Patents

Literature

62results about How to "Realize automatic dumping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

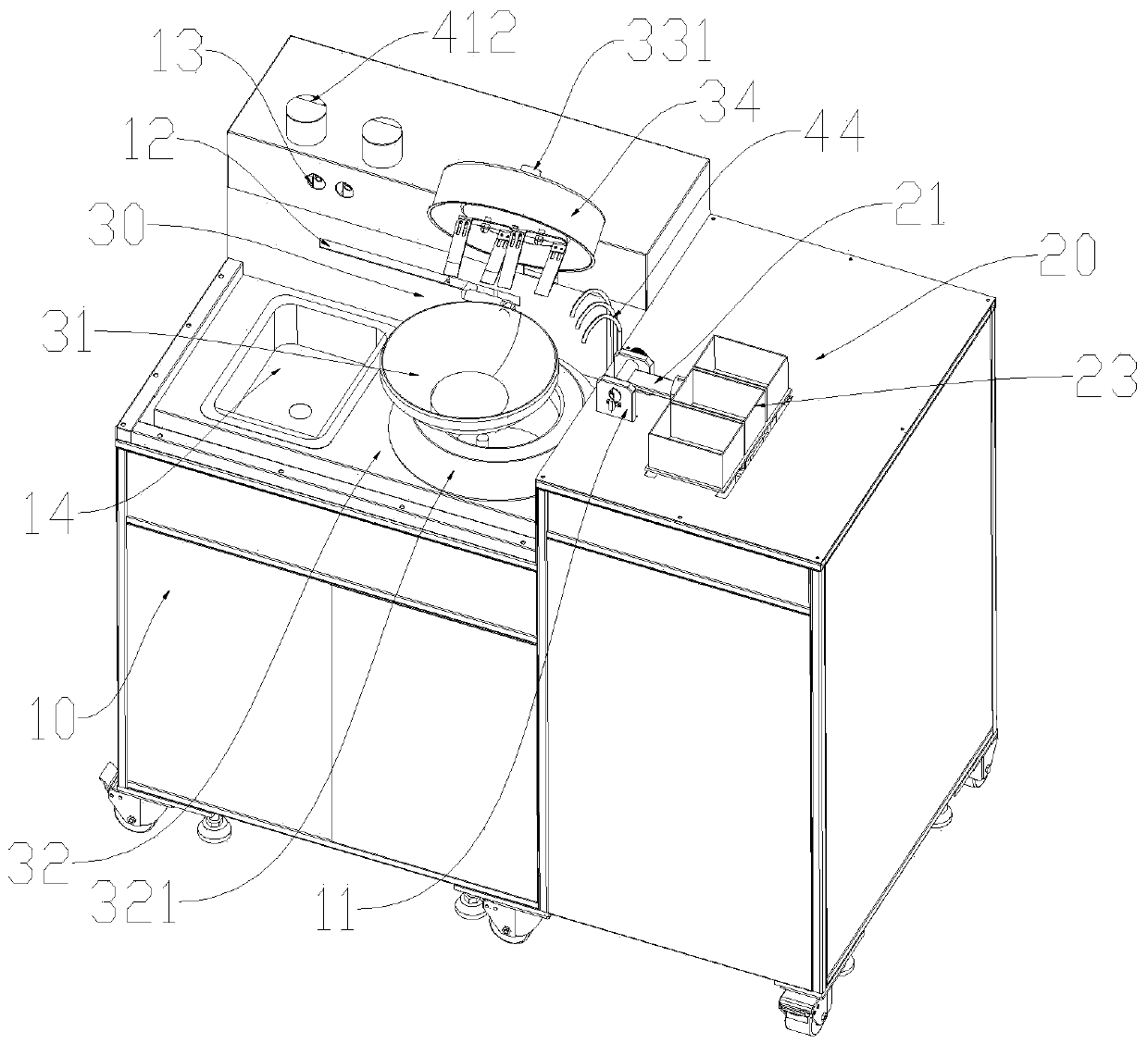

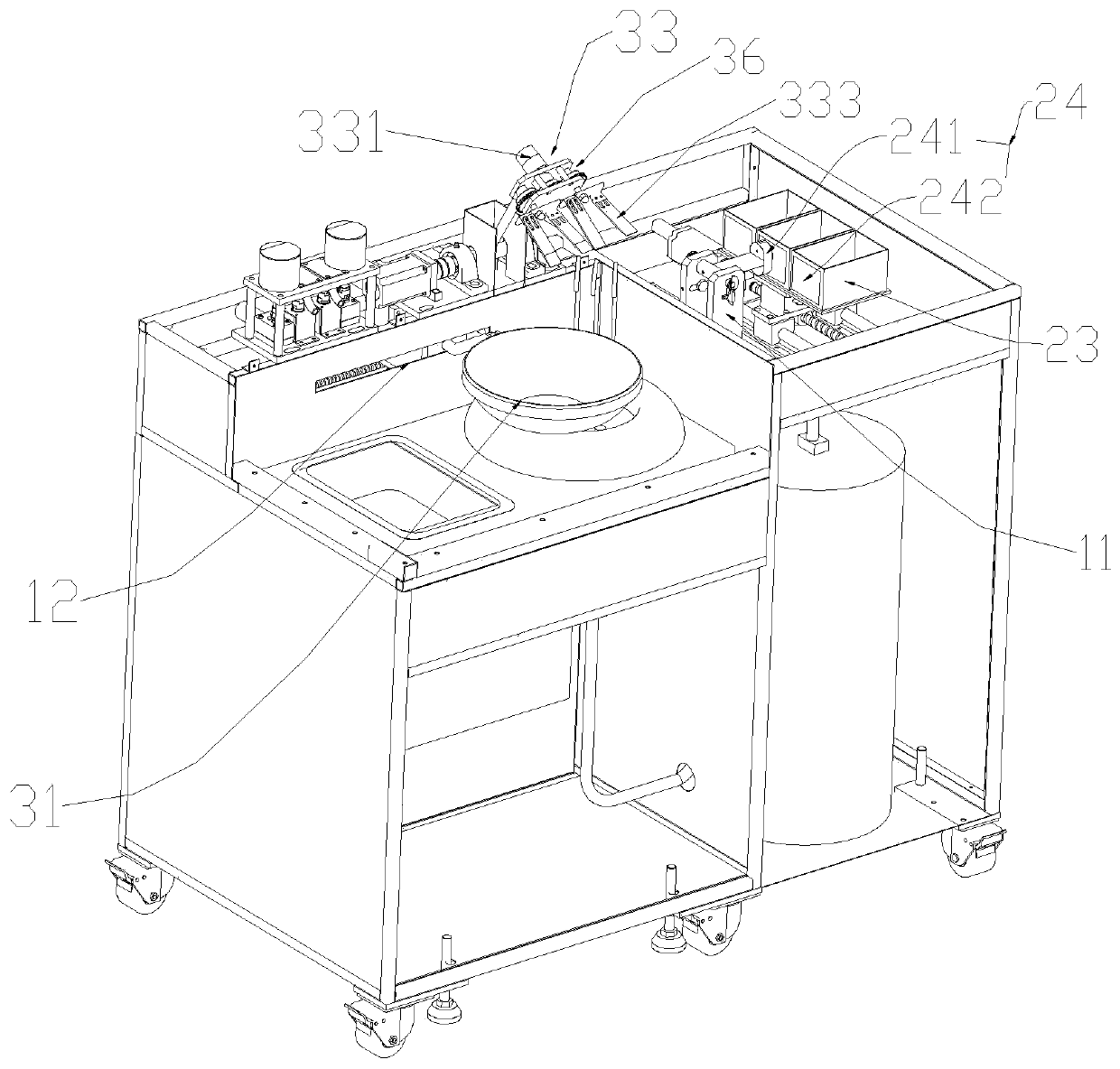

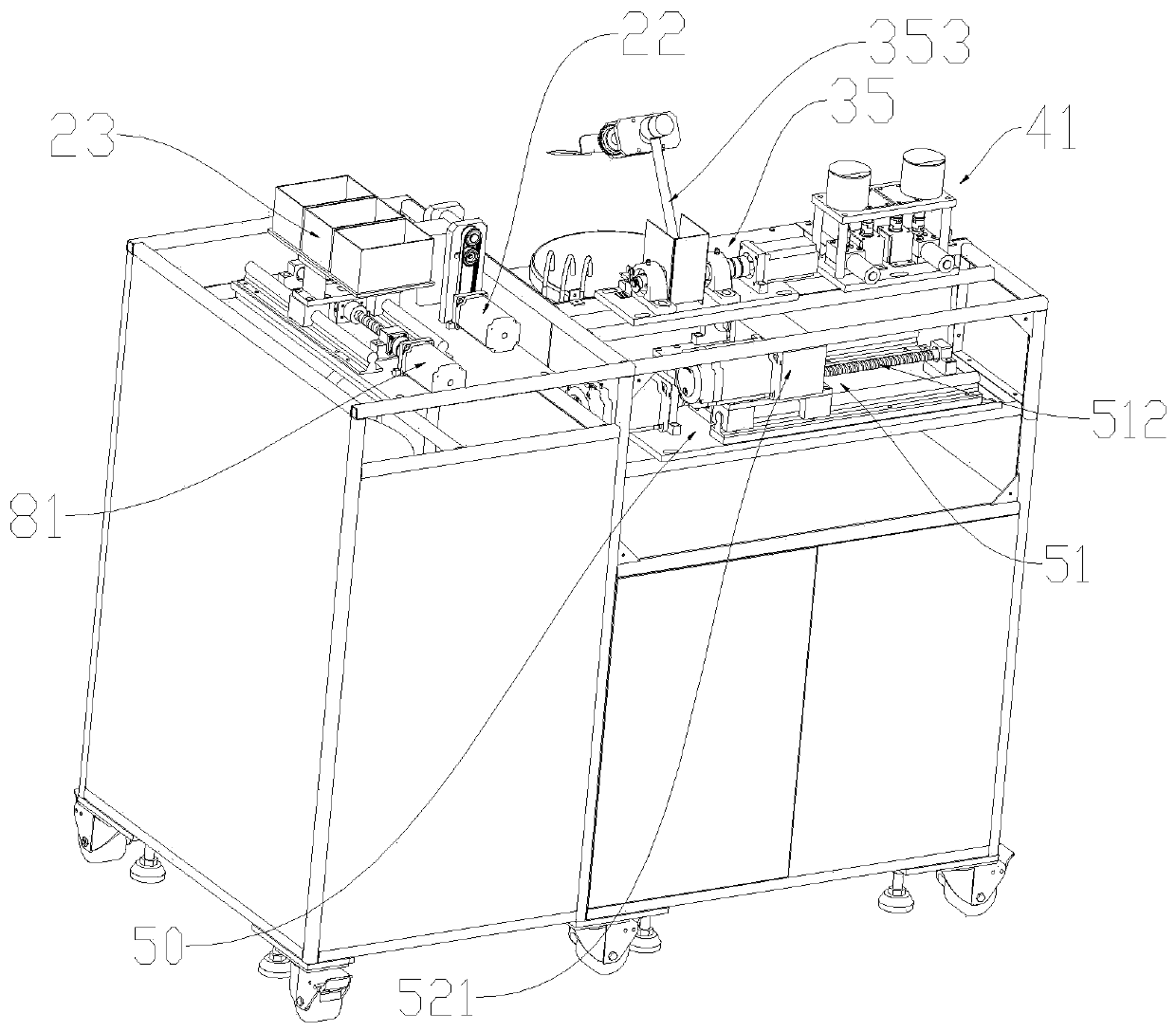

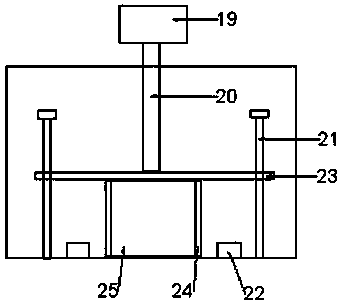

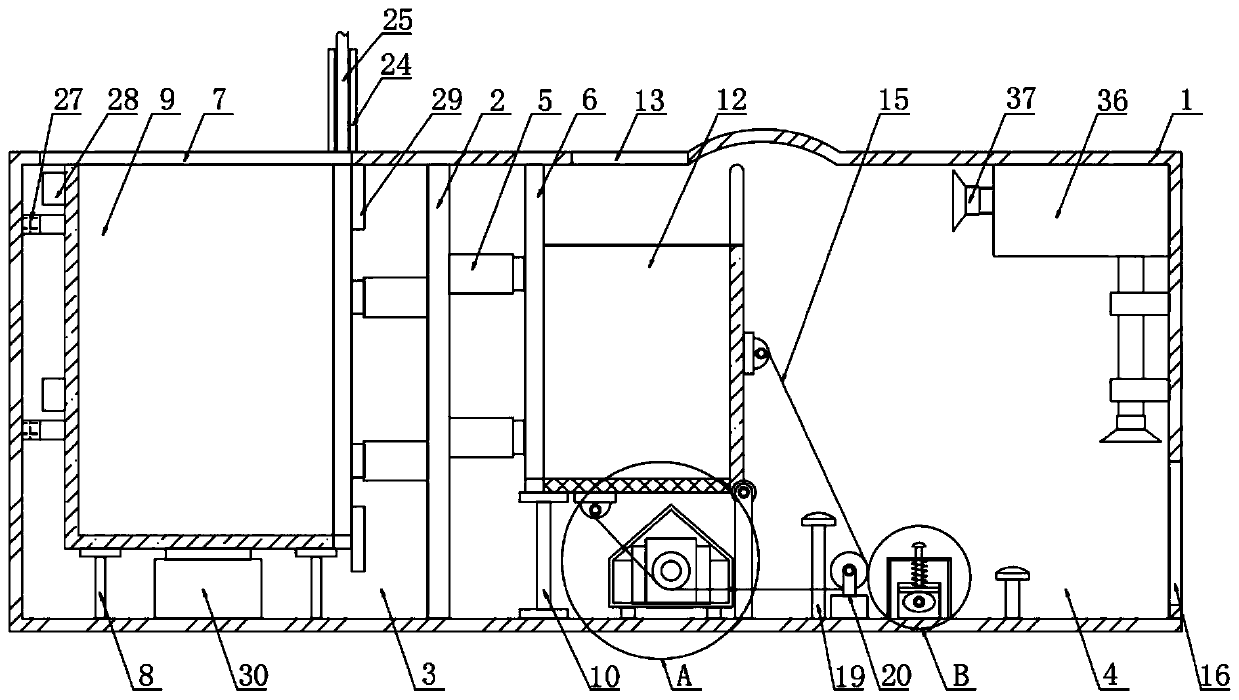

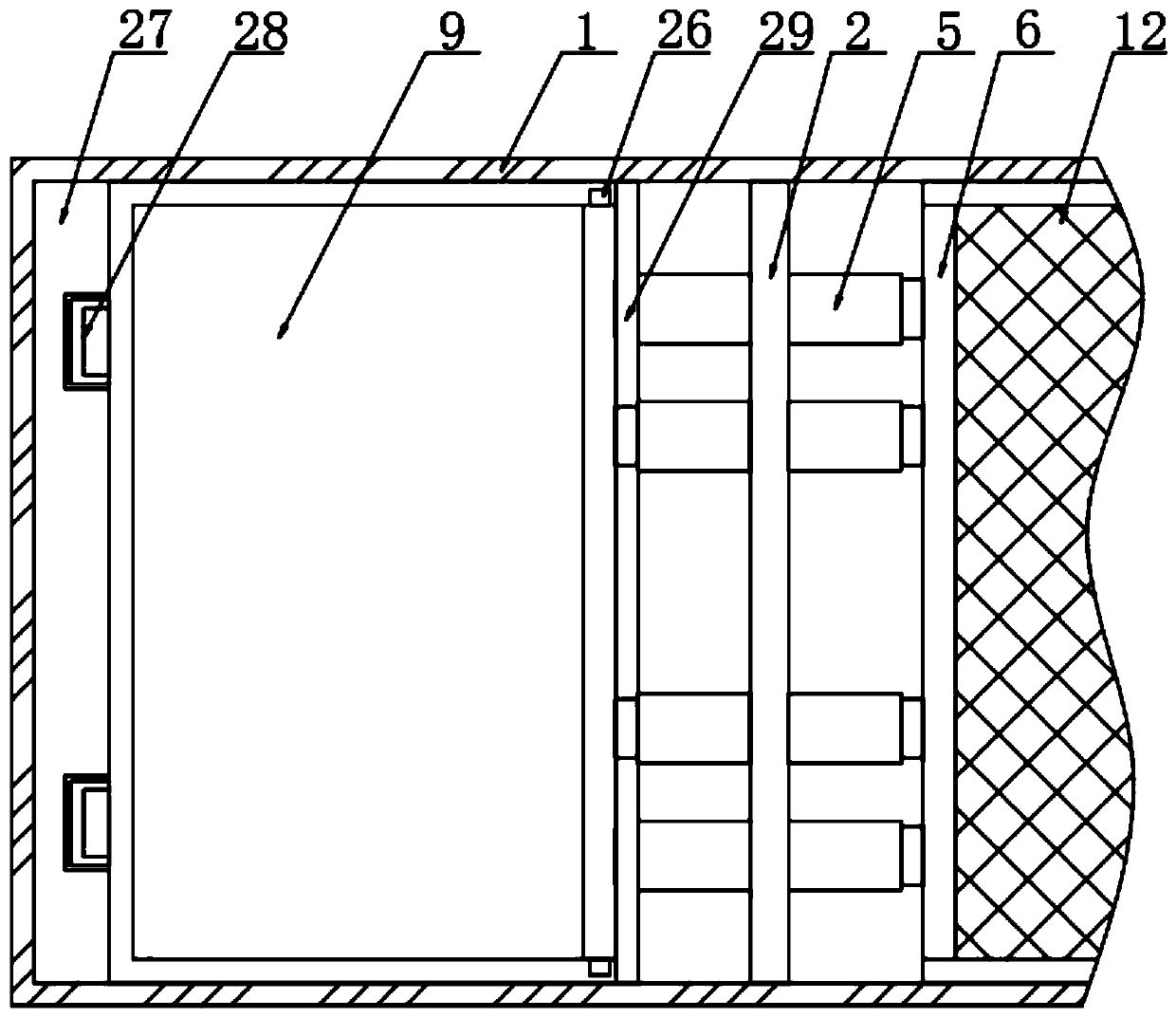

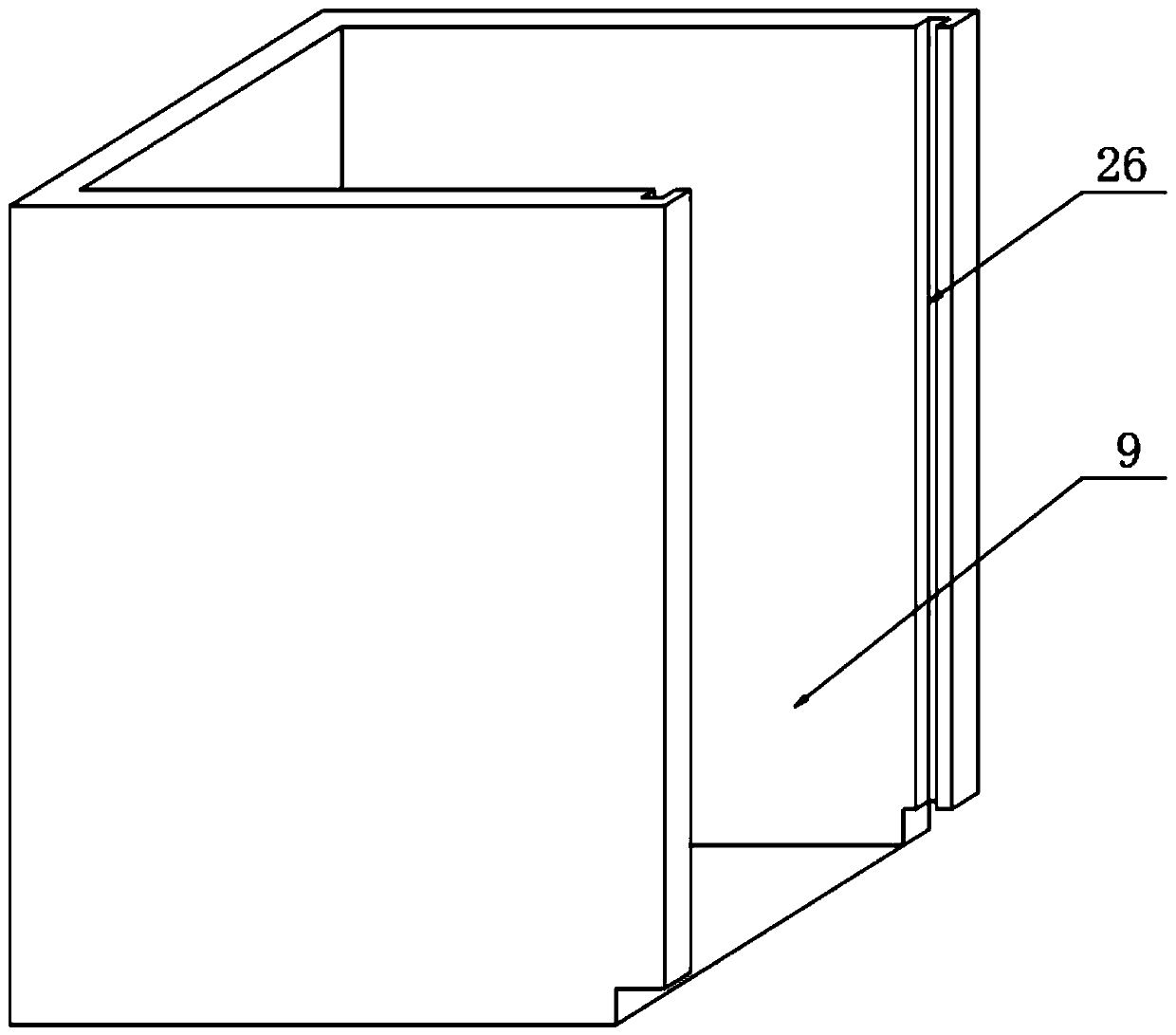

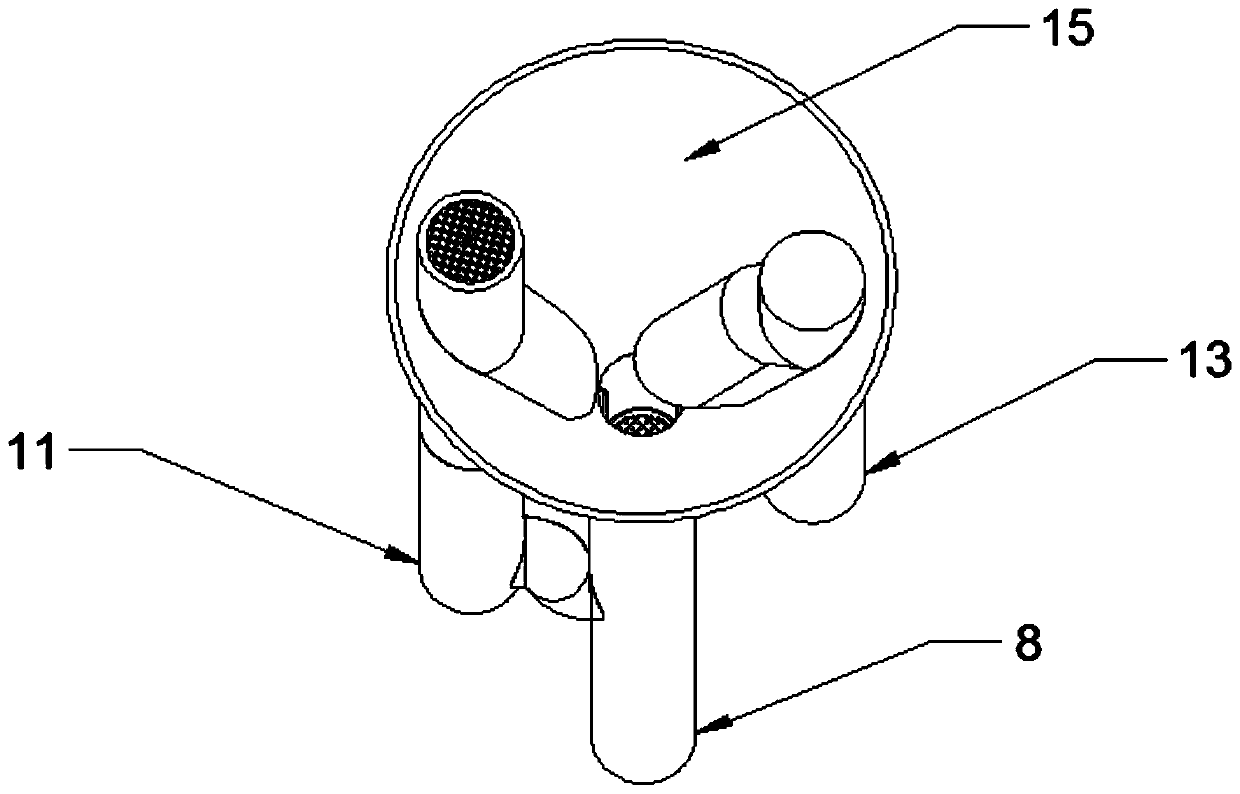

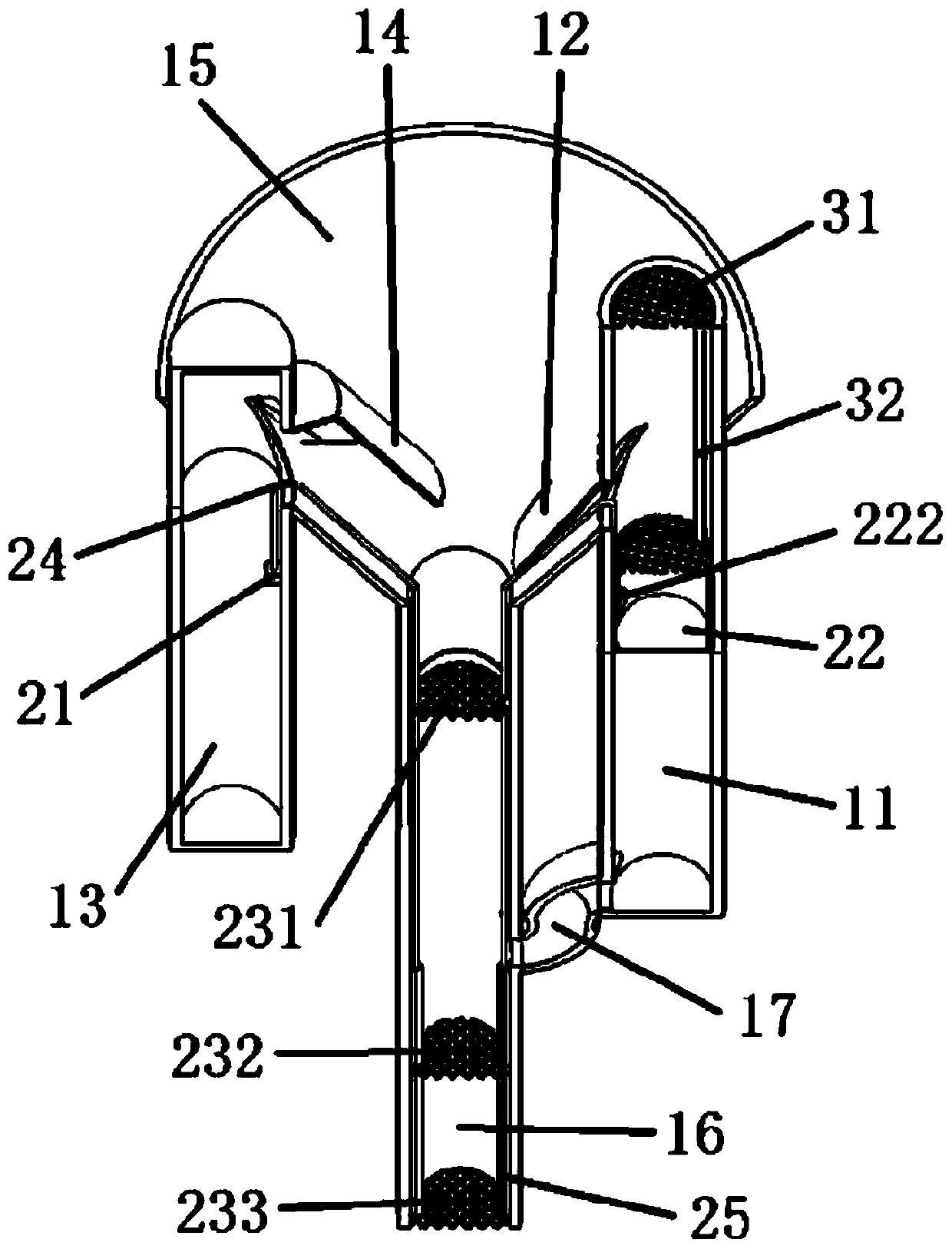

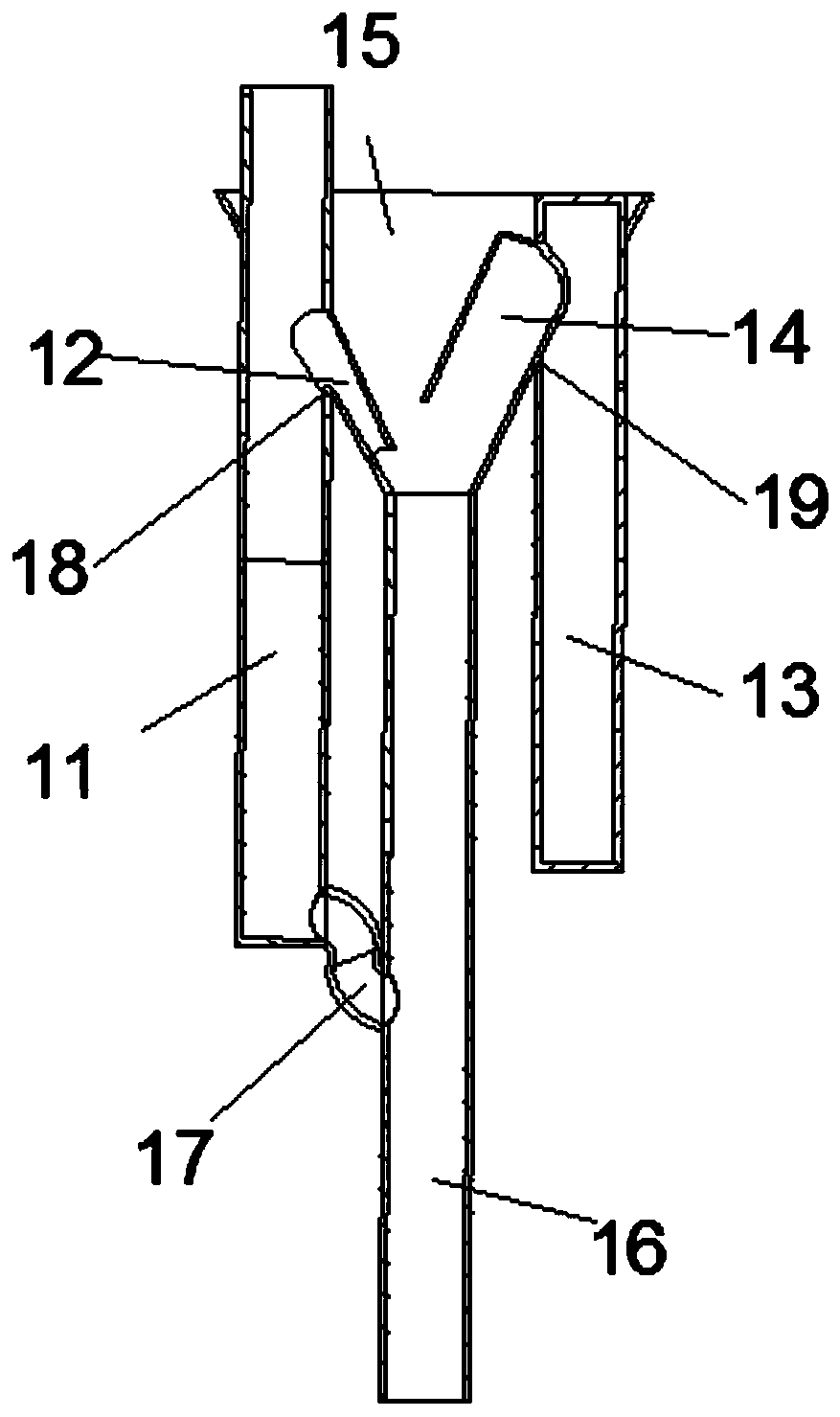

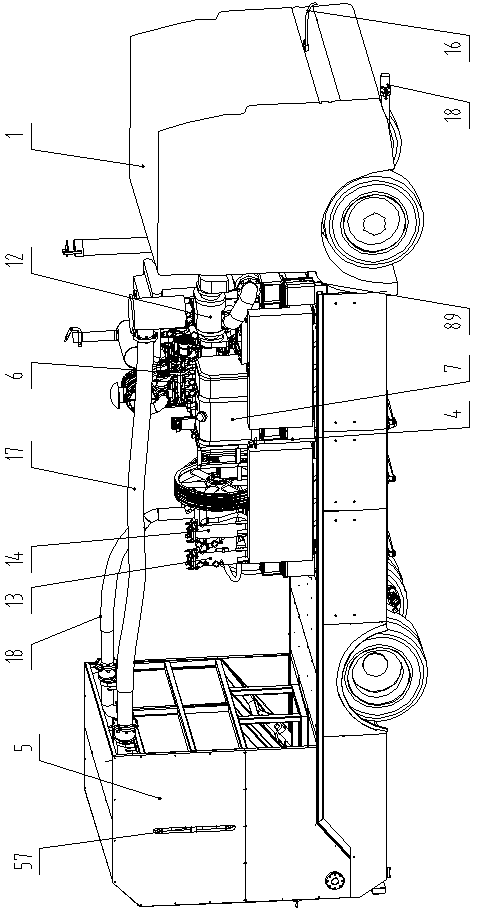

Automatic cooker for kitchen

ActiveCN109730523AFunction as a switchImprove adsorption capacityCooking-vessel lids/coversCooking insertsEngineeringCooked food

The invention relates to an automatic cooker for a kitchen, comprising a cabinet, wherein a disk feeding unit, a dish processing unit, a seasoning feeding unit and a cooked food delivering unit are arranged on the cabinet; the feeding unit comprises a rotary rod, a motor A, a dish box and an adsorbing device, and the adsorbing device is arranged on the rotary rod; the dish processing unit comprises a heating device, a stir pan and a stir-frying mechanism used for stirring and frying the dish in the stir pan, the stir pan is located above the heating device, and the stir-frying mechanism is located above the stir pan; the seasoning feeding unit comprises a solid seasoning feeding unit and a liquid seasoning feeding unit; the cooked food delivering unit comprises a stir pan delivering mechanism and a stir pan dumping mechanism, so as to realize the functions of automatic dish feeding, automatic stirring and frying, automatic and quantitative feeding of seasonings and automatic dumping ofdishes, further realize the aim of automatic cooking dishes, and further reducing the work intensity of personnel of the kitchen and effectively saving human cost.

