Deep sea self-induction emergency load rejection mechanism

A self-sensing, deep-sea technology, applied in underwater operation equipment, transportation and packaging, ships, etc., can solve problems such as the inability to truly achieve automatic loading and surfacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

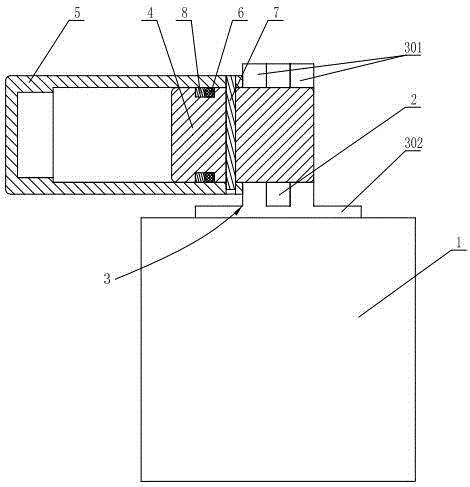

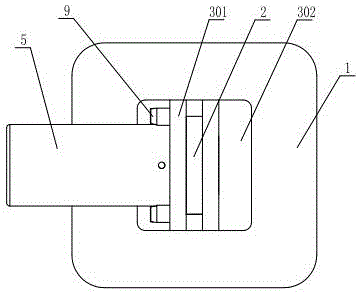

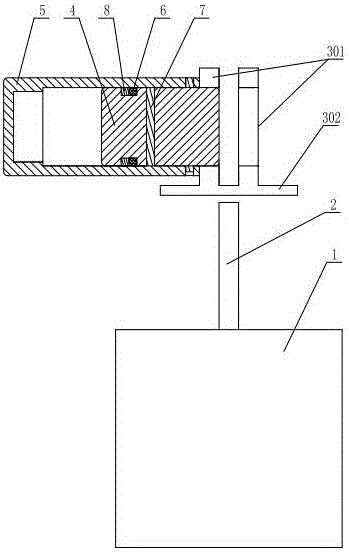

[0018] The specific embodiments of the present invention will be described below in conjunction with the drawings.

[0019] see figure 1 , figure 2 , The present invention includes ballast 1, the upper part of ballast 1 is fixed with lifting lugs 2, and the underwater equipment body is fixed with a mounting frame 3 through screws 9. The mounting frame 3 includes ear plates 301, lifting lugs 2 and ear plates 301 Each is provided with a through hole for the plunger 4 to pass through and slide; a cylinder block 5 is fixedly mounted on the mounting frame 3, and the cylinder block 5 has a hollow cavity with an opening at one end, and one end of the plunger 4 is inserted through the opening. Said hollow cavity, and the plunger 4 and the hollow cavity are sealed by a seal 6 which usually adopts an O-ring seal. The sealed hollow cavity is pre-filled with internal pressure, and the cylinder block 5 and The plunger 4 is connected by a positioning pin 7. The positioning pin 7 preferably us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com