Silicon wafer vacuum adsorption manipulator

A vacuum adsorption, manipulator technology, applied in conveyor objects, sustainable manufacturing/processing, electrical components, etc., can solve the problems of high breakage rate, long loading time, high production cost, avoid collision damage and improve production efficiency , the effect of reducing rigid impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present invention provides a silicon chip vacuum adsorption manipulator, comprising: a rotating power device 1, a mounting bracket 2, a detection device 6, a vacuum chamber 7 with a vacuum pipeline inside, and a comb-shaped vacuum adsorption finger 8;

[0042] The rotating power device 1 and the detection device 6 are fastened on the mounting bracket 2 by a fastening device;

[0043] The output shaft of the rotating power device 1 is firmly connected with the upper end surface of the vacuum chamber 7;

[0044] The detection device 6 includes several position sensors 12 that feed back position information for precisely positioning the rotational movement of the floating support 4;

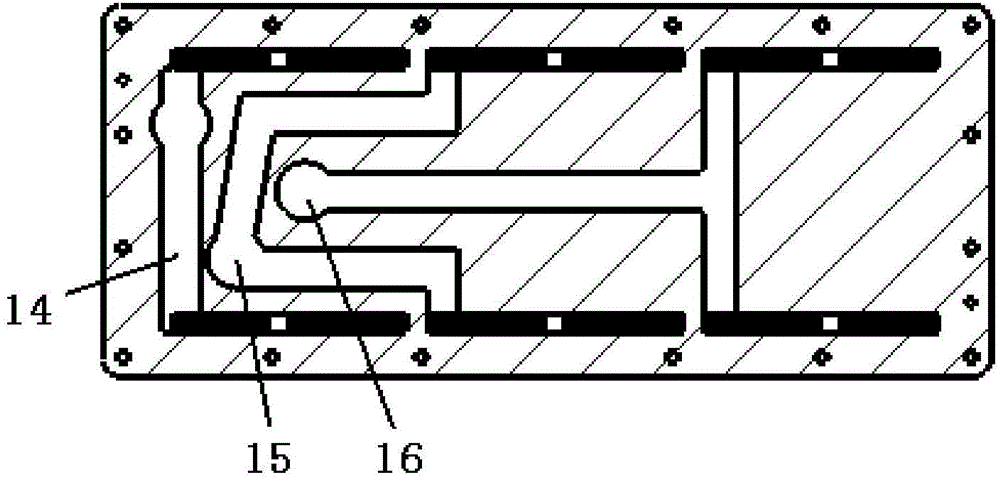

[0045] The vacuum chamber 7 is provided with a pipe joint 17 communicating with the vacuum pipeline;

[0046] The comb-tooth-shaped vacuum suction finger 8 is internally provided with independent vacuum pumping pipelines that are consistent with the number of comb-tooth gaps; The upper ...

Embodiment 2

[0052] The present invention provides a vacuum adsorption manipulator for silicon wafers, comprising: a rotating power device 1, a mounting bracket 2, a rotating mechanism 3, a detection device 6, a vacuum chamber 7 with a vacuum pipeline inside, and a comb-shaped vacuum adsorption finger 8;

[0053] The rotating power device 1, the rotating mechanism 3 and the detection device 6 are fastened on the mounting bracket 2 by a fastening device;

[0054] A speed reducer 9 is fastened inside the rotating mechanism 3; the output shaft of the rotating power unit 1 realizes transmission connection with the input shaft of the speed reducer 9 through a transmission device;

[0055] The output shaft of the reducer 9 is fastened to the upper end surface of the vacuum chamber 7 through a connecting piece;

[0056] The detection device 6 includes several position sensors 12 that feed back position information for precisely positioning the rotational movement of the floating support 4;

[00...

