Spherical filter material and preparation method thereof

A kind of filter material and spherical technology, applied in the field of air purification, can solve the problems of scattered ability to deal with peculiar smell, irregular shape, low efficiency, etc., and achieve the effect of efficient removal of peculiar smell, regular shape and convenient filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

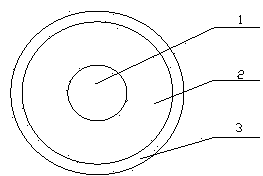

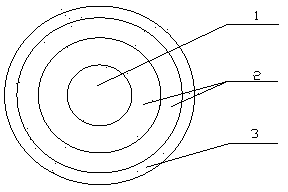

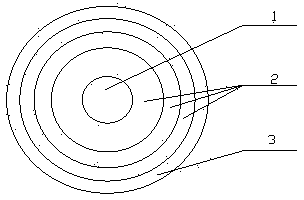

Image

Examples

Embodiment 1

[0032] The spherical filter material prepared in this example is 60 parts of kaolin powder with a particle size of 0.1 μm, 15 parts of persimmon tannin powder with a particle size of 10 μm, 10 parts of sepiolite powder with a particle size of 10 μm, and 5 parts of hydroxyl It is prepared from ethyl cellulose, 5 parts of guar gum, 2 parts of urea and 3 parts of polyvinylpyrrolidone. Concrete preparation process is as follows:

[0033] (1) Mix 5 parts of hydroxyethylcellulose, 2 parts of urea and 3 parts of polyvinylpyrrolidone with 60 parts of kaolin powder, roll continuously in a rolling ball coating pan, and apply evenly through an automatic sprayer Moisture makes the powder molding to form a cue ball, and the amount of water sprayed accounts for 50% by weight of the mixture;

[0034] (2) Mix 3 parts of guar gum with 15 parts of persimmon tannin powder, then roll the powder and cue balls in a rolling ball coating pan, apply water evenly through an automatic sprayer, and the ...

Embodiment 2

[0039] The spherical filter material prepared in this example is 35 parts of kaolin with a particle size of 100 μm, 20 parts of iron-manganese composite oxide with a particle size of 0.1 μm, 30 parts of modified activated carbon powder with a particle size of 45 μm, 10 parts of granular Bentonite with a diameter of 20 μm, 4.5 parts of hydroxypropyl methylcellulose and 0.5 part of urea are used as raw materials. Concrete preparation process is as follows:

[0040] (1) Mix 1.5 parts of hydroxypropyl methylcellulose, 0.5 parts of urea and 35 parts of kaolin, roll continuously in a rolling ball coating pan, apply water evenly through an automatic sprayer, and shape the powder to form a matrix Ball, the amount of water spray accounts for 60% by weight of the mixture;

[0041] (2) Mix 1 part of hydroxypropyl methylcellulose with 20 parts of iron-manganese composite oxide, then roll the powder and cue balls in a rolling ball coating pan, and use a coating with 30% water spray proce...

Embodiment 3

[0046]The spherical filter material prepared in this example is 32 parts of sepiolite powder with a particle size of 100 μm, 24 parts of iron-manganese composite oxide with a particle size of 0.5 μm, 10 parts of copper-manganese composite oxide with a particle size of 2 μm, 10 parts of Ginkgo biloba powder and tea polyphenol powder mixture with a particle size of 100 μm (mixing ratio is 1:1), 8 parts of diatomaceous earth powder with a particle size of 5 μm, 8 parts of carboxymethyl cellulose, and 7 parts of asparagus Glue, 0.5 parts of polyvinyl alcohol and 0.5 parts of ethanol are prepared as raw materials. Concrete preparation process is as follows:

[0047] (1) Mix 4 parts of squash gum, 0.5 parts of polyvinyl alcohol and 0.5 parts of ethanol with 32 parts of sepiolite powder, roll continuously in a rolling ball coating pan, and apply water evenly through an automatic sprayer to shape the powder , forming a cue ball, the amount of water sprayed accounts for 48% by weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com