Rice processing screening device

A screening device, rice processing technology, applied in the direction of cyclone device, filter screen, solid separation, etc., can solve the problems of low efficiency, discontinuous production, poor screening effect, etc., to improve screening efficiency, ensure screening Separation effect, improve the effect of sieving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

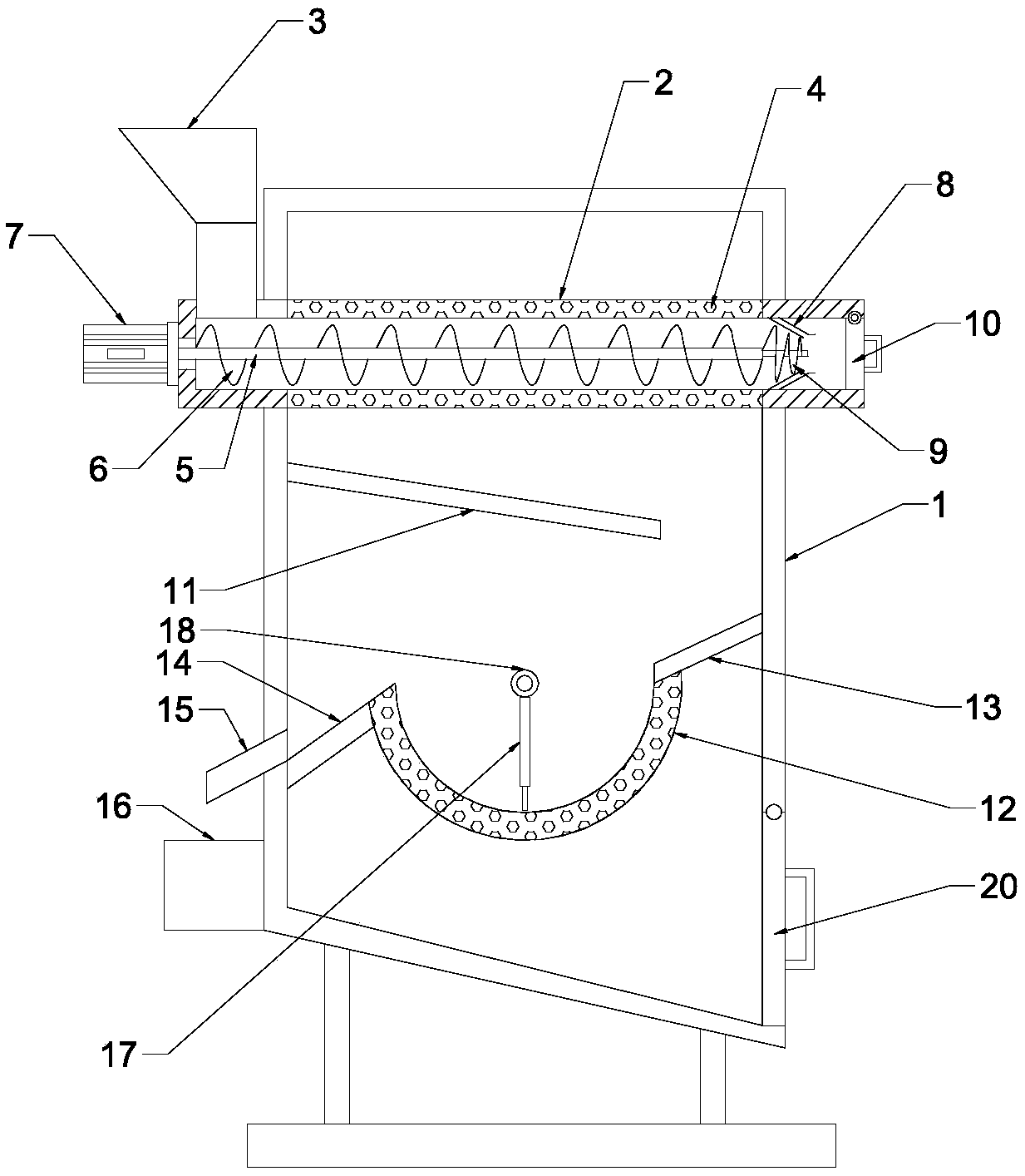

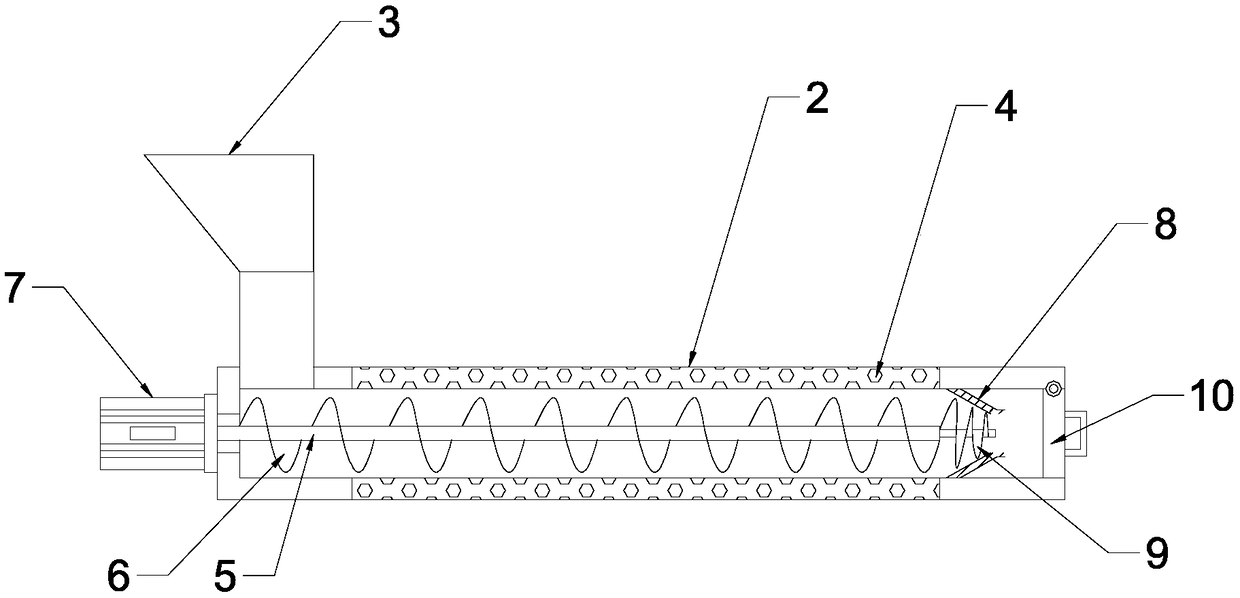

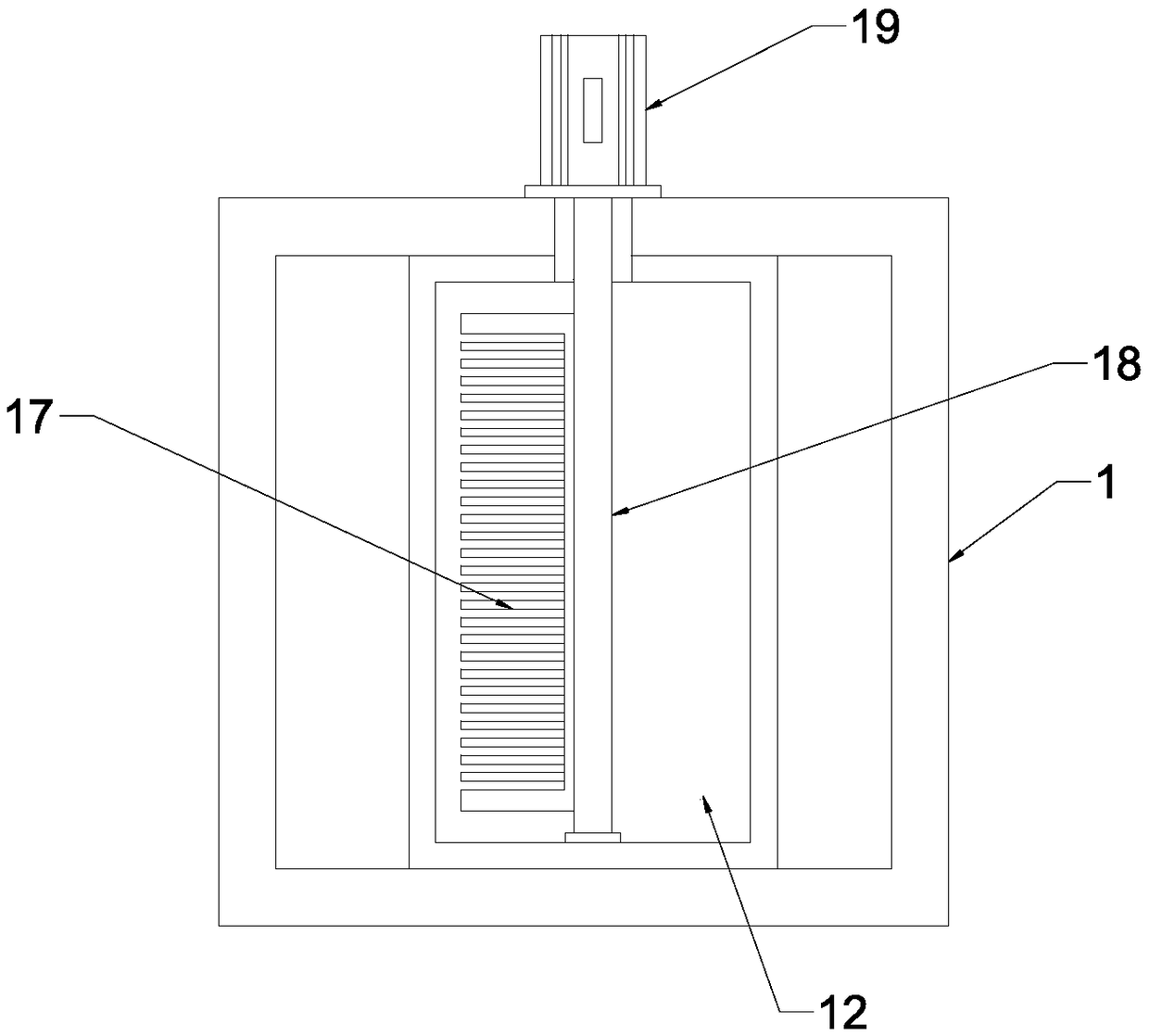

[0022] see Figure 1~3 , in an embodiment of the present invention, a rice processing and screening device includes a box body 1, a primary screening mechanism and a secondary screening mechanism; On both sides of the box body 1, the left