Device for improving loosening rate of tobacco block

A loose, cigarette block technology, used in tobacco, tobacco preparation, sustainable manufacturing/processing, etc., can solve the problems of cigarette blocks falling to the bottom vibration groove, insufficient looseness, etc., to improve product quality, facilitate production line installation, and ensure The effect of quality of workmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

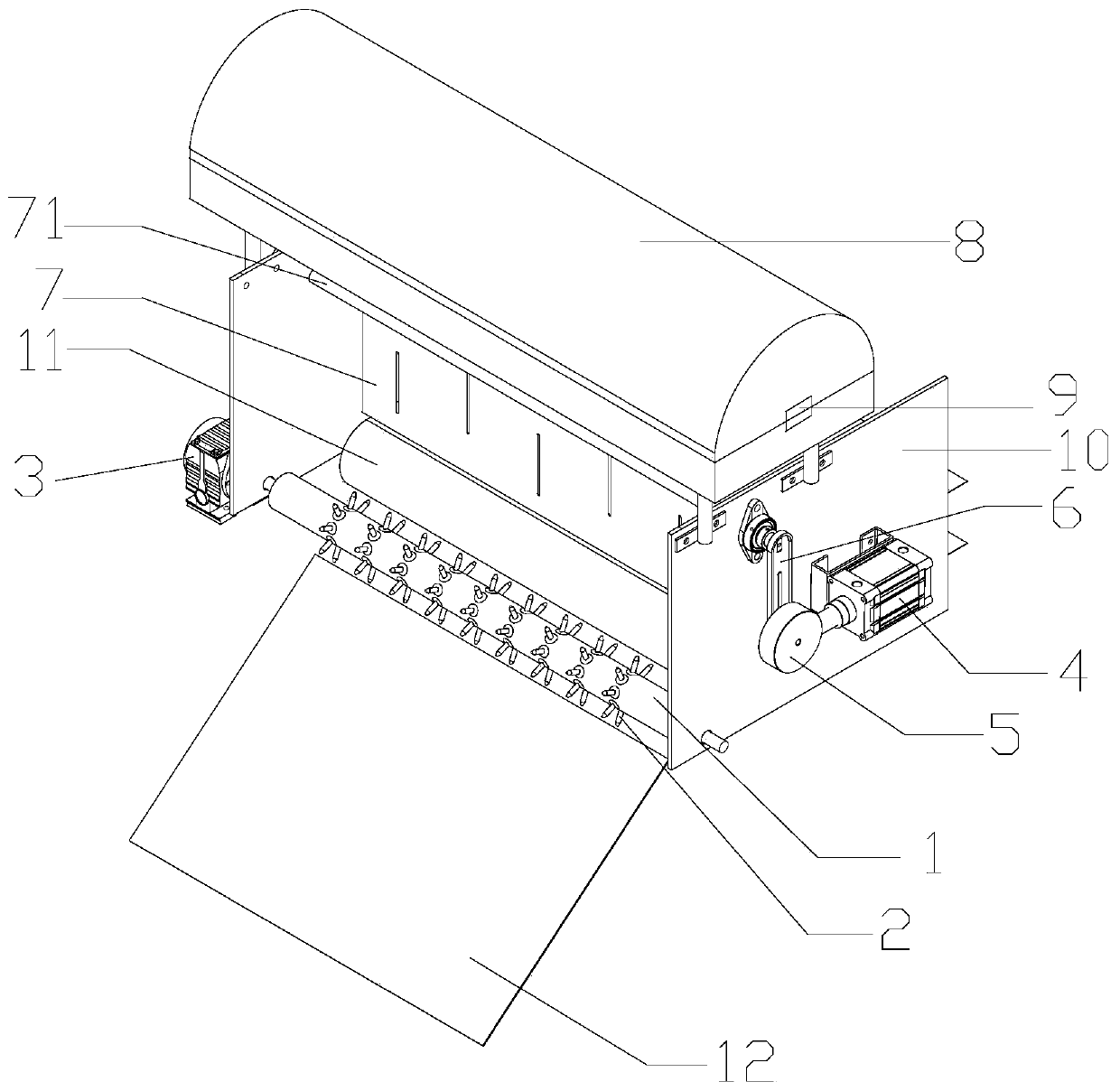

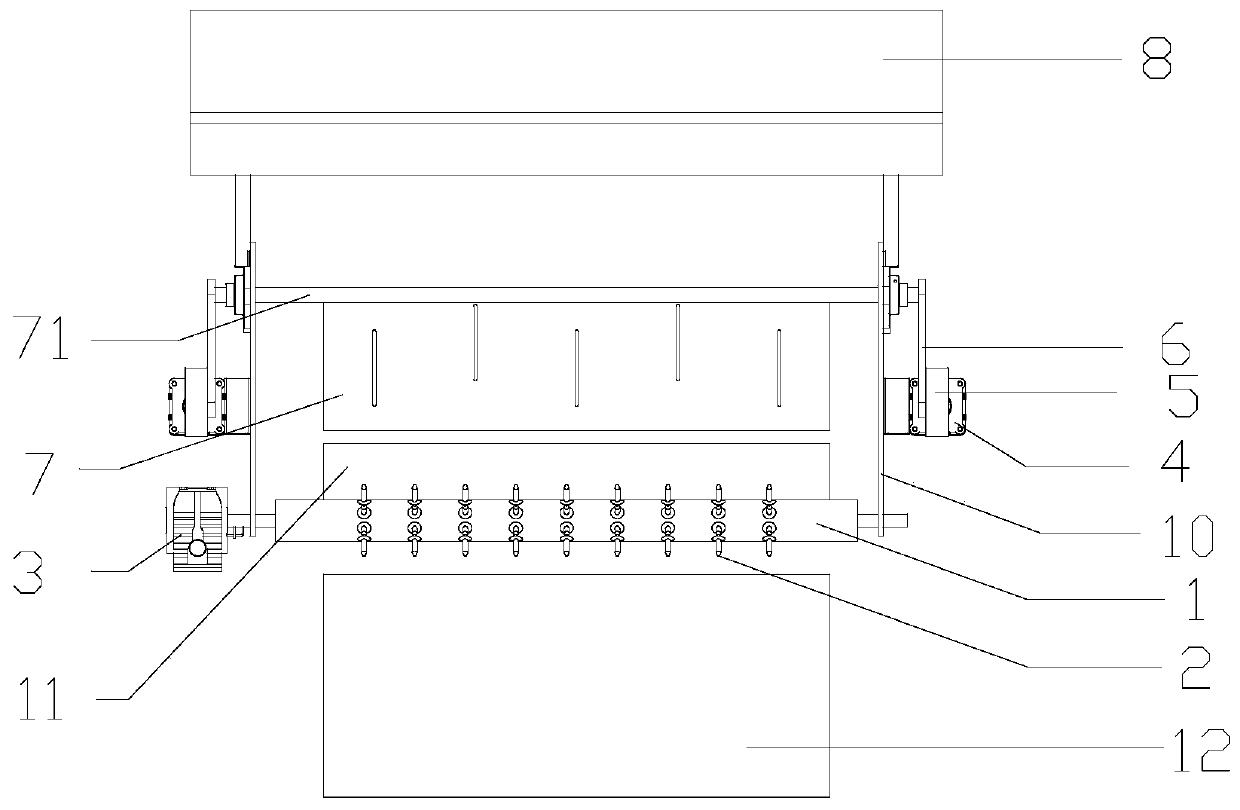

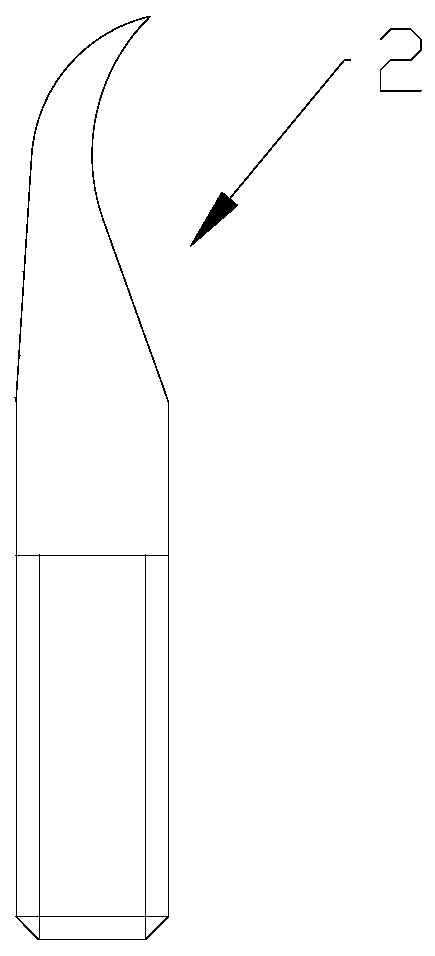

[0026] like figure 1 , figure 2 As shown, a device for increasing the loosening rate of cigarettes includes a loosening roller 1, an adjustable loosening roller needle 2, a frequency conversion drive motor 3, an anti-swing cylinder 4, a counterweight 5, an adjusting rod 6, an anti-dumping door panel 7, a protective Cover 8, safety interlock device 9 and frame 10.

[0027] The frame 10 is installed on both sides of the electronic belt scale 11, and the loose roller 1 is installed at the outlet position of the electronic belt scale 11, and the shafts at the two ends of the loose roller 1 are movably connected with the bearings on the frame 10. The loose roll 1 is driven by a variable frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com