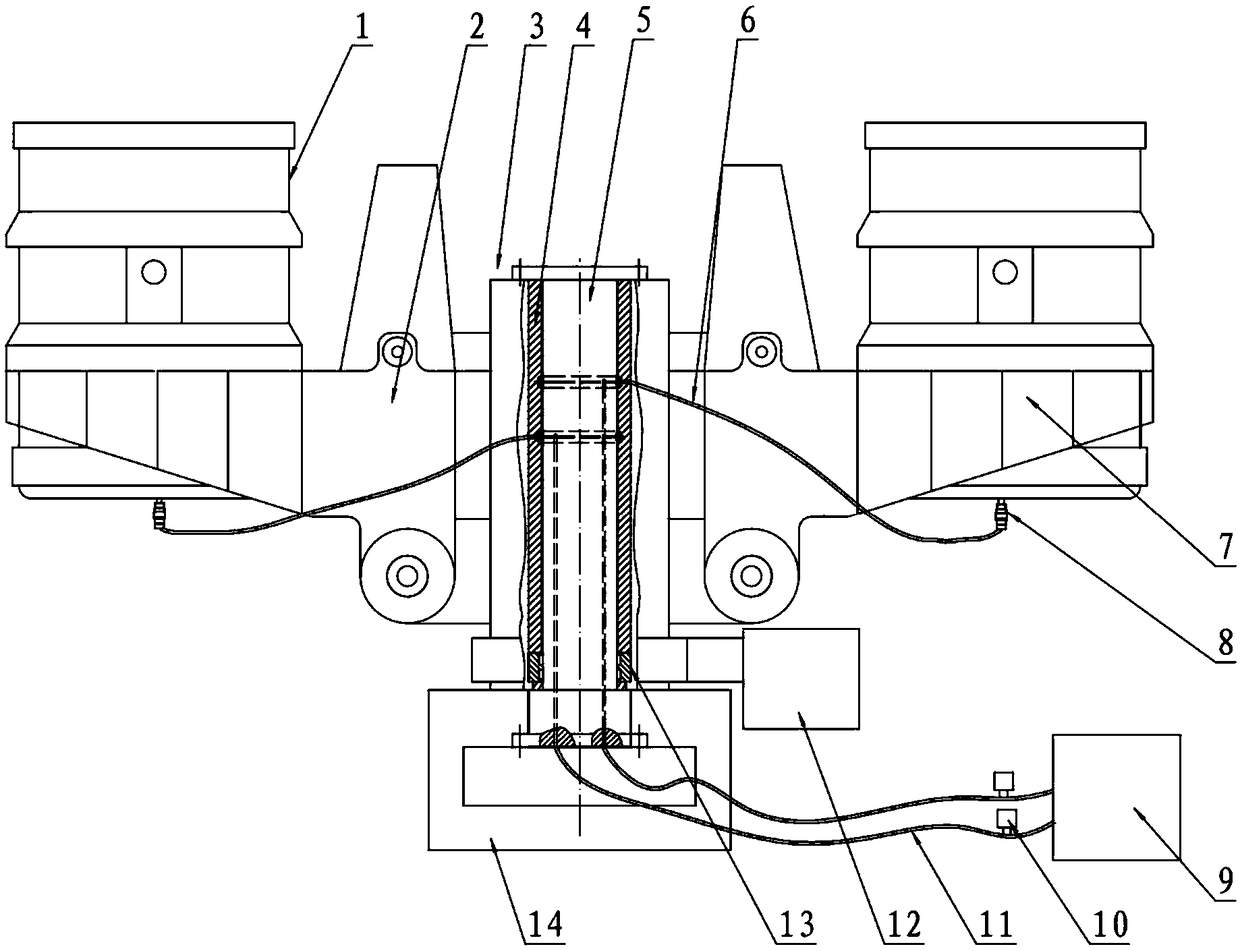

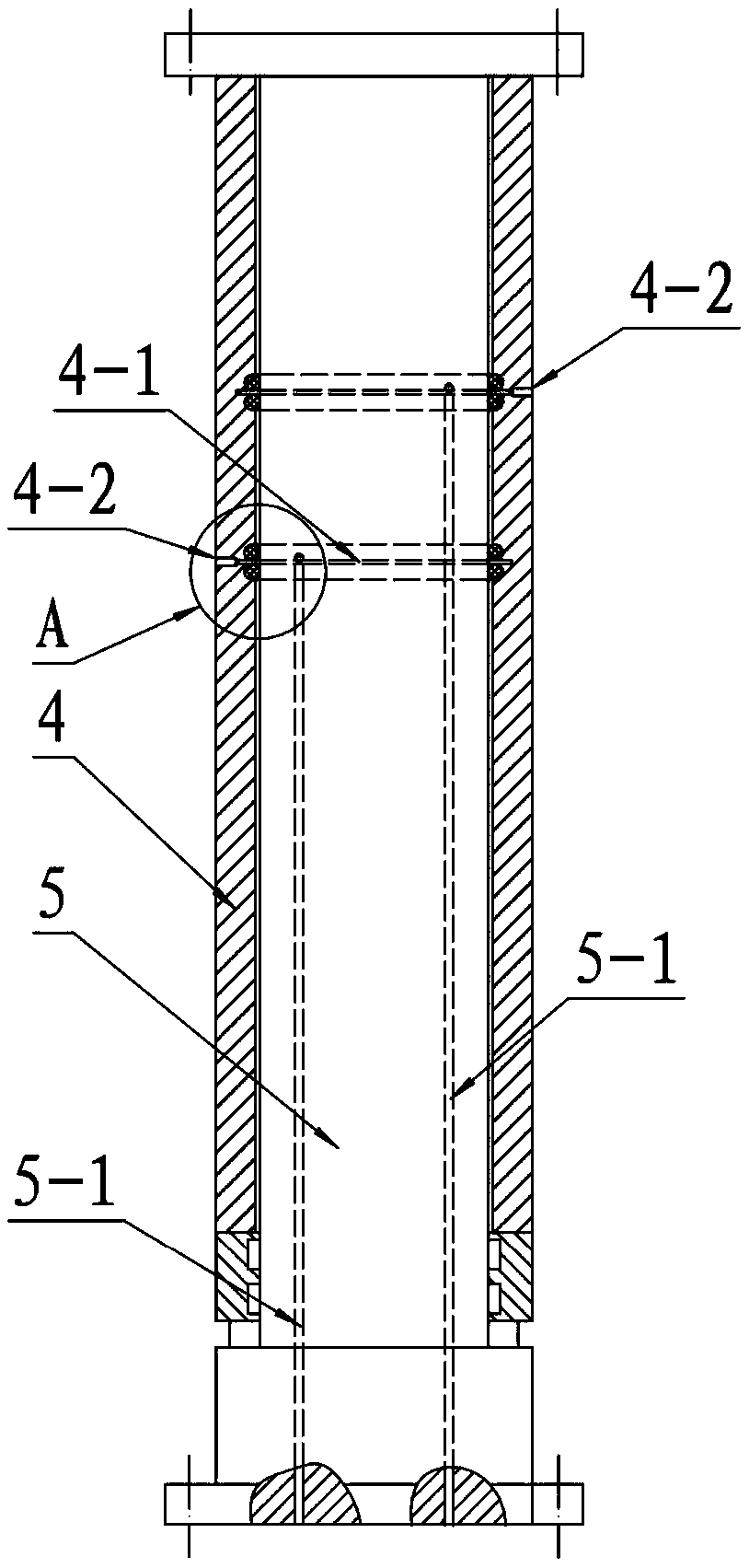

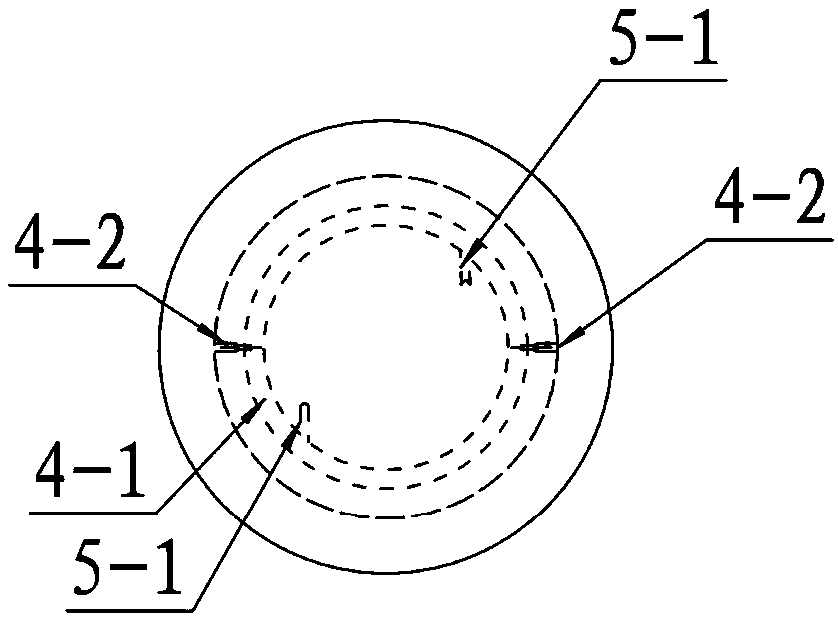

Argon blowing method of ladle turret and steel ladle argon blowing turret in continuous casting mode

A technology of turret table and ladle, which is applied in casting equipment, casting melt containers, manufacturing tools, etc., can solve the problems of maintaining the continuity of steelmaking production, improving the oxidation of molten steel, and high consumption of metal materials, so as to ensure the continuity of production, Effects of cost reduction and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]The target steel grade is cold-rolled base material Q195, furnace number: 81-03033, molten iron temperature 1366°C, molten iron composition: C: 4.59%, Si: 0.36%; Mn: 0.33%; S: 0.023%; P: 0.102%, the oxygen supply time is 13 minutes and 32 seconds. Steel core aluminum and silicon-manganese alloy are used for tapping and alloying (the Al purity in the steel core aluminum is >99%, and the Al content is 70%; the Mn content of the silicon-manganese alloy is 66%).