Owner:张维加

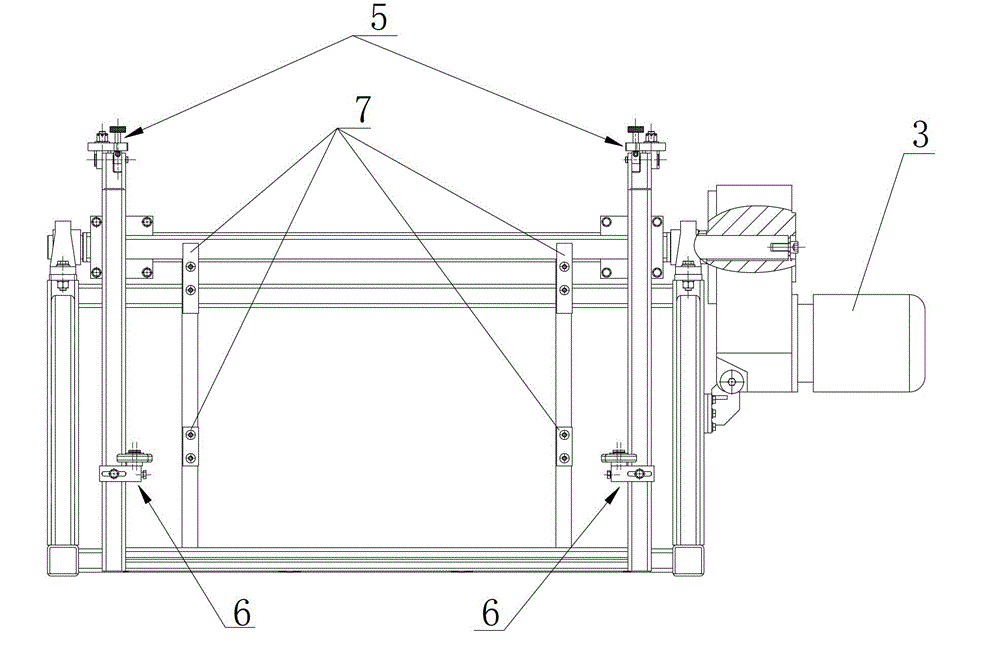

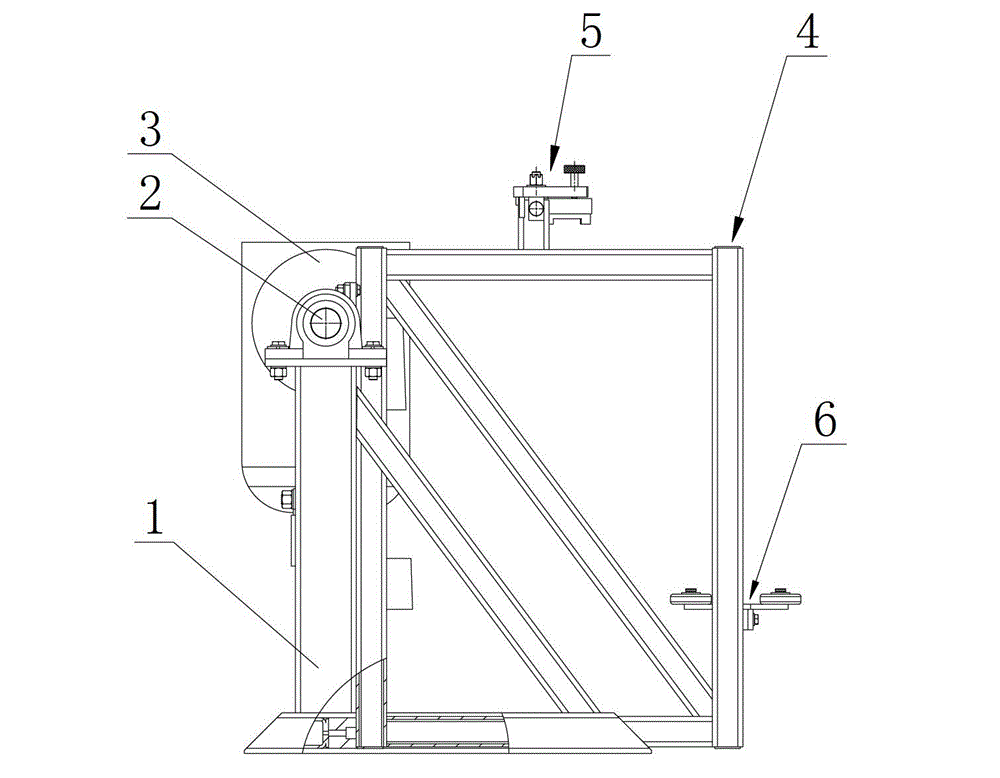

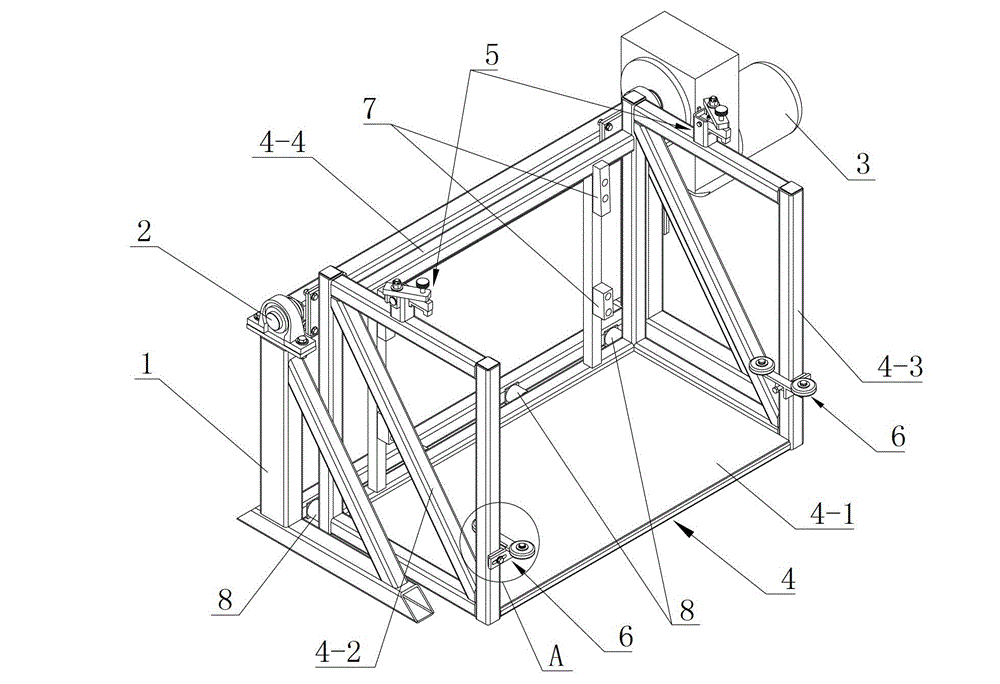

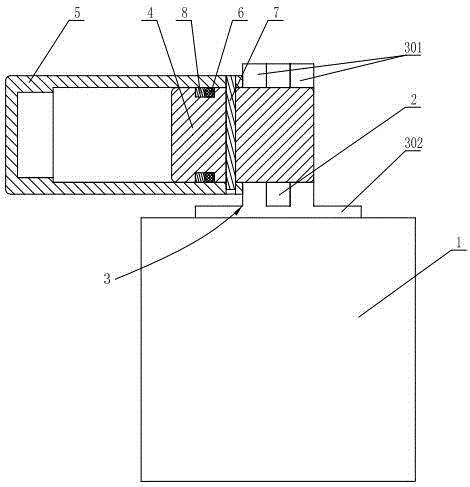

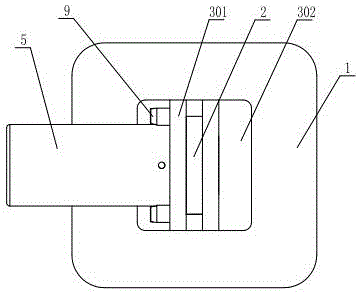

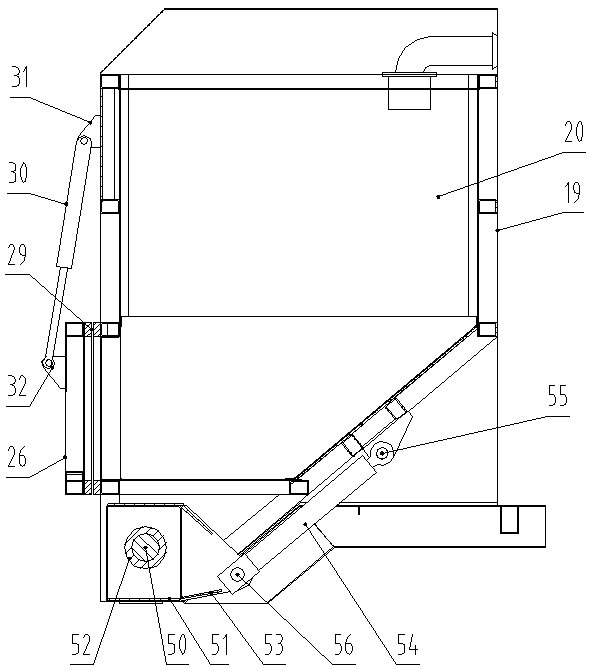

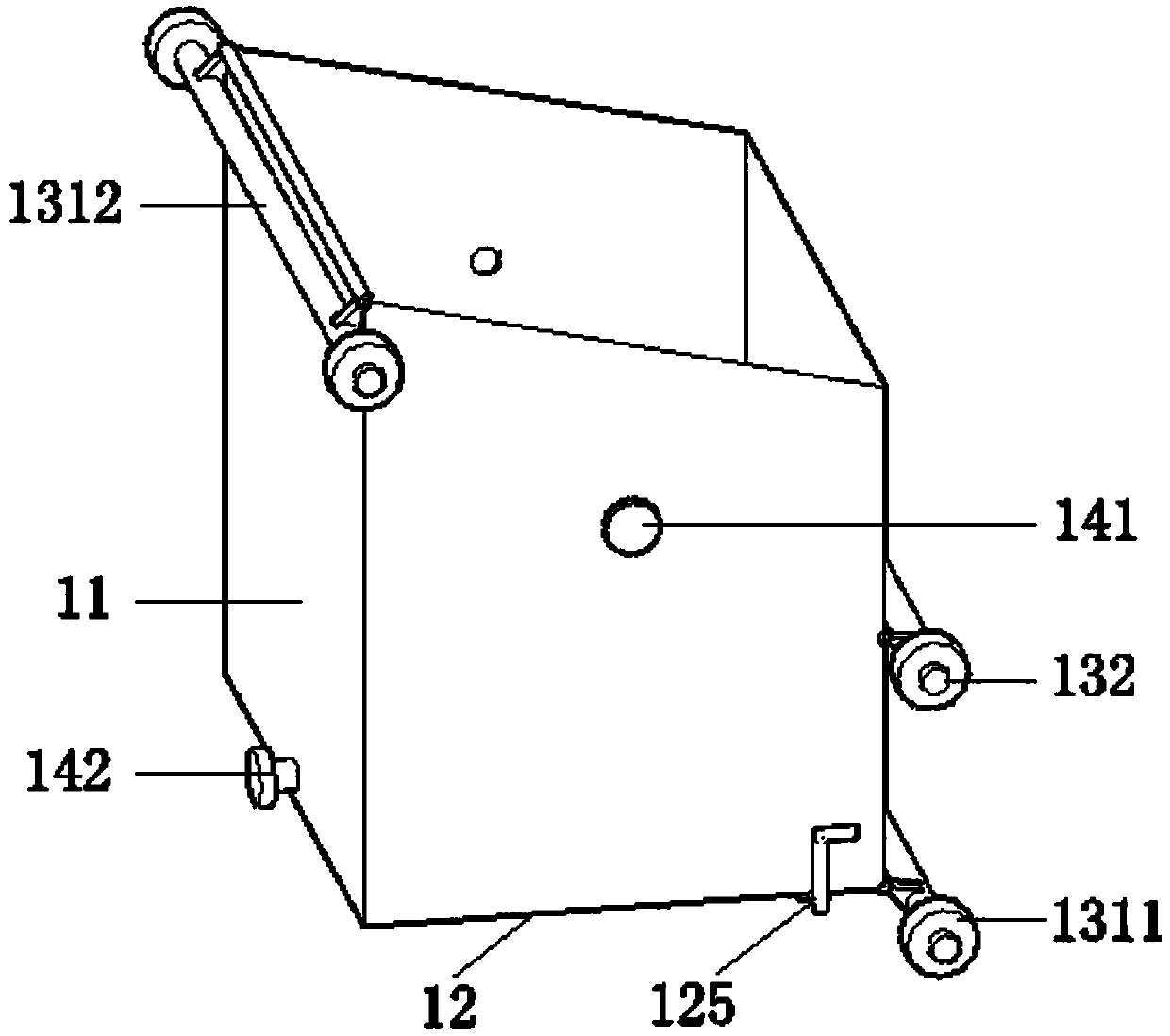

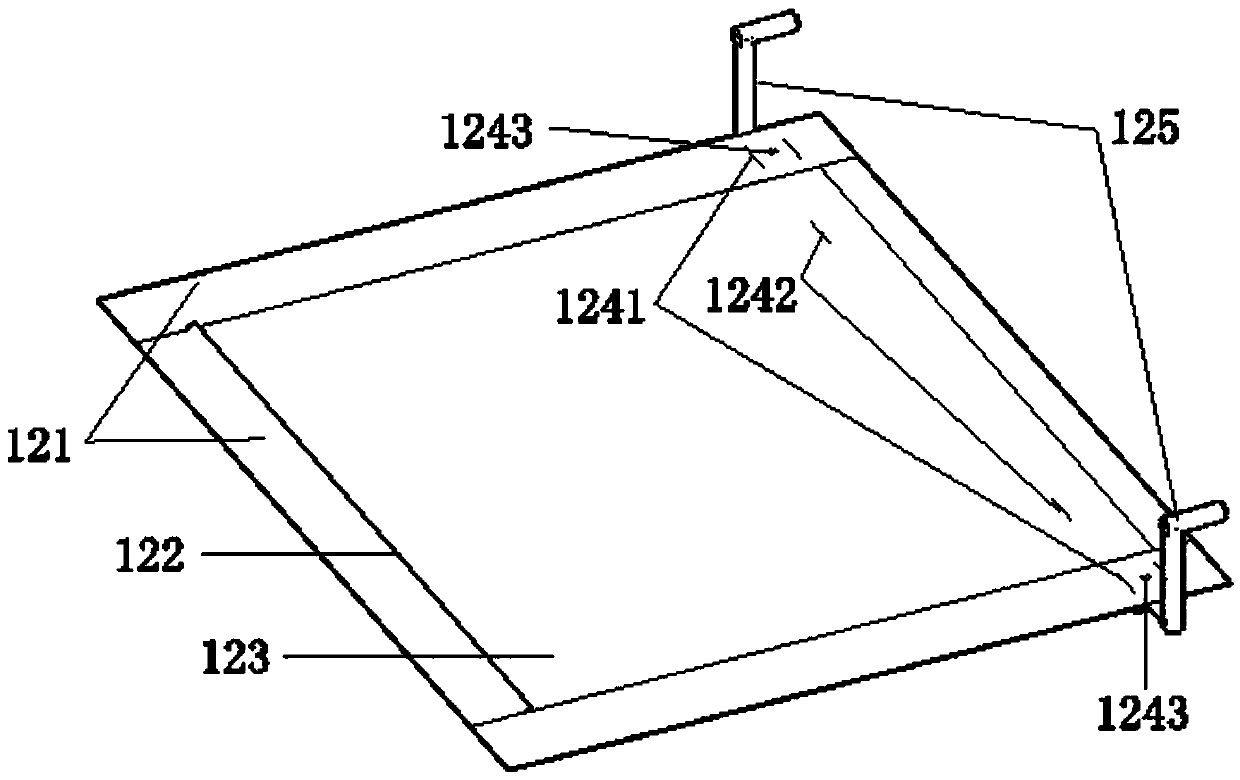

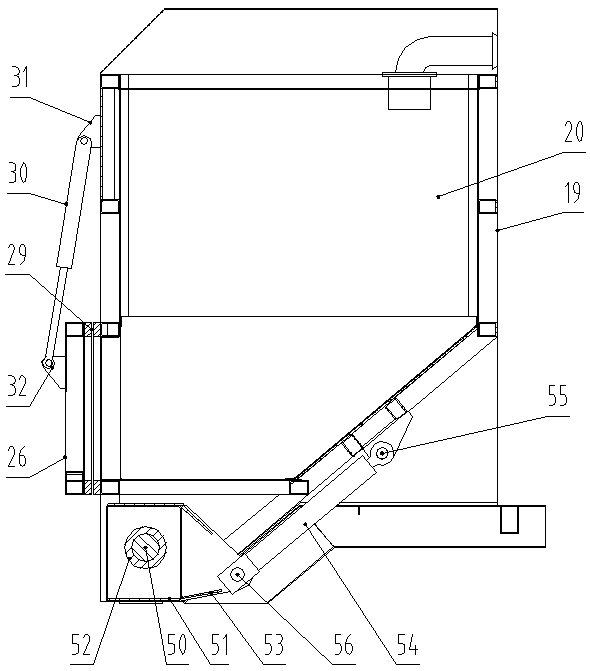

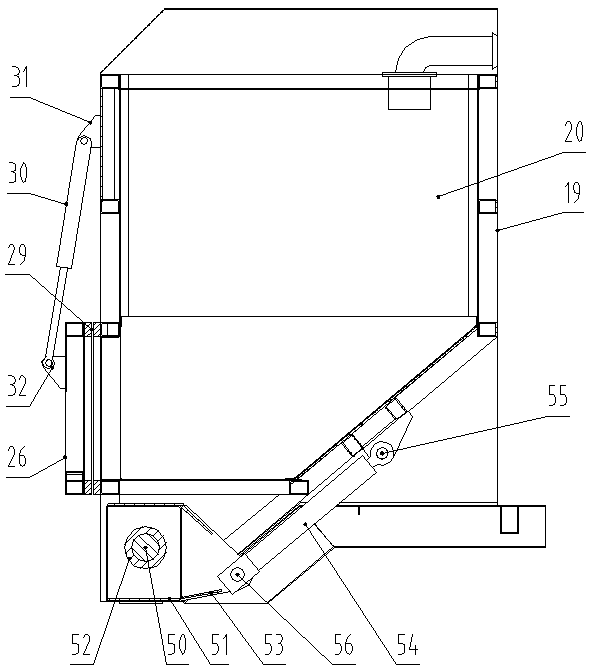

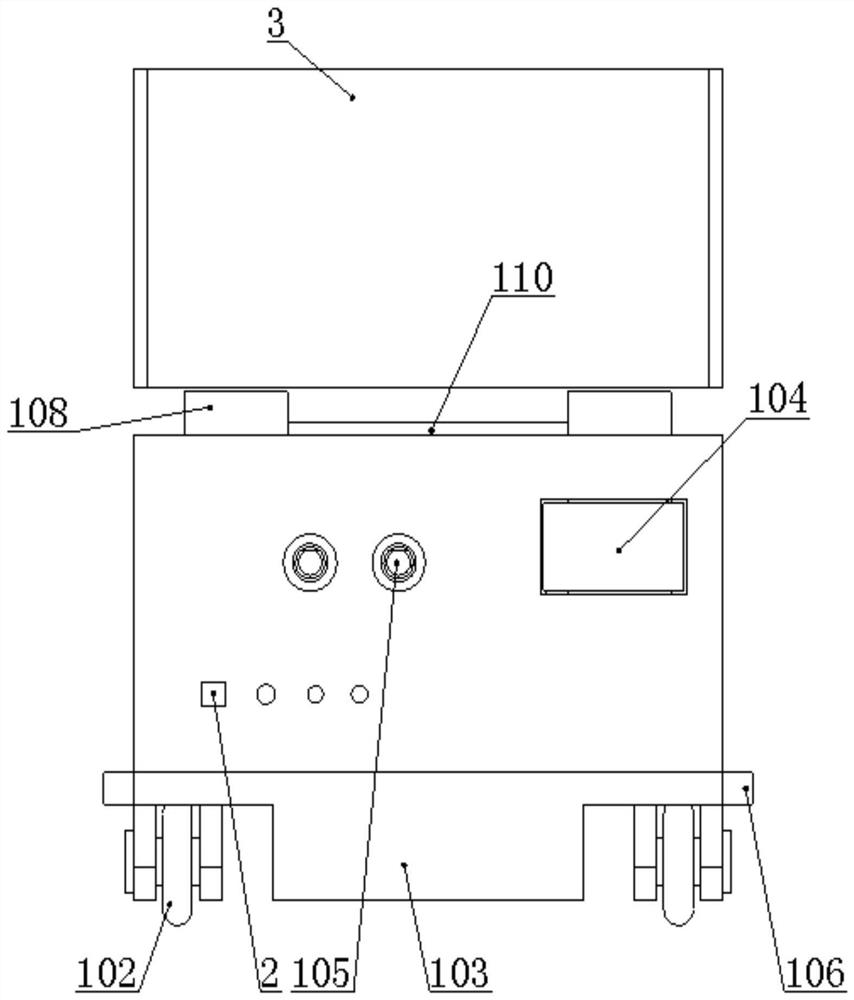

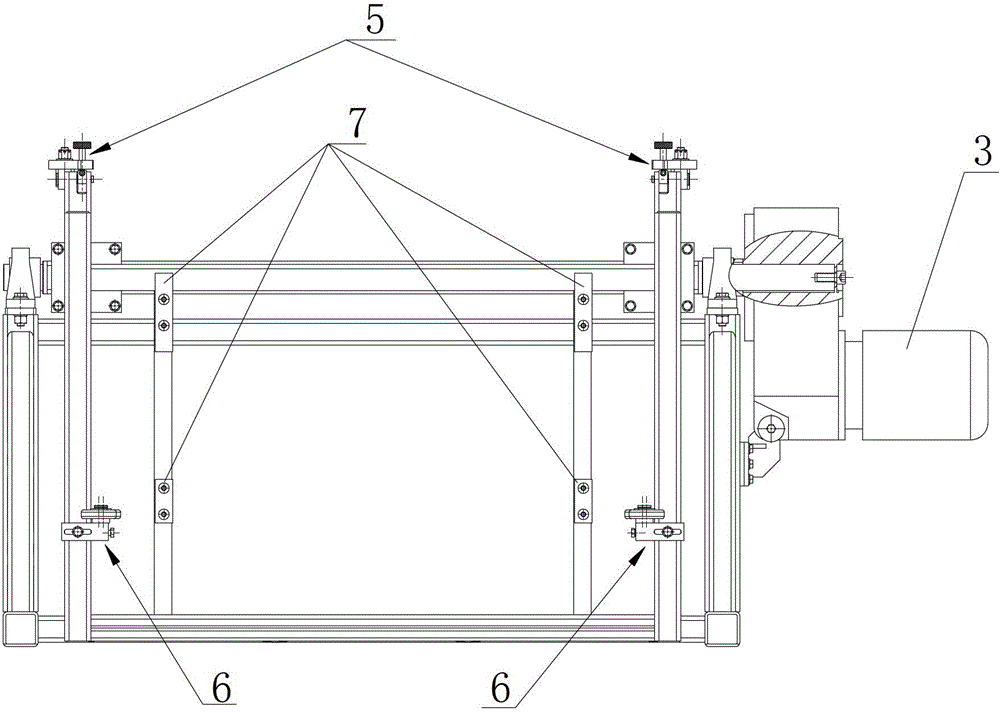

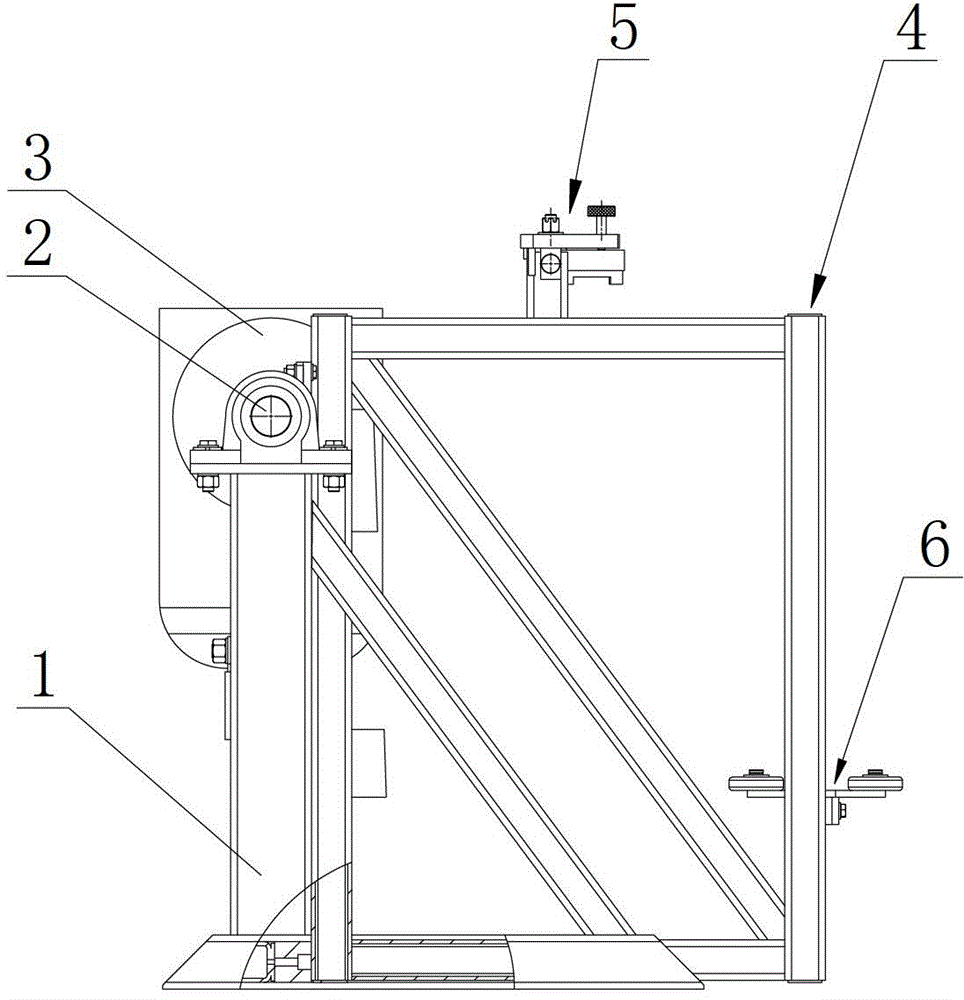

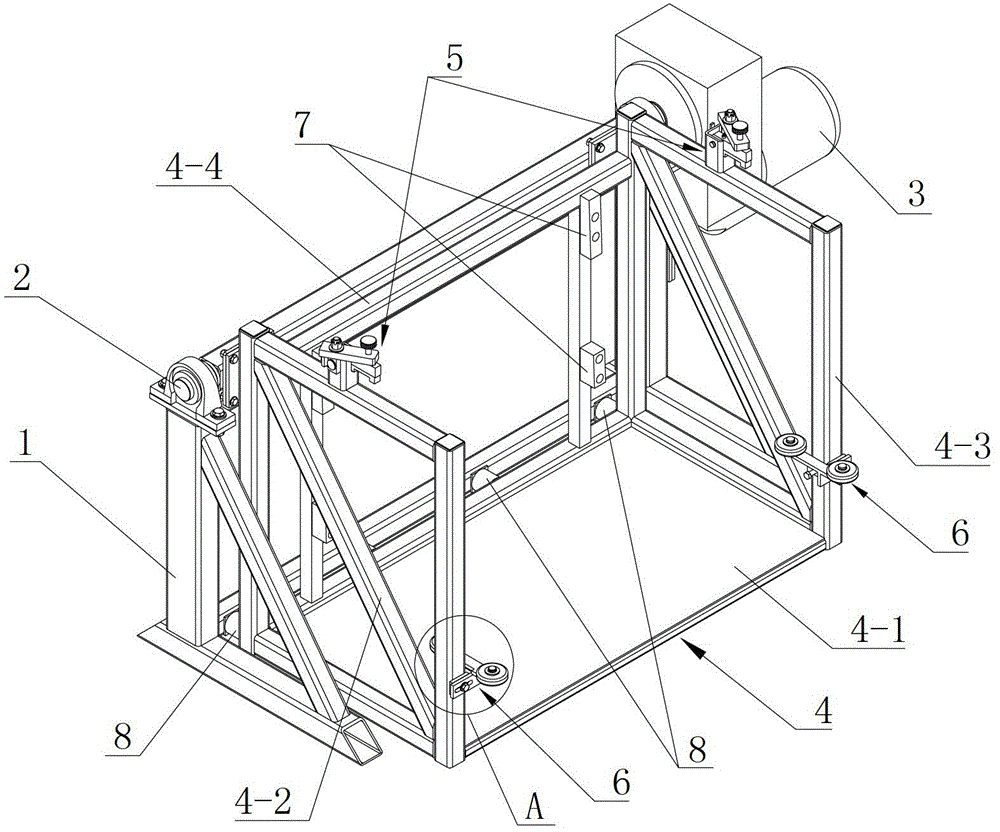

Medical rubbish bin dumping device

The invention relates to a medical rubbish bin dumping device which is characterized in that the medical rubbish bin dumping device comprises a fixing frame, a support shaft supported at the upper end of the fixing frame, and a slowdown motor which is installed at one lateral end of the fixing frame and is in transmission connection with the support shaft. An overturning box consisting of a bottom support part, a left support part, a right support part and a back support part is arranged inside the fixing frame; clamping devices are arranged at the upper ends of the left and right support parts; and the part of the back support part, which is close to the upper end, is fixedly connected with the support shaft. The medical rubbish bin dumping device realizes automatic dumping of the medical rubbish, and an operator only needs to mount a medical rubbish bin on the medical rubbish bin dumping device and then demount the emptied medical rubbish bin from the dumping device. Compared with the conventional manual dumping manner, the medical rubbish bin dumping device has the advantages of lightening the work intensity, and improving the dumping efficiency. Moreover, in the dumping process, the operator can be far away from the medical rubbish bin, so direct contact between the operator and the medical rubbish is avoided. Therefore, the medical rubbish bin dumping device is safe and hygienic, and reduces the probability of iatrogenic infection of the operator.

Owner:天津百利阳光环保设备有限公司

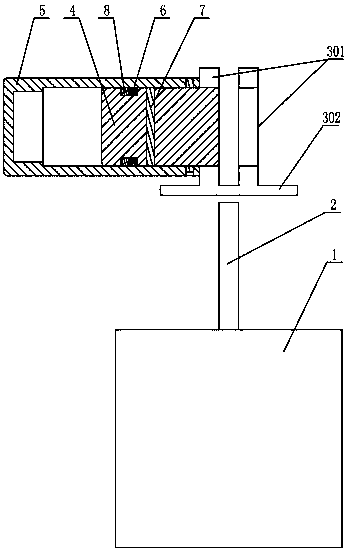

Deep sea self-induction emergency load rejection mechanism

The invention provides a deep sea self-induction emergency load rejection mechanism. The mechanism comprises a ballast, wherein a lifting lug is fixedly arranged at the upper part of the ballast; an installation rack is fixedly installed on a subsea equipment body and comprises lug plates; through holes for passing and sliding of a plunger are formed in the lifting lug and the lug plates; a cylinder block is fixedly installed on the installation rack and is provided with a hollow cavity with an opening in one end; one end of the plunger is stuffed in the hollow cavity; the plunger and the hollow cavity are sealed by sealing