Screening system and combine harvester

A screen frame and tail screen technology, which is applied to harvesters, cutters, agricultural machinery and tools, etc., can solve the problems of waste of resources and low screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

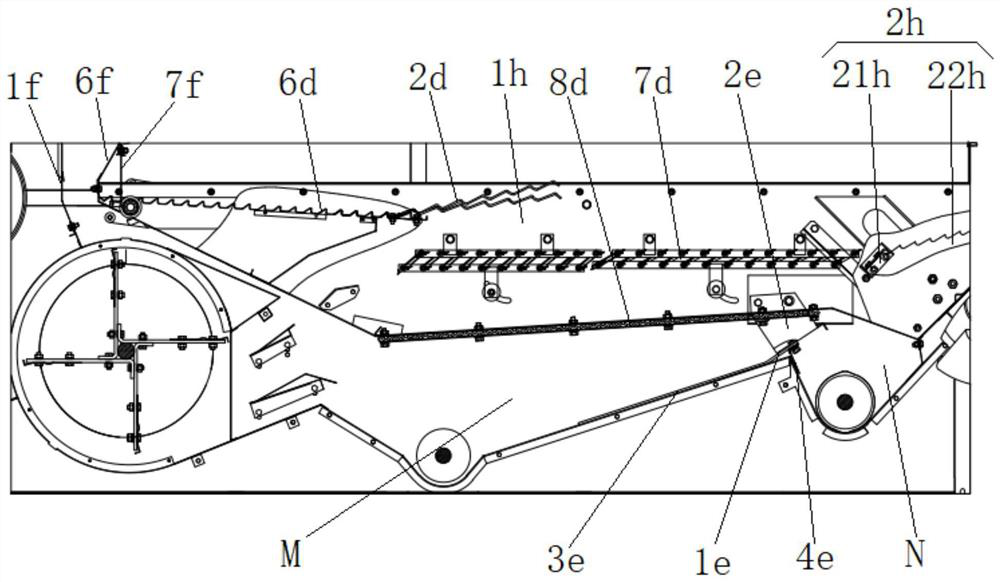

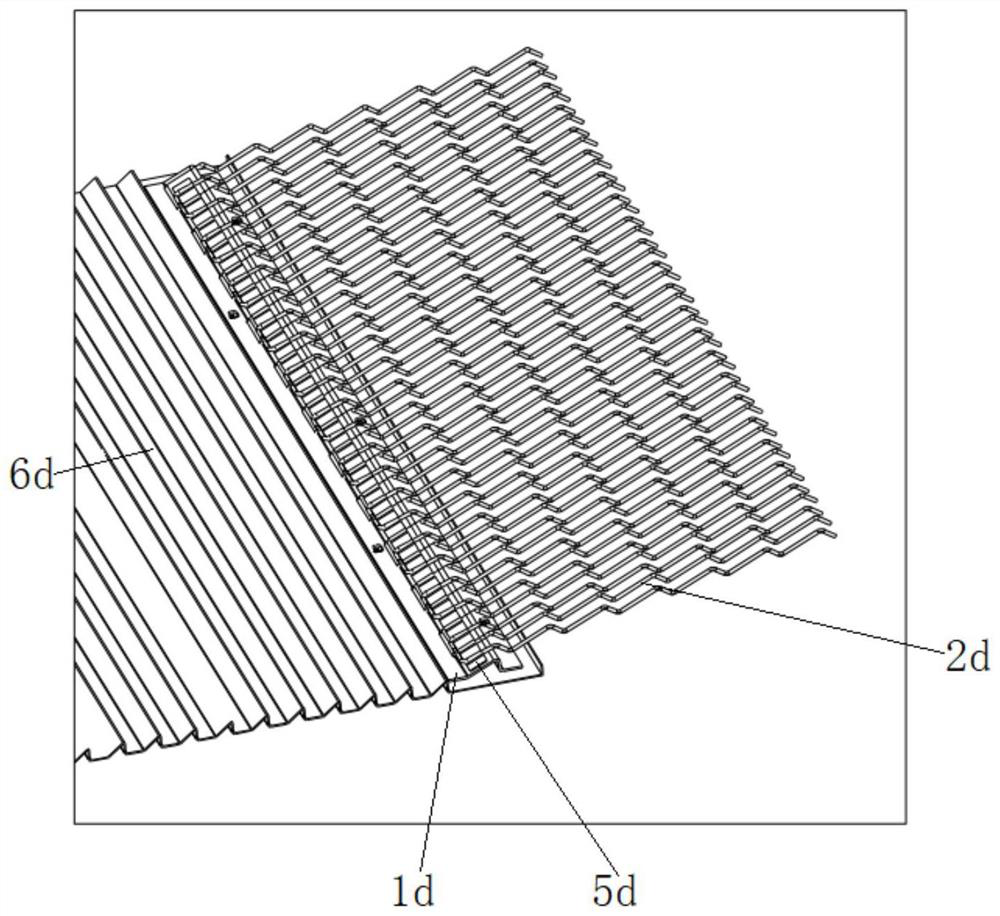

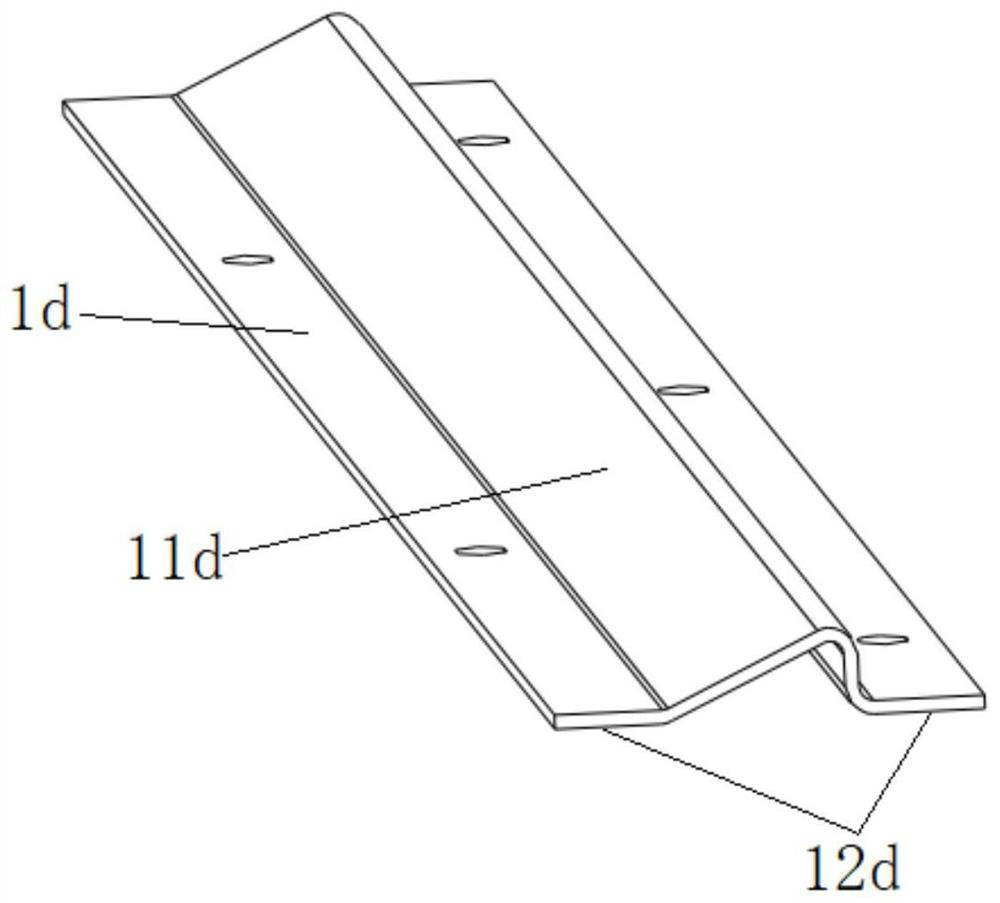

[0084] This embodiment provides a screening system, such as figure 1 , Figure 5 , Figure 11 with Figure 12 As shown, it includes vibrating screen H, front sealing structure, grain separation structure and driving structure. The vibrating screen H has an upper screen area and a lower screen 8d area. In the upper screen area, a lifting structure is set at the end of the corrugated plate 6d to increase the drop between the corrugated plate 6d and the fish scale screen 7d, and cooperate with the tail screen 2h at the end to form two Duan Yangsheng fully shakes the agglomerated crops to loosen them, so as to avoid the entrainment of crop stalks and discharge of grains, resulting in waste. At the same time, a front sealing structure is provided at the front end of the corrugated plate 6d to prevent the grain from being thrown out by the vibrating screen H. A grain separation structure is set between the grain collection area M and the residue collection area N below the vibra...

Embodiment 2

[0111] This embodiment provides a combine harvester, including the screening system in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com