[0032] The temperature measurement at the end point of the converter molten steel is 1629°C, and the sampling composition at the end point is: C: 0.042%, Mn: 0.10%, S: 0.016%, P: 0.015%. The end point composition and temperature are suitable. Once the steel is poured out, 350Kg of steel core aluminum and 230Kg of silicon-manganese alloy are added through the high-level feed bin when the steel is tapped for 1 / 2. When the steel is tapped, the ladle is turned on with argon gas throughout the process, and the atmosphe...

Embodiment 2

[0036] The target steel type is cold rolling base material Q195L, furnace number: 82-03093, molten iron temperature 1385°C, molten iron composition: C: 4.55%, Si: 0.34%; Mn: 0.32%; S: 0.020%; P: 0.115%, the oxygen supply time is 13 minutes and 16 seconds. Steel core aluminum and silicon-manganese alloy are used for tapping and alloying (the Al purity in the steel core aluminum is >99%, and the Al content is 70%; the Mn content of the silicon-manganese alloy is 66%).

[0037] The temperature measurement at the end point of the converter molten steel is 1628°C, and the sampling composition at the end point: C: 0.041%, Mn: 0.09%, S: 0.015%, P: 0.017%. The end point composition and temperature are suitable. Once the steel is poured out, 1 / 2 of the steel is tapped, and 365Kg of steel core aluminum and 240Kg of silicon-manganese alloy are added through the high-level feed bin. When the steel is tapped, the ladle is turned on with argon gas throughout the process, and the atmosphere...

Embodiment 3

[0042] Taking cold-rolled base material SPHC as the target steel type, furnace number: 81-03196, molten iron temperature 1380°C, molten iron composition: C: 4.57%, Si: 0.36%; Mn: 0.30%; S: 0.021%; P: 0.105%, the oxygen supply time is 12 minutes and 57 seconds. Steel core aluminum and medium carbon ferromanganese alloy are used for tapping and alloying (the Al purity in the steel core aluminum is >99%, and the Al content is 70%; the medium carbon ferromanganese Mn content is 74%).

[0043] The temperature measurement at the end point of the converter molten steel is 1625°C, and the sampling composition at the end point is: C: 0.038%, Mn: 0.08%, S: 0.017%, P: 0.015%. The end point composition and temperature are suitable. Once the steel is poured out, 386Kg of steel core aluminum and 270Kg of medium carbon ferromanganese are added through the high-level feed bin when the steel is tapped for 1 / 2. When the steel is tapped, the ladle is turned on with argon gas throughout the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com