elements; the sealed hollow cavity is pre-filled with internal pressure; the cylinder block and the plunger are connected by a locating pin; the other end of the plunger passes through the through hole of the lifting lug and the through holes of the lug plates; under the actions of the internal and external pressures of the sealed hollow cavity, the plunger is connected with the through hole of the lifting lug or breaks away from the through hole of the lifting lug so that the ballast is connected with the installation rack or breaks away from the installation rack. The mechanism achieves automatic load rejection through self induction of internal and external pressures.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

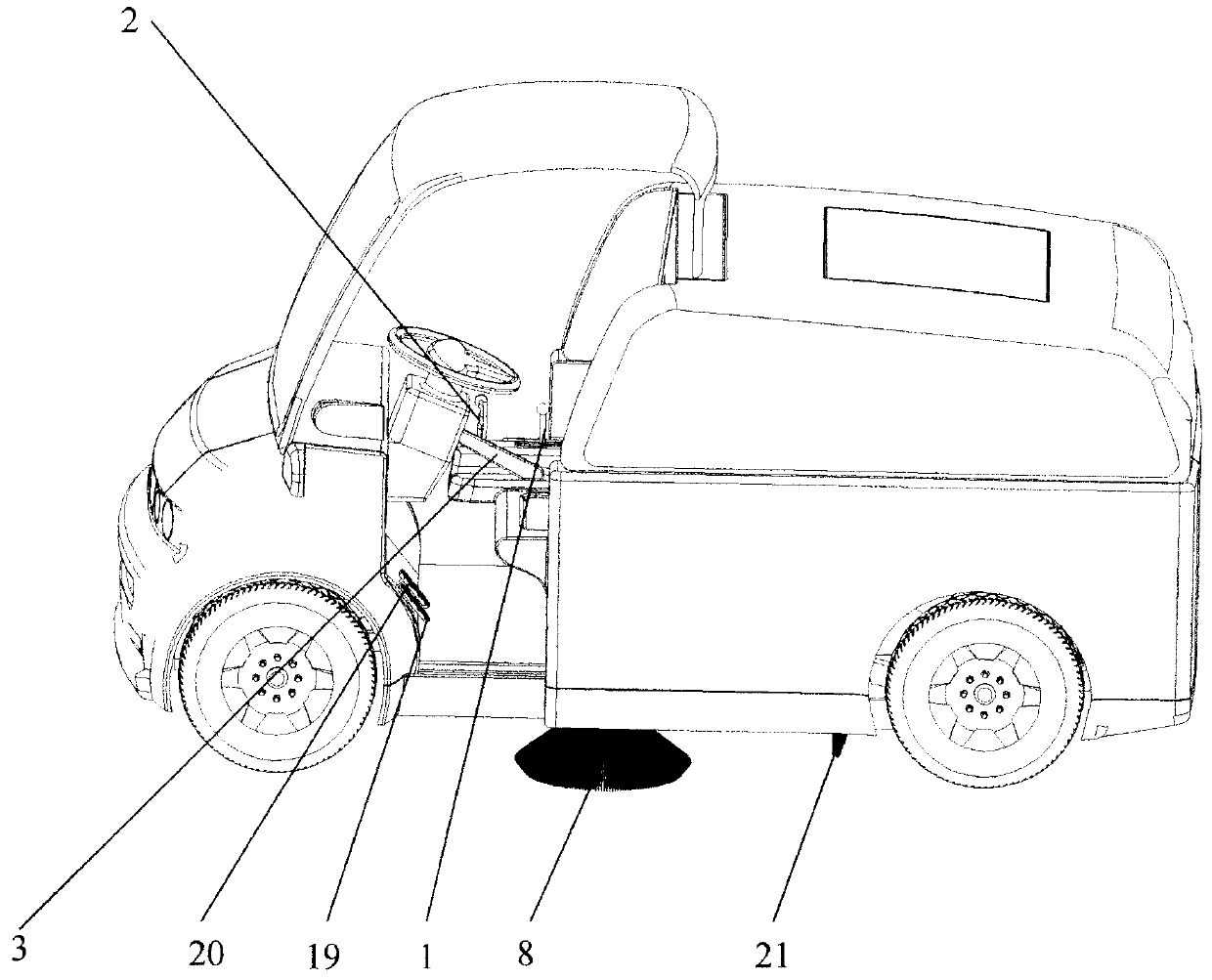

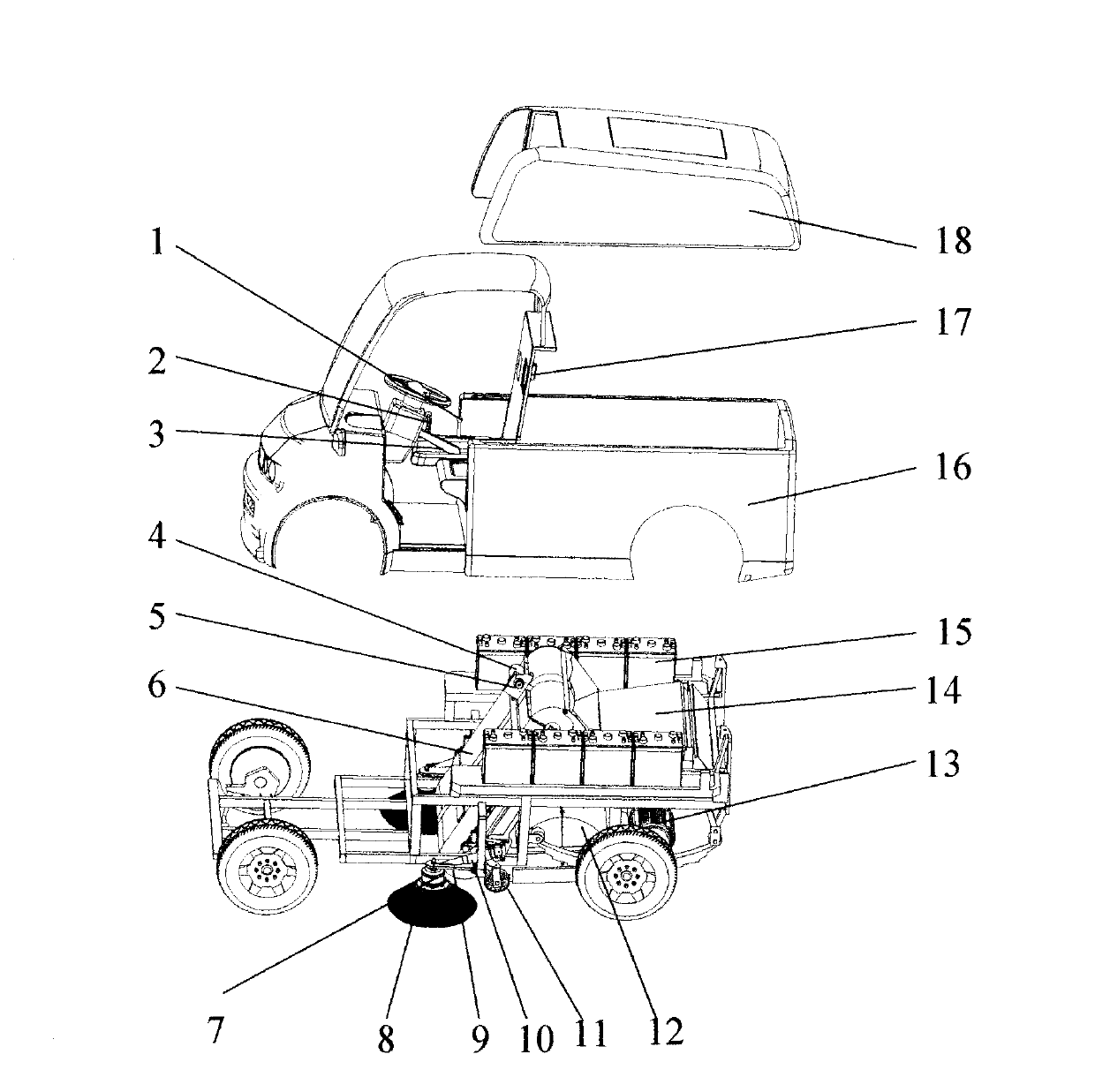

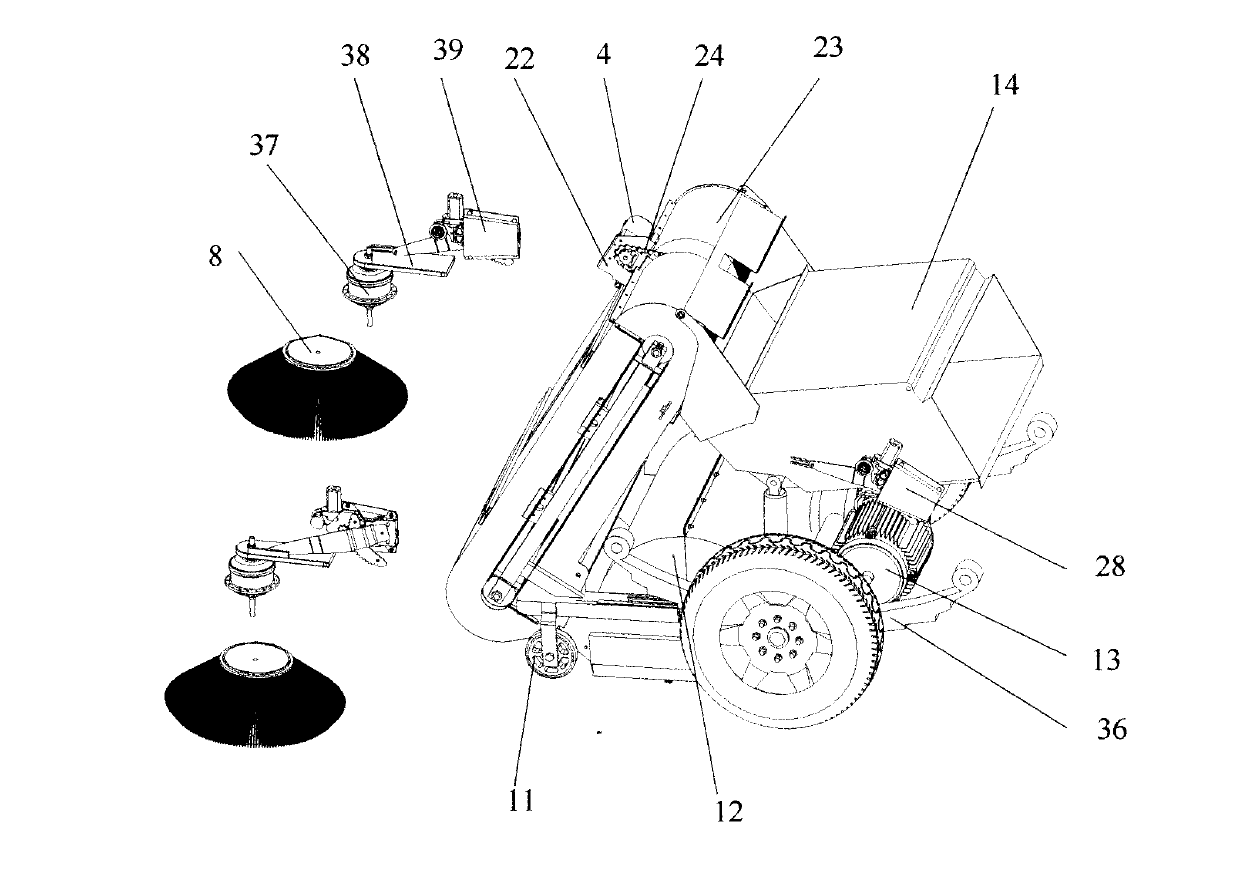

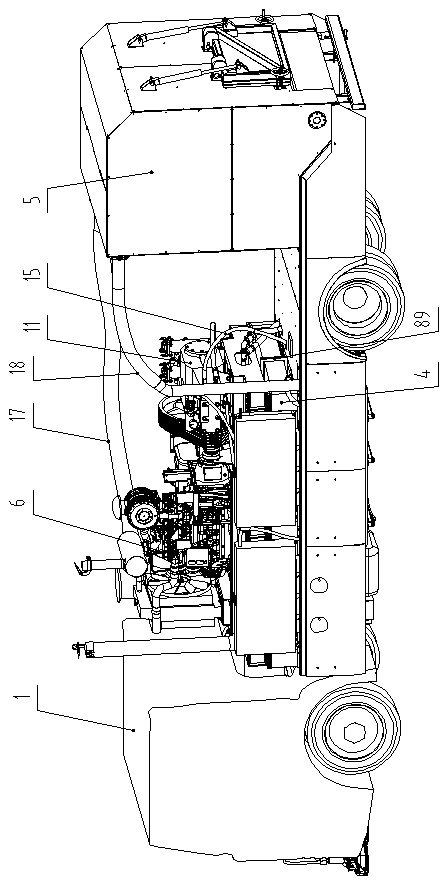

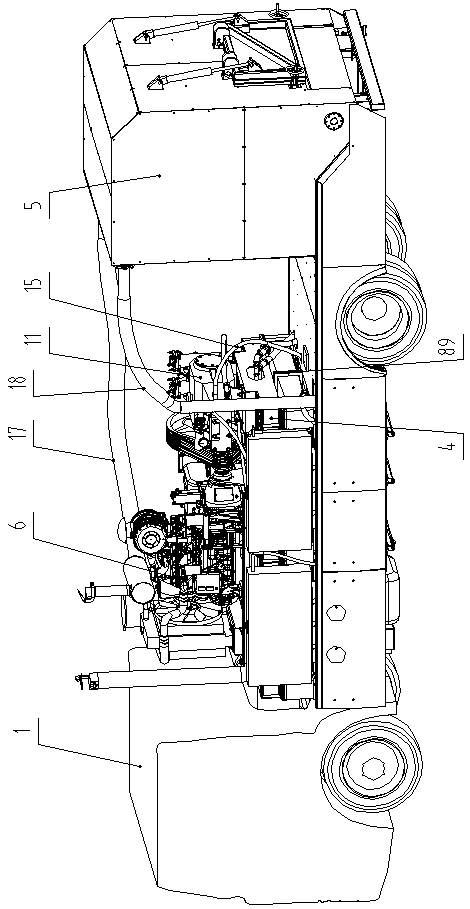

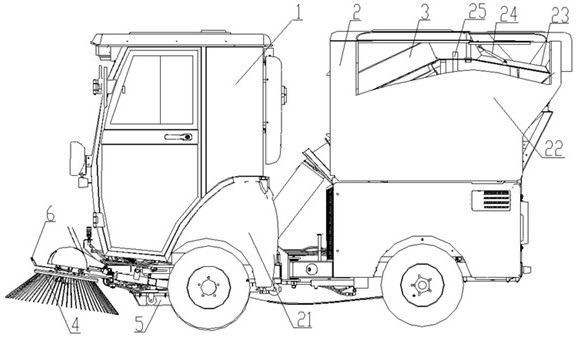

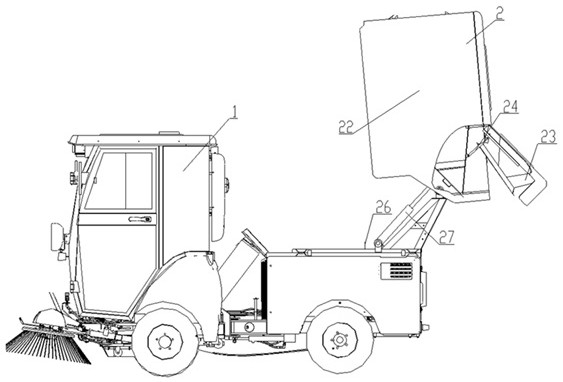

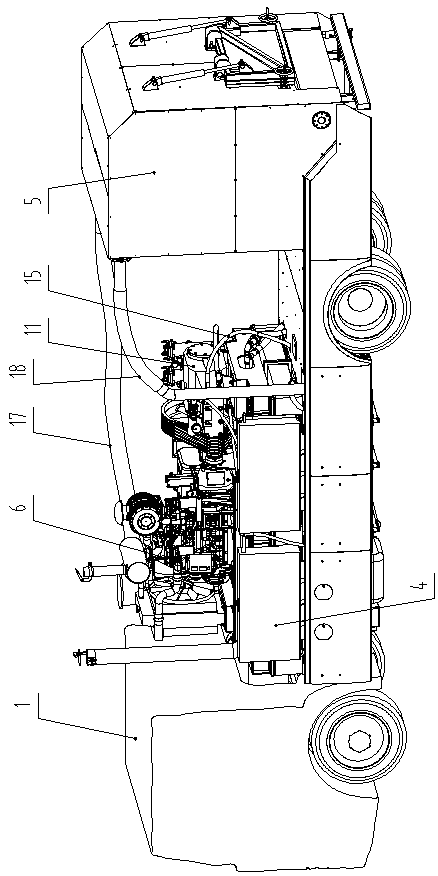

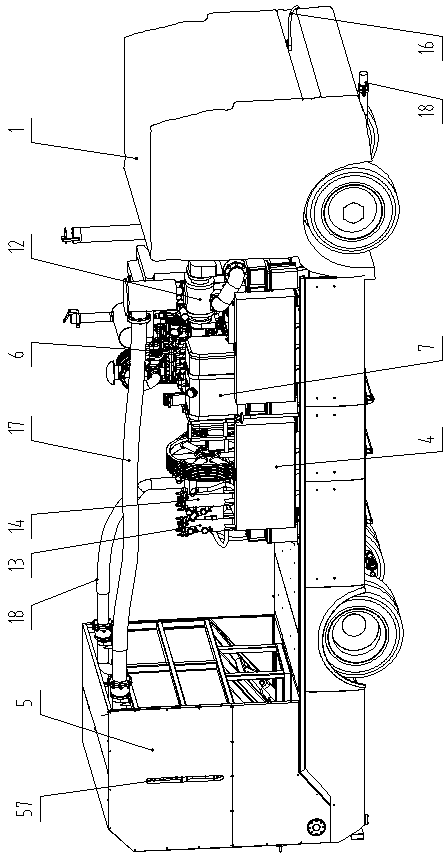

Electric sweeper

The invention relates to an electric sweeper. Power of the electric sweeper adopts eight 6V190Ah lead acid batteries and a DC (Direct Current) brushless motor in which a rear axle is arranged; the electric sweeper consists of a motor controller, a DC-DC (Direct Current to Direct Current) control module, a liquid level sensor conditioning circuit, a rotating speed sensor and other control circuits on circuit and structurally comprises a vehicle body, a frame, a sweeping mechanism, a lifting mechanism, a refuse hopper and a spraying mechanism; the sweeping mechanism adopts two side brushes rotating reversely, a lifting motor connected with the two side brushes, a middle brush and a protective frame; the lifting mechanism comprises a refuse lifting belt, a hoisting motor, a chain, a belt supporting seat and a housing for packaging the refuse lifting belt; both sides of the refuse hopper are provided with lifting motors; and the spraying mechanism consists of a water tank, a water pump and a conduit connected with the water pump. The electric sweeper has the key points that the two side brushes and the middle brush are respectively provided with one hub motor; the hub motors on the two side brushes have opposite rotating directions, so that refuse is guaranteed to move towards the middle and then is sent into a feed inlet of the lifting belt housing by the middle brush; the lifting motor drives the refuse lifting belt by the chain to send the refuse into the refuse hopper; the two side brushes are connected with the lifting motors to ensure that the side brushes are separated from the ground when the sweeper runs; combination of the refuse hopper and the lifting motors implements the automatic dumping of the refuse.

