Wind motor vane propeller-changing device

A wind turbine, blade pitch technology, applied in wind turbine, wind turbine control, engine and other directions, can solve the problems of meshing impact, vibration, affecting the life of gear pairs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

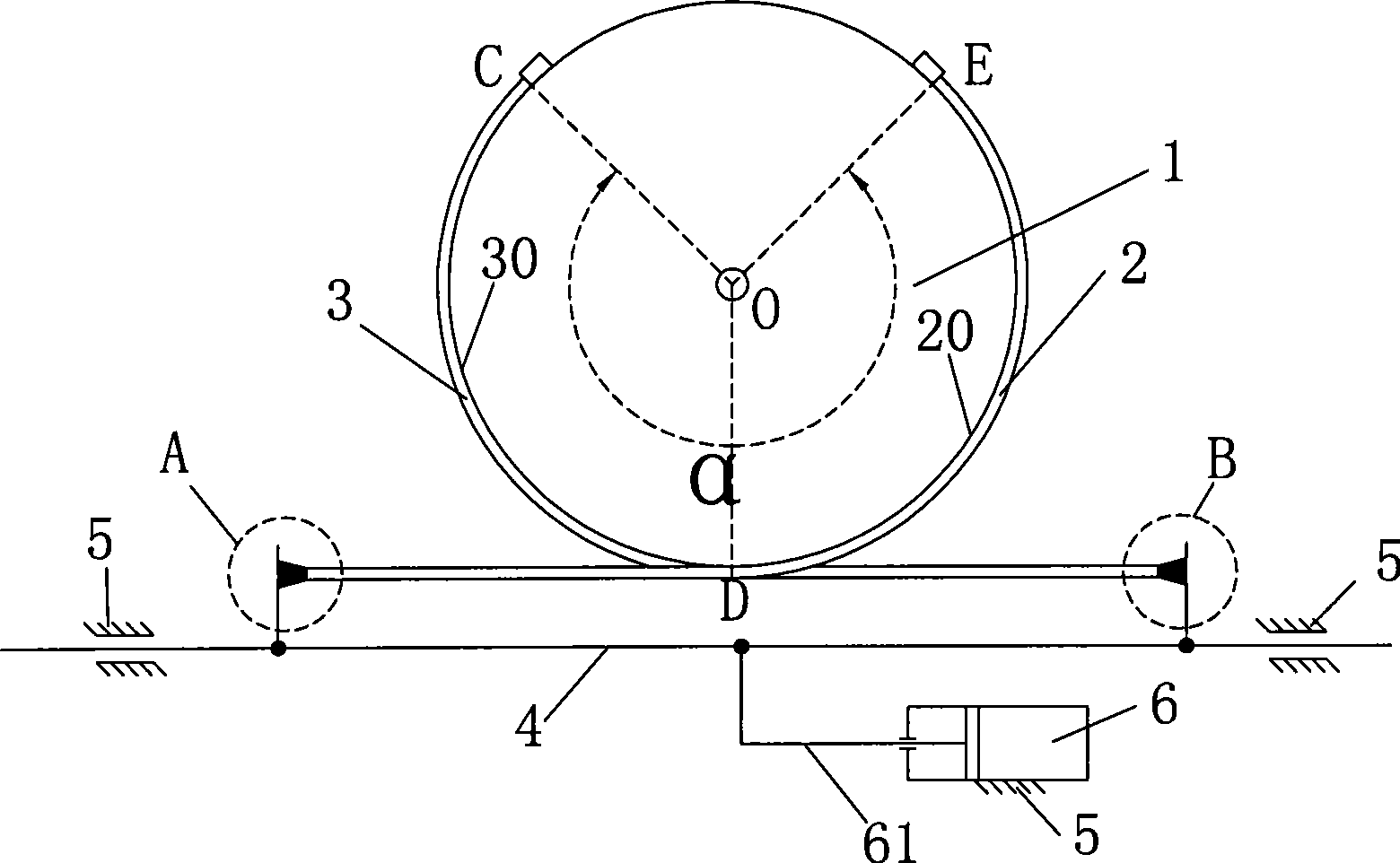

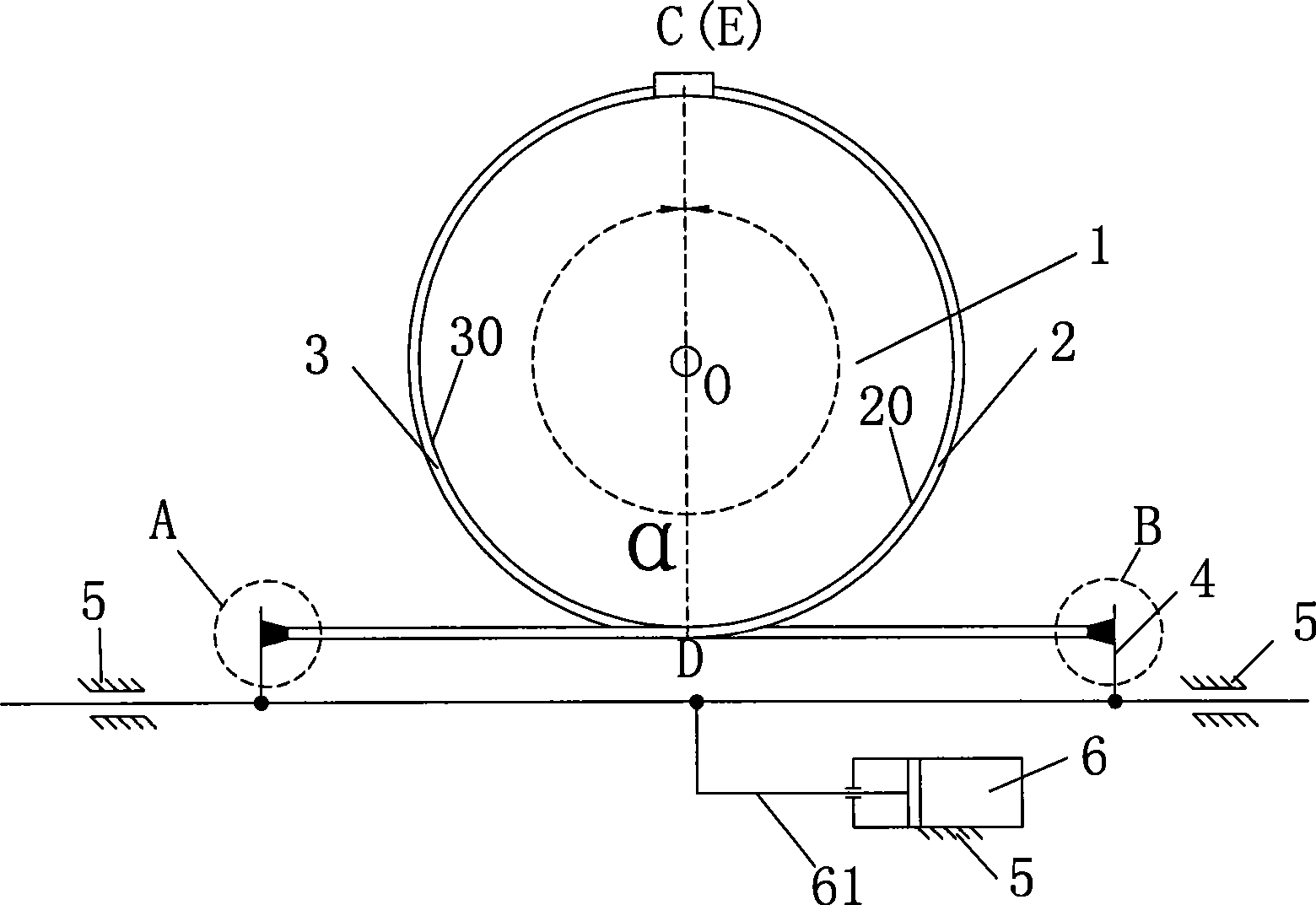

[0028] Such as figure 1 As shown, the pitch control device of this embodiment includes a linear drive device 6 and a transmission device. The blade root 1 is cylindrical and is rotatably arranged on the hub 5 through a pitch bearing (not shown in the figure). The linear drive device 6 The power output member 61 moves linearly. The transmission device includes a push-pull rod 4 having a first connection end A and a second connection end B. The transmission device also includes a first flexible member 2 and a second flexible member 3 . Wherein, one end of the first flexible member 2 is connected with the first connecting end A of the push-pull rod, and the other end is connected with the blade root 1 through the connector E, and a part of the first flexible member 2 is covered on the first connecting end A of the blade root 1. On one side 20, the first connecting end A of the push-pull rod 4 is driven by the first flexible member 2 to rotate forwardly to realize the pitch change...

no. 2 example

[0035] Such as figure 2 and 2 As shown in a, the pitch control device of this embodiment includes a linear drive device 62 and three transmission devices, a coupling frame 72 and a spring 97, each transmission device correspondingly drives a blade, and the blade is rotatably arranged through a pitch bearing 82 On the hub 52, the power output member 621 of the driving device 62 moves linearly. The transmission device of this embodiment is the same as the transmission device of the first embodiment and the connection method with the blade root 12 is also the same, but most basically, each The transmission device includes a linearly movable push-pull rod 42, a first flexible member 22 and a second flexible member 32; wherein, the linearly movable push-pull rod 42 has a first connection end A2 and a second connection end B2; the first One end of the flexible member 22 is connected to the first connection end A2 of the push-pull rod, and the other end is connected to the blade ro...

