Application of mud-resistant slump-retaining type water reducing agent to building solid waste recycled aggregate concrete

A technology of recycled concrete and recycled aggregate, applied in the field of concrete, can solve the problems of high shrinkage rate, low dispersibility and slump retention of polycarboxylate superplasticizer, and high water demand, and achieves improved fluidity and cohesion, The effect of shortening the mold turnover cycle and accelerating the hydration reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] An embodiment of the mud-resistant and slump-preserving water-reducer of the present invention, the mud-resistant and slump-preserving water-reducer described in this embodiment is prepared by the following method:

[0050] In a 500ml four-necked glass flask equipped with a stirrer, a thermometer, and a reflux condenser, add metered 50wt% PEI aqueous solution and phosphorous acid H 3 PO 3 ,, 0.3 milliliters of 37wt% concentrated hydrochloric acid (volume accounted for 0.1% of the total reaction system), fully stirred, heated to 40 ° C, slowly added dropwise metered 37% formaldehyde solution, after 2 hours, slowly heated to 80 ° C, Continue to react for 3 hours, the solution is yellow-brown, reduce the temperature to below 40°C, add 40% sodium hydroxide solution, adjust the pH=8-9, and obtain the product sodium polyethyleneimine phosphite.

[0051] Among them, PEI: H 3 PO 3 : The molar ratio of HCHO is 1.0:0.2:0.9.

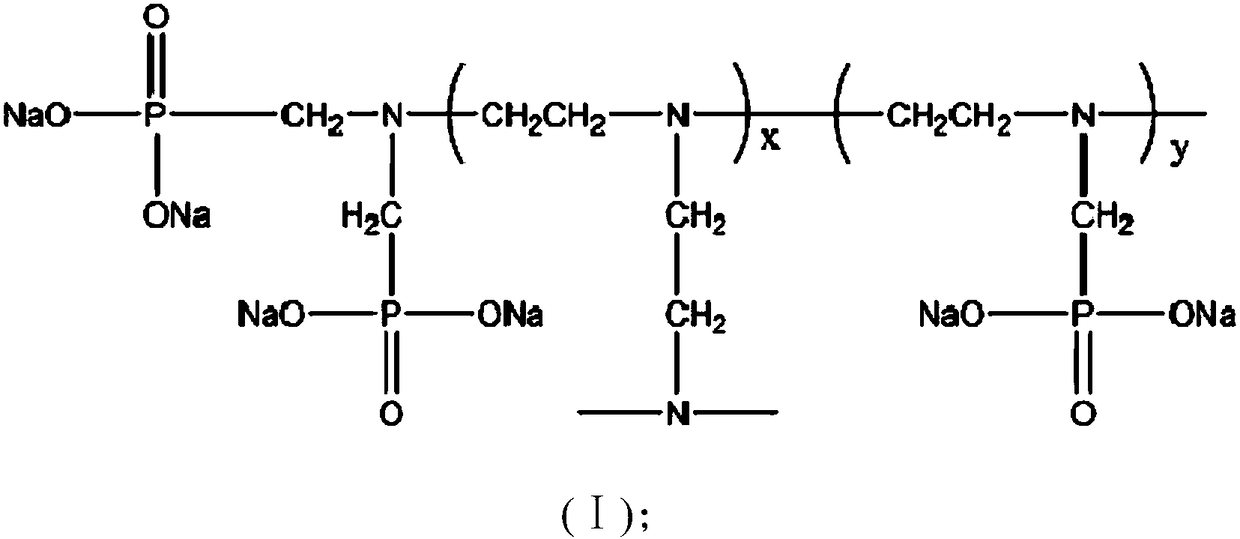

[0052] The PEI structure of this embodiment is a l...

Embodiment 2

[0057] As an embodiment of the present invention, the mud-resistant and slump-retaining water reducer described in this embodiment is prepared by the following method:

[0058] In a 500ml four-necked glass flask equipped with a stirrer, a thermometer, and a reflux condenser, add metered 50wt% PEI aqueous solution and phosphorous acid H 3 PO 3 , 0.25 milliliters of 37wt% concentrated hydrochloric acid (volume accounts for 0.08% of the total reaction system), fully stirred, heated up to 45 ° C, slowly added dropwise metered 37% aqueous formaldehyde solution, and after 2.5 hours, the dropwise addition was completed, slowly heated to 85 ° C, continued React for 2 hours, the solution is yellow-brown, reduce the temperature to below 40°C, add 40% sodium hydroxide solution, adjust the pH=8-9, and obtain the product polyethyleneimine sodium phosphite.

[0059] Among them, PEI: H 3 PO 3 : The molar ratio of HCHO is 1.0:1.5:0.2.

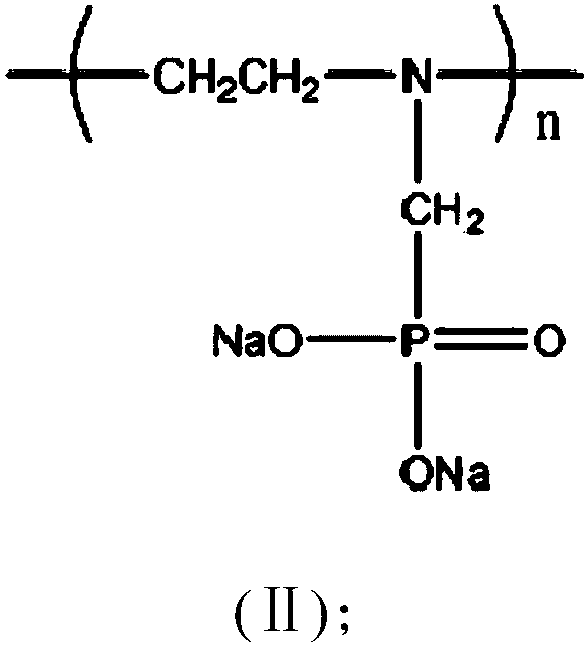

[0060] The PEI structure of this embodiment is diffe...