Owner:CHANGSHA YUANCHUANG ENVIRONMENTAL PROTECTION TECH

Waste lead-acid battery disassembling and electrolyte recycling device

InactiveCN111934046AGuaranteed stabilityPlay a protective effectWaste accumulators reclaimingBattery recyclingElectrical batteryEnvironmental engineering

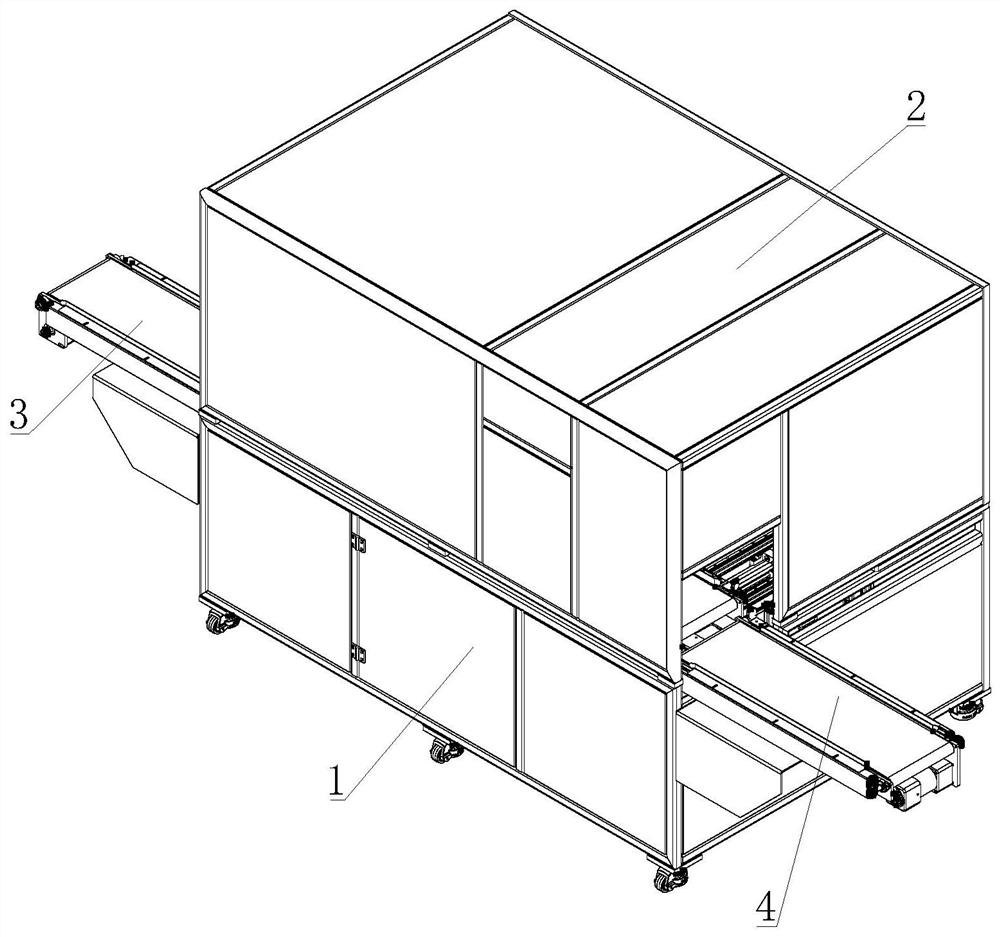

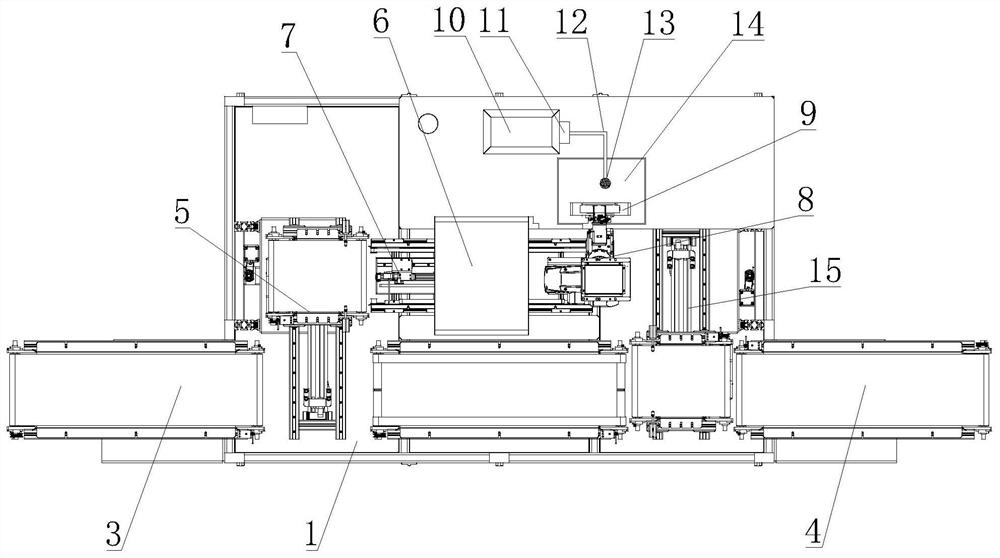

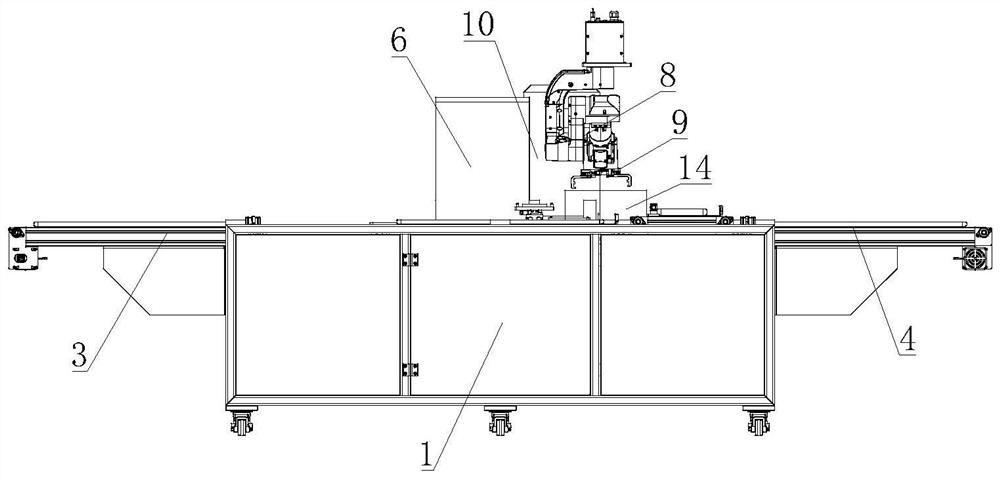

The invention discloses a waste lead-acid battery disassembling and electrolyte recycling device. An upper rack is fixedly mounted on a lower rack, and shell plates are arranged on the periphery of the upper rack and the periphery of the lower rack. A feeding conveying belt and a discharging conveying belt are fixedly mounted on the two sides of the lower rack correspondingly. The feeding conveying belt is used for conveying the waste lead-acid batteries into the upper rack; the discharging conveying belt is used for conveying the waste lead-acid batteries out of the upper rack; the waste lead-acid battery is automatically carried and steered by arranging the manipulator assembly; the feeding conveying belt, the discharging conveying belt and a transfer conveying belt are arranged, the waste lead-acid batteries are automatically conveyed, workers do not need to make direct contact with the batteries in the whole conveying process, the workers are effectively protected, the clamping mechanism is arranged in a cutting machine box to clamp the waste lead-acid batteries, the stability during battery cutting is ensured, the lead screw drives the cutter to automatically move to cut and disassemble the lead-acid batteries, and the disassembling efficiency is improved.

Owner:太和县大华能源科技有限公司

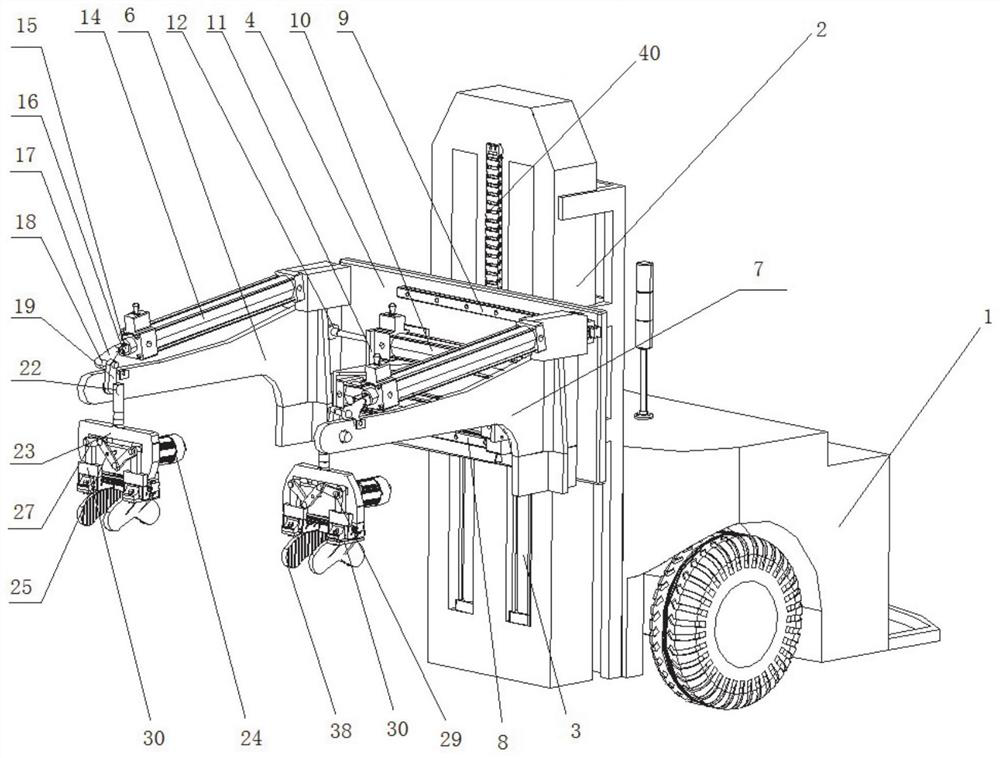

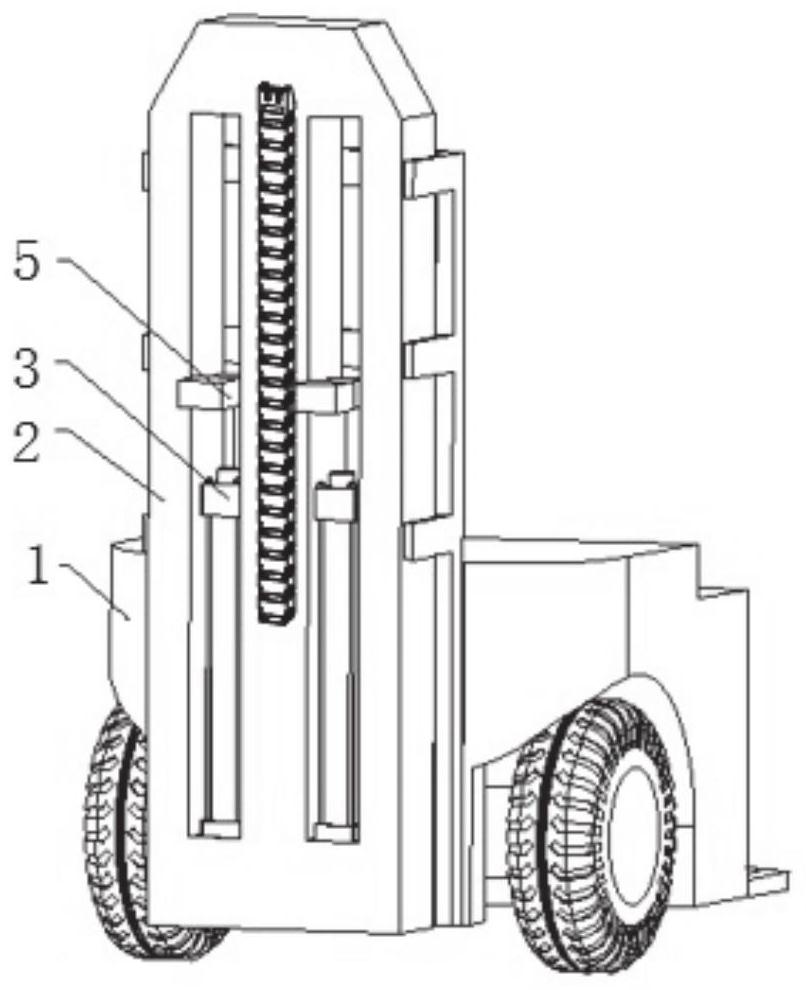

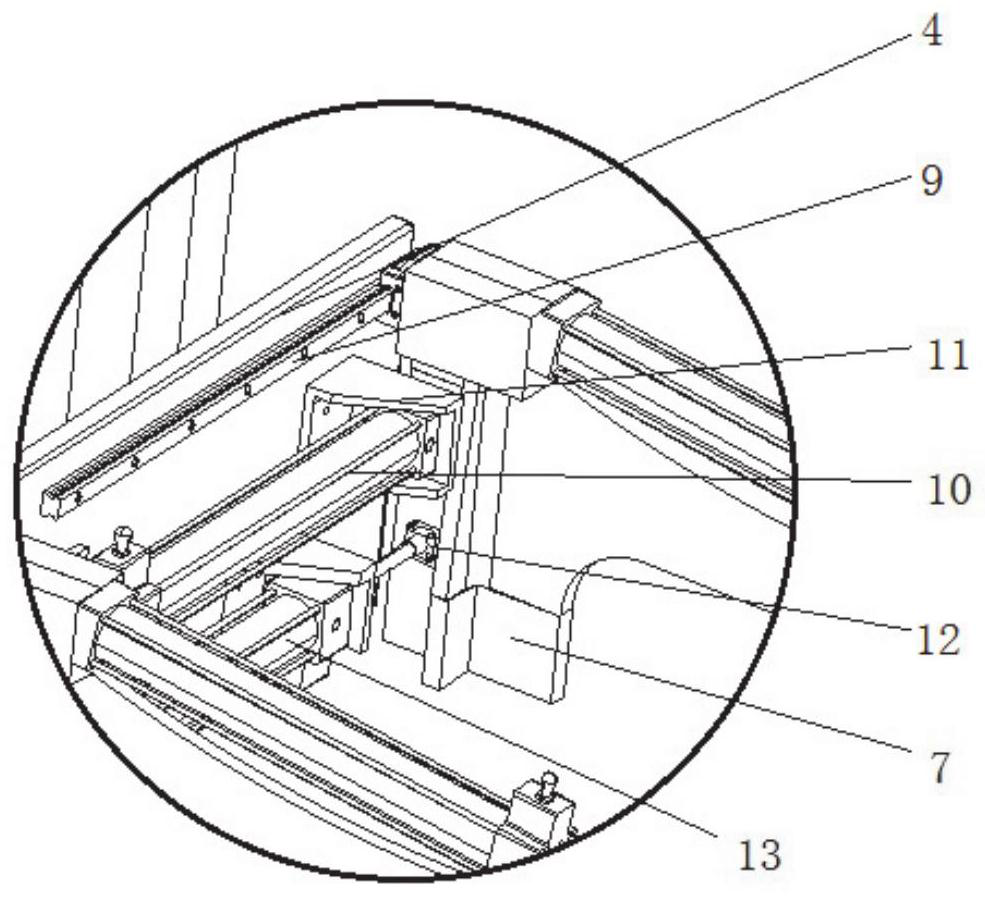

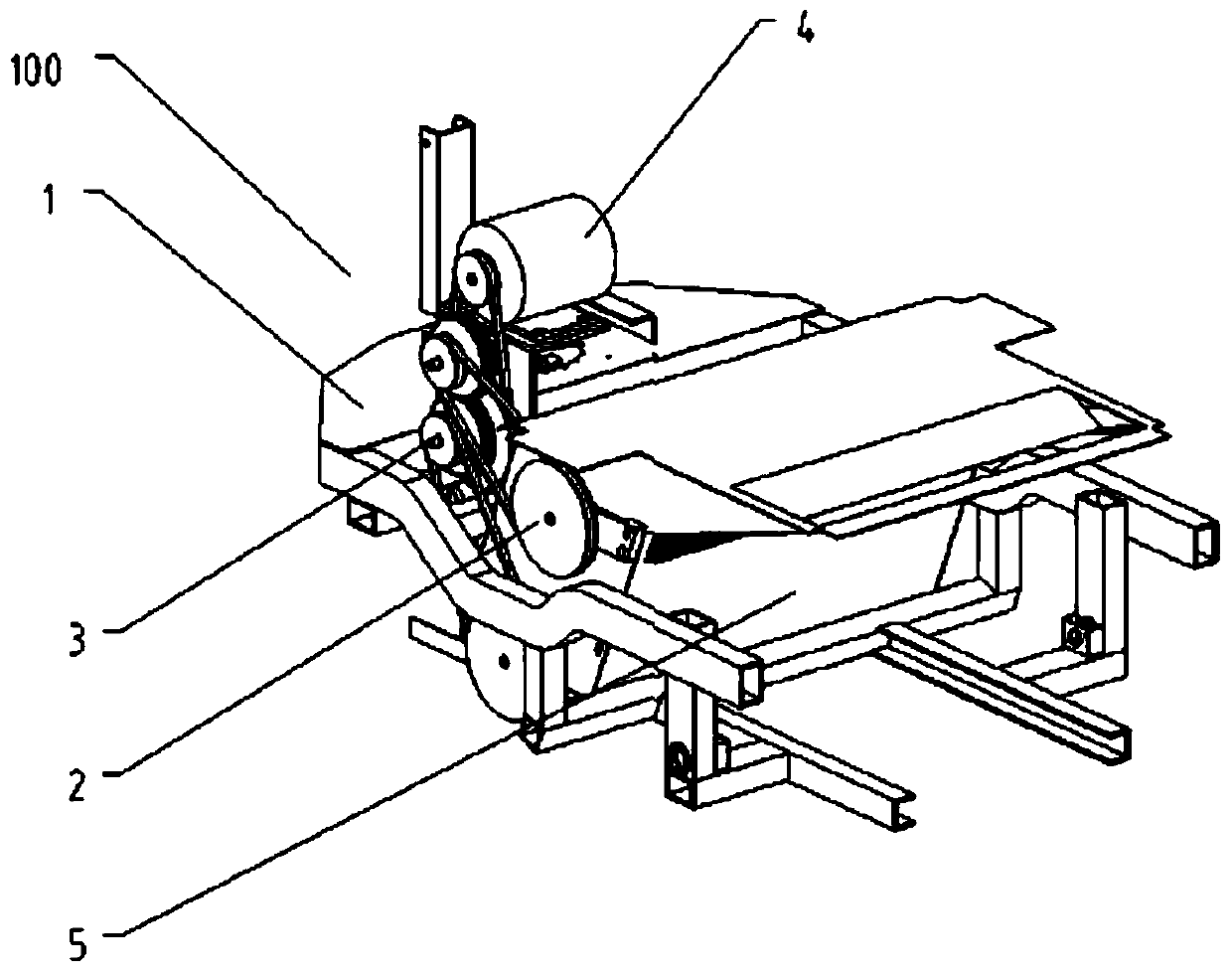

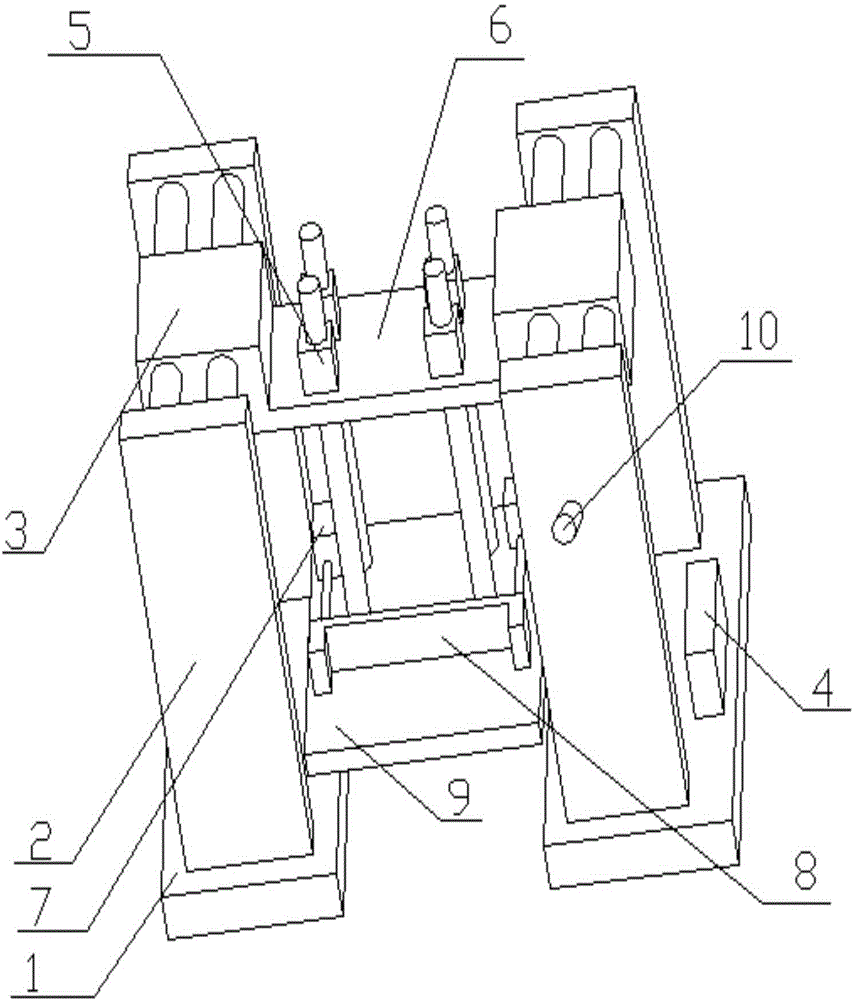

Automatic material frame clamping, overturning and transporting device and working method

PendingCN112408259AImplement automatic placementEasy to placeLifting devicesControl engineeringControl theory

