Prepn of zeolite carried polymer metal cluster

A polymer and metal cluster technology, applied in the fields of chemistry and chemical industry, can solve the problems of narrow distribution range, uneven distribution of metal particles, small metal particles, etc., and achieves the effect of simple method, easy operation, and avoiding high temperature roasting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Example 1 Preparation of Pt (0.25mM)-PVP (1.25mM) / Beta (1g)

[0024] Weigh 1g of dried Beta molecular sieve, add 4×10 -3 mol / L of chloroplatinic acid hexahydrate (H 2 PtCl 6H 2 O) methanol / water (volume ratio is 1: 1) solution 64ml, and 2 * 10 -2 mol / L of polyvinylpyrrolidone (PVP) methanol / water (volume ratio is 1: 1) solution 63ml, at 10-20 ℃, stirred with a magnetic stirrer for 10 hours, then heated to 80 ℃, reflux, the color of the solution turns from yellow to black, continue to reflux for 3 hours, take it out, pour it into a rotary evaporator, heat it in a water bath to 40 ℃, and dry it in vacuum to obtain a gray-black powder of Beta molecular sieve loaded polymer platinum metal clusters.

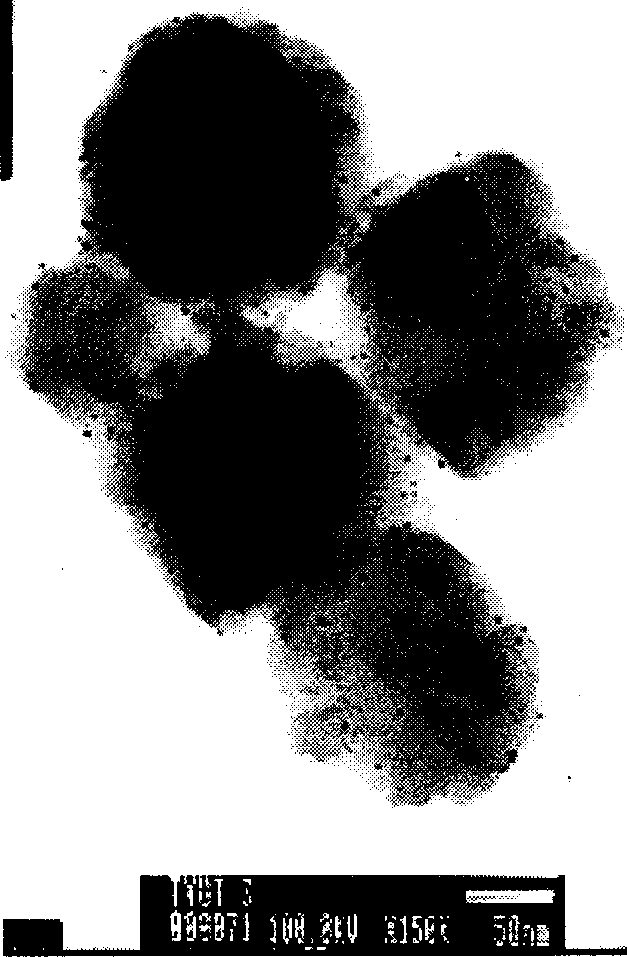

[0025] TEM observation result, surface average particle diameter 4.0nm (attachment figure 1 ). The results of methane conversion on the catalyst "Example 1" are shown in Table 1

[0026] Table 1 Quantity and distribution o...

Embodiment 3

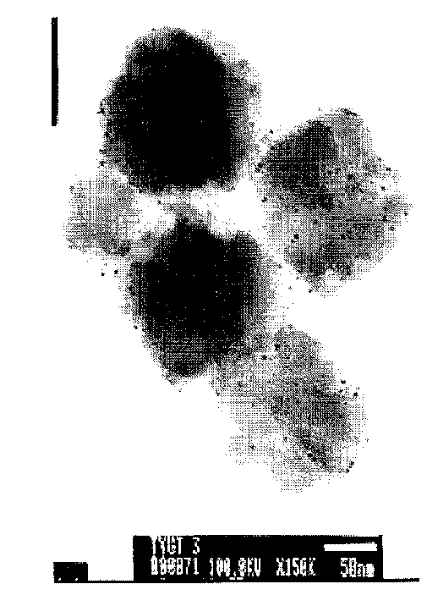

[0032] As a result of TEM observation, the surface average particle diameter is 3.3nm. Example 3 Preparation of Pd (0.25mM)-PVP (1.25mM) / Beta (1g)

[0033] Weigh 1g of dried Beta molecular sieve, add 4×10 -3 mol / L palladium chloride (PdCl 2 ) alcohol / water (1:1 by volume) solution 62.5ml, and 2×10 -2The methanol / water (volume ratio is 1: 1) solution 62.5ml of the polyvinylpyrrolidone (PVP) of mol / L, at 10-20 ℃, stirred with magnetic stirrer 8 hours, then, heated to Reflux at 80°C. After the color of the solution changes from yellow to brown, continue to reflux for 2 hours, take it out, pour it into a rotary evaporator, heat it in a water bath to 40°C, and dry it in vacuum to obtain a light brown powder of Beta molecular sieve-loaded polymer palladium metal clusters.

[0034] As a result of TEM observation, the surface average particle size is 3.0 nm.

Embodiment 4

[0035] The preparation of embodiment 4, Ru (0.3mM)-PVP (1.5mM) / Beta (1g)

[0036] Weigh 1g of dried Beta molecular sieve, add 5×10 -3 mol / L of ruthenium chloride trihydrate (RuCl 3 ·3H 2 O) ethanol / water (volume ratio is 1: 1) solution 60ml, and 1 * 10 -2 mol / L polyvinylpyrrolidone (PVP) ethanol / water (volume ratio is 1: 1) solution 150ml, at 10-20 ℃, stirred with a magnetic stirrer for 5 hours, then heated to 90 ℃, reflux, the color of the solution changes from orange yellow to black brown, continue to reflux for 3 hours, take it out, pour it into a rotary evaporator, heat it in a water bath to 50 ℃, and dry it in vacuum to obtain a brown powder of Beta molecular sieve loaded polymer ruthenium metal clusters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com