Lightweight insulation board and preparation method thereof

A thermal insulation board, lightweight technology, applied in the field of building materials, can solve problems such as inconvenient lifting and use of boards, cracking of boards during use, uneven quality of boards, etc., to improve thermal insulation effect, improve early strength and improve surface quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

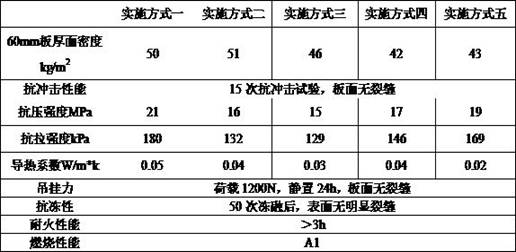

Embodiment approach 1

[0023] This embodiment improves a light-weight insulation board, which is composed of the following components by mass: 300 parts of slag powder, 20 parts of sodium hydroxide, 10 parts of potassium silicate, 100 parts of modifier, 1200 parts of aggregate, 20 parts of thickener, 150 parts of water.

[0024] The above-mentioned modifier is composed of 5 parts of titanium white slag, 30 parts of lithium slag, 20 parts of attapulgite, 30 parts of carbide slag, 10 parts of fluorite powder and 5 parts of zinc-iron slag; the preparation method of the modifier is: 1) Mix modifiers in proportion and grind to 300m 2 / kg; 2) Press the mixture into balls; 3) Put the mixture balls into the electric arc furnace, heat up to 800°C at 10°C / min, keep warm for 0.5h, and then cool rapidly; 4) Grind to fineness for 400 2 / kg.

[0025] The above-mentioned aggregate is composed of 10 parts of slag sand, 10 parts of pearl sand, 5 parts of closed-cell perlite and 75 parts of lightweight aggregate; ...

Embodiment approach 2

[0032] This embodiment improves a light-weight insulation board, which is composed of the following components by mass: 300 parts of slag powder, 100 parts of fly ash, 100 parts of metakaolin, 20 parts of sodium hydroxide, 10 parts of sodium silicate, carbonic acid 5 parts of sodium, 5 parts of calcium acetate, 3 parts of calcium formate, 2 parts of calcium propionate, 5 parts of calcium chloride, 200 parts of modifier, 1200 parts of aggregate, 60 parts of thickener, and 250 parts of water.

[0033] The above-mentioned modifier is composed of 20 parts of titanium white slag, 30 parts of lithium slag, 20 parts of attapulgite, 20 parts of carbide slag, 5 parts of fluorite powder and 5 parts of zinc-iron slag; the preparation method of the modifier is: 1) Mix modifiers in proportion and grind to 500m 2 / kg; 2) Press the mixture into a cake; 3) Put the mixture cake into an electric arc furnace, raise the temperature to 1000°C at 10°C / min, keep it warm for 1.0h, and then cool it ra...

Embodiment approach 3

[0041] This embodiment improves a light insulation board, which is composed of the following components by mass: 200 parts of fly ash, 200 parts of metakaolin, 20 parts of potassium hydroxide, 10 parts of sodium silicate, 5 parts of lithium carbonate, acetic acid 5 parts of calcium, 3 parts of calcium formate, 2 parts of calcium propionate, 5 parts of sodium bromide, 150 parts of modifier, 800 parts of aggregate, 40 parts of thickener, 200 parts of water.

[0042] The above-mentioned modifier is composed of 5 parts of titanium white slag, 30 parts of lithium slag, 20 parts of attapulgite, 20 parts of carbide slag, 15 parts of fluorite powder and 10 parts of zinc-iron slag; the preparation method of the modifier is: 1) Mix modifiers in proportion and mill to 400m 2 / kg; 2) Press the mixture into a cake; 3) Put the mixture cake into an electric arc furnace, heat up to 900°C at a rate of 10°C / min, keep it warm for 0.5h, and then cool it rapidly; 4) Grind it to fineness for 500 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com