Owner:山东大学日照智能制造研究院 +1

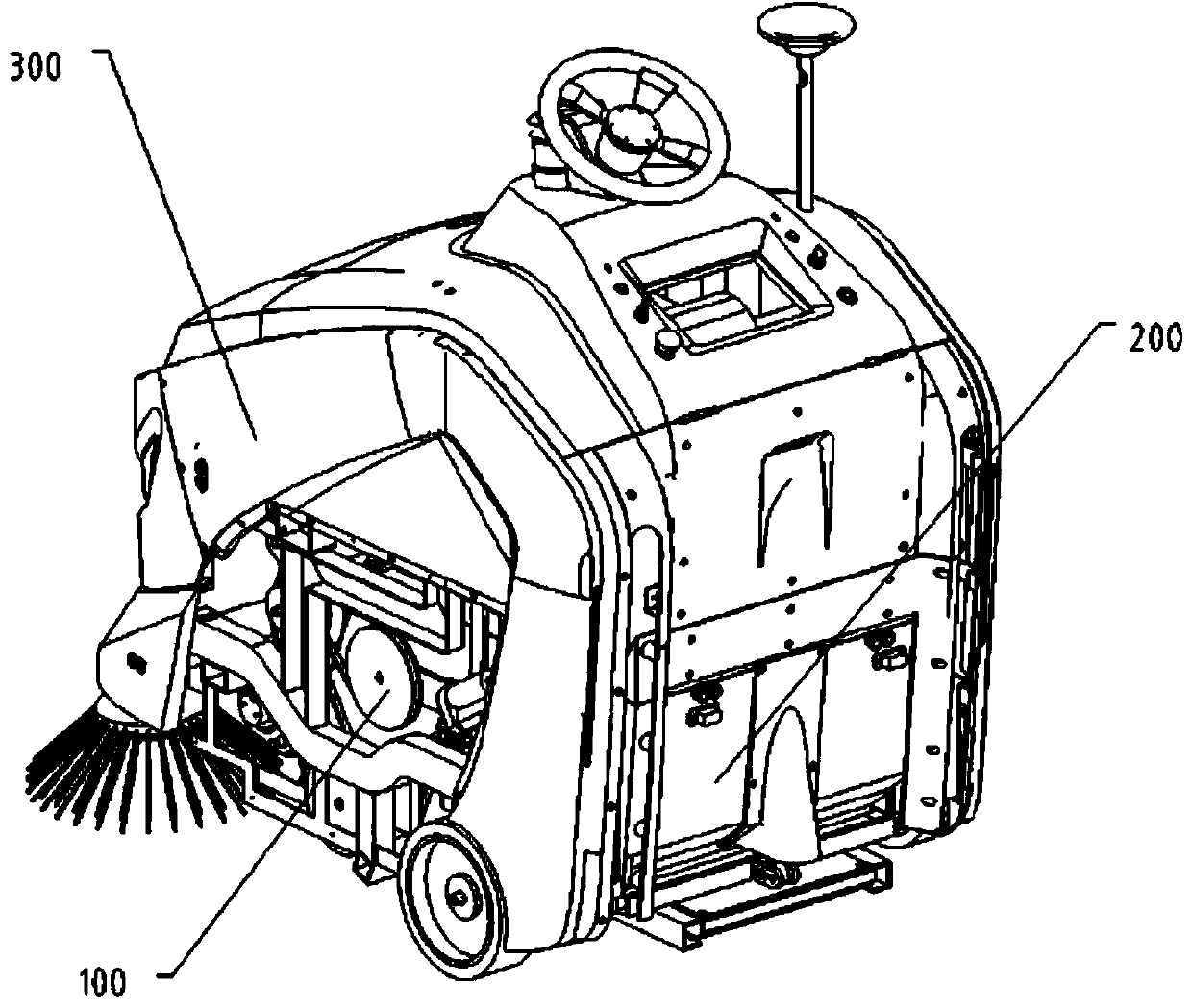

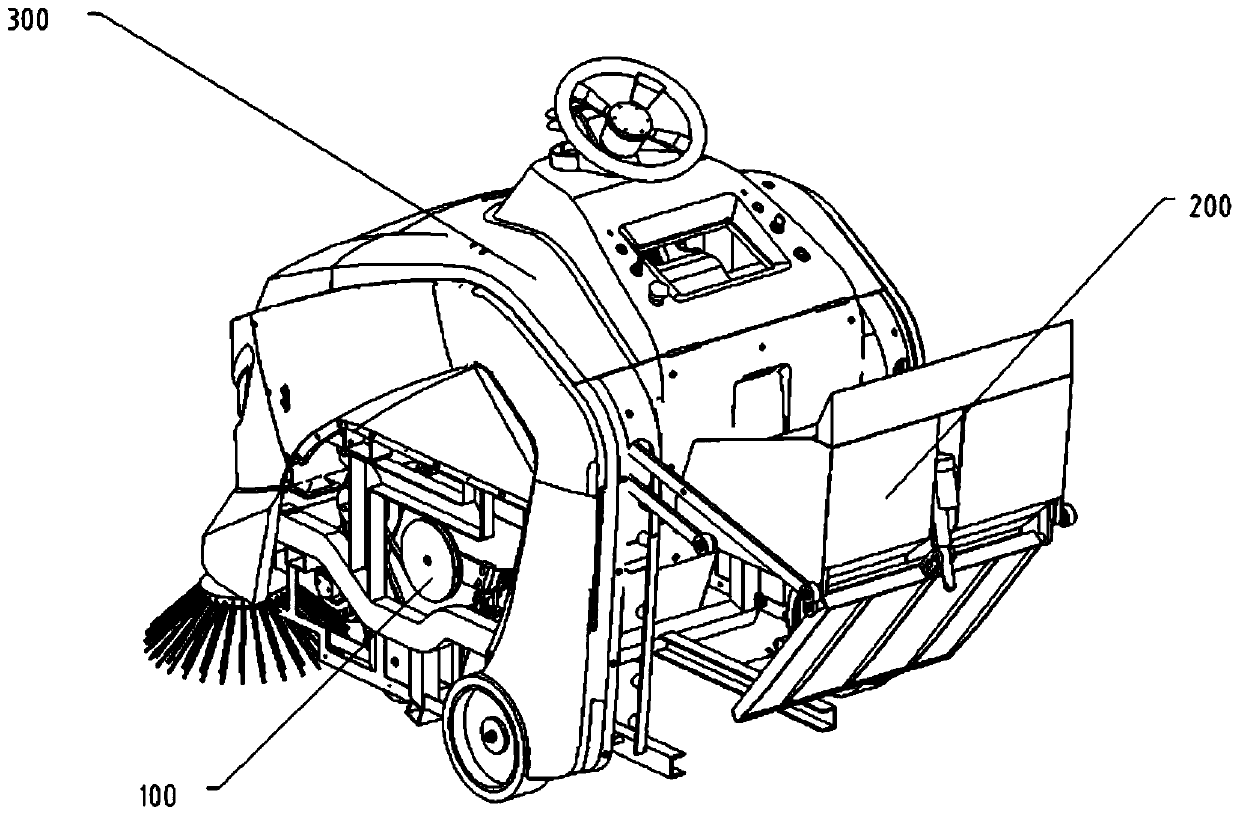

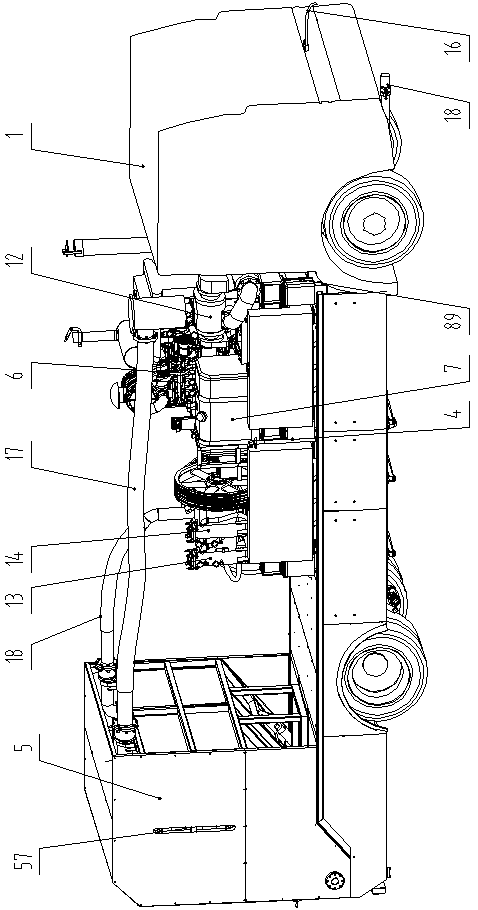

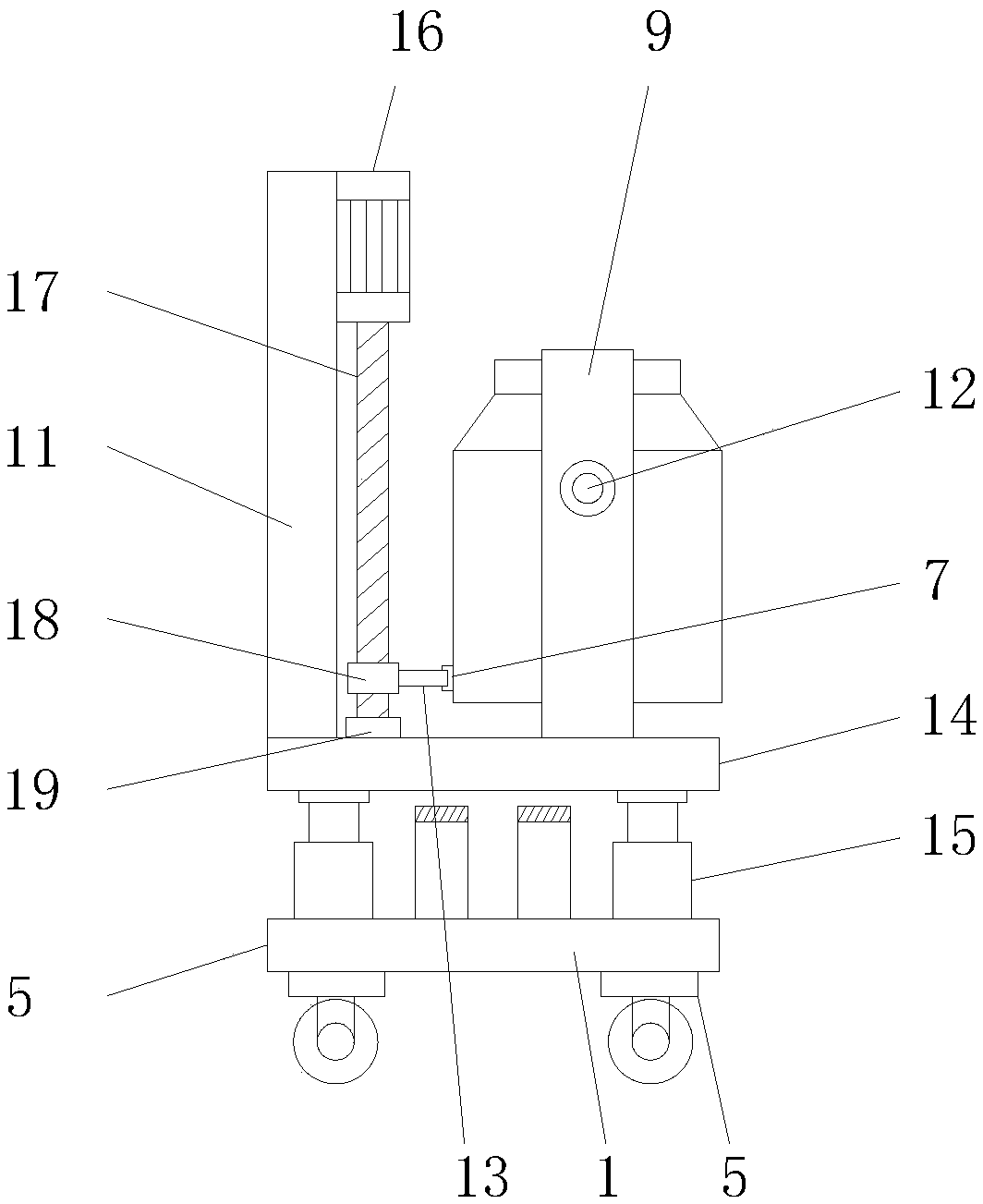

Automatic garbage collection and dumping device of intelligent cleaning robot

PendingCN110284477AImprove work efficiencyHigh degree of automationWater cleaningRefuse receptaclesRefuse collectionVehicle frame

The invention relates to the technical field of intelligent cleaning robots, in particular to an automatic garbage collection and dumping device of an intelligent cleaning robot. The automatic garbage collection and dumping device includes a garbage collection device and a garbage automatic dumping device installed at the rear end of the garbage collection device. The garbage collection device and the garbage automatic dumping device are all installed in the intelligent cleaning robot with a vehicle shell, and the garbage collection device is used for automatically collecting garbage, and the garbage automatic dumping device is used for automatically dumping the garbage. The garbage collection device includes a vehicle frame, a rolling brush assembly, a rolling brush transmission mechanism, a driving motor and a flow guiding device. The garbage automatic dumping device includes the vehicle frame, a lifting electric cylinder, a garbage can, a connecting rod mechanism and an overhead door electric cylinder. Compared with the prior art, more garbage can be collected, automatic dumping can be realized with no human input, the automation of the intelligent cleaning robot is improved, and the labor burden of people is reduced.

Owner:苏州高之仙自动化科技有限公司 +1

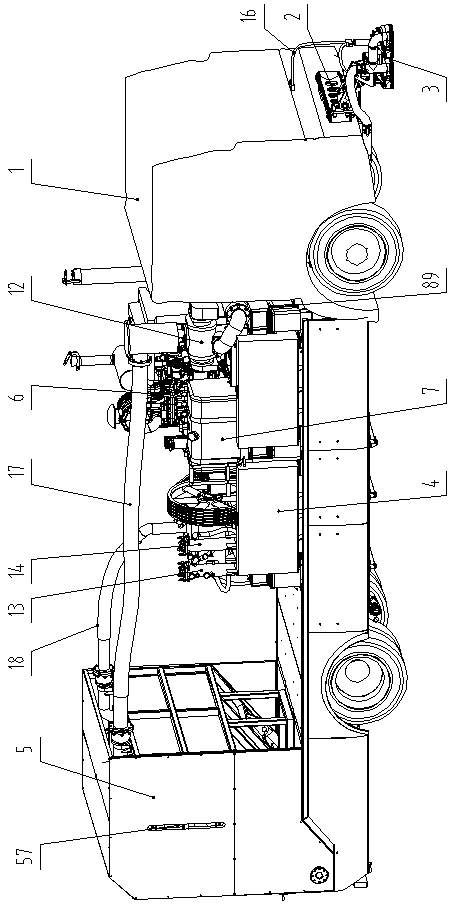

Marked line removing vehicle for highway construction

InactiveCN108149558AHigh strengthAvoid intensityRoad cleaningRoads maintainenceSlagHigh pressure water

A marked line removing vehicle for highway construction comprises a flat panel transporting truck, a double-disc type high pressure water removing trolley is arranged on the lower portion of the frontend of the flat panel transporting truck through a front swing lifting mechanism, a supporting frame and a pulpwater collecting and draining device located on the rear side of the supporting frame are arranged on a chassis of the flat panel transporting truck, a clean water tank is arranged in the supporting frame, a hydraulic system is arranged on the lower portion of the chassis of the flat panel transporting truck, an engine, a diesel tank, a power generator, a storage battery, an upper water pump, a high pressure water pump, a vacuum pump, a first-level filter system and a second-level filter system are arranged on the supporting frame, and a pulpwater inlet of the pulpwater collecting and draining device is connected with a pulpwater suction port of the double-disc type high pressurewater removing trolley through a flexible connection type slag suction pipe assembly. The marked line removing vehicle is convenient to operate, convenient to use and very good in removing effect, and can effectively improve the construction efficiency and the construction effect. Meanwhile, the marked line removing vehicle improves the automation degree of high pressure water removing, relievesthe labor intensity of workers, and accordingly promotes the popularization and application of high pressure water at the aspects of automation and industrialization.

Owner:WELL ROAD MACHINERY CO LTD

Combined type marking removal engineering vehicle for road construction

A combined type marking removal engineering vehicle for road construction comprises a flatbed transporter and a hand-push high-pressure water removal vehicle located on the front side of the flatbed transporter. The flatbed transporter is provided with a slag and water collection and drainage device, a clean water tank, a hydraulic system, an engine, a diesel tank, a generator, a storage battery,a charging pump, a high-pressure water pump, a vacuum pump, a primary filtration system and a secondary filtration system. The water outlet of the high-pressure water pump is connected to the water inlet of the hand-push high-pressure water removal vehicle through a high-pressure water outlet pipe. The suction port of the vacuum pump is connected to the upper portion of the front side of the slagand water collection and drainage device through a vacuumization pipe. The slag and water inlet of the slag and water collection and drainage device is connected to the slag and water suction port ofthe hand-push high-pressure water removal vehicle through a fixable connection type slag suction pipe assembly. The combined type marking removal engineering vehicle for road construction has a good removal effect, the waste water and the slag can be recovered, the construction efficiency and the construction effect are effectively improved, the degree of automation of high-pressure water removalis also improved, the labor intensity of the workers is reduced, and the popularization and application of high-pressure water to the fields of automation and industrialization are promoted.

Owner:WELL ROAD MACHINERY CO LTD

Automatic garbage dumping device

The invention relates to an automatic garbage dumping device, belonging to the field of public facilities. The automatic garbage dumping device is composed of a base, side walls, air cylinders 1, a three-position five-way solenoid valve, air cylinders 2, a first steel plate, air cylinders 3, a second steel plate, a third steel plate and a switch, wherein the side walls are vertically arranged on the base, the air cylinders 1 are arranged between the side walls by air cylinder shafts, the three-position five-way solenoid valve is arranged on the base, the air cylinders 2 are arranged on the first steel plate, the first steel plate is arranged between the air cylinders 1, the air cylinders 3 are arranged on the third steel plate, the second steel plate is arranged at the front end of air cylinder shafts of the air cylinders 3, the third steel plate is arranged at the lower end of air cylinder shafts of the air cylinders 2, and the switch is arranged on the side wall. The automatic garbage dumping device can automatically dump garbage.

Owner:JIANGSU NAQI ELECTROMECHANICAL EQUIP ENG CO LTD

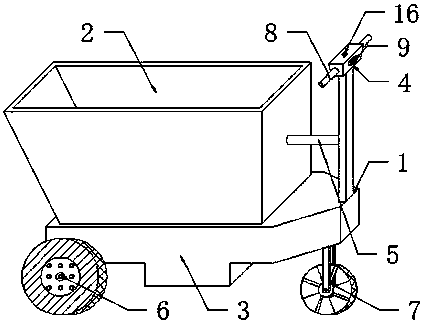

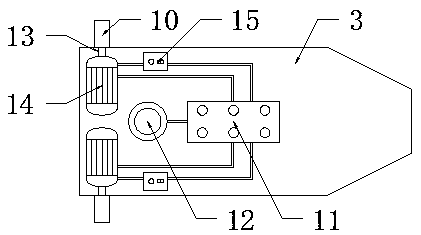

Transportation equipment special for construction engineering

InactiveCN107672655ARelieve pressureRealize automatic transportationSupporting partsHand carts with multiple axesDrive shaftArchitectural engineering

The invention discloses a special transportation equipment for construction engineering, which comprises a main body of the equipment, and the main body of the equipment is composed of a bucket arranged on the top of the main body of the equipment, a base arranged at the bottom of the bucket, and a hand pusher arranged on the top of the base. Special transportation equipment for construction projects, using the power of the battery to drive the Y2-90L-4 motor to rotate, and then drive the front wheel to rotate through the transmission shaft and bearings, so as to move forward quickly and realize automatic transportation, which greatly saves human resources and reduces work. The pressure of personnel improves the work efficiency. At the same time, the speed governor is controlled by the adjustment knob to adjust the speed of the Y2‑90L‑4 motor. The transportation speed can be adjusted arbitrarily according to the needs. It is easy to use and has very strong applicability, and through The electro-hydraulic rod pushes the body to make the body tilt to a position close to the ground to realize automatic dumping, which is very convenient and labor-saving.

Owner:威海红印食品有限公司

Automatic dumping garbage can based on motor driving

The invention discloses an automatic dumping garbage can based on motor driving, and relates to the technical fields of environmental sanitation and environmental protection. The automatic dumping garbage can comprises a supporting device, a box and a chuck; the box is fixedly hung on the supporting device and rotatably dumps garbage through motor driving, and a circular clamping base is fixed to the end of a supporting column; the clamping base is connected with the box in the mode of cooperating with the chuck; and a circular groove is in interference fit with a transmission rod. According to the automatic dumping garbage can based on motor driving, a servo motor is arranged to control the box to rotate, a sanitation worker does not need to manually dump garbage, automatic garbage dumping is achieved, cleaning work of the sanitation worker is convenient, and the advantages of being simple in structure, convenient to use and practical are achieved; by arranging the supporting device, the box is supported, vertical rotation of the box is achieved, therefore, the assembling mode among structures is reduced, structural materials are reduced, the production cost is reduced, and the installing and maintaining efficiency is improved.