Embodiment 3

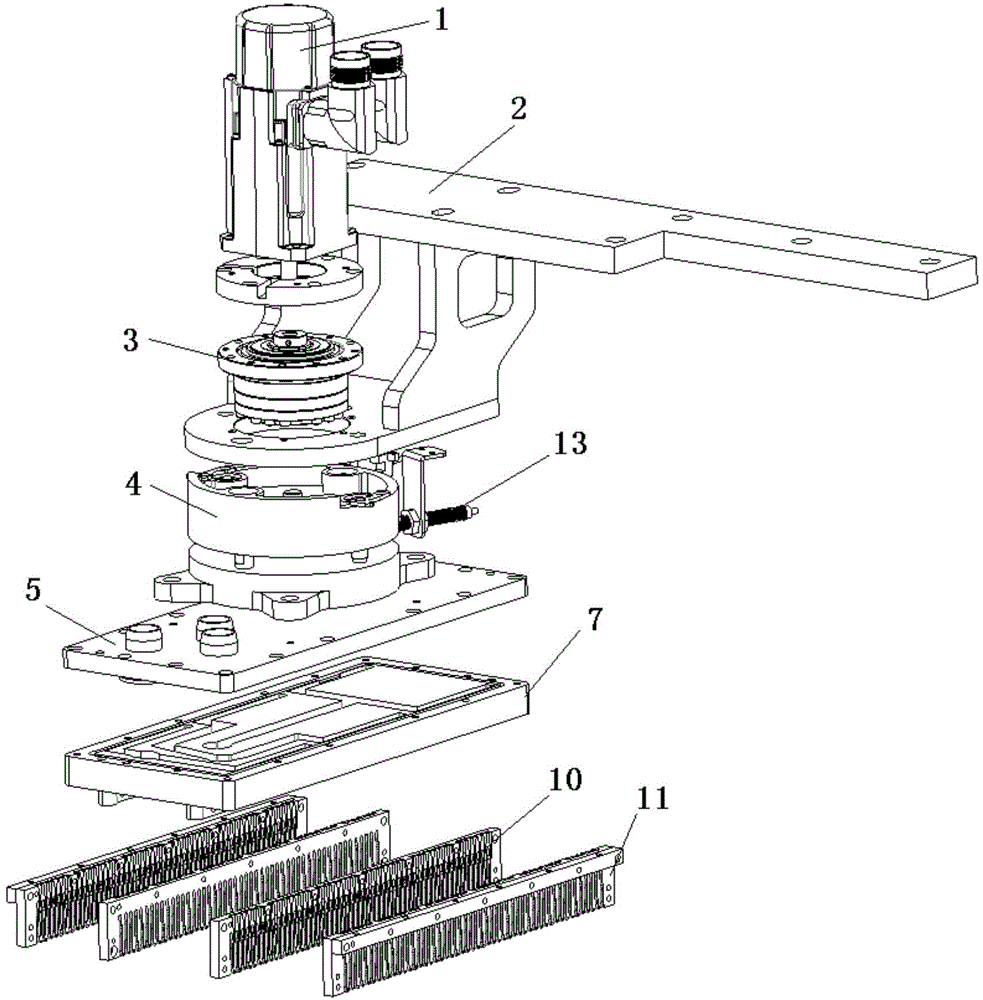

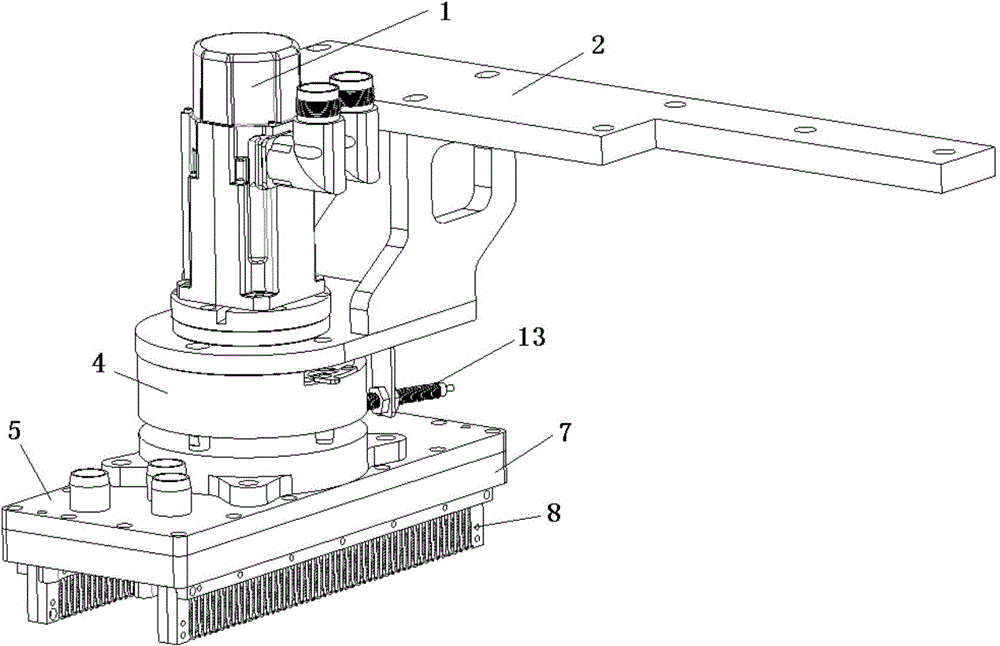

[0062] Figure 1~4 As shown, the present invention provides a vacuum adsorption manipulator for silicon wafers comprising: a precision rotating power device 1, a mounting bracket 2, a rotating mechanism 3, a sealing cover 5, a detection device 6, a vacuum chamber 7 and a comb-shaped vacuum adsorption finger 8 ;

[0063] The precision rotating power device 1, the rotating mechanism 3 and the detection device 6 are fastened on the mounting bracket 2 by a fastening device;

[0064] A precision reducer 9 is fastened inside the rotating mechanism 3; the output shaft of the precision rotating power device 1 is connected to the input shaft of the precision reducer 9 through a transmission device;

[0065] The output shaft of the precision reducer 9 is tightly connected to the upper end surface of the sealing cover plate 5 through a connecting piece;

[0066] The detection device 6 includes several position sensors 12 that feed back position information for precisely positioning the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com