Recovery system for noble metals for electroplating

A precious metal recovery and waste water collection technology, applied in the direction of process efficiency improvement, etc., can solve the problems of inability to guarantee the complete adsorption and recovery of metal ions, low efficiency and recovery rate, and uncontinuous recovery, so as to ensure production continuity, improve efficiency, The effect of reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

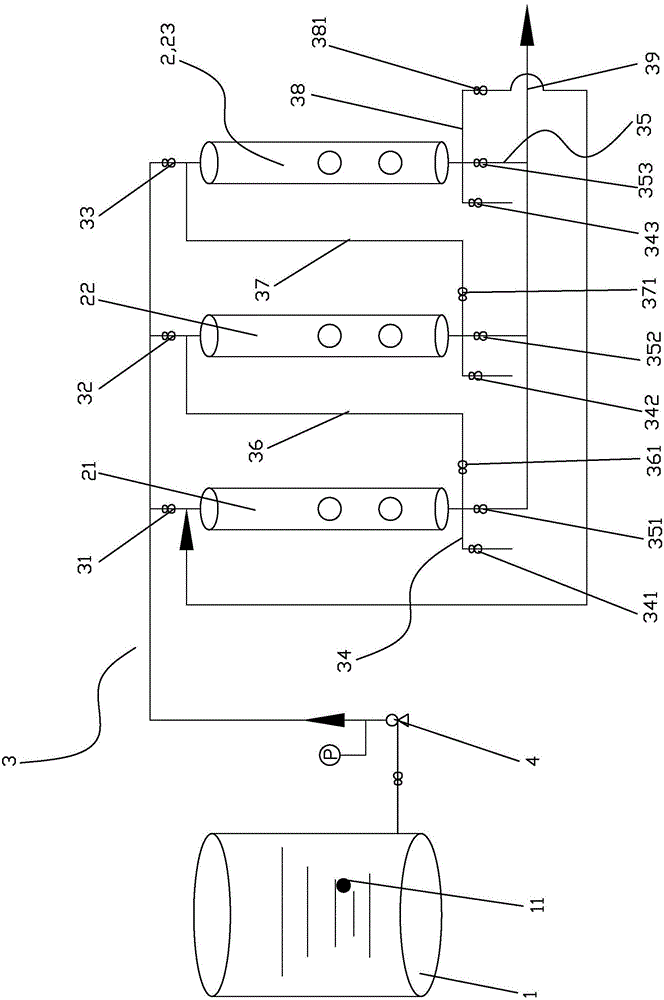

[0018] Such as figure 1 Shown, a kind of precious metal recycling system for electroplating comprises gold-containing waste water collecting tank 1, and the outlet pipe of this gold-containing waste water collecting tank 1 is connected with at least three filter towers 2 connected in series, and a plurality of filter towers 2 are connected with gold-containing waste water The collection tank 1 is provided with a circulation pipeline 3 for transporting waste water and for adjusting the order of filtration.

[0019] A plurality of filter towers 2 are respectively filter tower A21, filter tower B22 and filter tower C23, and the circulation pipeline 3 includes the outlet pipes used to control the waste water from the gold-containing wastewater collection tank 1 to enter the filter tower A21, filter tower B22, and filter tower respectively. The water inlet valve A31, wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com