Owner:合肥巨步机械科技有限公司

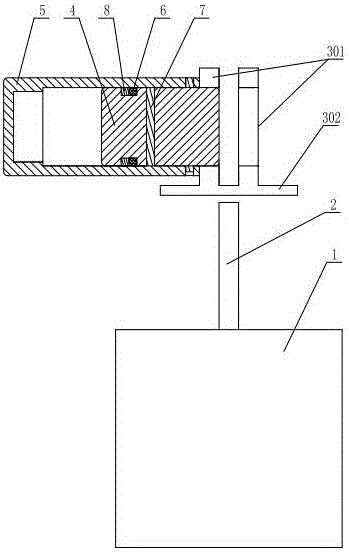

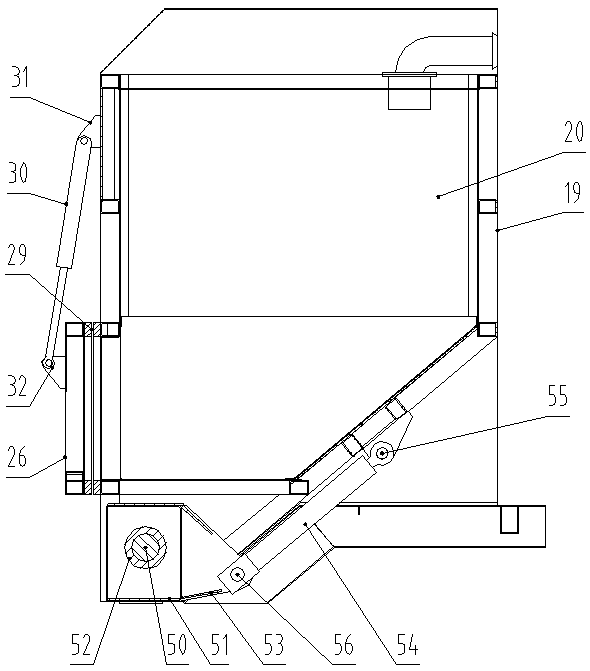

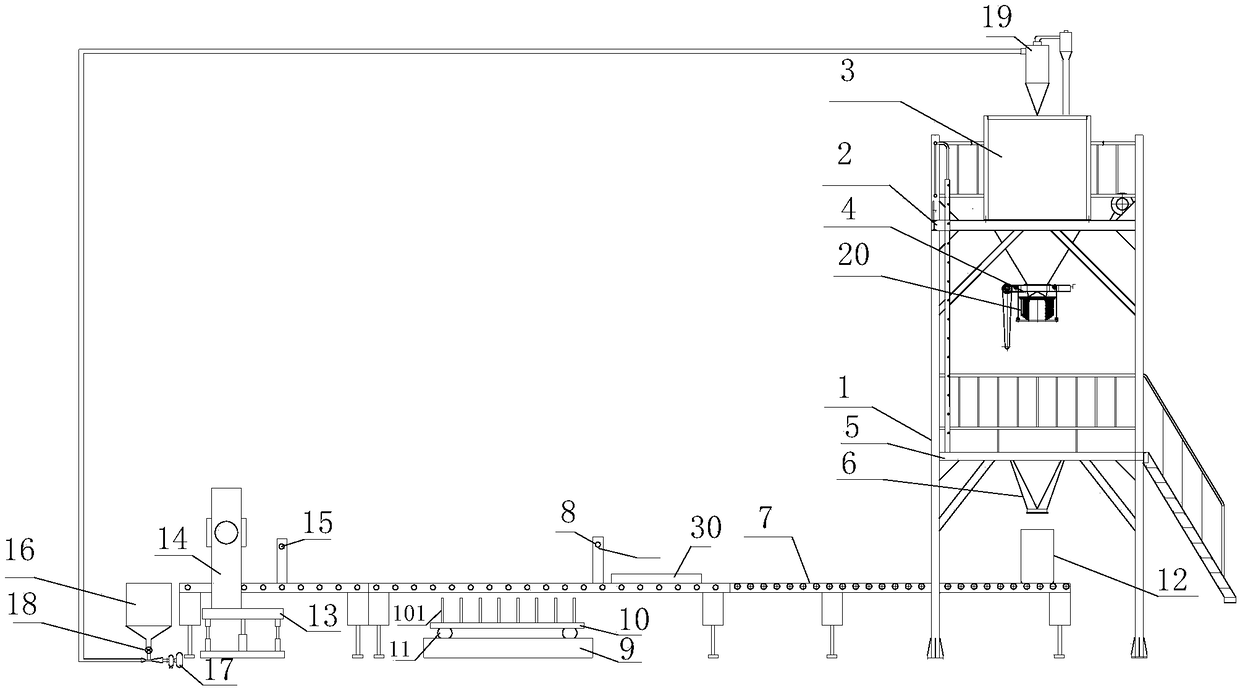

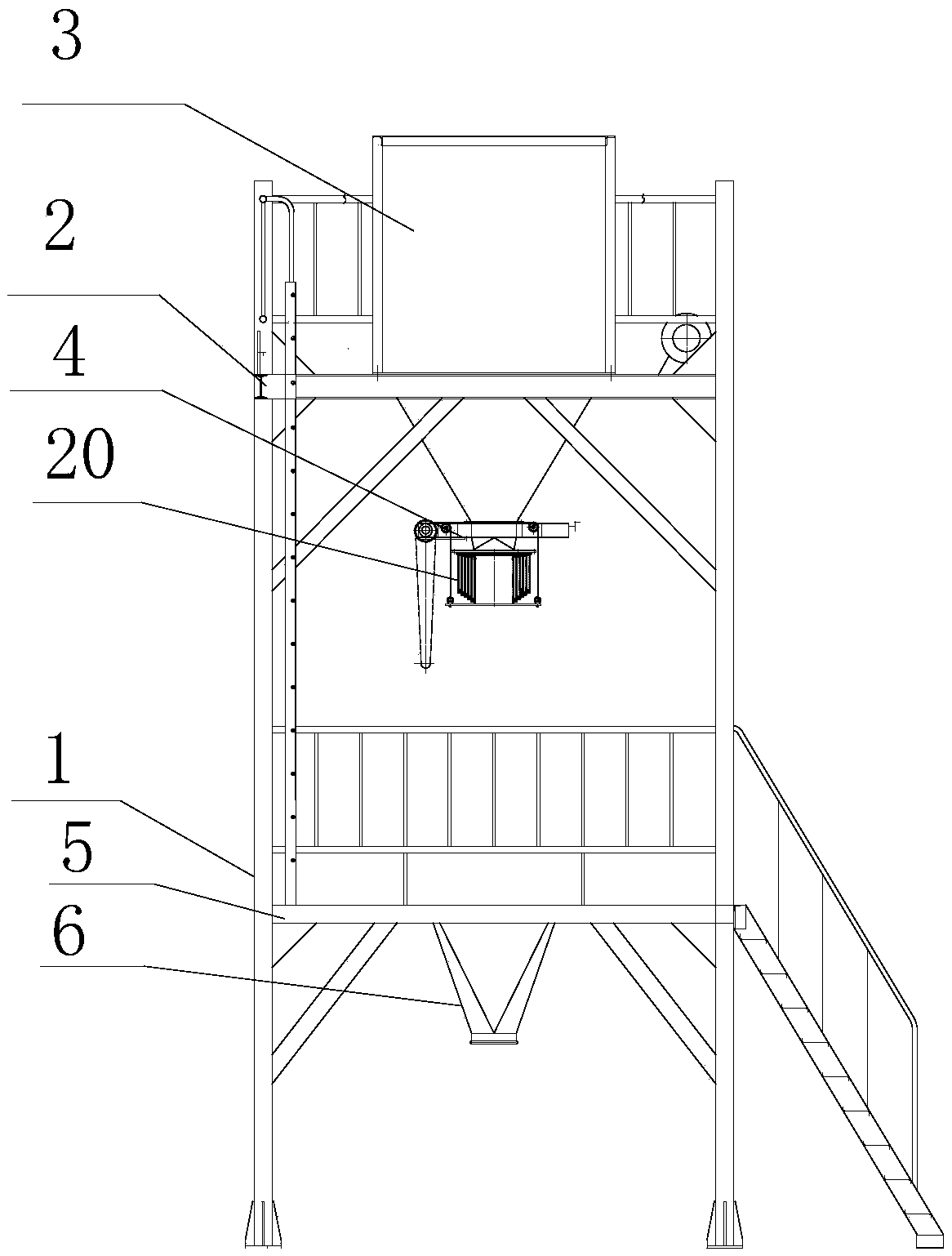

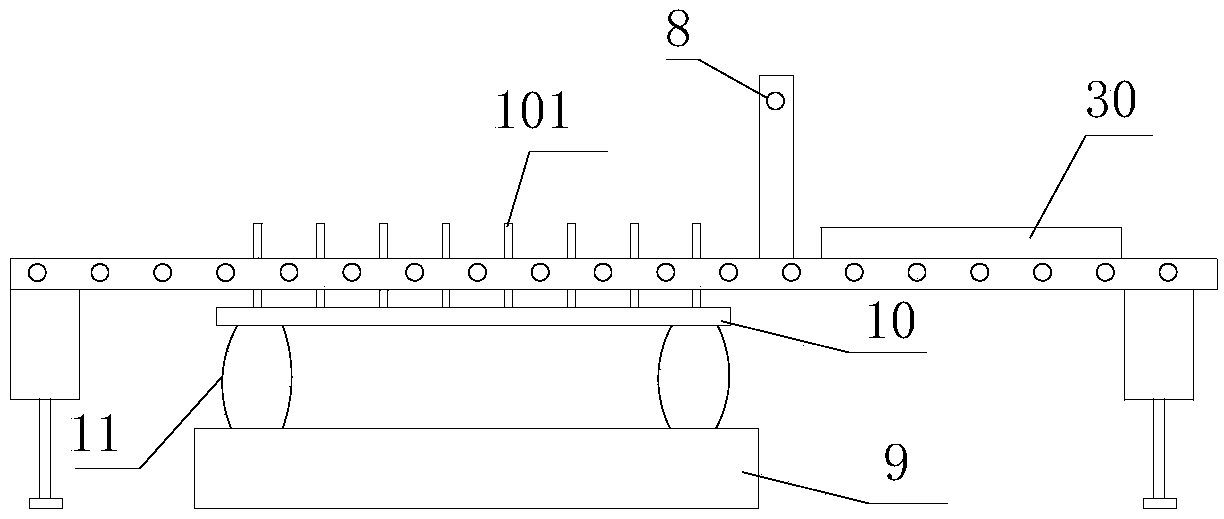

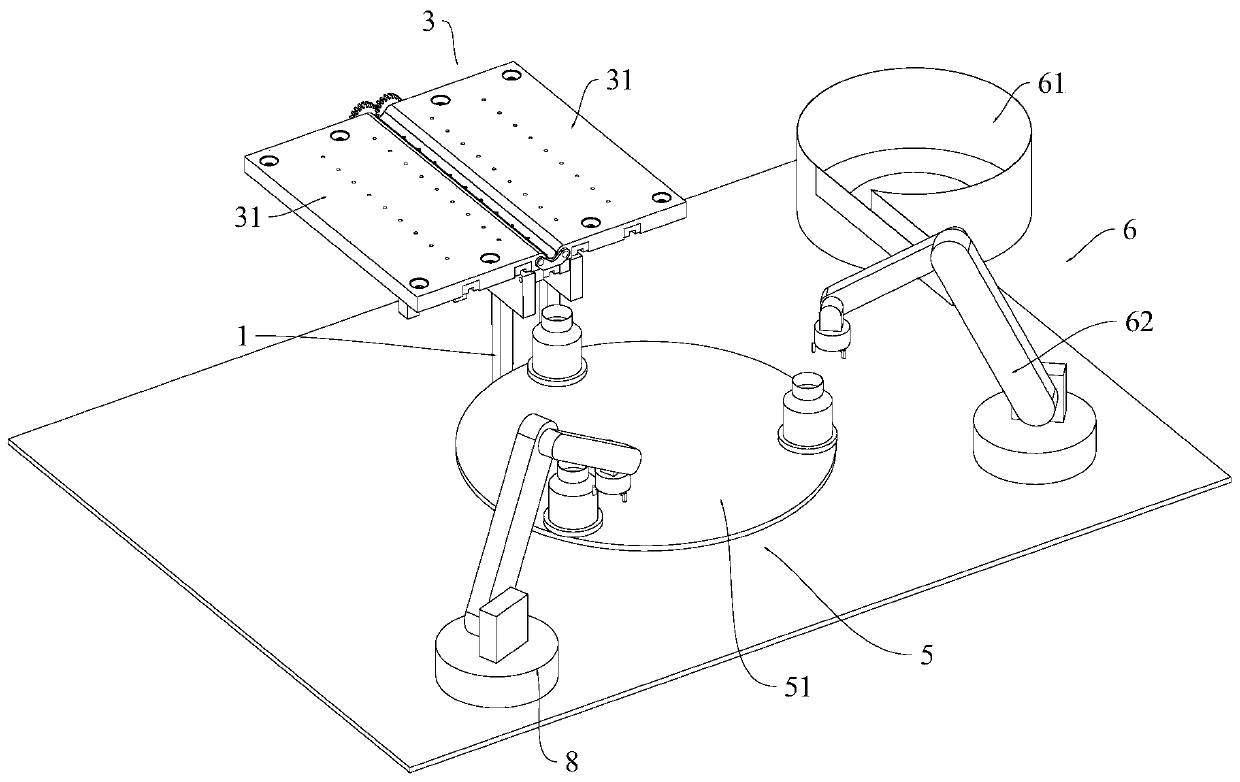

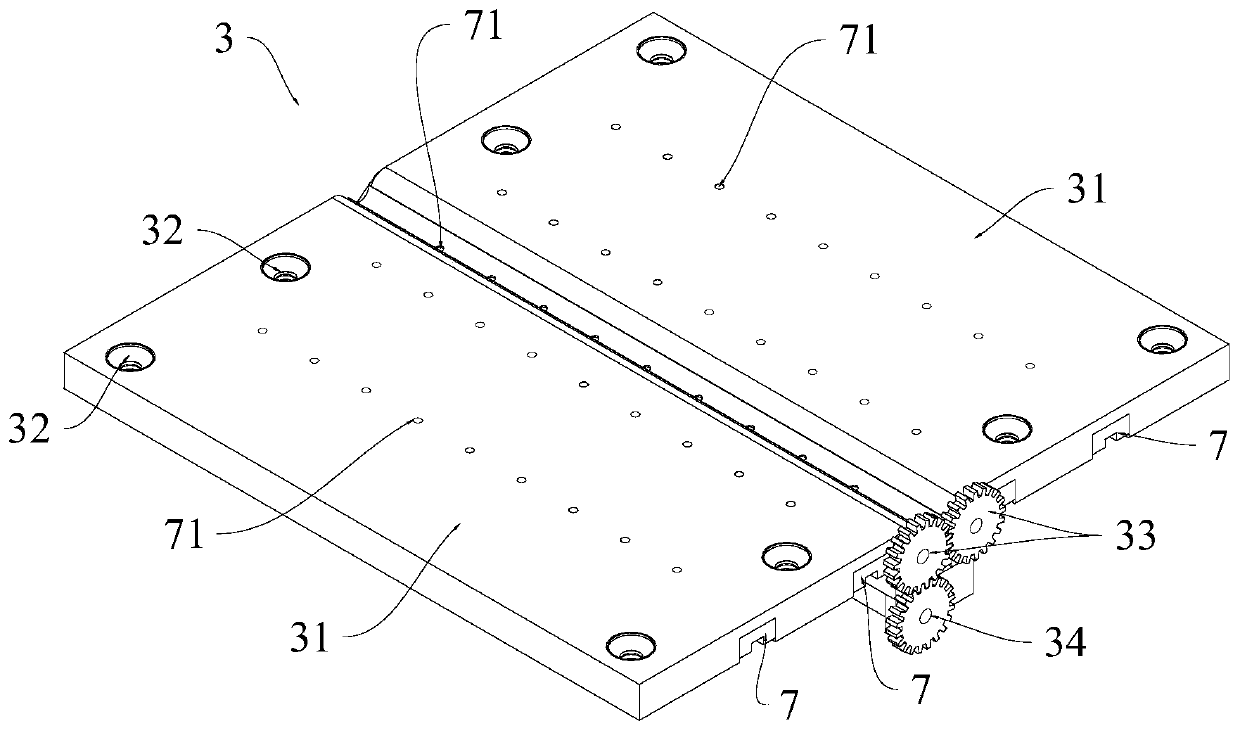

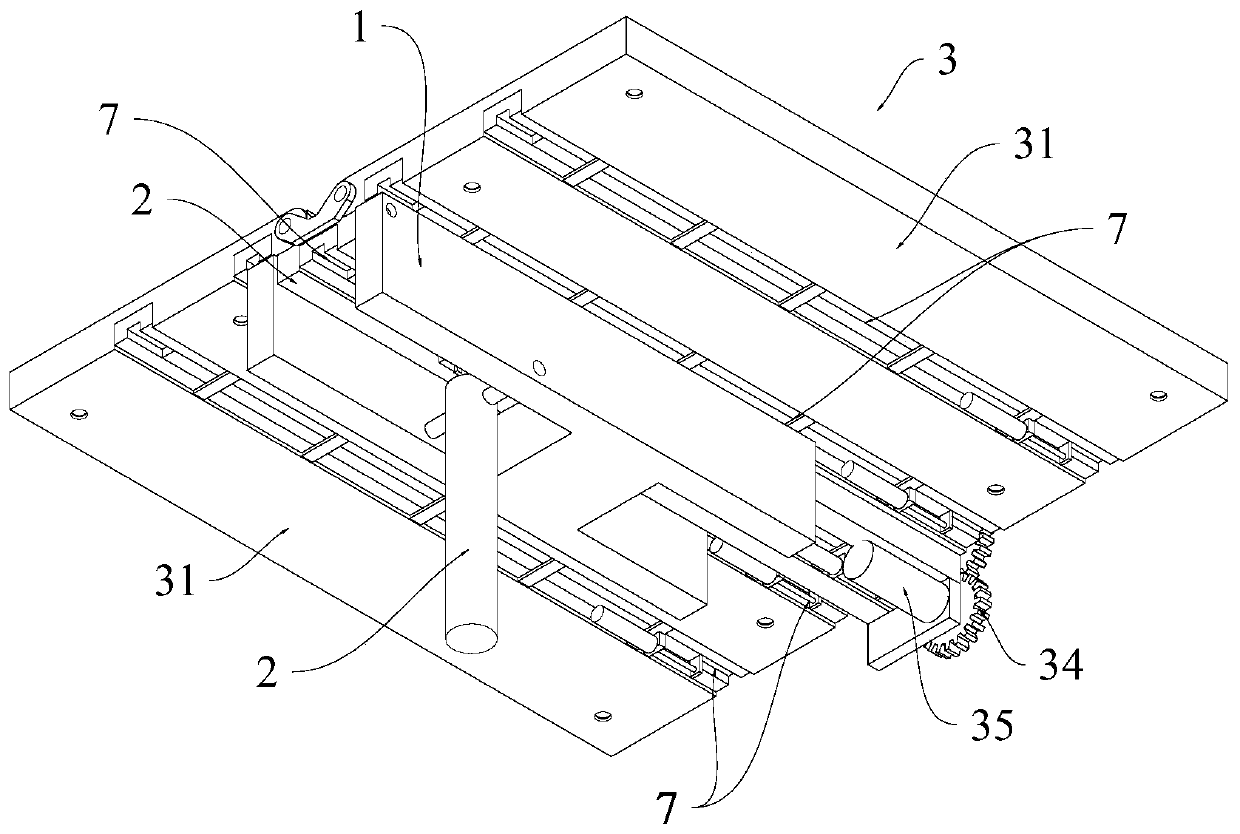

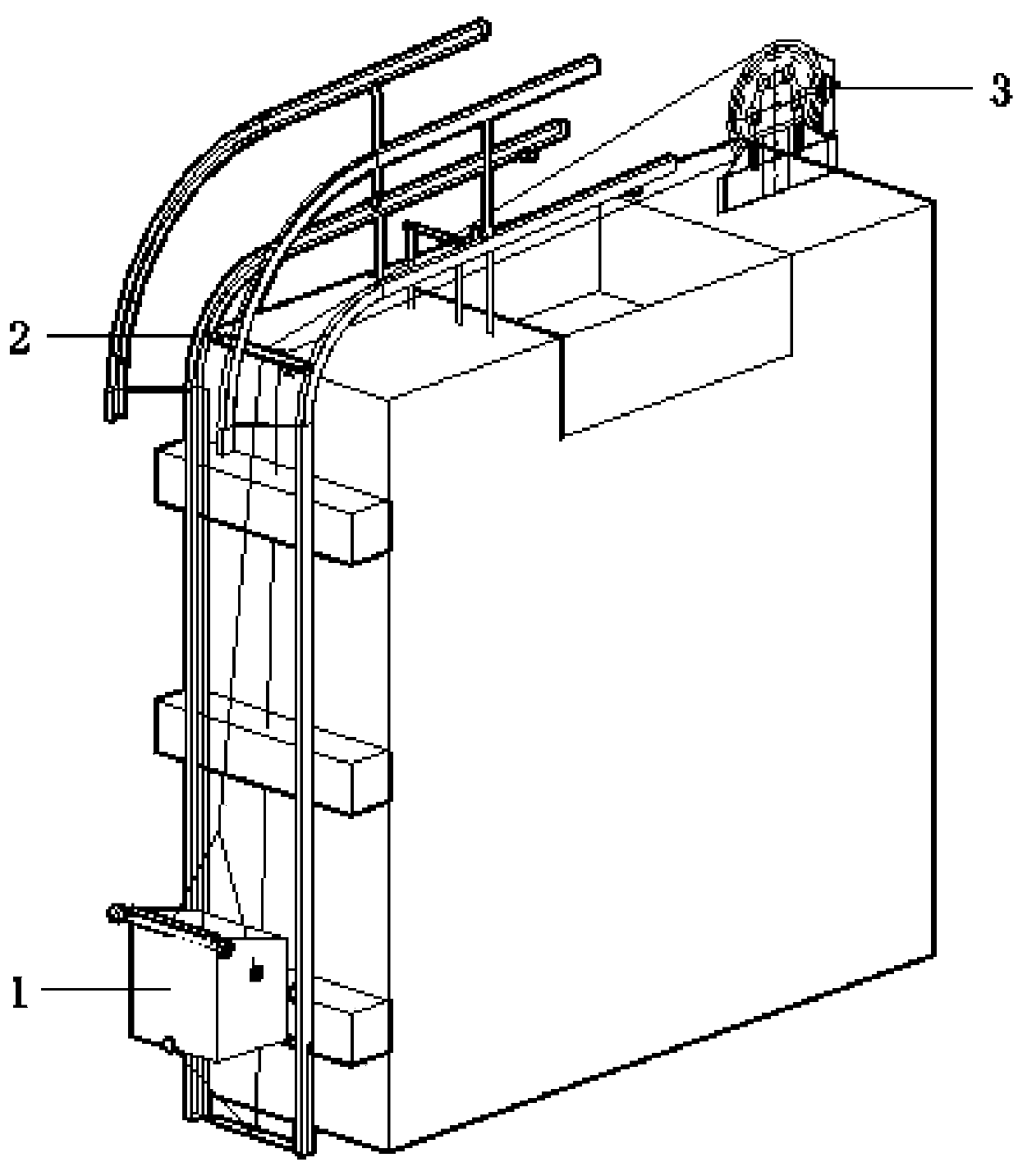

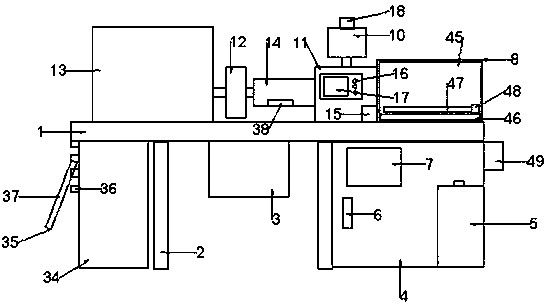

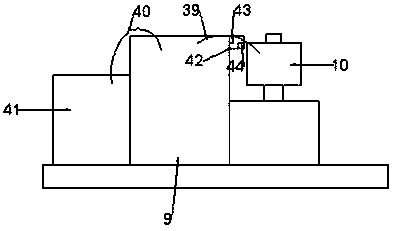

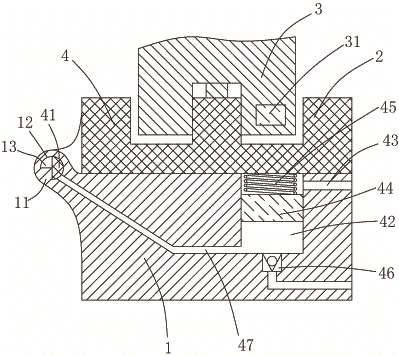

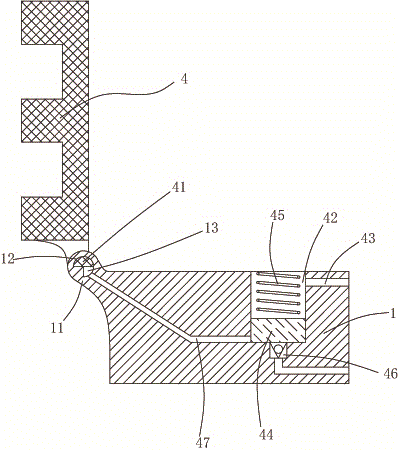

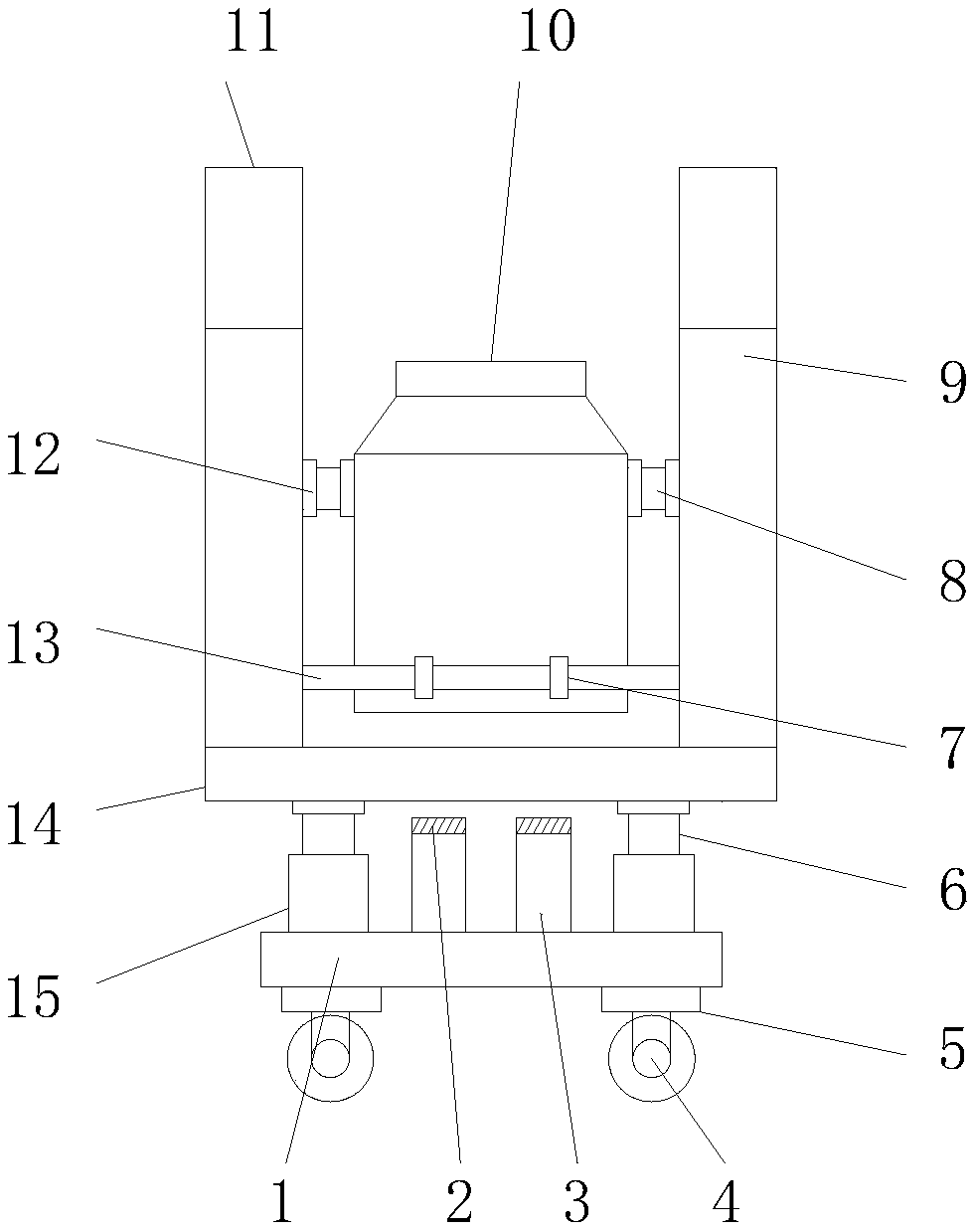

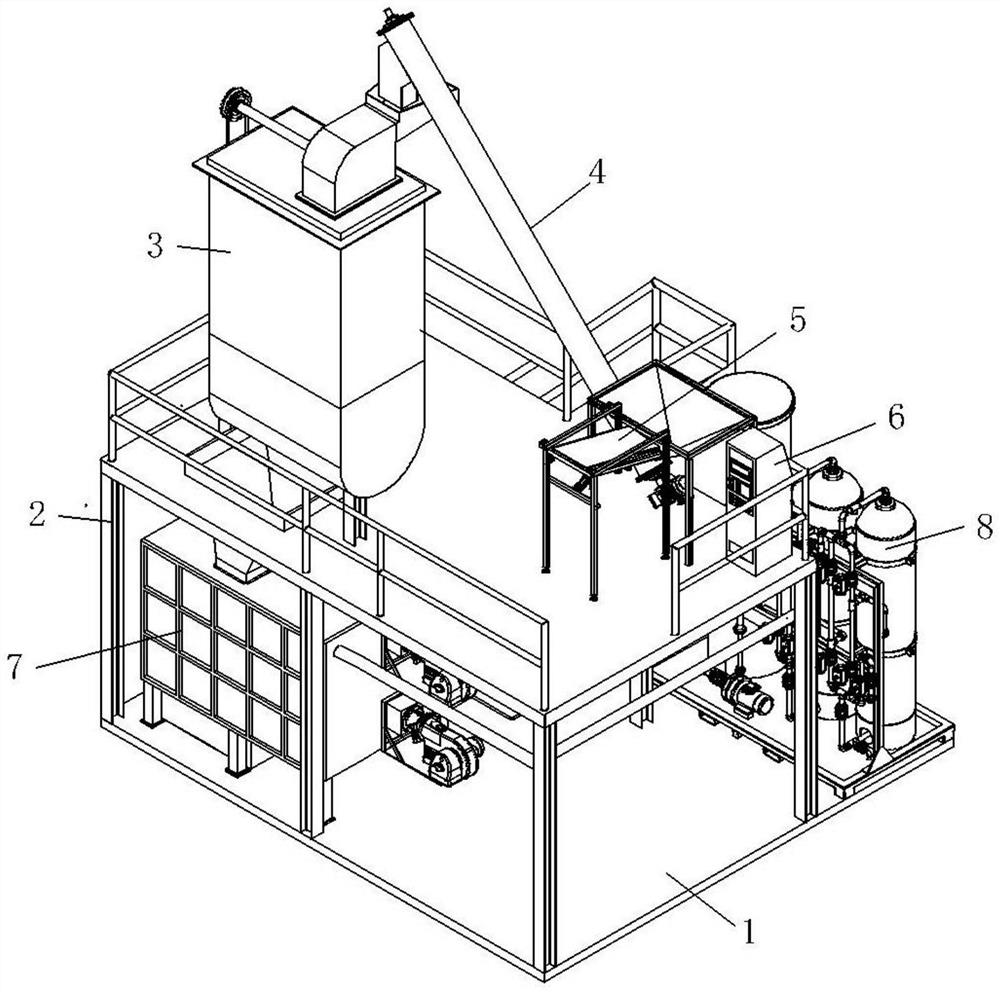

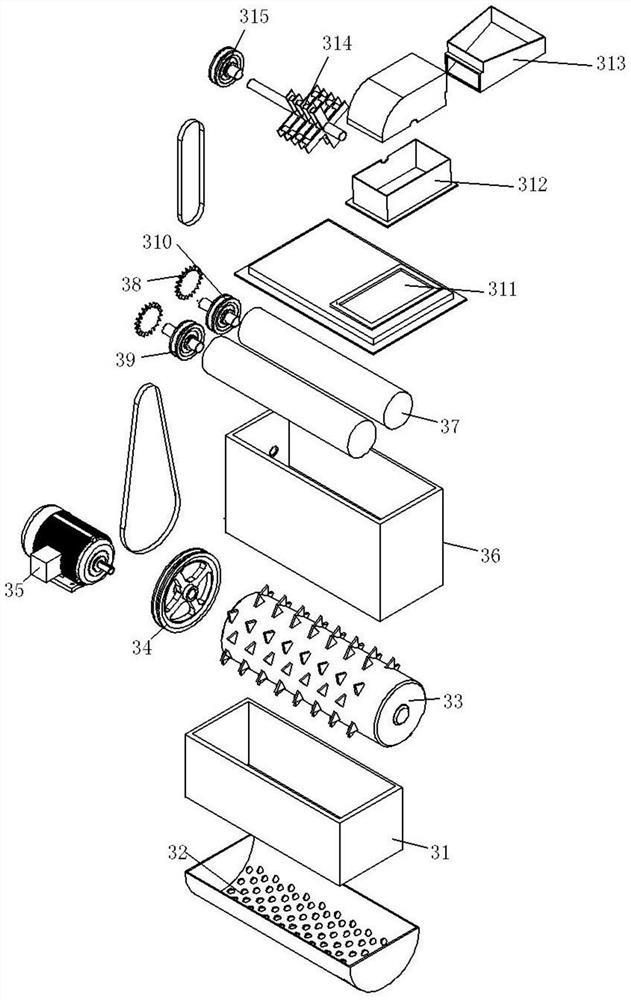

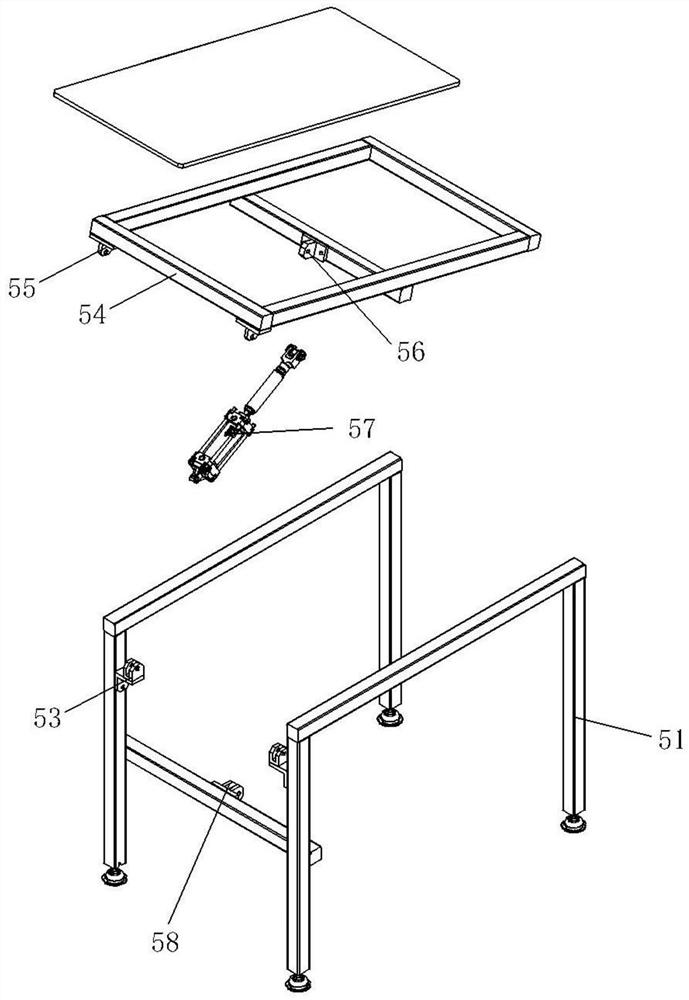

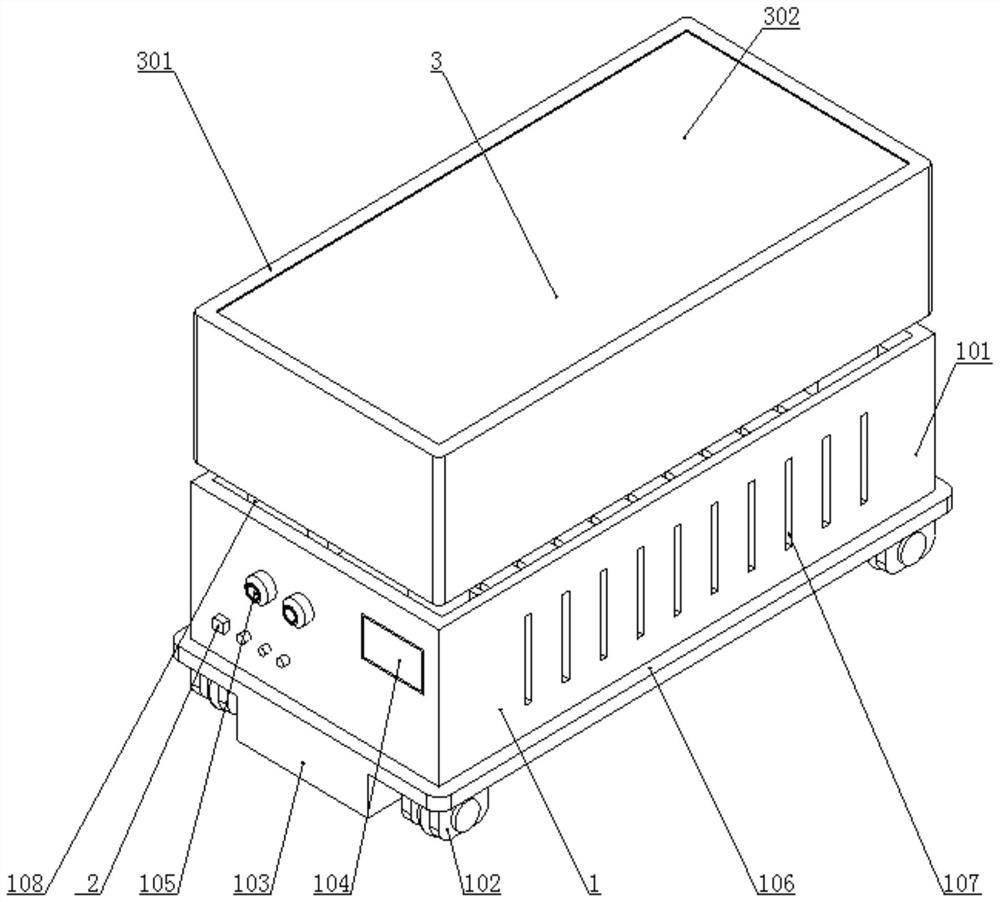

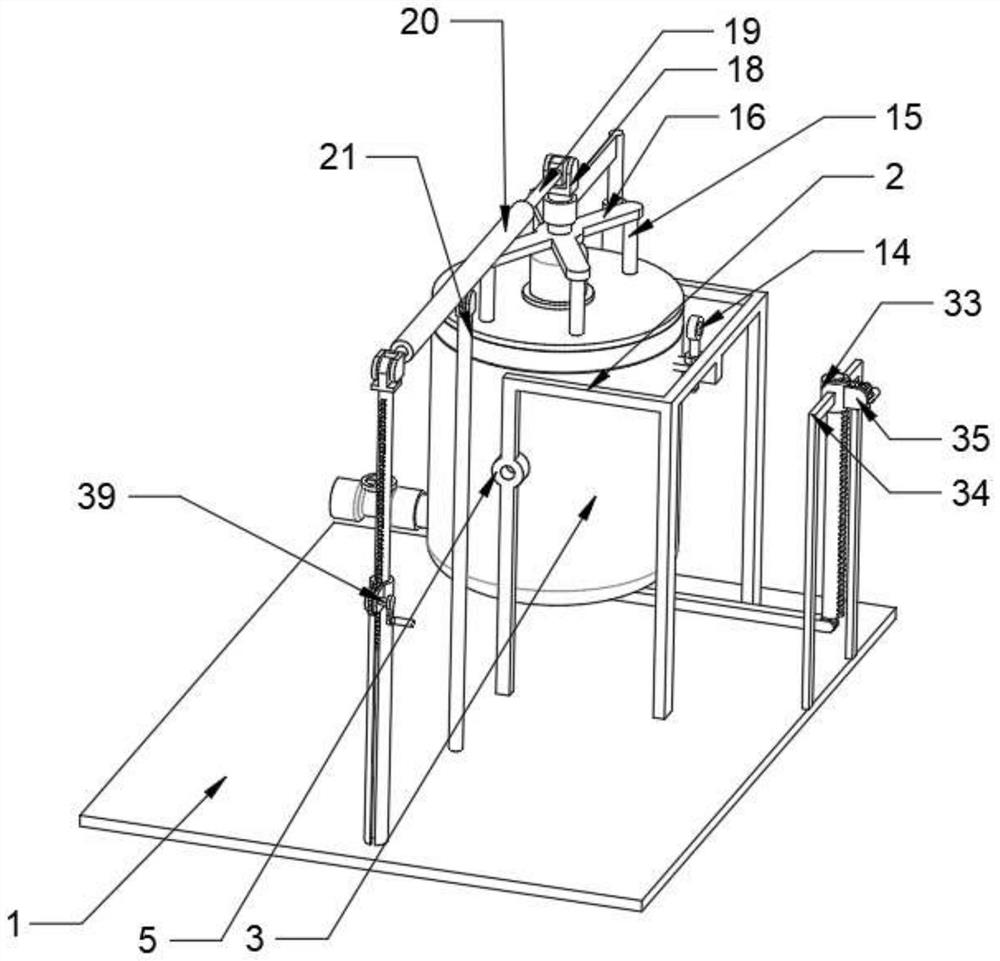

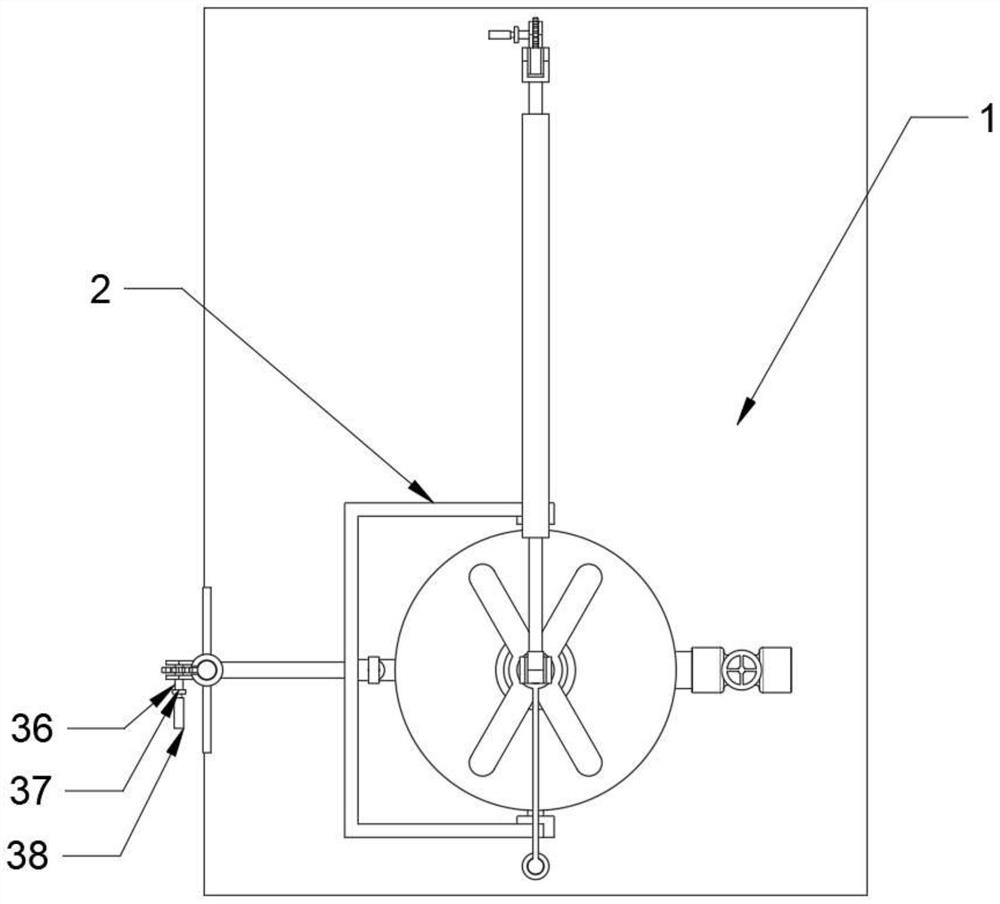

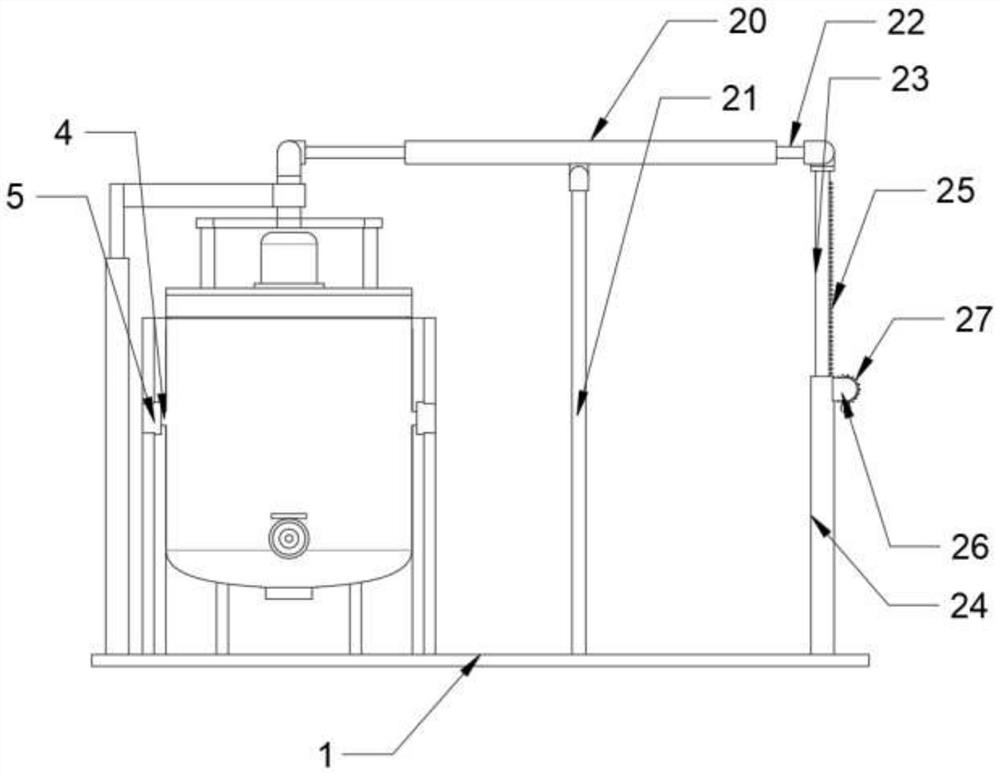

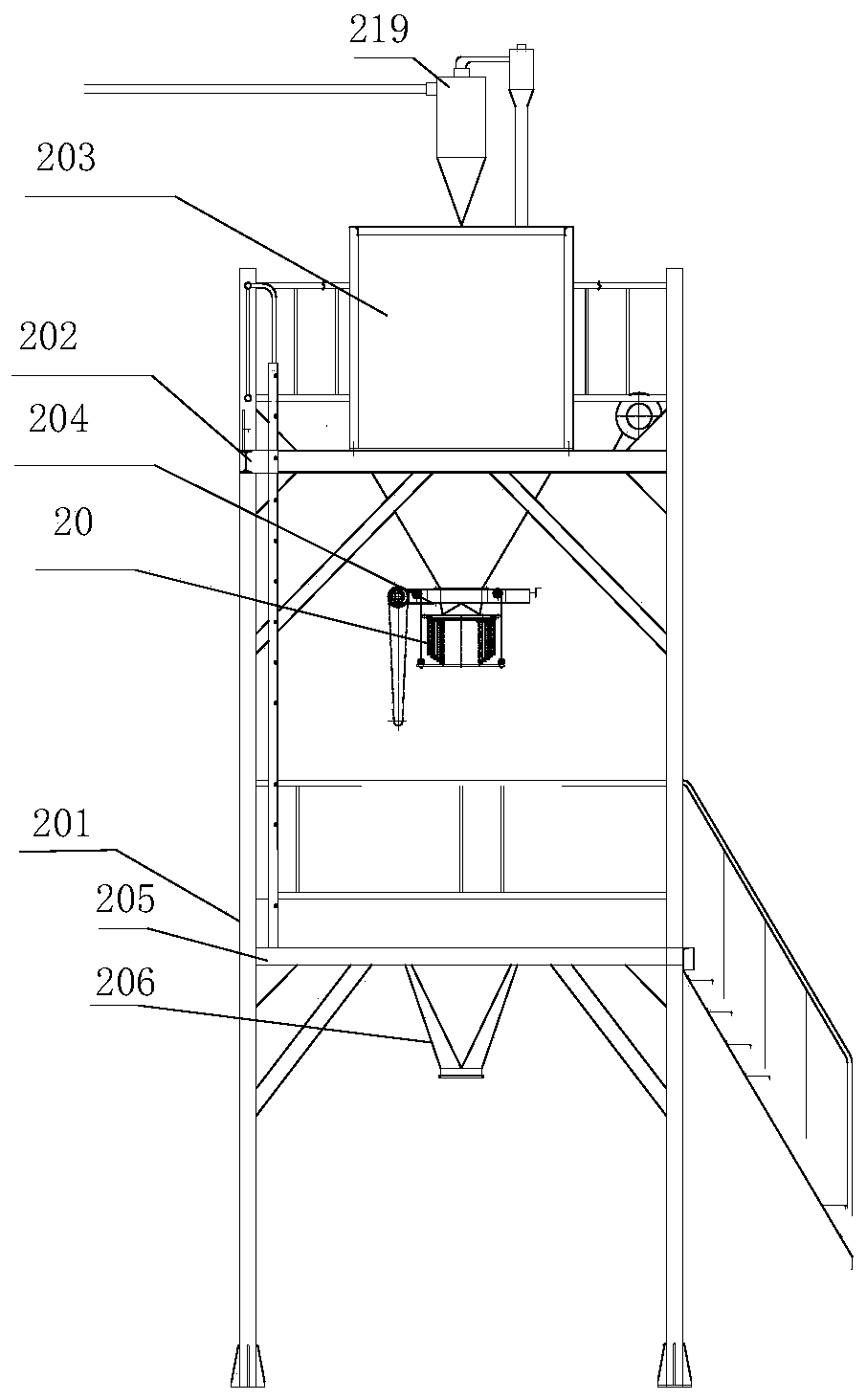

Automatic detection system for solid material measurement of gravity type automatic-charging weighing apparatus

ActiveCN109399235AImplement automatic detectionRealize automatic dumpingLoading/unloadingStorage devicesEngineeringAutomatic testing

The invention provides an automatic detection system for solid material measurement of a gravity type automatic-charging weighing apparatus. A feed system is used for feeding powder or particle materials to a to-be-detected gravity type automatic-charging weighing apparatus; the to-be-detected gravity type automatic-charging weighing apparatus implements weighing in real time; after weighing is ended, the materials fall into a container via a discharging pipe and are conveyed to a detection station through a conveying line; the detection system is used for weighing the weight of the materialsinside the container, calculating the net weight and rechecking the weighing; after weighing is ended, the conveying line is started to convey the container to an unloading station; after an unloadingsystem detects the container, a clamping mechanism is used for clamping and fixing the container; a lifting platform moves up; a turnover mechanism turns over to pour the materials inside the container to the unloading station; after unloading is ended, the unloading system is reset; and a returning system is used for returning the materials into a first bin of the feed system in order to implement automatic recycling of the materials and automatic replenishing of the first bin. The detection system provided by the invention can realize automatic detection of the dynamic measurement performance of the gravity type automatic-charging weighing apparatus.

Owner:JIANGSU INST OF METROLOGY

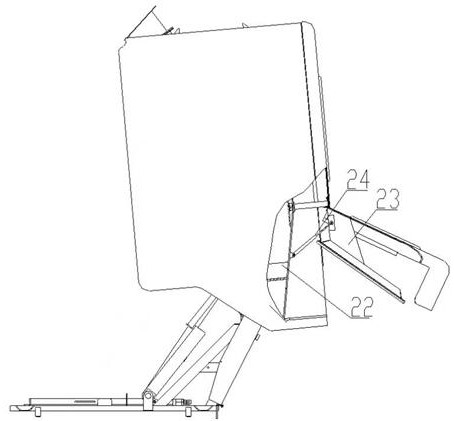

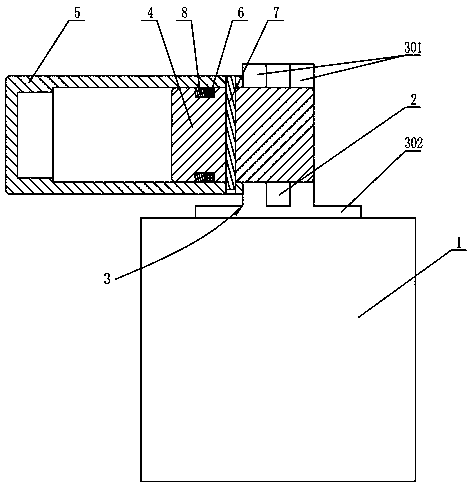

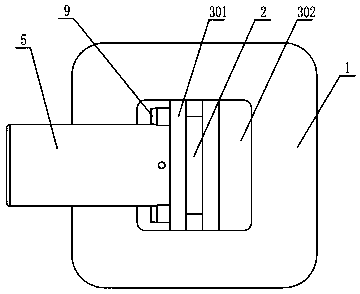

Pouring and packaging device and method for powdery medicine

ActiveCN110789748AImprove efficiencyAvoid adverse effectsPackaging automatic controlSolid materialStructural engineeringManufacturing engineering

The invention discloses a pouring and packaging device and method for powdery medicine. The device comprises a pouring assembly and a vessel carrying cover assembly. The pouring assembly comprises anassembly base body, an overturning base body and a folding and collecting assembly; and one side of the overturning base body is rotationally mounted relative to the assembly base body, and relative rotation is driven by a first driving unit. The folding and collecting assembly comprises two folding plates, the two folding plates are symmetrically mounted on the overturning base body, and the twofolding plates can be switched between an unfolded state and a folded state. A plurality of suction cups are arranged on the two folding plates. The vessel carrying cover assembly comprises a vessel carrying device and a cover mounting device. According to the pouring and packaging device and method for the powdery medicine, by arranging the overturning base body and the folding and collecting assembly, the processes of automatically pouring the powdery medicine into a vessel and packaging the vessel can be achieved, the efficiency is high, and the adverse effect of dust generated by the powdery medicine on people can be avoided because manual operation is not needed.

Owner:SHANDONG XIEHE UNIV

Automatic slag discharging device for rapid construction of subway and automatic slag discharging method

PendingCN109665469ASave construction siteReduce on-site operations and ground coordination personnelLifting devicesSlagSteel columns

The invention provides an automatic slag discharging device for rapid construction of a subway and an automatic slag discharging method. The device comprises a slag car for conveying muck, a travelingmechanism for enabling the slag car to travel, and a power system for providing traveling power for the slag car; the bottom plate of the slag car is provided with a bolt catch and a bolt; a steel column is erected and welded in right angle steel of the bolt catch; the door bolt is a three-way cylindrical curved rod, a horizontal rod member making contact with a door panel of the door bolt is provided with a cylindrical hole perpendicular to the axis of the horizontal rod member; the cylindrical hole is sleeved with the steel column; when the slag car advances to a designated position, the door bolt clamped in the right angle steel rotates around the steel column on the bolt catch, the door panel is opened, and slag is discharged; and when the slag car is subjected to reverse force, the door bolt rotates in the opposite direction, and the door panel is closed. Through the slag discharging device, automatic dumping of the muck and automatic reset of the bottom plate of the slag car canbe achieved, on-site operation and ground coordination personnel are reduced, the labor intensity of workers is relieved, and safe production is promoted.

Owner:ZHONGJIAN SUIDAO CONSTR CO LTD +2

an injection molding machine

ActiveCN109228114BTo achieve the effect of positioning and lockingNo manual operationTemperature controlElectric machinery

