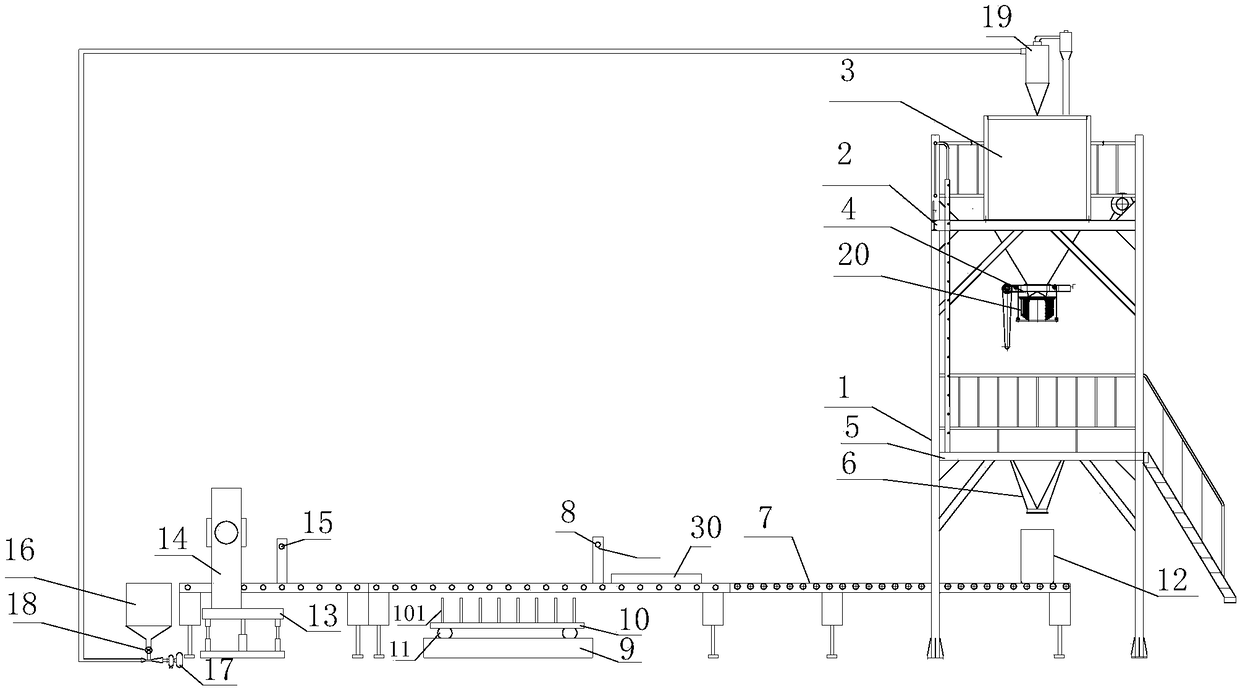

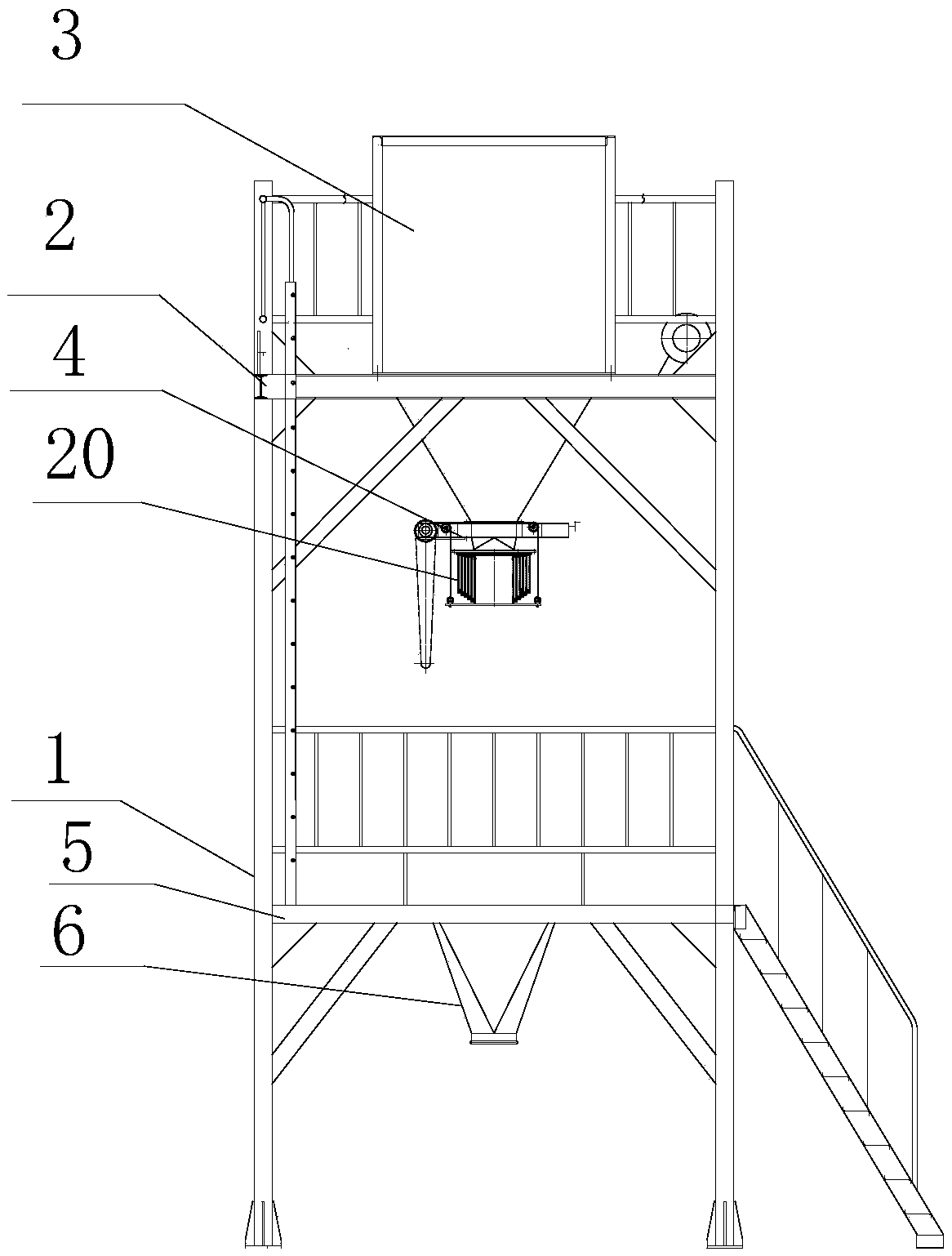

Automatic detection system for solid material measurement of gravity type automatic-charging weighing apparatus

A technology for automatic loading and material measurement, which is applied to storage devices, transportation and packaging, loading/unloading, etc. It can solve the problems of low detection efficiency, hidden dangers to personnel safety, time-consuming and labor-intensive problems, and achieve strong versatility and save manpower and material resources , the effect of improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

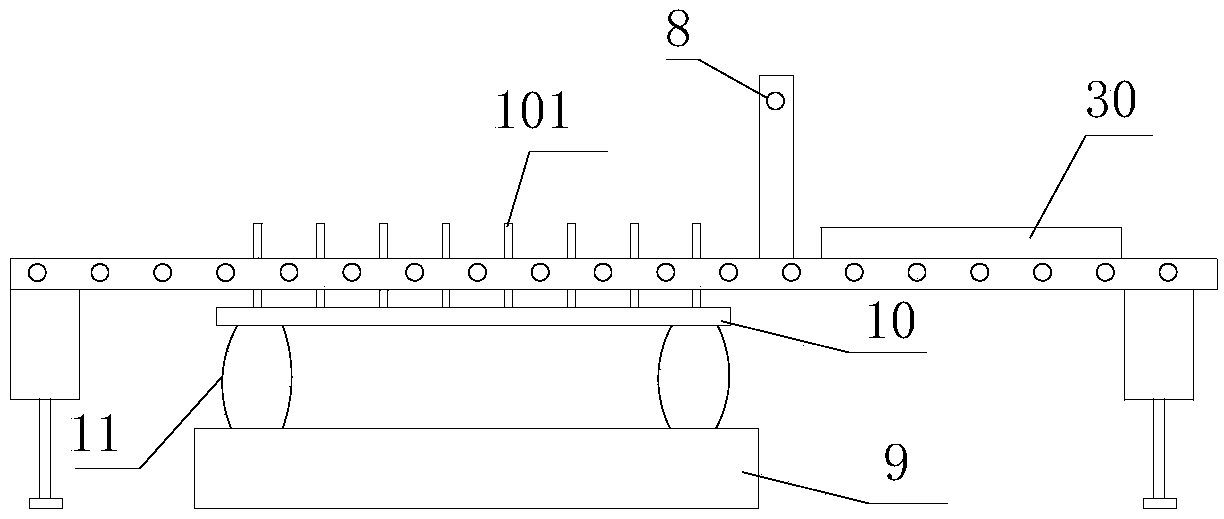

[0032] As an implementation, the first detection unit 8 is a photoelectric sensor, and the transmitter and receiver of the photoelectric sensor are respectively fixed on both sides of the conveying line 7 through brackets, and are located at the front side of the weighing device 9 . After the photoelectric sensor detects the container 12, the conveying line 7 stops, the lifting mechanism lifts the supporting platform 10, and the supporting plate 101 lifts the container 12 from the conveying line 7.

[0033] As an embodiment, the lifting mechanism includes a plurality of air bags 11 and a gas generating device; the air bag 11 is arranged between the weighing device 9 and the support platform 10, and the gas generating device is used to inflate or Deflate to realize the lifting of the lifting mechanism.

[0034] Further, combine Figure 4 , the gas generating device comprises a gas source 21, a first electromagnetic valve 22, a pressure reducing valve 23, and a second electromagn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com