Novel coil stock placing device for transverse silicon steel sheet shearing line

A technology of unwinding device and cross-cutting line, which is applied in the direction of coiling strips, thin material handling, transportation and packaging, etc., can solve problems such as affecting the continuity of production and increasing the labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

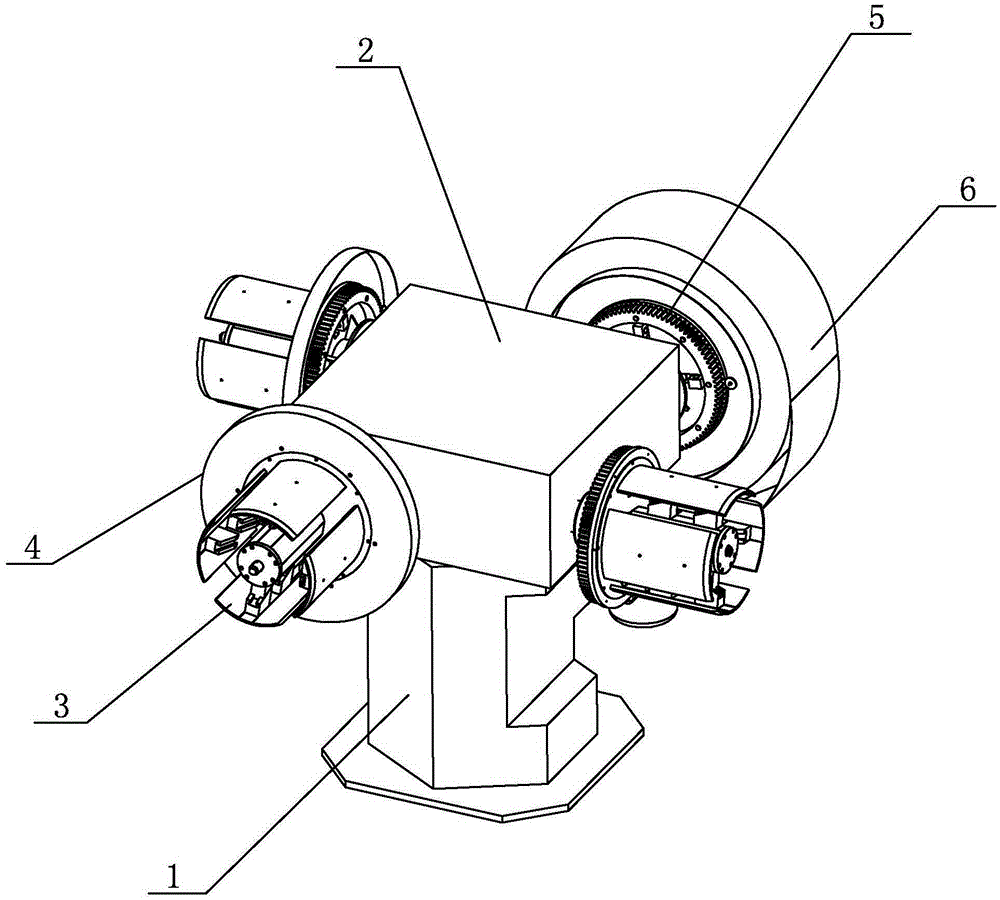

[0017] refer to figure 1 , the preferred embodiment provided by the present invention, a new type of coil feeding device for silicon steel sheet cross-cutting line, including a support 1, a square lifting table 2 is arranged above the support 1, and the four sides of the square lifting table 2 are respectively provided with The coiled material is placed on the cylinder 3, and the rolled sheet 6 is inserted on the coiled material placed on the cylinder 3.

[0018] A drive motor is provided in the support 1, and the drive motor is provided with connecting teeth that protrude from the support 1. Each roll material placement cylinder 3 is respectively provided with a drive gear 5. The driving gear 5 of a roll material placement tube 3 is engaged, and the drive motor drives the roll material placement tube 3 to rotate and discharge.

[0019] The support member 1 or the square lifting platform 2 is provided with a lifting mechanism that drives the square lifting platform 2 to go up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com