no. 3 example

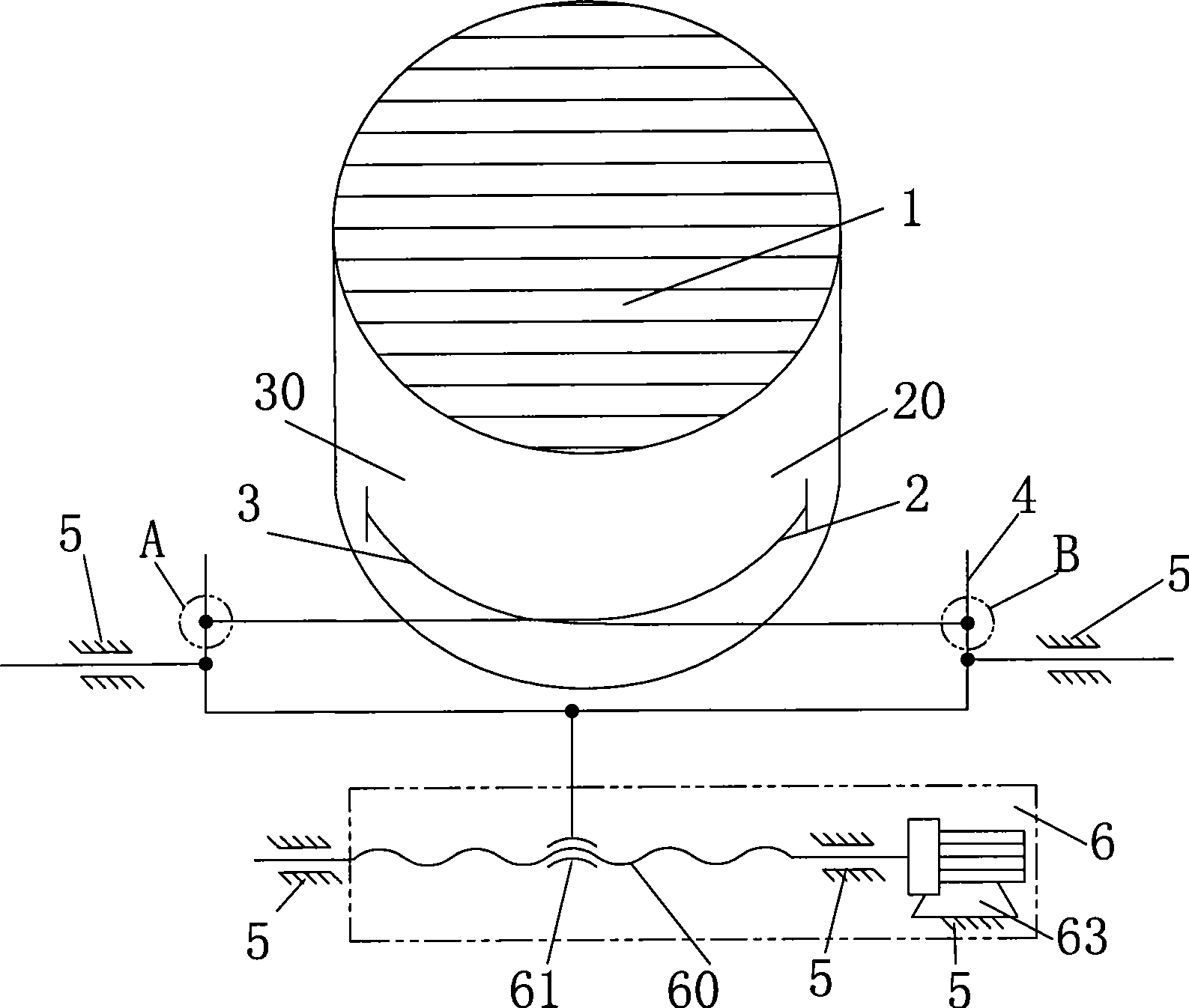

[0039] Also refer to image 3 , Figure 3a and figure 1 , the difference between this embodiment and the first embodiment is that the end of the flexible member is connected with a tension adjusting device, image 3 or Figure 3a The tension adjuster shown is available for figure 1 The first connecting end A and the second connecting end B of the middle push-pull rod 4 .

[0040] Wherein, numerals 23a and 23b indicate flexible parts, numeral 10a indicates screws, numerals 43a and 43b indicate baffles, numeral 91 indicates adjusting nuts, numeral 90 indicates lock nuts, numeral 92 indicates washers, and numeral 10b indicates connecting rods.

[0041] as attached image 3 As shown, the tension adjusting device of this embodiment includes a screw 10 a , an adjusting nut 91 , and a lock nut 90 . The flexible part 23a passes through the central hole of the screw 10a and is fixed at the end of the screw 10a. The baffle plate 43a connected with the push-pull rod has a hole and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com