Marked line removing vehicle for highway construction

A road and marking technology, which is applied in the field of marking removal vehicles for highway construction, can solve the problems of low degree of automation, limited promotion and application of high-pressure water removal machines, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

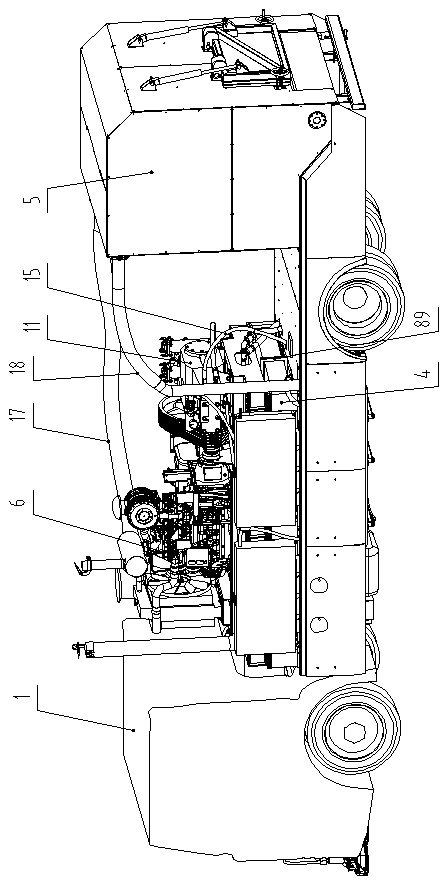

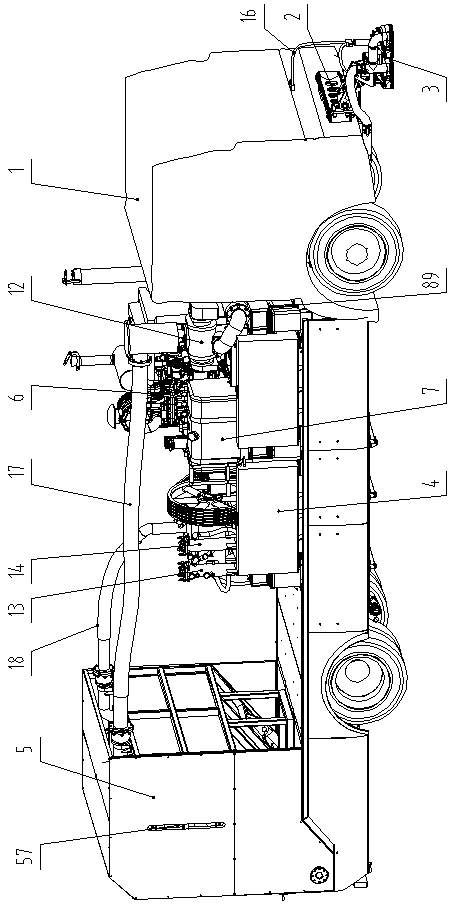

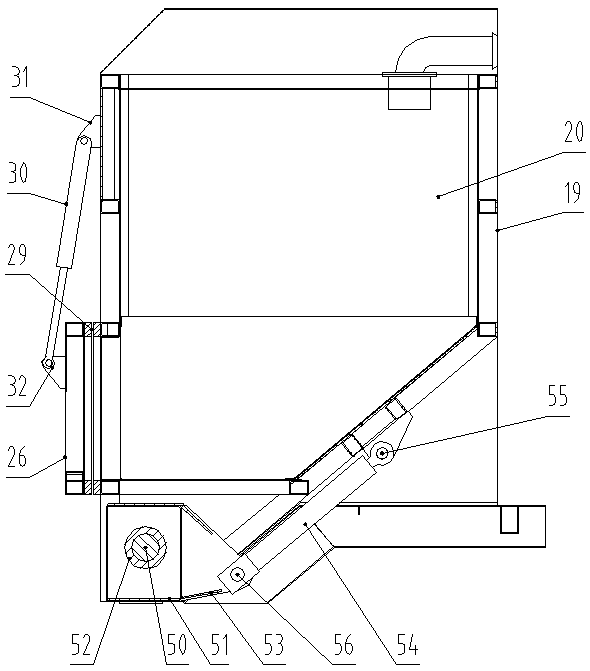

[0041] Such as Figure 1-Figure 10 As shown, the highway construction marking clearing vehicle of the present invention comprises a flatbed transport vehicle 1, the lower front end of the flat transport vehicle 1 is provided with a double-disc high-pressure water removal trolley 3 through a front swing lifting mechanism 2, and the chassis of the flat transport vehicle 1 A support frame 89 and a slag water collection and discharge device 5 located at the rear side of the support frame 89 are arranged on the top, a fresh water tank 4 is arranged in the support frame 89, a hydraulic system is arranged under the chassis of the flatbed transport vehicle 1, and an engine is arranged on the support frame 89. 6. Diesel tank 7, generator, storage battery, upper water pump, high pressure water pump 11, vacuum pump 12, primary filter system 13 and secondary filter system 14, the power output end of engine 6 is respectively connected with hydraulic system and upper water pump through trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com