end of the screen drum 2 is connected with a feeding hopper 3, and the rice to be screened is put into the feeding hopper 3; the screen drum 2 is provided with a central shaft 5, and the central shaft 5 is fixedly connected to the first helical blade. Group 5, the first helical blade group 5 pushes the rice to move to the right, the part of the screen cylinder 2 located in the box 1 is evenly distributed with screen holes 4, and the rice passes through the screen holes 4 and enters the box body 1; the screen cylinder 2 pairs The waste residue is intercepted and continues to push the waste residue to move to the right. The right end of the screen cylinder 2 is nested with a conical cover 8. The conical cover 8 is a hollow conical cylinder with...

Embodiment 2

[0025] see Figure 4 The difference between this embodiment and Embodiment 1 is that: the lower end of the first material guide plate 11 is fixedly connected with a blower 21, and the blower 11 is connected to a blower 23 through an air pipe 22, and the blower 23 is fixed to the outer wall of the box body 1. Connected, the box 1 is located on the inner wall of the blowing head 11 and is provided with an ash discharge tank 24. The ash discharge tank 24 is arranged obliquely to prevent rice grains from entering the ash discharge tank 24; the ash discharge tank 24 is connected with an ash collection cover 25 , The dust collection cover 25 communicates with the cyclone settling cylinder 26 through the pipeline to settle the dust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com