Mixed material temporary storage system of asphalt stirring device

A technology for asphalt mixing and finished materials, which is applied in roads, road repairs, roads, etc., can solve the problems of limited construction time, short construction period, finished product silo capacity and number restrictions, etc., and achieve the effect of ensuring the continuity of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the technical solutions of the present invention, the embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

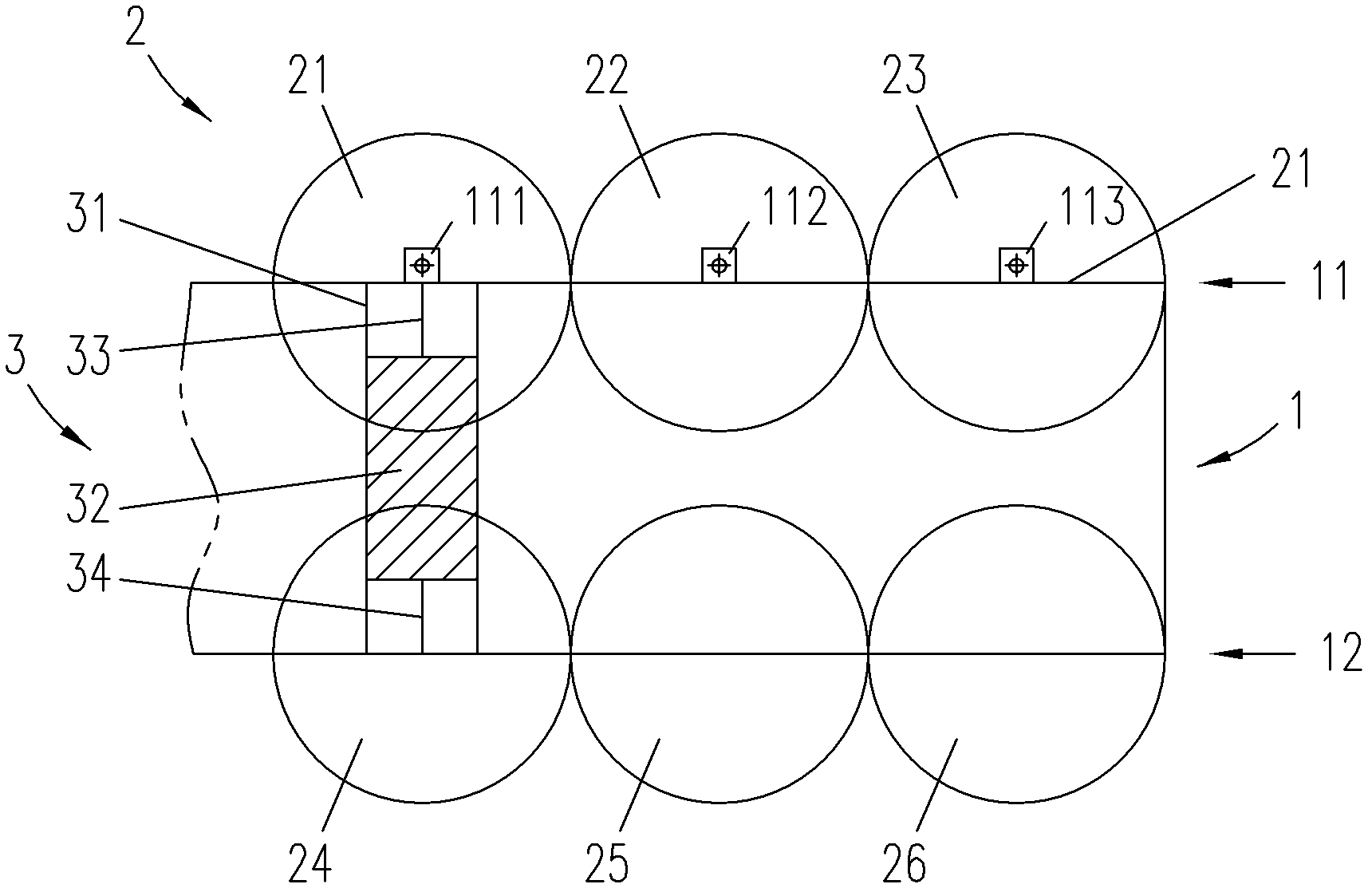

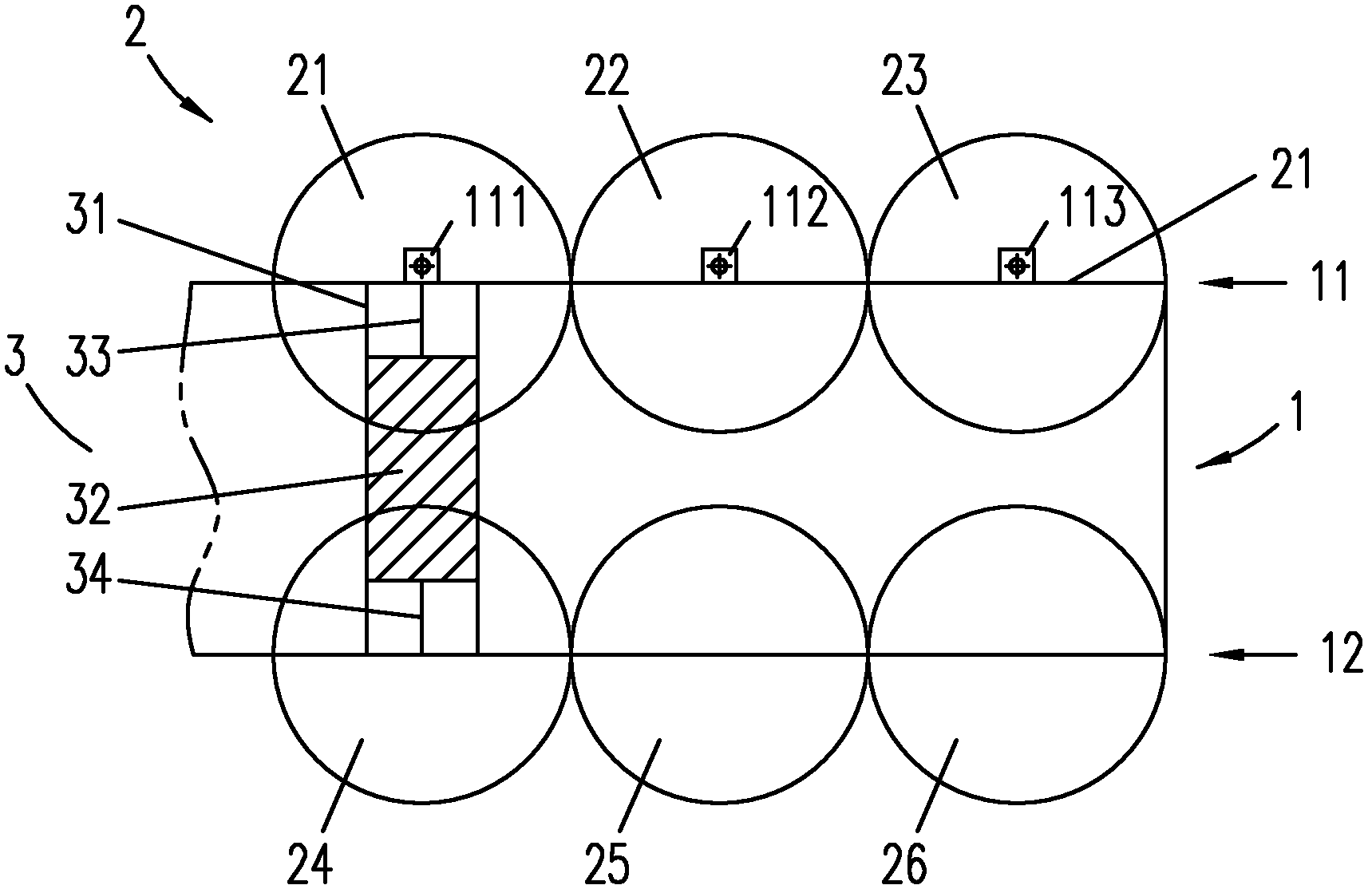

[0017] refer to figure 1 As shown, the finished material temporary storage system of the asphalt mixing plant of the present invention includes a bin body track 1, a finished asphalt bin 2, and a material delivery device 3; in this embodiment, two parallel bin body rails 11 are provided. , 12, 3 asphalt finished product silos 21, 22, 23 are arranged below the warehouse body track 11, and 3 asphalt finished product silos 24, 25, 26 are also provided with the warehouse body track 12 below, and the material transport device 3 left and right two The ends are erected on the bin body rails 11 and 12 respectively, and the material transport device 3 moves between the two bin body rails and can unload in the asphalt finished product bin below the bin body rails at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com