Supported tricobalt tetroxide catalyst and its preparation method and application

A tricobalt tetroxide catalyst, technology of tricobalt tetroxide, which is applied in combustion methods, incinerators, combustion types, etc., can solve the problems of reduced catalyst activity and low catalyst activity, and achieve the effects of reduced production, high reactivity, and avoiding high-temperature roasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

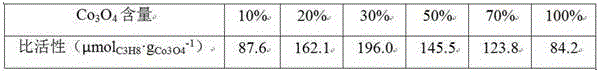

Embodiment 1

[0015] Weigh 0.55g of Co(NO 3 ) 2 ·6H 2 O was dissolved in 100 mL of deionized water; 1.5 g of γ-Al 2 O 3 Add to the above solution, stir evenly, dropwise add 1 mol / L sodium carbonate (Na 2 CO 3 ) solution to a pH of about 9, react at 50 °C for 1 h, wash with deionized water until neutral, dry at 60 °C, and calcinate at 300 °C for 3 h to obtain 10% Co 3 O 4 / γ-Al 2 O 3 .

Embodiment 2

[0017] Weigh 1.09g of Co(NO 3 ) 2 ·6H 2 O was dissolved in 100 mL of deionized water; 1.5 g of γ-Al 2 O 3 Add to the above solution, stir evenly, dropwise add 1 mol / L sodium carbonate (Na 2 CO 3 ) solution to a pH of about 9, react at 50 °C for 1 h, wash with deionized water until neutral, dry at 60 °C, and calcinate at 300 °C for 3 h to obtain 20% Co 3 O 4 / γ-Al 2 O 3 .

Embodiment 3

[0019] Weigh 1.64g of Co(NO 3 ) 2 ·6H 2 O was dissolved in 100 mL of deionized water; 1.5 g of γ-Al 2 O 3 Add to the above solution, stir evenly, dropwise add 1 mol / L sodium carbonate (Na 2 CO 3 ) solution to a pH of about 9, react at 50 °C for 1 h, wash with deionized water until neutral, dry at 60 °C, and calcinate at 300 °C for 3 h to obtain 30% Co 3 O 4 / γ-Al 2 O 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com