Sheet tobacco pack loosening equipment and method thereof

A loose, cigarette-wrapped technology, applied in tobacco, tobacco preparation, application, etc., can solve problems affecting the uniformity of moisture regain of tobacco materials, increasing tobacco processing costs, and affecting tobacco processing efficiency, so as to improve various indicators, specific functions, and Evenly rehydrated and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, the present invention will be further described.

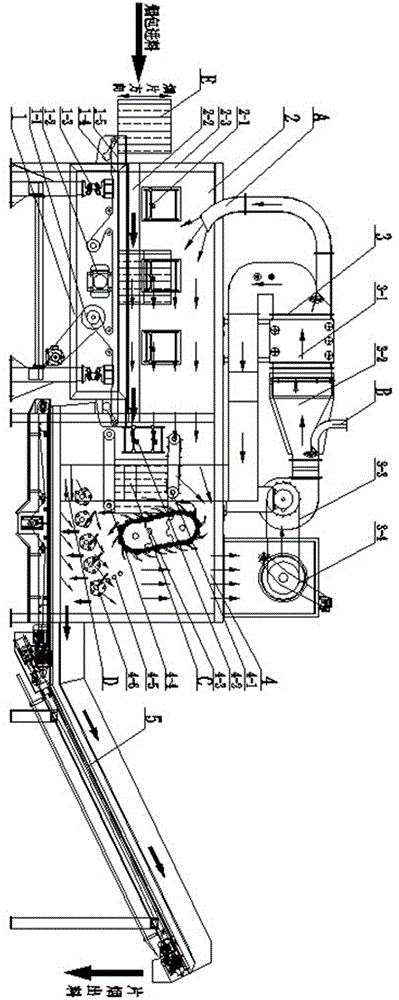

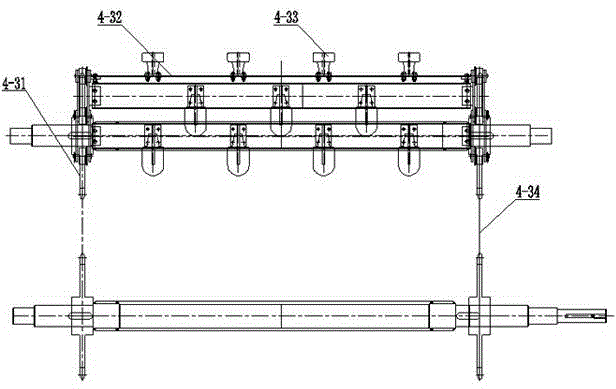

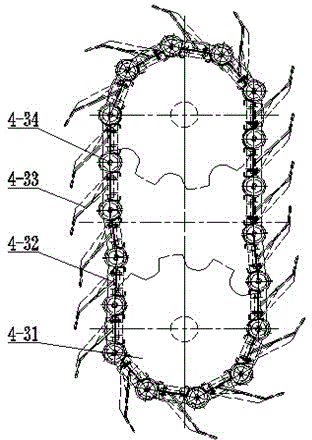

[0038] Such as figure 1As shown, the loosening equipment of the present invention includes a vibrating belt conveyor 1, a loose box body 2, a hot air circulation system 3, a flexible mechanical loosening device 4, a collection belt conveyor 5 and a control system, etc.; the vibrating belt conveyor 1 top is provided with a loose box body 2, the flexible mechanical loosening device 4 is arranged at the rear end of the vibrating belt conveyor 1 and the loose box body 2, the feeding end of the flexible mechanical loosening device 4 communicates with the discharging end of the vibrating belt conveyor 1, and the collecting belt conveyor 5 is placed Below the flexible mechanical loosening device 4. A feed cover 2-3 and a feed photoelectric switch 2-1 are arranged at the feed port of the loose box body 2. A hot air circulation system 3 is arranged on the top of the loose box bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com