Thermal insulation material transfer device for thermal insulation board production line

A technology of thermal insulation materials and transfer devices, which is applied in ceramic molding machines, manufacturing tools, ceramic molding workshops, etc., can solve the problems of low production efficiency of thermal insulation boards, complex processing techniques, and inability to guarantee production continuity, so as to ensure continuous production Sexuality, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

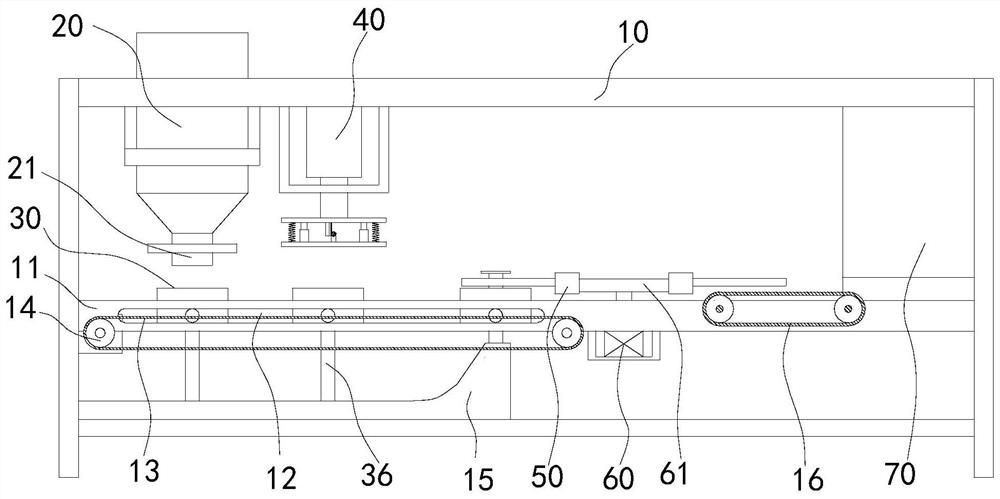

[0034] Such as Figure 1-13 As shown, the present invention provides a line insulation material transfer device for insulation board production, including:

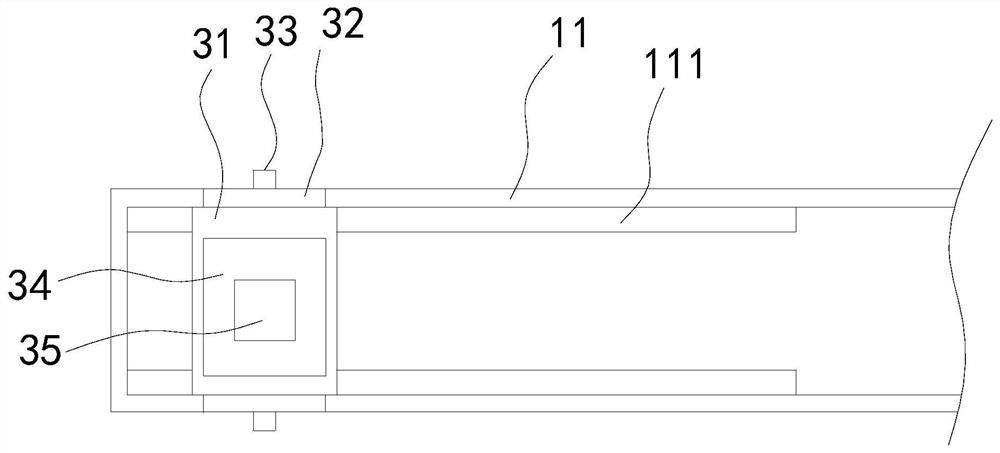

[0035] Frame 10, the upper middle part of frame 10 is provided with fixed mount 11, and the upper left end of fixed mount 11 is provided with feed tank 20, and the bottom of feed tank 20 is provided with feeding pipe 21; Plate 111, the forming mold 30 is slidably arranged on the limiting plate 111;

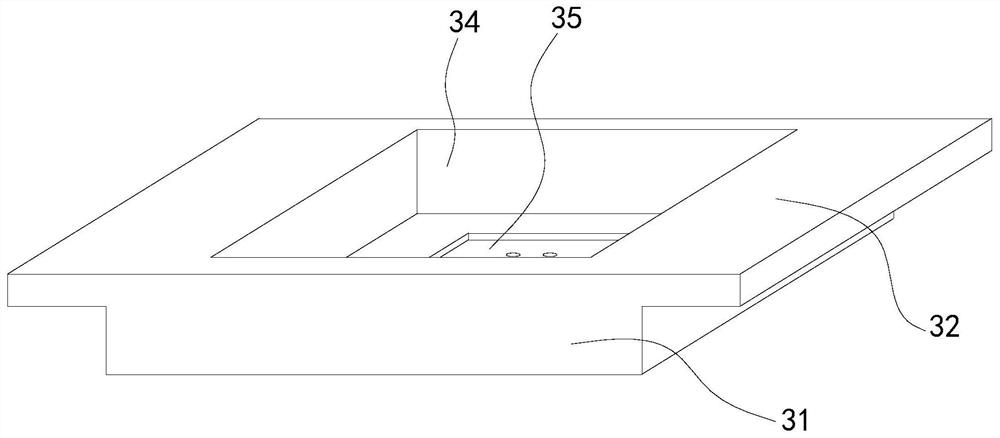

[0036] Forming mold 30, forming mold 30 comprises plate body 31, the clamping plate 32 that is arranged on plate body 31 two ends, and plate body 31 middle position is provided with forming groove 34, and the middle position of forming groove 34 is provided with groove 35, and groove 35 is inward A pair of support columns 36 are arranged vertically, the bottom of the support columns 36 is provided with a first pulley 37, and the top of the support columns 36 is fixedly provided with a pusher plate 38, and the pusher plate 38...

Embodiment 2

[0045] Such as Figure 1-13 As shown, the present invention provides a line insulation material transfer device for insulation board production, including:

[0046] Frame 10, described frame 10 upper middle part is provided with fixed frame 11, and the upper left end of described fixed frame 11 is provided with feeding tank 20, and the bottom of described feeding tank 20 is provided with feeding pipe 21; The inner wall of the left end of the frame 11 is provided with a limiting plate 111, and the forming mold 30 is slidably arranged on the limiting plate 111;

[0047] Forming mold 30, described forming mold 30 comprises plate body 31, the clamping plate 32 that is arranged on described plate body 31 two ends, described plate body 31 middle position is provided with forming groove 34, and the middle position of described forming groove 34 is provided with Groove 35, a pair of supporting columns 36 are movable vertically downwards in the groove 35, the bottom of the supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com