A kind of highly active hydrogenation refining catalyst and preparation method thereof

A hydrofining and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as metal loss, avoid high-temperature roasting, increase loading capacity and dispersion, and solve The effect of metal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

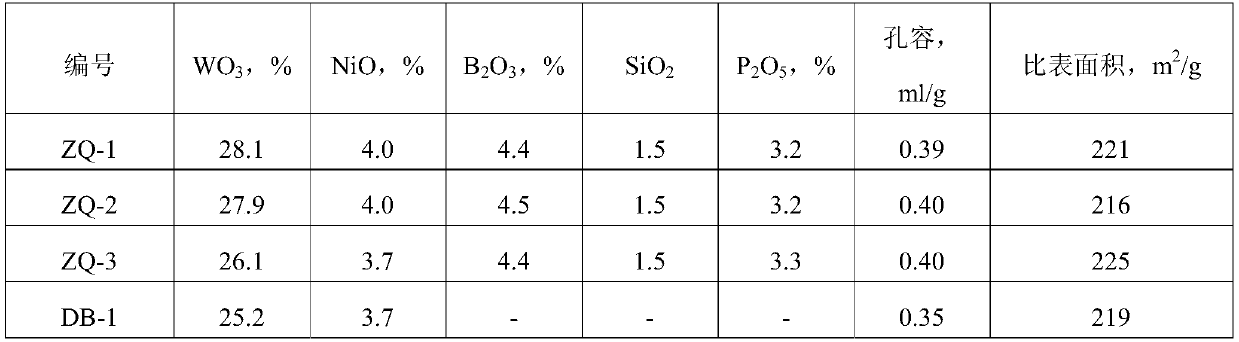

Embodiment 1

[0050] Put 100g of calcined silicon-containing, phosphorus-containing alumina powder (wherein, SiO 2 The mass fraction is 3.3%, P 2 o 5 The mass fraction is 7%, and the balance is Al 2 o 3 ) into 300ml water (the mass fraction of water in the gained slurry is 75%), after stirring for 5min, add 18.7g boric acid (in the form of B 2 o 3 On a mass basis, the addition of boric acid is 4.6% of the prepared hydrorefining catalyst quality), 73g ammonium metatungstate (in terms of WO 3 In terms of mass, the addition of ammonium metatungstate is 28.4% of the prepared hydrorefining catalyst quality) and 37g nickel nitrate (in terms of NiO, the add-on of nickel nitrate is 4.1% of the prepared hydrorefining catalyst quality ), continue to stir for 1h, filter after standing for 2h, and the filtrate is heated to 95m, with 55gSB powder (addition is 19% of the quality of the hydrorefining catalyst prepared) and 4ml concentrated nitric acid (for the quality of silicon-containing and phosph...

Embodiment 2

[0052]Put 100g of calcined silicon-containing, phosphorus-alumina powder (wherein, SiO 2 The mass fraction is 3.3%, P 2 o 5 The mass fraction is 7%, and the balance is Al 2 o 3 ) into 250ml water (the mass fraction of water in the gained slurry is 71%), after stirring for 5min, add 18.7g boric acid (in the form of B 2 o 3 On a mass basis, the addition of boric acid is 4.6% of the prepared hydrorefining catalyst quality), 73g ammonium metatungstate (in terms of WO 3 In terms of mass, the addition of ammonium metatungstate is 28.4% of the prepared hydrorefining catalyst quality) and 37g nickel nitrate (in terms of NiO, the add-on of nickel nitrate is 4.1% of the prepared hydrorefining catalyst quality ), continue to stir for 1h, filter after leaving standstill 2h, filtrate and 55gSB powder (add-on is 19% of the hydrorefining catalyst quality of preparation) and 4ml concentrated nitric acid (for silicon-containing, 3.6% of phosphorus-containing alumina powder quality) Made ...

Embodiment 3

[0054] Put 100g of calcined silicon-containing, phosphorus-alumina powder (wherein, SiO 2 The mass fraction is 3.3%, P 2 o 5 The mass fraction is 7%, and the balance is Al 2 o 3 ) into 255ml water (the mass fraction of water in the gained slurry is 75%), after stirring for 5min, add 18g boric acid (in the form of B 2 o 3 On a mass basis, the addition of boric acid is 4.6% of the prepared hydrorefining catalyst quality), 64g ammonium metatungstate (in terms of WO 3 In terms of mass, the addition of ammonium metatungstate is 26.4% of the prepared hydrorefining catalyst quality) and 32g nickel nitrate (in terms of NiO, the add-on of nickel nitrate is 3.8% of the prepared hydrorefining catalyst quality ), continue to stir for 1h, filter after leaving standstill 2h, filtrate and 55gSB (add-on is 19% of the hydrorefining catalyst quality of preparation) and 3.8ml concentrated nitric acid (for silicon-containing, 3.5% of phosphorus-containing alumina powder quality) Made into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com