High-voltage electrolyte for lithium ion battery

A lithium-ion battery, high-voltage technology, applied in the field of lithium-ion batteries, can solve the problems of flatulence, affecting the battery rate performance of the separator wettability, high viscosity, etc., and achieve the effect of improving the rate performance, improving the poor stability of the high-temperature cycle, and improving the wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

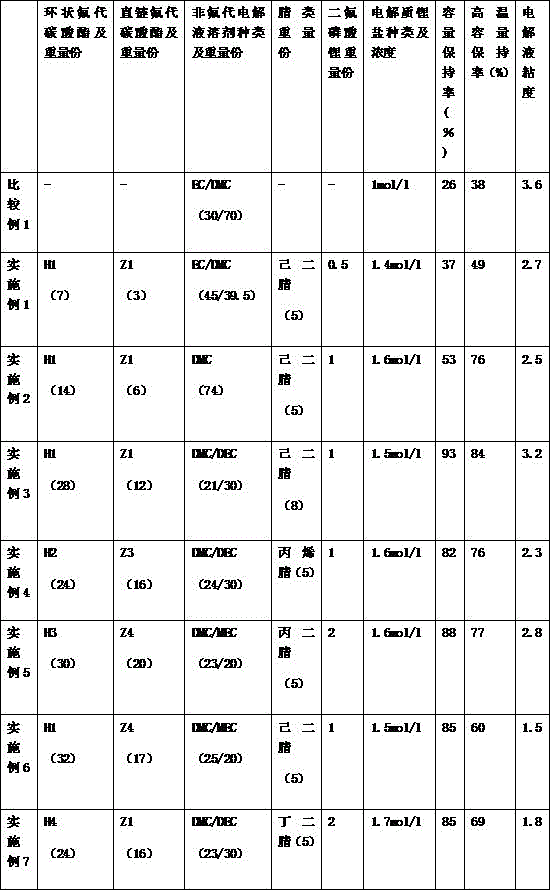

Examples

Embodiment

[0041] Preparation of the battery: The test battery was assembled according to the conventional battery preparation method, with modified lithium cobaltate as the positive electrode, graphite as the negative electrode, and the current collectors of the positive and negative electrodes were aluminum foil and copper foil, respectively. The production method of the modified lithium cobaltate is as follows: polyvinylidene fluoride with a mass percentage of 3% is dissolved in 1-methyl-2-pyrrolidone solution, and LiCoO with a mass percentage of 94% 2 Add 3% conductive agent carbon black to the above solution and mix well.

[0042] Electrolyte preparation: in a glove box with an argon atmosphere (H 2 O6 Mix in certain proportions. The above-mentioned raw materials are added in sequence, fully stirred evenly, and the lithium-ion battery electrolyte (free acid<15 ppm, moisture<10 ppm) of the present invention is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com