Embodiment 3

[0067] As an embodiment of the present invention, the mud-resistant and slump-retaining water reducer described in this embodiment is prepared by the following method:

[0068] In a 500ml four-necked glass flask equipped with a stirrer, a thermometer, and a reflux condenser, add metered 50wt% PEI aqueous solution and phosphorous acid H 3 PO 3 , 0.3 milliliters of 37wt% concentrated hydrochloric acid (volume accounts for 0.1% of the total reaction system), fully stirred, heated up to 43 ° C, slowly added dropwise metered 37% formaldehyde solution, and the dropwise addition was completed in 3 hours, slowly heated up to 90 ° C, continued React for 3 hours, the solution is yellow-brown, reduce the temperature to below 40°C, add 40% sodium hydroxide solution, adjust the pH=8-9, and obtain the product sodium polyethyleneimine phosphite.

[0069] Among them, PEI: H 3 PO 3 : The molar ratio of HCHO is 1.0:2.2:2.1.

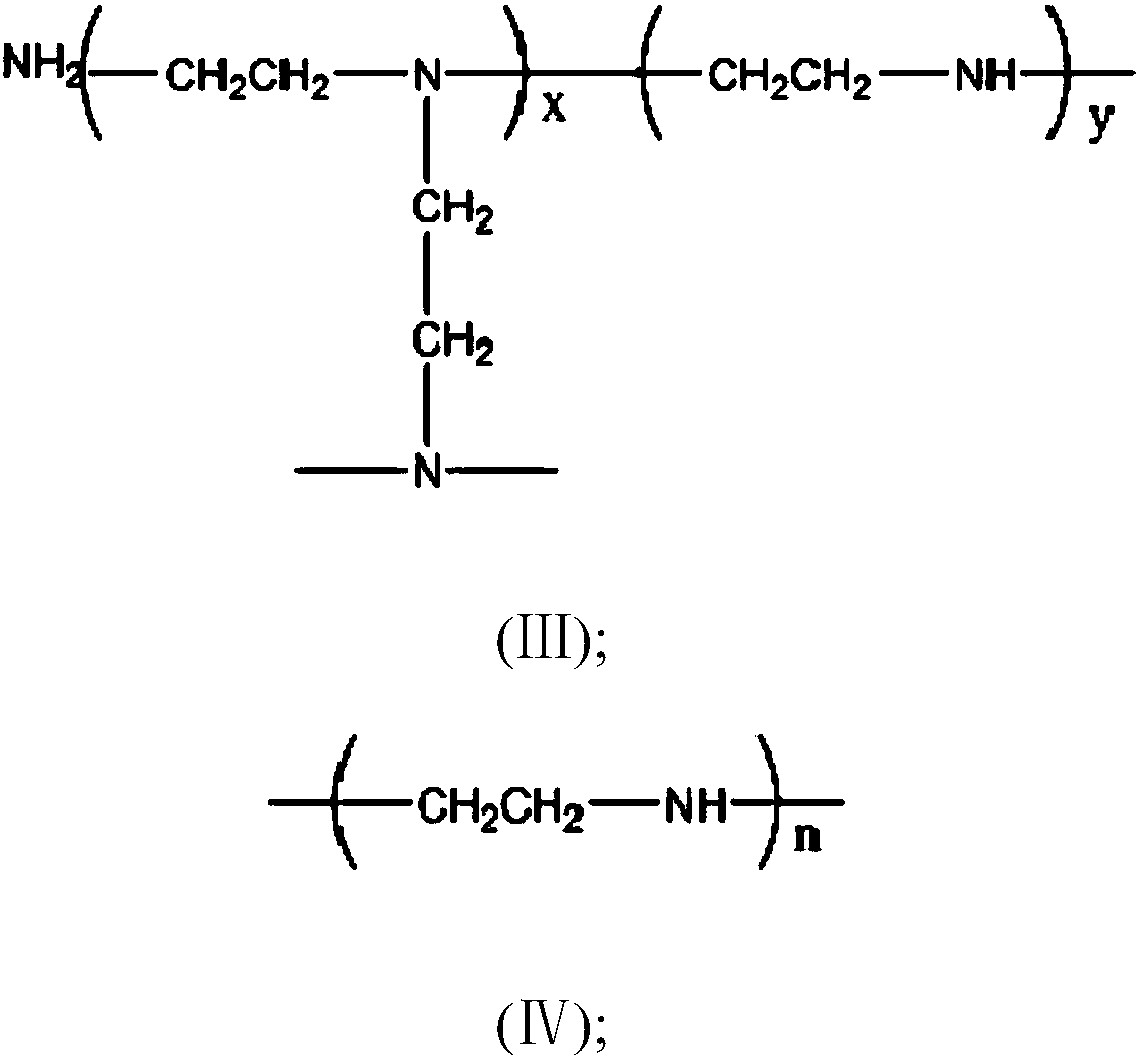

[0070] The PEI structure of the present embodiment is branched PE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com