Preparation and use process for electroslag remelting slag

A technology of electroslag remelting and process, applied in the field of electroslag metallurgy, can solve the problems of oxygen increase, high production cost, hydrogenation of steel ingots, etc., achieve the effect of reducing foaming of slag liquid, reducing production cost, and meeting technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

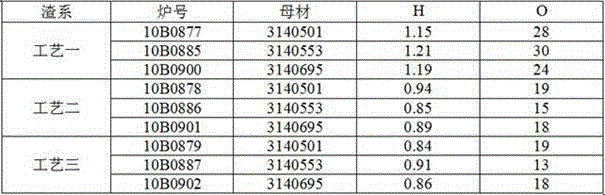

Examples

Embodiment Construction

[0017] A process for the preparation and use of slag for electroslag remelting, pre-melting 1000kg of slag material, the slag material is composed of 200kg of fluorite powder, 400kg of alumina powder and 400kg of lime block, the slag material is baked and dried before slag melting, of which the slag material is After baked at not less than 600°C for 4 hours, keep warm at not less than 200°C and take it out as needed; after baking alumina and lime at not less than 680°C for 4 hours, keep warm at not less than 200°C and take it out immediately after use. Pick up. Place the conductive slag in the center of the spindle guard, and surround it with appropriate amount of fluorite powder to prevent the bottom copper plate from being damaged after the conductive slag is melted. Graphite electrodes are used to start the arc coldly. When adding slag material, add fluorite powder first, and then add some alumina powder (the amount added is about one-third of the total weight of 400kg) aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com