Method for clamping porous parts by applying general vacuum platform

A vacuum platform and parts technology, applied in the direction of metal processing machinery parts, clamping, positioning devices, etc., can solve the problems of unstable processing and easy air leakage, and achieve the effects of increased vacuum adsorption strength, enhanced manufacturability, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiment.

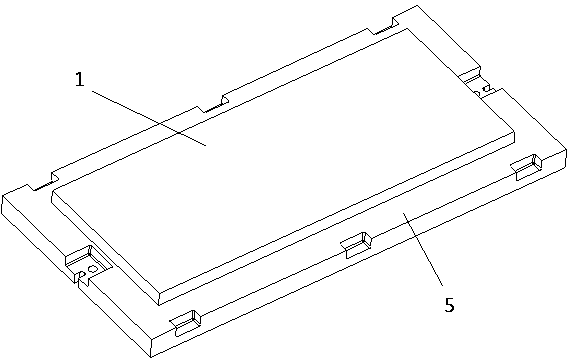

[0024] See Figure 1 to Figure 6 , the steps of a method for clamping porous parts using a general-purpose vacuum platform in the present invention are as follows:

[0025] Hole 2 is made on the positioning surface of part 1, that is, the vacuum adsorption surface is opened, and the depth of hole 2 is: web thickness + milling cutter bottom tooth R + 1mm;

[0026] Use plaster 3 to fill the opening of part 1;

[0027] After the gypsum 3 is solidified, scrape off the position above the positioning to ensure that it is flush with the positioning surface;

[0028] Use tape 4 to seal the hole, the diameter of the hole should be less than 50mm; the bonding width between tape 4 and the periphery of the hole is greater than 10mm, and the bonding length in the direction of the tape length is greater than 30mm;

[0029] Clamp the part 1 to the general vacuum platform 5 for vacuum adsorption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com