The invention discloses an injection molding machine. The injection molding machine comprises a rack, wherein a supporting leg is arranged below the rack; a motor is arranged at the left side below the rack; a cabinet is arranged at the right side below the rack; a dehumidification device is arranged on an inner wall of the cabinet and a cabinet door is arranged on an outer wall of the cabinet; acontrol panel is arranged on the surface of the cabinet door; the control panel is connected with a motor; an extruding machine, a feeding barrel, a heating cavity, a filtering cavity and a power device are arranged above the rack in sequence from front to back; the extruding machine and a driving device are connected and the driving device is located at one side of the rack; the extruding machineis connected to an inner wall of the heating cavity; the heating cavity is connected with the filtering cavity through a material conveying pipeline; a temperature detector is mounted on the inner wall of the heating cavity, and a temperature controller and a temperature display instrument are arranged on the surface of the heating cavity; a treatment box is arranged at the top of the feeding barrel and the treatment box is connected with a dehumidifier. The injection molding machine is simple in structure and convenient to use; the production cost is greatly saved, and the injection moldingtemperature can be monitored in real time; impurities in melted plastic grains can be filtered and the working efficiency is improved.

Owner:邵东市顺发工业有限公司

Containerization treatment case for environmental protection engineering

ActiveCN110524931AEasy to disengageGuaranteed shipping volumeTransportation and packagingSolid waste disposalContainerizationEngineering

The invention discloses a containerization treatment case for environmental protection engineering, including a container and a partition plate, wherein the periphery of the partition plate is fixedlyconnected with the inner surface of the container; the container is divided into a dry treatment chamber and a wet treatment chamber by the partition plate; first hydraulic telescopic rods are fixedly connected to the left side and the right side of the partition plate correspondingly; extrusion plates are fixedly connected to the surfaces of push rods of the first hydraulic telescopic rods; a first inlet is formed in the top of the container and located in the top of the dry treatment chamber; and first supporting rods are fixedly connected to the bottom of an inner cavity of the dry treatment chamber. The invention relates to the technical field of environmental protection engineering. According to the containerization treatment case, dry garbage is directly packaged in the container; the wet garbage is subjected to moisture treatment, so that the transportation volume of the dry garbage is effectively guaranteed, the wet garbage can be directly pretreated in the transportation process, the work of a garbage treatment plant in the later period is facilitated, the efficiency is greatly improved, generation of dangerous environments is effectively reduced, and the environment is protected.

Owner:HANGZHOU BAOLI SPORTS FACILITIES ENG

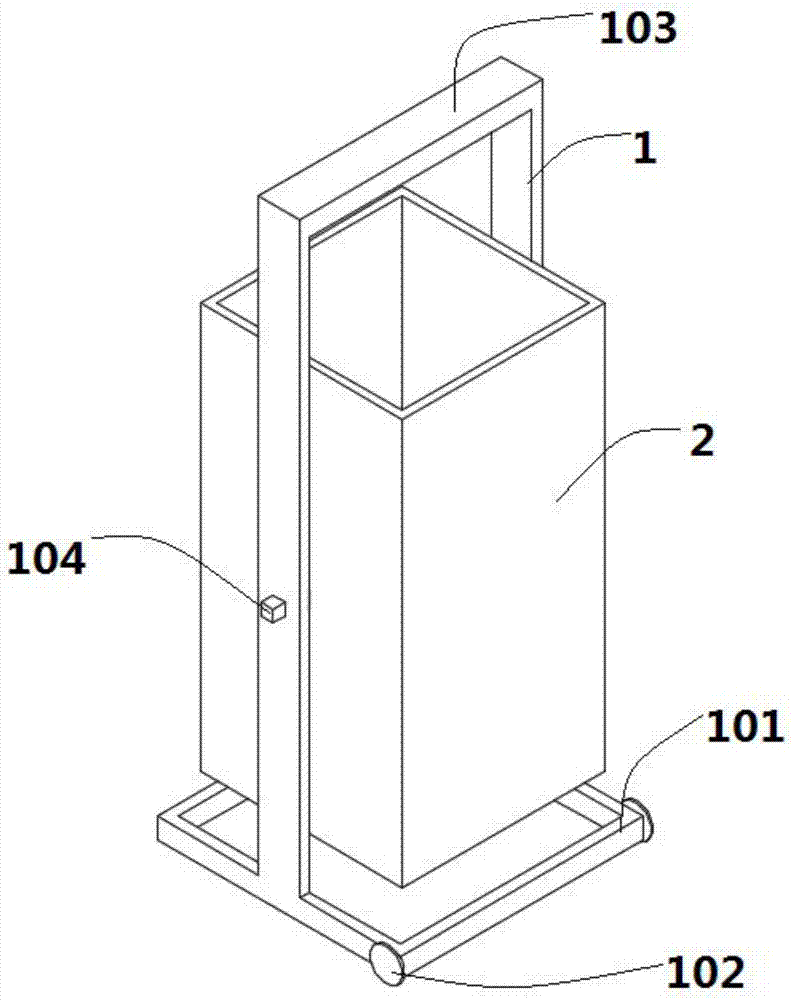

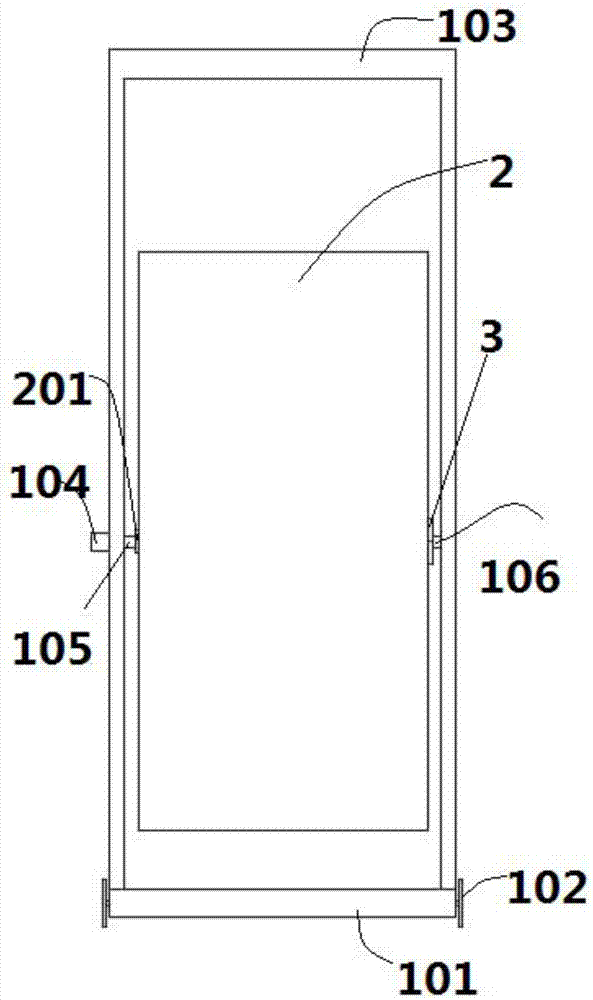

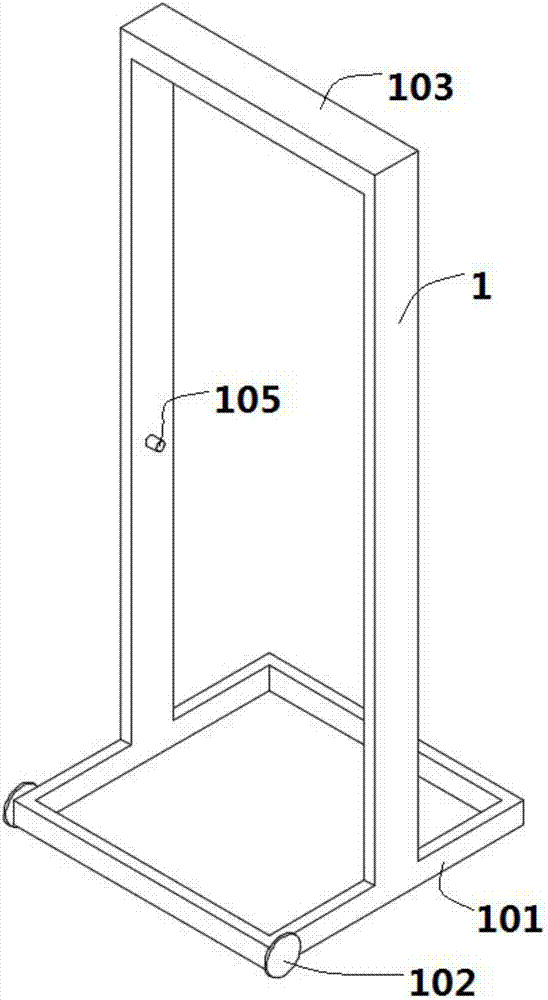

Combined type window frame

ActiveCN106837059ARealize automatic dumpingAvoid accumulationWindow/door framesWindow cleanersControl theoryMagnet

The invention discloses a combined type window frame. The combined type window frame comprises a window frame body. A sliding track is arranged on the window frame body, and a window is arranged on the sliding track. The sliding track is formed by combining a plurality of sliding blocks, a rotating shaft is arranged on the sliding blocks, a connecting arm with a through-hole is arranged on the window frame body, and the rotating shaft rotates in the through-hole. A channel with the position changing along with the rotating of the rotating shaft is formed between the rotating shaft and the side wall of the through-hole. A groove is formed in the bottom of the rotating blocks, a vent hole is formed in the side face of the upper end of the groove, a first magnet is arrange in the groove, a spring is arranged at the upper end of the first magnet, a one-way valve for air inlet is arranged at the bottom of the groove, and an air channel is formed between the bottom of the groove and the connecting arm. The air channel is disconnected with the channel when the rotating blocks are attached to the window frame body, and the air channel communicates with the channel when the rotating blocks are separated from the window frame body. A second magnet matched with the first magnet is arranged at the bottom of the window. By adoption of the combined type window frame, automatically dumping of dust in the sliding track is achieved, and thus dust and impurities are prevented from accumulating in the sliding track of the window fame body.

Owner:南京长恒建筑节能有限公司

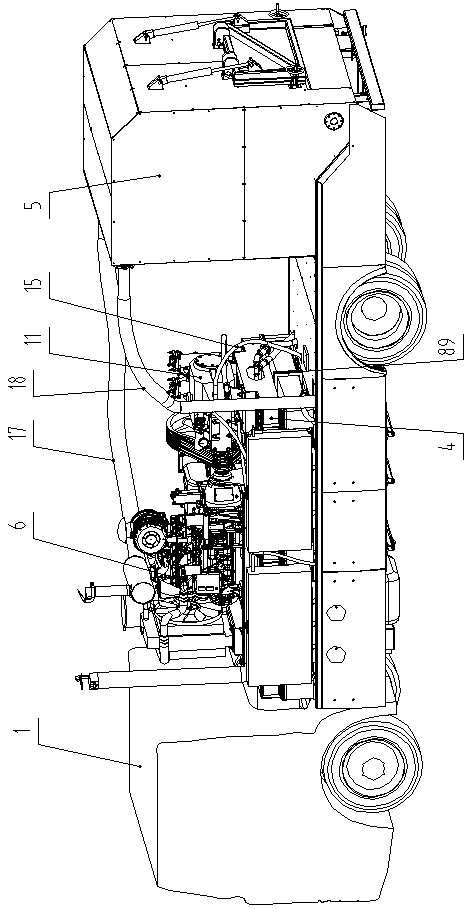

Garbage self-dumping road sweeper and garbage self-dumping method

The invention discloses a garbage self-dumping road sweeper and a garbage self-dumping method. The garbage self-dumping road sweeper comprises a drive-by-wire chassis, a fan assembly, a box assembly, a sweeping device, a dust suction device and an unmanned driving module. The box assembly comprises a garbage box body, a lifting oil cylinder and an automatic opening and closing mechanism, the fan assembly is arranged on the garbage box body, a rear door is arranged on the garbage box body, and the automatic opening and closing mechanism is arranged between the garbage box body and the rear door and used for driving the rear door to be opened or closed relative to the garbage box body; and the unmanned driving module is used for acquiring feedback data of the sweeping device, the garbage box body and the drive-by-wire chassis and controlling the sweeping device, the fan assembly, the lifting oil cylinder, the dust collection device and the drive-by-wire chassis to execute related instructions. The road sweeper travels to the garbage dumping point along the optimal path, garbage is automatically dumped by adjusting the posture of the road sweeper, manual operation is not needed in the garbage self-dumping process, and the sweeping operation efficiency is remarkably improved.

