Novel centrifugal granulated fertilizer dryer

A granular fertilizer and centrifugal technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of fertilizers being easily broken into powder and poor drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

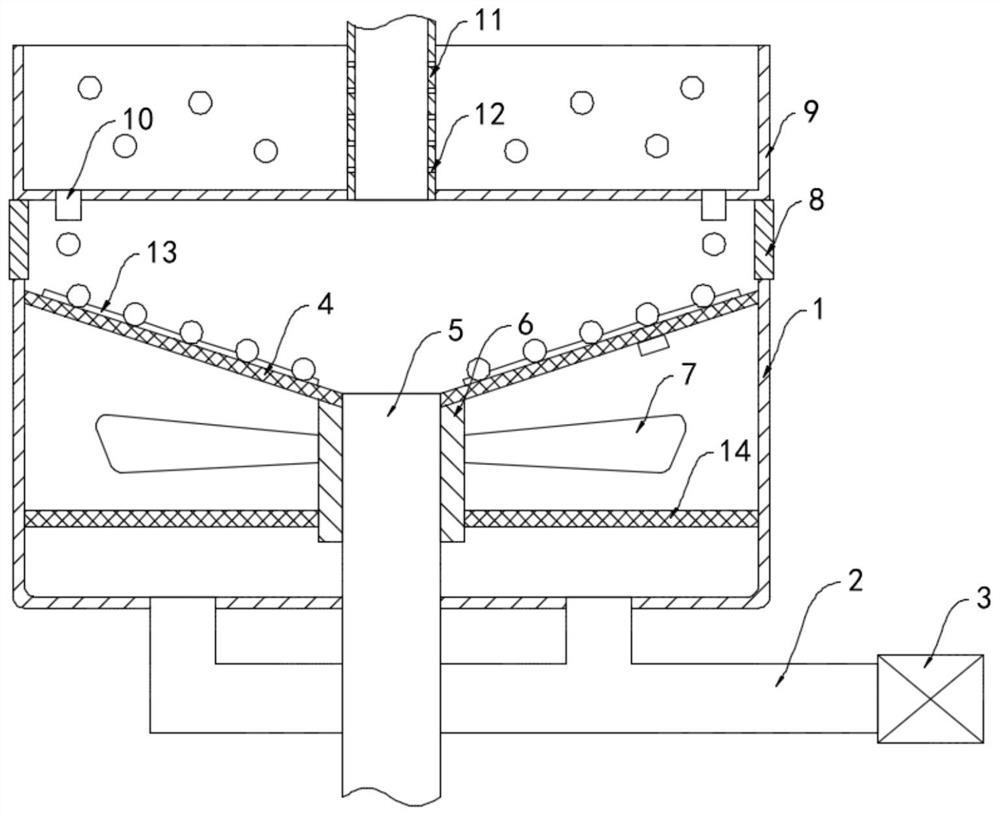

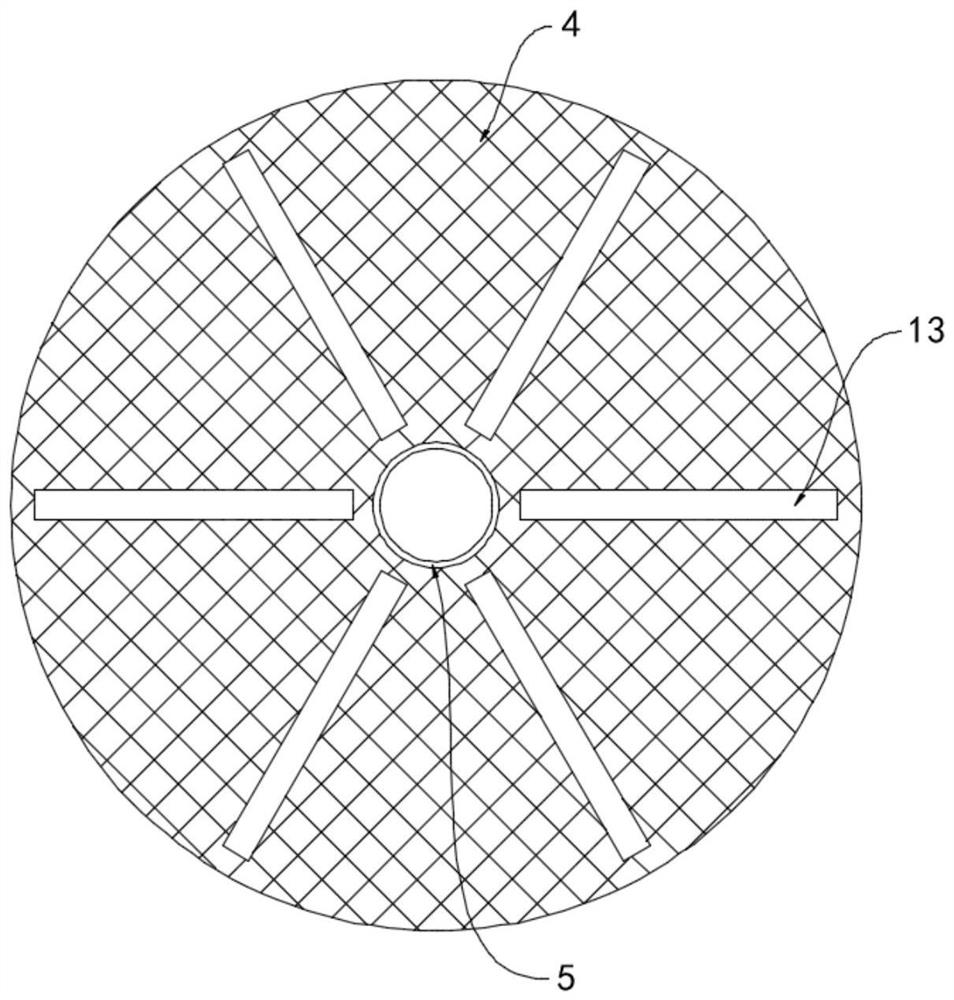

[0024] Such as Figure 1-2 As shown, a novel centrifugal granular fertilizer dryer includes a housing 1, the lower end of the housing 1 is fixedly connected with an air intake pipe 2, and the other end of the air intake pipe 2 is fixedly connected with a hot air blower 3, and the upper end of the housing 1 is opened. , the inner side wall of the upper end of the housing 1 is rotatably connected with a drying screen 4, the drying screen 4 is set in a downwardly concave conical shape, and the upper surface of the drying screen 4 is circumferentially arranged with a plurality of The shunt bar 13 that extends all around.

[0025] The center of the bottom surface of the drying net plate 4 is fixedly connected with a feeding pipe 5, the lower end of the feeding pipe 5 runs through the bottom surface of