Discharging door for stock bin of finished asphalt concrete

A technology for asphalt concrete and finished product silos, applied in the field of discharge doors, which can solve the problems affecting the working life of the mixing station and the continuity of production, the inability to meet the construction requirements of asphalt finished materials, and the inability to effectively ensure the overall quality of heating, etc., to achieve heat preservation Good effect, guaranteed production continuity, reliable heat load performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the technical solutions of the present invention, the embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

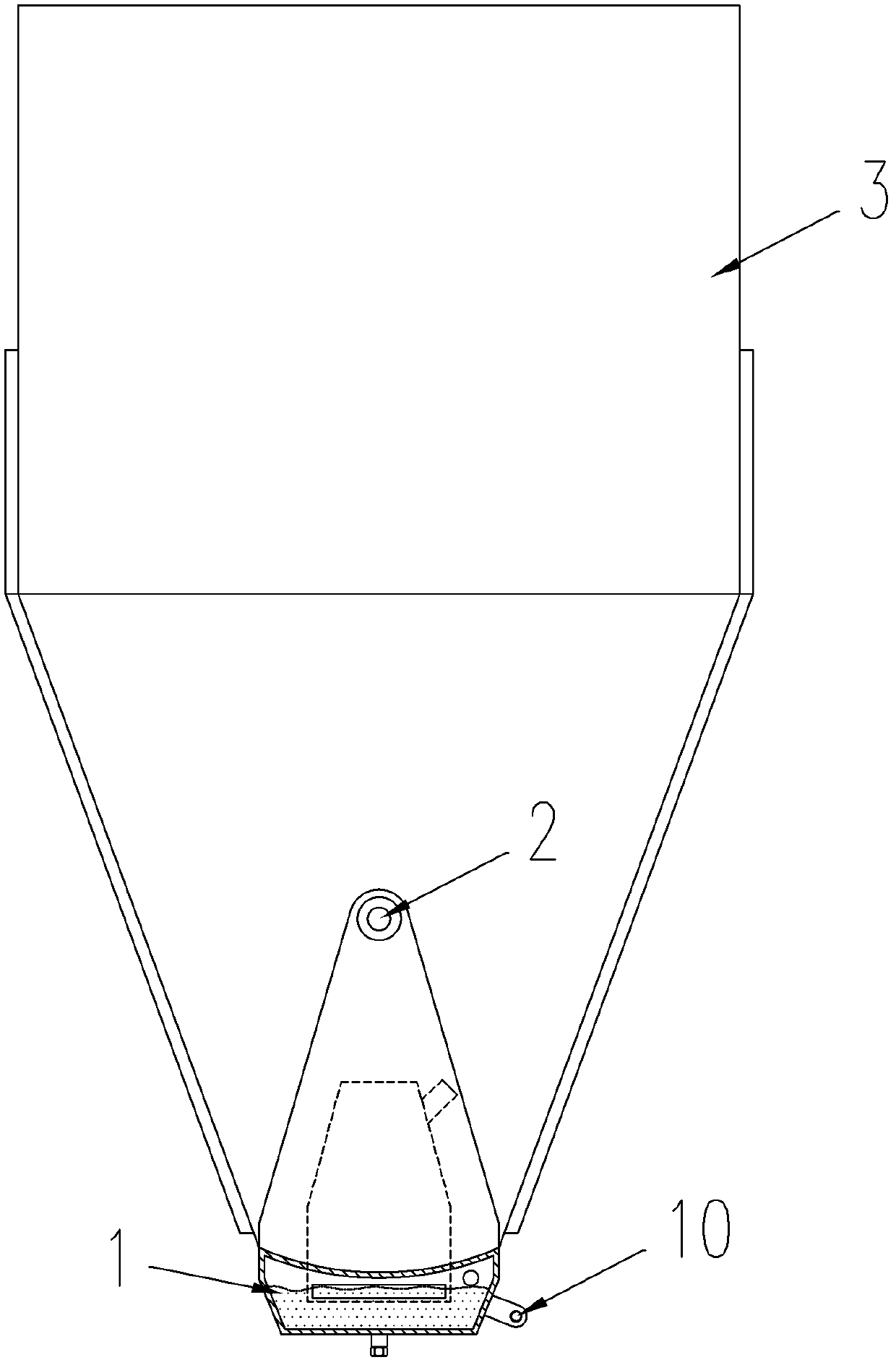

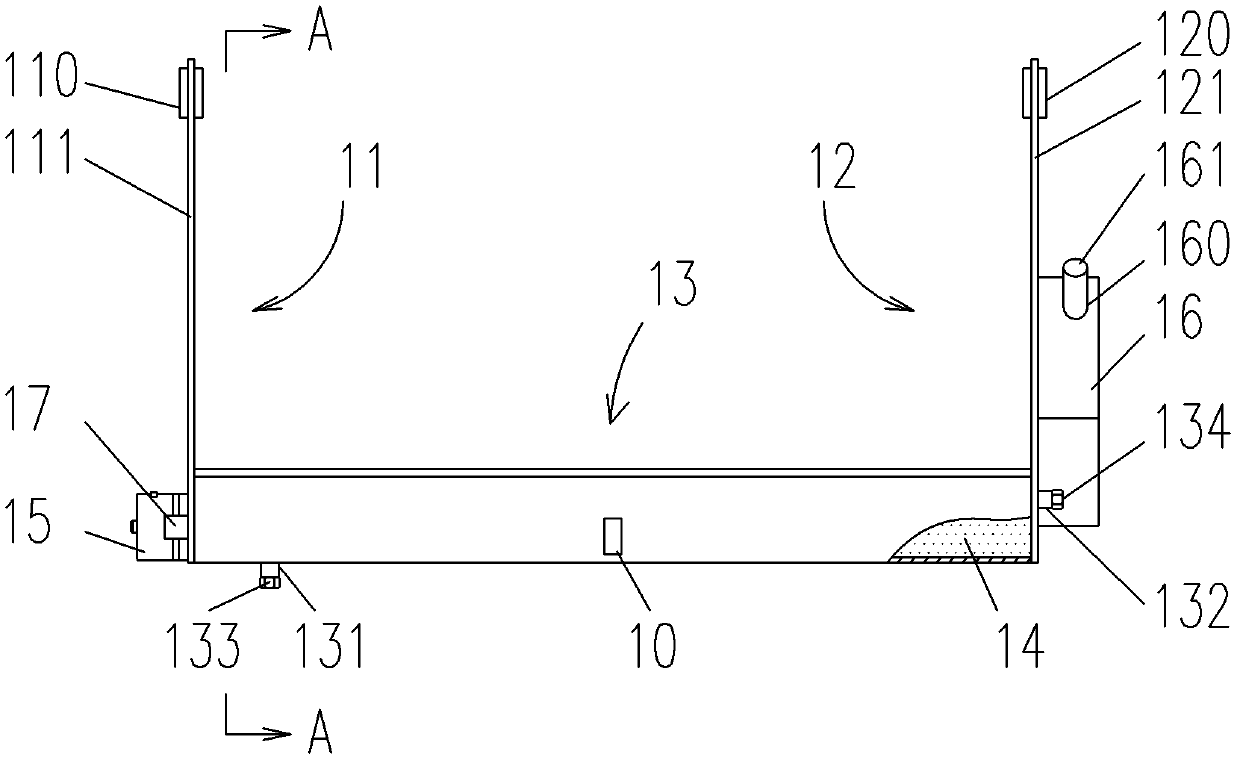

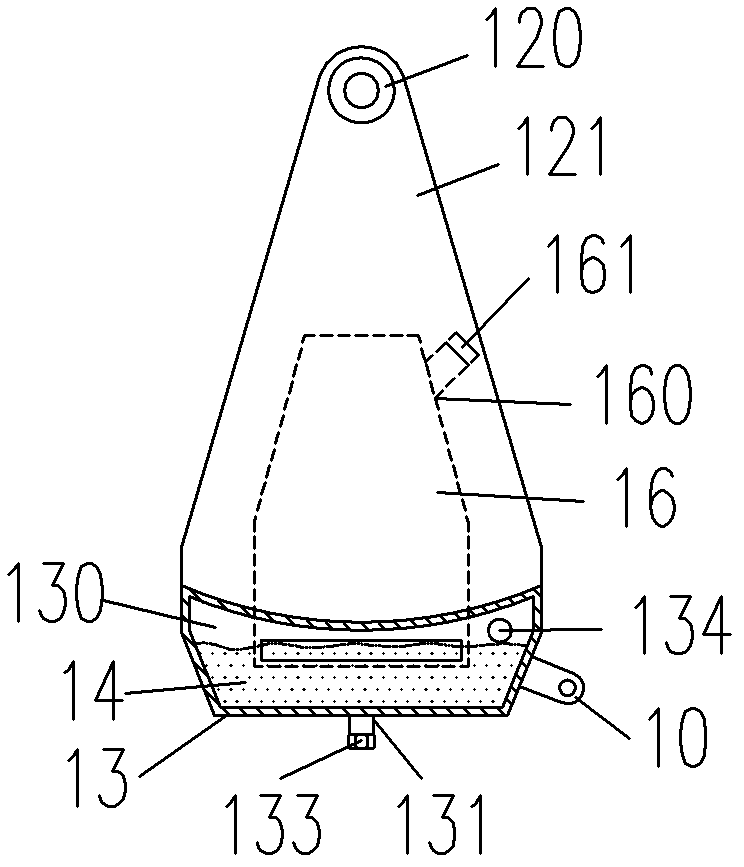

[0020] refer to figure 1 , figure 2 As shown, the discharge door 1 of the asphalt concrete finished product silo of the present invention is arranged below the discharge port of the asphalt concrete finished product silo 3 through the fixed shaft 2, and the asphalt concrete finished product silo 3 is provided with a door opening on the discharge door 1. The driving mechanism (not shown) connected to the lifting lug 10 is to control the opening and closing of the discharge door 1, and the discharge door 1 includes a left side plate 11, a right side plate 12, and a discharge valve arranged between the left and right side plates. The lower door support body 13, and the heating system and temperature control device arranged on the discharge door 1.

[0021] refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com