Owner:XUZHOU XUGONG ENVIRONMENTAL TECH CO LTD

Dye barrel with automatic pouring function for chemical engineering

InactiveCN109160062ASmooth rotationRealize automatic dumpingBottle emptyingExternal fittingsHydraulic cylinderPiston

The invention discloses a dye barrel with automatic pouring function for chemical engineering. The dye barrel comprises a base, the two ends of the top of the base are provided with hydraulic cylinders, the output ends of the hydraulic cylinders are provided with a mounting plate through piston push rods, the two ends of the top of the mounting plate are provided with first fixing rods, the portions, on one sides of the first fixing rods, of the top of the mounting plate are provided with second fixing rods, connecting rods are arranged between a barrel body and the first fixing rods through first bearings, a fixing ring is arranged at the bottom end of the surface of the barrel body, a motor is installed at the top end of the surface of each second fixing rod, the output ends of the motors are connected with second bearings through rolling screw rods, rolling nuts are installed on the rolling screw rods, and a connecting rope arranged between the rolling nuts penetrate through the fixing ring. According to the dye barrel, the hydraulic cylinders, the motors, the rolling screw rods, the rolling nuts, the connecting rope, the fixing ring and the first bearing structures are arranged, so that the problems that automatic pouring can not be achieved, and the lifting function is not achieved are solved.

Owner:芜湖芬特勘测服务有限公司

Drainage filtering system suitable for steel structure building

ActiveCN111501981AAchieve cloggingRealize automatic dumpingFatty/oily/floating substances removal devicesSewerage structuresPipe waterArchitectural engineering

The invention discloses a drainage filtering system suitable for a steel structure building. The drainage filtering system comprises a water guiding device, a first filtering device, a flooding watercollecting device and a filter residue collecting device, wherein a bucket pipeline is arranged on the right side of the system, an air inlet is formed in the top of the bucket pipeline, air in the bucket pipeline communicates with outside air, and a bucket pipeline cover plate is arranged on the upper portion of the left side of the bucket pipeline; the filter residue collecting device is arranged on the left side of the system, the top of the filter residue collecting device is closed, and a filter residue pipeline cover plate is arranged on the upper portion of the right side of the filterresidue pipeline; and the first filtering device occupies the lower middle position, and the side wall of the middle of a sewer pipeline in the first filtering device communicates with the bottom of the bucket pipeline through an arranged connecting pipe. According to the drainage filtering system suitable for the steel structure building, the structural distribution is adopted in the system, water flow is fully filtered, a filter screen is not prone to being blocked, automatic garbage dumping can be achieved, labor cost is reduced, and work efficiency is improved.

Owner:黑龙江省建筑安装集团有限公司

Large-scale engineering vehicle and manual-push combined type road marking removal device

InactiveCN108086111ACompact layoutIncrease the volume of the water tankRoads maintainenceWater pipeElectric generator

Owner:WELL ROAD MACHINERY CO LTD

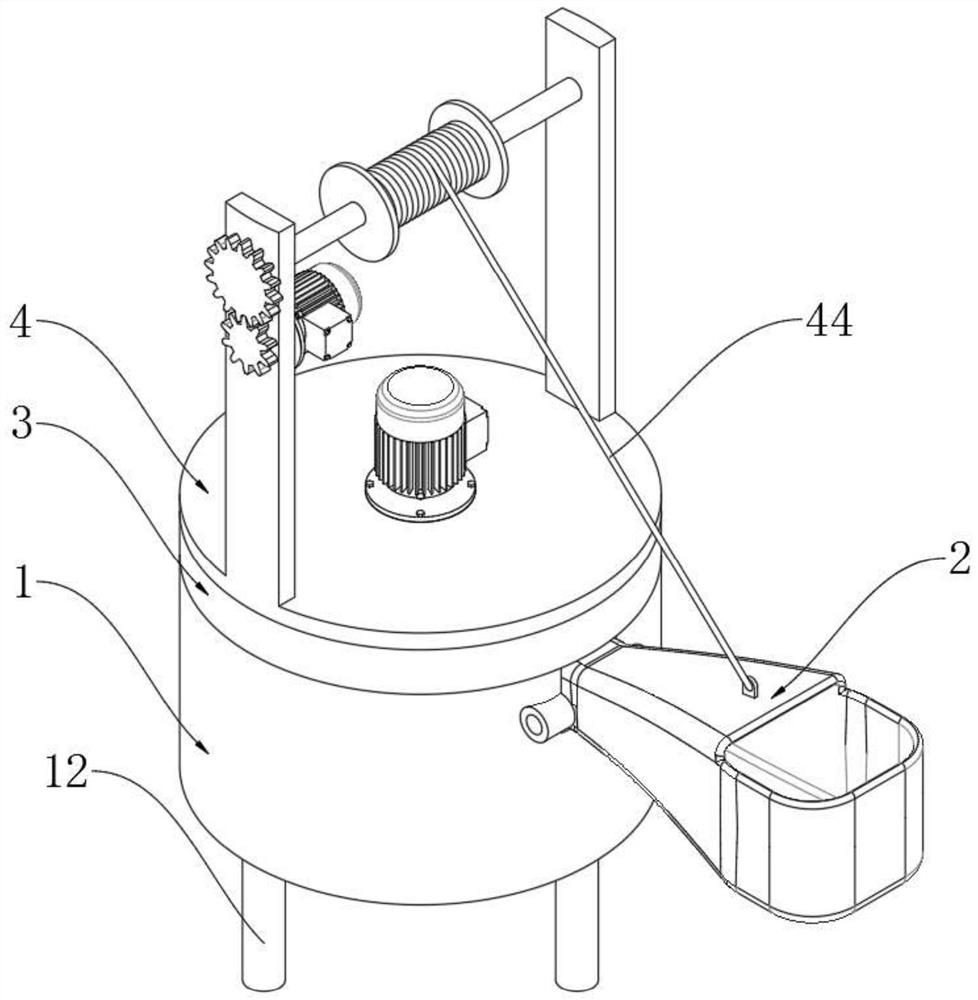

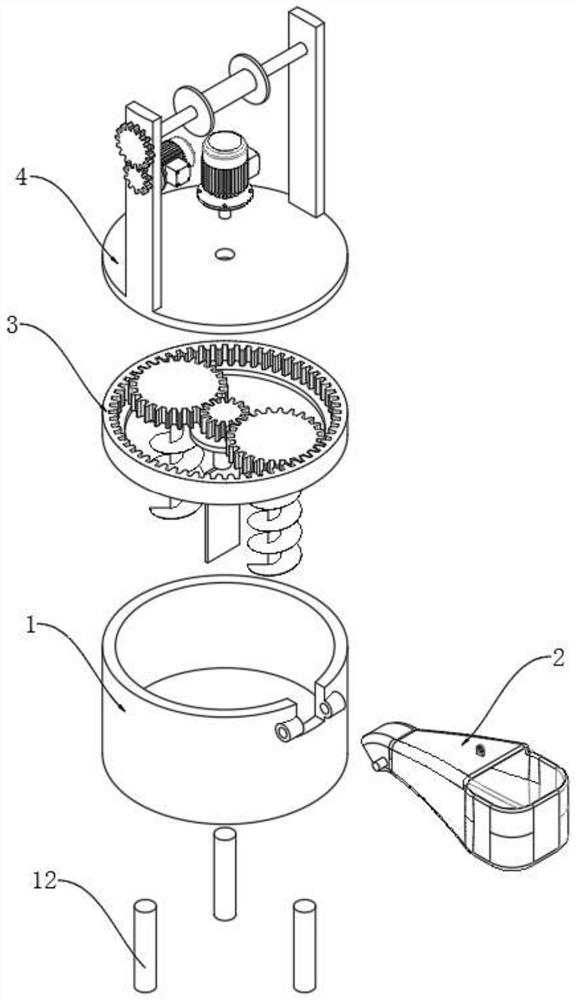

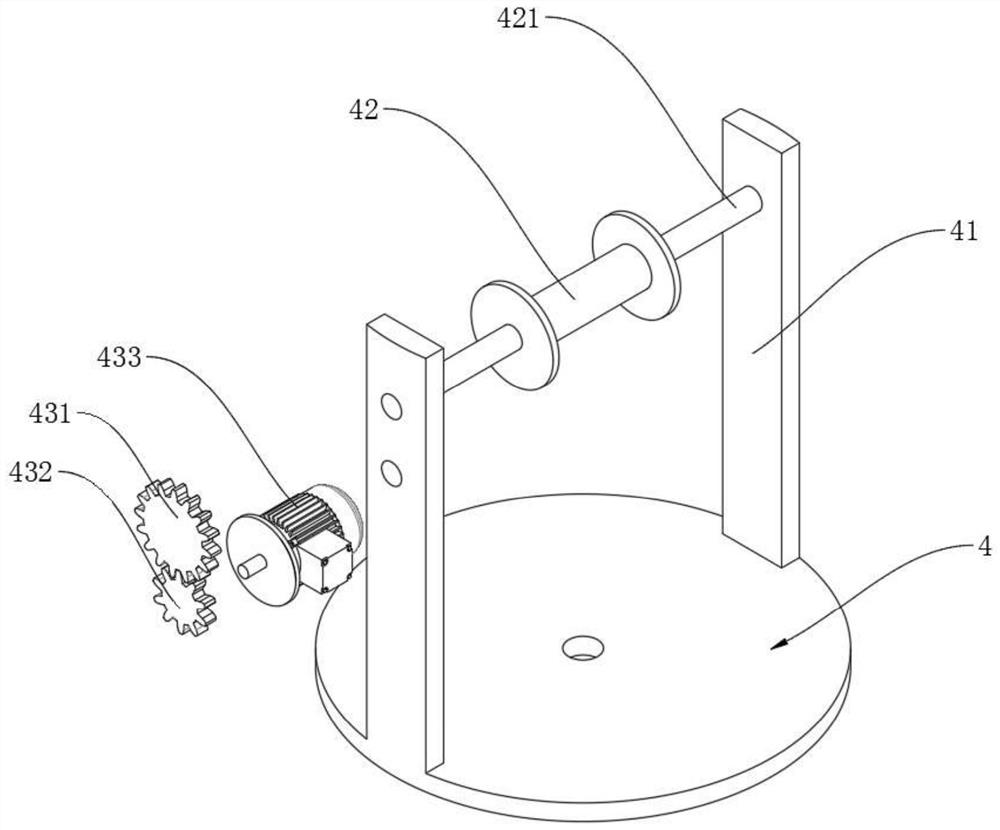

Planetary stirring device realizing convenient material pouring for building construction

InactiveCN111688022ARealize automatic dumpingStir quicklyMixing operation control apparatusCement mixing apparatusGear toothRotating drum

The invention discloses a planetary stirring device realizing convenient material pouring for building construction. The device comprises a stirring bin, wherein the interior of the stirring bin is provided with an inner cavity, the side wall of the top end of the stirring bin is provided with a feeding notch, the stirring bin is provided with a planetary stirring structure, the planetary stirringstructure comprises an inner tooth edge ring, the inner tooth edge ring is located at the upper end of the stirring bin, the inner tooth edge ring is internally provided with internal gear teeth, anda limiting edge ring is fixedly arranged at the bottom end inside the inner tooth edge ring. According to the device, an arranged spiral stirring shaft performs revolution and autorotation motion inthe stirring bin, and meanwhile, stirring blades perform autorotation motion, so that material in the stirring bin is rapidly stirred; and an arranged rotating drum is rotated to take up a winding rope, and a feeding bin is pulled to rotate by taking a rotating shaft as an axis to the position, where the end away from the stirring bin of the feeding bin is obliquely upwards, so that material in the feeding bin is automatically poured into the stirring bin to solve the problems set forth in the background art.

Owner:王翔宇

Device for destroying unqualified seeds in modern agriculture

InactiveCN112254145AAchieve destructionAvoid accumulationIncinerator apparatusGrain treatmentsAgricultural scienceAgricultural engineering

The invention discloses a device for destroying unqualified seeds in modern agriculture. The device comprises a base, a mounting frame, a crushing mechanism, a spiral conveying device, a dumping mechanism, a control box, an incineration device and an air purification device, wherein the mounting frame is arranged at the top end of the base; the crushing mechanism is mounted at the left front partof the top end of the mounting frame in the vertical direction; the spiral conveying device is arranged at the right rear part of the top end of the mounting frame; the dumping mechanism is arranged at the top end of the mounting frame and located in front of the right portion of a feeding port of the spiral conveying device; and the incineration device is arranged at the top end of the base and located on the inner side of the mounting frame. According to the device for destroying unqualified seeds in modern agriculture, integrated operation of crushing and incinerating unqualified seeds canbe achieved, the unqualified seeds are thoroughly destroyed, lawbreakers are prevented from reutilizing the seeds that are incompletely destroyed, automatic dumping of the seeds can be achieved, manual operation items of workers are reduced, and more time and labor are saved.

Owner:薛刚

Combined motor vehicle for highway and bridge marked line clearing

InactiveCN108118600AIncrease the outer diameterIncrease the sealing areaRoads maintainenceSlagHigh pressure water

The invention provides a combined motor vehicle for highway and bridge marked line clearing. The combined motor vehicle comprises a flat plate transportation vehicle and a driving type water clearingvehicle positioned at the front side of the flat plate transportation vehicle, wherein a clean water box, a hydraulic system, a first engine, a diesel tank, a power generator, a storage battery, a water feeding pump, a high-pressure water pump and a vacuum pump are arranged on the flat plate transportation vehicle; a water inlet of the high-pressure water pump is connected with the bottom of the clean water box through a high-pressure water inlet pipe; an air extraction opening of the vacuum pump is connected with a water outlet of the high-pressure water pump connected with the upper part ofthe front side of a slag and water collecting and discharging device through a vacuum pumping pipe and is connected with a water inlet of a high-pressure water clearing disc assembly through a high-pressure water outlet pipe; a slag and water inlet of the slag and water collecting and discharging device is connected with a slag suction water opening of the high-pressure water clearing disc assembly through a fixed slag suction pipe. The combined motor vehicle has the advantages that the clearing effect is very good; waste water and residue slag can be recovered; the construction effect and theconstruction effect can be effectively improved. The high-pressure water clearing automation degree is improved; the work intensity of workers is reduced, so that the popularization and the application of the high-pressure water in aspects of automation and industrialization can be promoted.

Owner:WELL ROAD MACHINERY CO LTD

AGV guiding system based on multi-module application and AGV trolley of application system

InactiveCN113009913ATo achieve the effect of cleaning and vacuumingSolve the problem of manual cleaningPosition/course control in two dimensionsVehiclesControl engineeringHand held

The invention discloses an AGV guiding system based on multi-module application and an AGV trolley of an application system. The AGV guiding system comprises a vehicle body assembly, a starting control key and a storage assembly, the starting control key is arranged on the outer side of the vehicle body assembly, the starting control key is arranged at the lower left corner of the front face of the vehicle body assembly, and the storage assembly is arranged at the top of the vehicle body assembly; the AGV guiding system comprises a power system, a driving system, a traveling system, an operating system, a safety sensing system, a landmark sensing system and an automatic charging system, the AGV achieves the effect of automatic movable cleaning and dust collection through cooperation between the dust collection assembly and the moving wheels, the problem that cleaning needs to be conducted through manual hand holding in the past is solved, and through the cooperation between the anti-collision stopper and the infrared photoelectric sensor, the functions of detecting automatic stop and avoiding stop during automatic operation are achieved, and the problem that the effect cannot be achieved by manually holding the dust collection box in the past is solved.

Owner:深圳易行机器人有限公司

Medical rubbish bin dumping device

The invention relates to a medical rubbish bin dumping device which is characterized in that the medical rubbish bin dumping device comprises a fixing frame, a support shaft supported at the upper end of the fixing frame, and a slowdown motor which is installed at one lateral end of the fixing frame and is in transmission connection with the support shaft. An overturning box consisting of a bottom support part, a left support part, a right support part and a back support part is arranged inside the fixing frame; clamping devices are arranged at the upper ends of the left and right support parts; and the part of the back support part, which is close to the upper end, is fixedly connected with the support shaft. The medical rubbish bin dumping device realizes automatic dumping of the medical rubbish, and an operator only needs to mount a medical rubbish bin on the medical rubbish bin dumping device and then demount the emptied medical rubbish bin from the dumping device. Compared with the conventional manual dumping manner, the medical rubbish bin dumping device has the advantages of lightening the work intensity, and improving the dumping efficiency. Moreover, in the dumping process, the operator can be far away from the medical rubbish bin, so direct contact between the operator and the medical rubbish is avoided. Therefore, the medical rubbish bin dumping device is safe and hygienic, and reduces the probability of iatrogenic infection of the operator.

Owner:天津百利阳光环保设备有限公司

Automatic pickling device for meat product processing

PendingCN114176197ARealize automatic picklingQuality assuranceFood shapingMechanical engineeringMaterials science

The invention relates to the field of food processing, and discloses an automatic pickling device for meat product processing, which comprises a base, the surface of the base is fixedly connected with a first fixing frame, the first fixing frame is internally provided with a pickling tank, the two sides of the pickling tank are fixedly connected with fixing shafts, the fixing shafts are rotatably connected in bearing bushes fixed on the first fixing frame, and the bearing bushes are fixedly connected with the first fixing frame. A tank cover is arranged at the top end of the pickling tank, a motor is fixedly connected to the top end of the tank cover, an output shaft of the motor penetrates through the tank cover and is fixedly connected with a rotating shaft, and a plurality of stirring rods are arranged on the rotating shaft; according to the meat product pickling device disclosed by the invention, the motor is arranged on the tank cover to drive the rotating shaft and the stirring rods to stir meat products in the pickling tank, so that automatic pickling of the meat products is realized; and the first sliding sleeve drives the first sliding rod to reversely turn over and drives the tank cover to open and close under the action of a lever with the supporting rod as a fulcrum, so that the operability of the device is enhanced.

Owner:ANHUI SHENHUA MEAT PROD

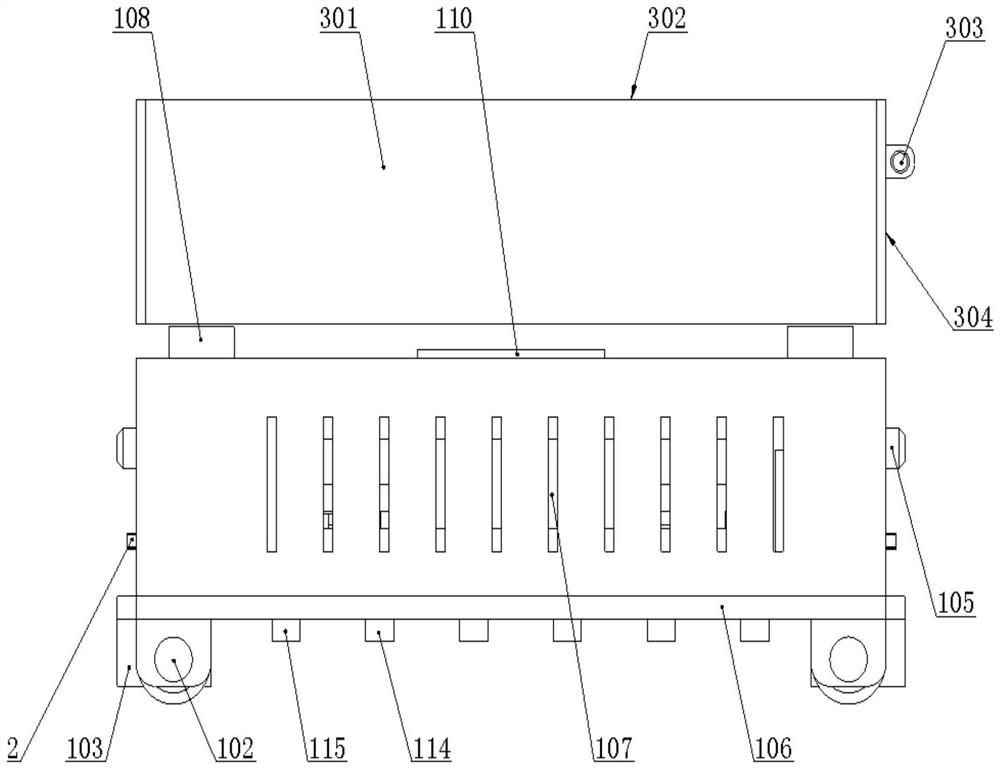

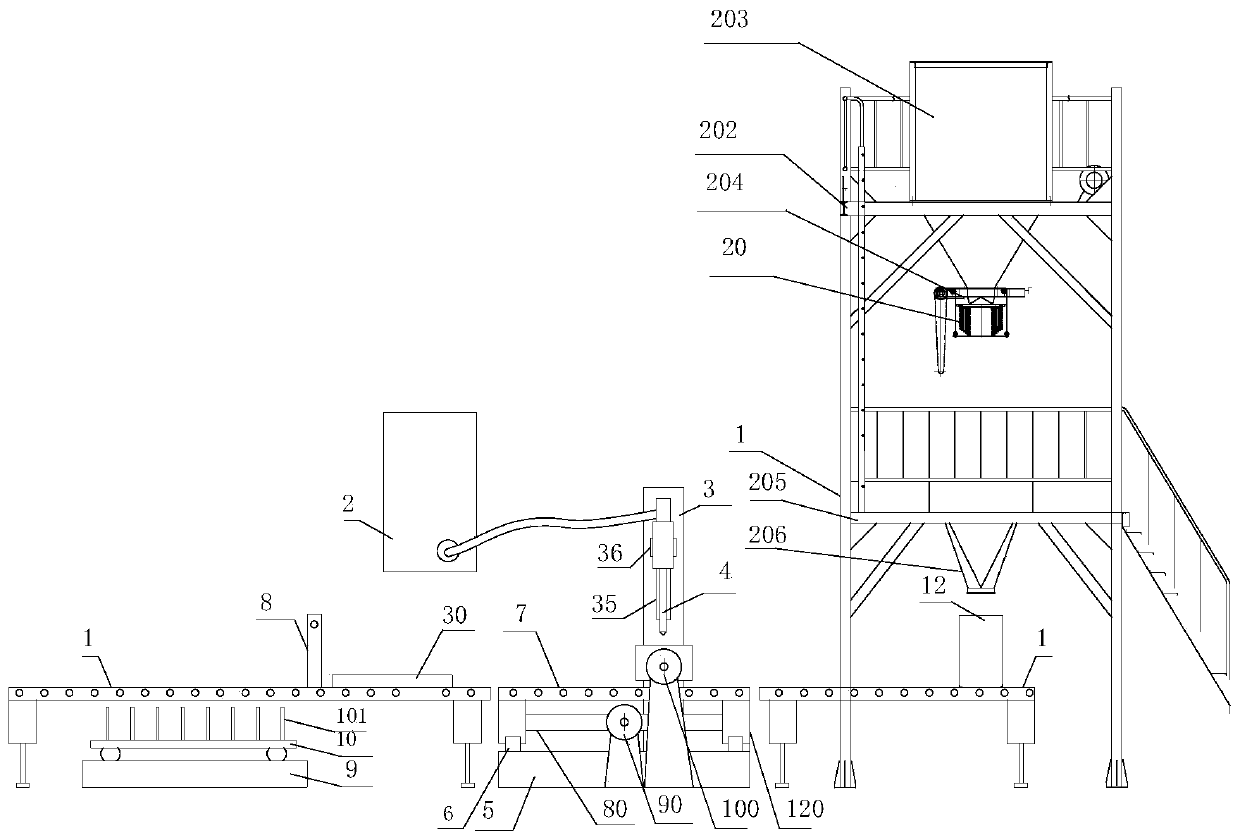

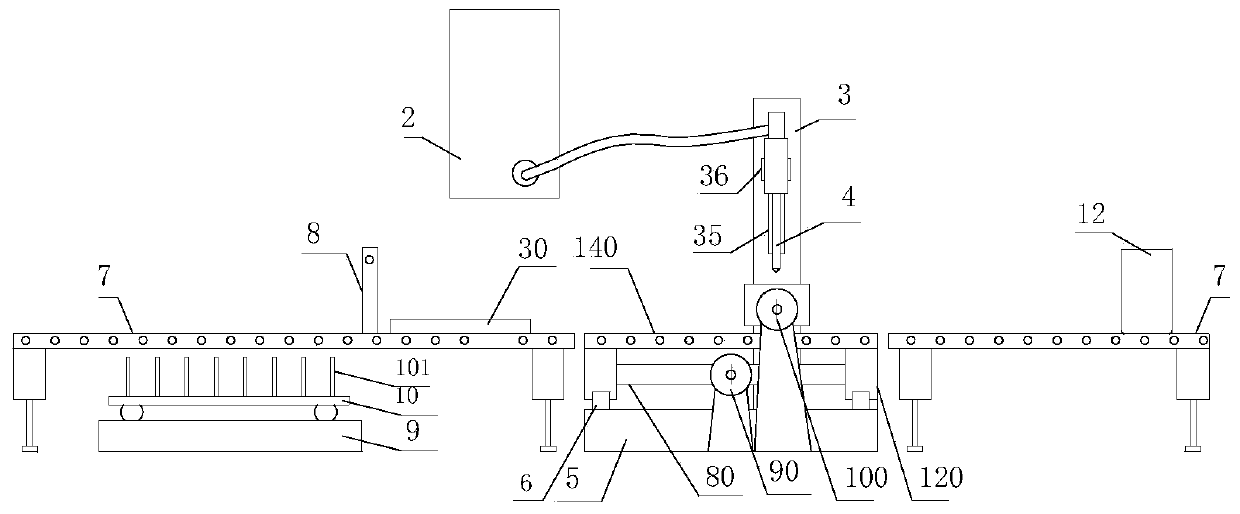

An automatic weighing instrument integrated detection device

ActiveCN109374104BRealize automatic dumpingRealize feedingWeighing apparatus testing/calibrationProcess engineeringPipe

The invention discloses an automatic weighing instrument integrated detecting device. A feeding system provides powder or granular materials for a to-be-detected gravity type automatic loading weighing instrument; weighing is carried out; after weighing completion, materials fall into a container through a blanking pipe and the materials are conveyed to a detection station by a conveying line; a detection system weighs the weight of the materials in the container; the conveying line is started and the container is conveyed to a next station; a liquid injection system caries out liquid injection on a filling scale and the filling scale carries out liquid injection on the container again and the weight is weighed; after weighing completion, a second automatic conveying line transports the container to the detection system and then the liquid injection system returns; the detection system weighs the weight of the materials in the container in an upgoing manner; and after weighing completion, a first automatic conveying line conveys the container to a next station and then the detection system returns. Therefore, the automatic detection of the dynamic weighing performance of the automatic weighing instrument is realized.

Owner:NANJING UNIV OF SCI & TECH

Deep-sea self-induction emergency load dumping mechanism

ActiveCN106314734BAchieve load dumpRealize automatic dumpingUnderwater equipmentLoad rejectionInternal pressure

The invention provides a deep sea self-induction emergency load rejection mechanism. The mechanism comprises a ballast, wherein a lifting lug is fixedly arranged at the upper part of the ballast; an installation rack is fixedly installed on a subsea equipment body and comprises lug plates; through holes for passing and sliding of a plunger are formed in the lifting lug and the lug plates; a cylinder block is fixedly installed on the installation rack and is provided with a hollow cavity with an opening in one end; one end of the plunger is stuffed in the hollow cavity; the plunger and the hollow cavity are sealed by sealing elements; the sealed hollow cavity is pre-filled with internal pressure; the cylinder block and the plunger are connected by a locating pin; the other end of the plunger passes through the through hole of the lifting lug and the through holes of the lug plates; under the actions of the internal and external pressures of the sealed hollow cavity, the plunger is connected with the through hole of the lifting lug or breaks away from the through hole of the lifting lug so that the ballast is connected with the installation rack or breaks away from the installation rack. The mechanism achieves automatic load rejection through self induction of internal and external pressures.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com