Domestic sludge aerobic composting method and system thereof

A technology of aerobic composting and domestic sludge, which is applied in the field of aerobic composting of domestic sludge and its system, can solve the problems of long decomposing period and poor sludge reduction effect, so as to reduce labor demand and reduce Labor intensity, the effect of ensuring the continuity of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

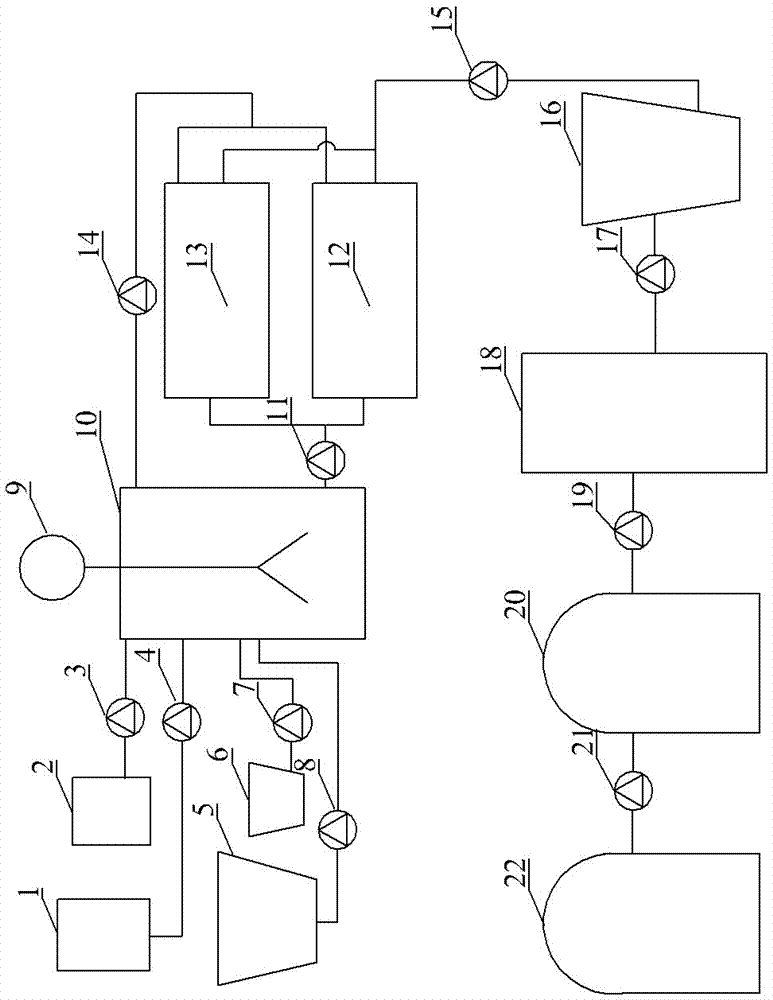

Image

Examples

Embodiment 1

[0029] A kind of aerobic composting method of domestic sludge, it may further comprise the steps:

[0030] step one,

[0031] First, adjust the solid content of the sludge to form an initial slurry. The solid content of the initial slurry is 3%-10%. The primary dewatered sludge with a moisture content of 80%-85% is mixed;

[0032] Secondly, add filter aid and curing agent to the initial mud in turn for conditioning, and stir and mix separately. The rotation speed of stirring and mixing is 100r / min, and the time is 15min. It is 10%~30% of the solid content of the sludge. The solidifying agent includes 5%-15% incinerator slag, 50%-70% carbide slag and 20%-35% desulfurization gypsum in terms of mass fraction. The filter aid is porous biomass Materials; porous biomass materials used as filter aids include any one or more of the following materials: sawdust, bamboo powder, mushroom residue, activated carbon, plant ash, plant seeds or fruit core shells; porous biomass materials ar...

Embodiment 2

[0047] The only difference between the aerobic composting method of Example 2 and the method of Example 1 is that step 1 uses the primary dewatered sludge alone or uses the concentrated sludge alone for deep dehydration; wherein, the primary dewatered sludge needs to be diluted with water, and the concentrated sludge It needs to stand still to remove the supernatant, so that the solid content of the initial mud is 3%-10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com