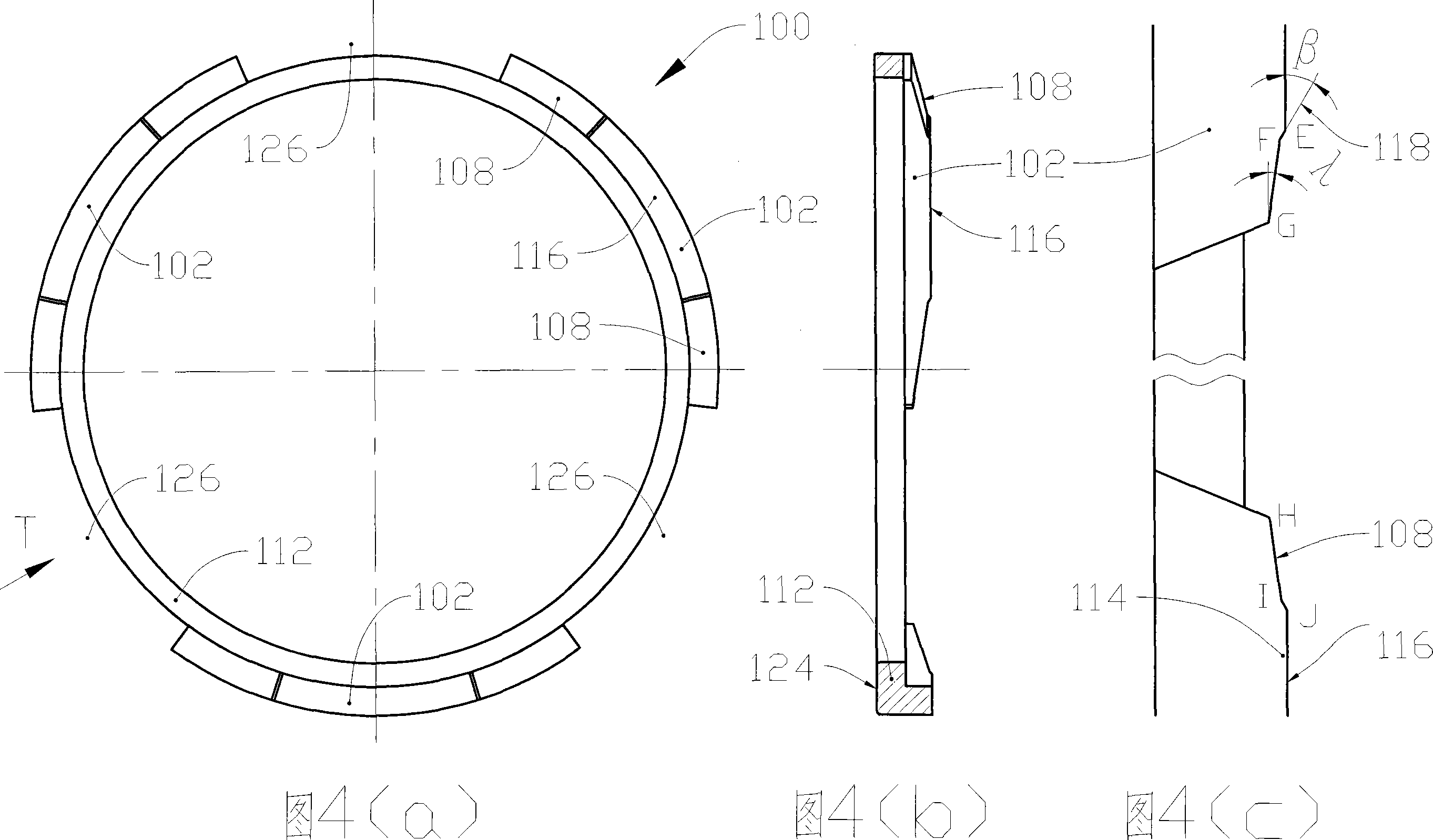

[0051] Figures 1 to 5 show the first embodiment of the present invention, which has the most typical structure of a spring steel ball safety clutch. As shown in FIG. 1, the fixed joint element 50 is sleeved on the outer cylindrical surface of the unthreaded end of the second sleeve 206 by one end of the steel ball hub 80, and is axially fixed by the snap ring 210. The second sleeve 206 and the steel ball hub 80 are made into a rigid body, as shown in FIG. 2. The blocking ring 100 is placed in the circular cavity of the fitting end of the fixing joint element 50. The restraining spring 120 is installed between the blocking ring 100 and the steel ball hub 80 to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com