the housing 1 and extends to the outside of the housing 1, and the outer rotating sleeve of the feeding pipe 5 is connected with a sliding sleeve 6. The upper end of the sleeve 6 is ...

Embodiment 2

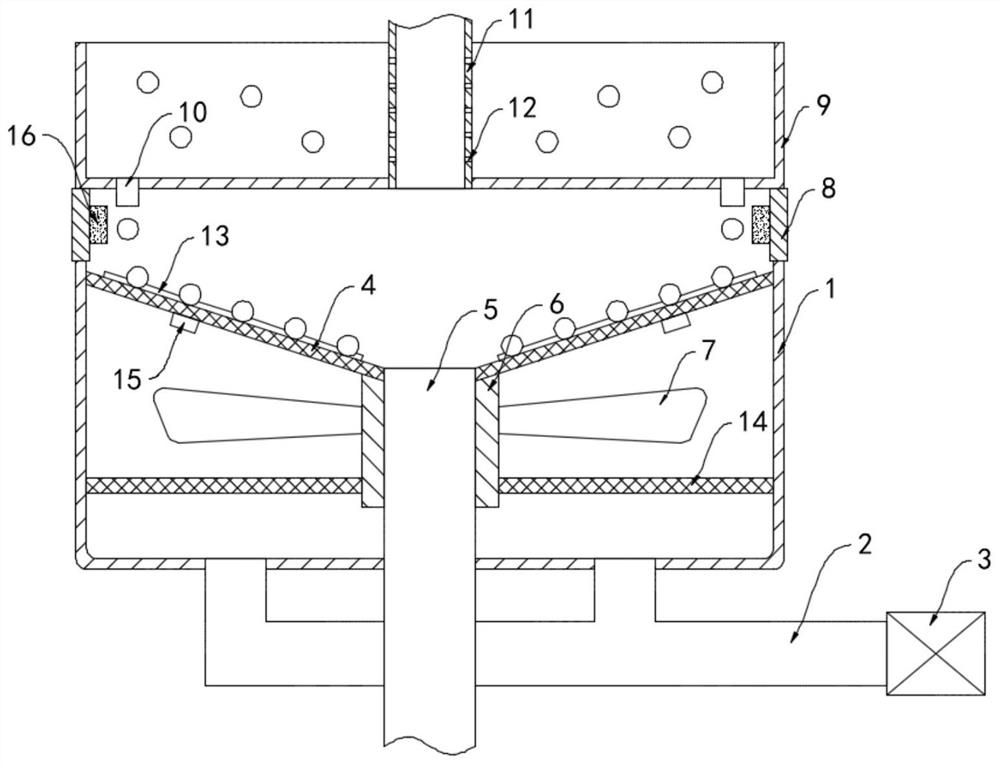

[0032] Such as Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 is that two permanent magnet blocks 15 are installed on the bottom surface of the drying screen 4 , and a ring magnet 16 is fixedly installed on the inner wall of the enclosure 8 .

[0033] In this embodiment, the drying screen 4 drives the permanent magnet block 15 to rotate, and the two permanent magnet blocks 15 alternately approach and move away from the N pole and the S pole of the ring magnet 16. Under the magnetic force, the ring magnet 16 is opposite to the permanent magnet block 15 Periodically changing attractive and repulsive forces drive the drying screen 4 to repeatedly deform and shake, and then drive the spherical granular fertilizer on the drying screen 4 to repeatedly turn to make it fully contact with the hot air flow, further improving its drying effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com